Abstract

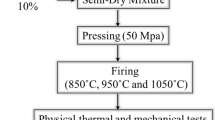

The purpose of this study is to assess the feasibility of using mirror and glass industry residues as a partial replacement for clay in clay brick production, with a focus on sustainable and eco-friendly techniques. Clay was mixed with raw sand residue (RSR) in various ratios: 87.5/12.5, 85/15, 82.5/17.5 and 80/20 wt%, extruded with the appropriate amount of moisture, dried at 110 °C and fired at temperatures from 850 to 1050 °C. Extensive analytical techniques, including thermogravimetric analysis, X-ray diffraction (XRD) mineralogical analysis, chemical characterisation using energy-dispersive X-ray analysis (EDX) and X-ray fluorescence (XRF), and scanning electron microscopy (SEM) morphological analysis, were employed to characterise the raw materials. Mechanical and thermal properties of the fired bricks were assessed, encompassing linear shrinkage, apparent porosity, apparent density, water absorption, thermal conductivity, dilatometry analysis, bending strength, compressive strength and freeze–thaw resistance. The results demonstrated that the incorporation of RSR as an additive yielded lightweight bricks with adequate strength, particularly when fired at lower temperatures. Notably, a clay–RSR mixture containing 12.5% RSR and fired at 1050 °C displayed an optimal balance between mechanical performance and porosity, exhibiting a porosity of 13%, an apparent density of 2 g/cm3, a thermal conductivity of 0.55 W/m K, and a compressive strength of 55 MPa. Furthermore, compressive strengths of the RSR replacement bricks ranged from 25 to 45 MPa, indicating the material's potential as a sustainable alternative to reduce clay consumption in brick production. The findings of this study highlight the promising potential of mirror and glass industry residues as an eco-friendly substitute in clay brick production.

Similar content being viewed by others

References

Kioupis, D.; Skaropoulou, A.; Tsivilis, S.; Kakali, G.: Valorization of Brick and Glass CDWs for the Development of Geopolymers Containing More Than 80% of Wastes. Minerals (2020). https://doi.org/10.3390/MIN10080672

Zhang, L.: Production of bricks from waste materials–A review. Constr Build Mater 47, 643–655 (2013). https://doi.org/10.1016/J.CONBUILDMAT.2013.05.043

Gencel, O.; Erdugmus, E.; Sutcu, M.; Oren, O.H.: Effects of concrete waste on characteristics of structural fired clay bricks. Constr Build Mater (2020). https://doi.org/10.1016/J.CONBUILDMAT.2020.119362

Abbas, S.; Saleem, M.A.; Kazmi, S.M.S.; Munir, M.J.: Production of sustainable clay bricks using waste fly ash: Mechanical and durability properties. Journal of Building Engineering 14, 7–14 (2017). https://doi.org/10.1016/J.JOBE.2017.09.008

Chidiac, S.E.; Federico, L.M.: Effects of waste glass additions on the properties and durability of fired clay brick. Can. J. Civ. Eng. 34, 1458–1466 (2007). https://doi.org/10.1139/L07-120

Hooda, R.K.N.: An experimental study on properties of fly ash bricks. Int J Mech Eng Robot Res 2, 56–67 (2014)

Carretero, M.I.: Clay minerals and their beneficial effects upon human health. A review. Appl Clay Sci 21, 155–163 (2002). https://doi.org/10.1016/S0169-1317(01)00085-0

Valášková, M.: Clays, clay minerals and cordierite ceramics-A review. Original Papers Ceramics-Silikáty 59, 331–340 (2015)

Chen, Y.; Zhang, Y.; Chen, T., et al.: Preparation of eco-friendly construction bricks from hematite tailings. Constr Build Mater 25, 2107–2111 (2011). https://doi.org/10.1016/J.CONBUILDMAT.2010.11.025

Madurwar, M.V.; Mandavgane, S.A.; Ralegaonkar, R.V.: Development and feasibility analysis of bagasse ash bricks. J Energy Eng 141, 04014022 (2015). https://doi.org/10.1061/(asce)ey.1943-7897.0000200

Korpayev, S.; Bayramov, M.; Durdyev, S., et al.: Effect of stone wool waste from greenhouse agriculture in brick production. J Build Eng 63, 105340 (2023). https://doi.org/10.1016/j.jobe.2022.105340

Korpayev, S.; Bayramov, M.; Durdyev, S.; Hamrayev, H.: Characterization of three amu-darya basin clays in ceramic brick industry and their applications with brick waste. Materials (2021). https://doi.org/10.3390/MA14237471

Demir, I.: Reuse of waste glass in building brick production. Waste Manage. Res. 27, 572–577 (2009). https://doi.org/10.1177/0734242X08096528

Korpayev, S.; Bayramov, M.; Kandymov, N.; Durdyev, S.: Recycling of agricultural irrigation canal sludge and mirror factory residue in green brick production. Constr Build Mater 346, 128474 (2022). https://doi.org/10.1016/J.CONBUILDMAT.2022.128474

Alonso-Santurde, R.; Coz, A.; Quijorna, N., et al.: Valorization of foundry sand in clay bricks at industrial scale. J Ind Ecol 14, 217–230 (2010). https://doi.org/10.1111/J.1530-9290.2010.00233.X

Mymrin V, Alekseev K, Catai RE, et al: Red ceramics from composites of hazardous sludge with foundry sand, glass waste and acid neutralization salts. (2015) https://doi.org/10.1016/j.jece.2015.07.015

Luo, H.L.; Lin, D.F.; Chung, M.L.; Chen, L.Y.: Waste foundry sand reused as clay replacement for tile manufacture. Int J Trans Sci Technol 3, 339–351 (2014). https://doi.org/10.1260/2046-0430.3.4.339

Sahani, K.; Joshi, B.R.; Khatri, K., et al.: Mechanical properties of plastic sand brick containing plastic waste. Adv Civil Eng (2022). https://doi.org/10.1155/2022/8305670

Raabe, D.: The materials science behind sustainable metals and alloys. Chem Rev 123, 2436–2608 (2023). https://doi.org/10.1021/acs.chemrev.2c00799

Korpayev, S.; Bayramov, M.; Durdyev, S.; Hamrayev, H.: Characterization of three amu-darya basin clays in ceramic brick industry and their applications with brick waste. Materials 14, 7471 (2021). https://doi.org/10.3390/ma14237471

ASTM C20-00: Standard test methods for apparent porosity, water absorption , apparent specific gravity , and bulk density of burned refractory brick and shapes by boiling water. Am. Soc. Test. Mater. (2015) https://doi.org/10.1520/C0020-00R10.2

ASTM International (2018) Standard test methods for sampling and testing brick and structural clay tile. ASTM C67/C67M-18

ASTM international: standard practice for classification of soils for engineering purposes (unified soil classification system). https://www.astm.org/d2487-17.html. (2017) Accessed 1 Aug 2022

Diko, M.L.; Ekosse, G.E.; Ayonghe, S.N.; Ntasin, E.B.: Note. Appl Clay Sci 3, 380–384 (2011). https://doi.org/10.1016/J.CLAY.2010.11.034

do Carmo e Silva Defáveri K, dos Santos LF, Franco de Carvalho JM, et al.: Iron ore tailing-based geopolymer containing glass wool residue: A study of mechanical and microstructural properties. Constr Build Mater 220, 375–385 (2019). https://doi.org/10.1016/J.CONBUILDMAT.2019.05.181

Milošević, M.; Logar, M.; Djordjević, B.: Mineralogical analysis of a clay body from Zlakusa, Serbia, used in the manufacture of traditional pottery. Clay Miner 55, 142–149 (2020). https://doi.org/10.1180/CLM.2020.20

Muñoz Velasco, P.; Morales Ortíz, M.P.; Mendívil Giró, M.A.; Muñoz Velasco, L.: Fired clay bricks manufactured by adding wastes as sustainable construction material–A review. Constr Build Mater 63, 97–107 (2014). https://doi.org/10.1016/J.CONBUILDMAT.2014.03.045

Sutcu, M.; Erdogmus, E.; Gencel, O., et al.: Recycling of bottom ash and fly ash wastes in eco-friendly clay brick production. J Clean Prod 233, 753–764 (2019). https://doi.org/10.1016/J.JCLEPRO.2019.06.017

Sutcu, M.; Alptekin, H.; Erdogmus, E., et al.: Characteristics of fired clay bricks with waste marble powder addition as building materials. Constr Build Mater 82, 1–8 (2015). https://doi.org/10.1016/J.CONBUILDMAT.2015.02.055

Maifala, B.; Nadiye-Tabbiruka, M.S.: Chemical and thermal characterization of a clayey material found near Gaborone Dam. J Appl Sci Environ Manage 11, 77–80 (2007)

Muttashar, H.L.; Bin, A.N.; Mohd Ariffin, M.A.; Hussin, M.W.: Microstructures and physical properties of waste garnets as a promising construction materials. Case Stud Constr Mater 8, 87–96 (2018). https://doi.org/10.1016/j.cscm.2017.12.001

Cai, L.; Ma, B.; Li, X., et al.: Mechanical and hydration characteristics of autoclaved aerated concrete (AAC) containing iron-tailings: Effect of content and fineness. Constr Build Mater 128, 361–372 (2016). https://doi.org/10.1016/j.conbuildmat.2016.10.031

Benlalla, A.; Elmoussaouiti, M.; Dahhou, M.; Assafi, M.: Utilization of water treatment plant sludge in structural ceramics bricks. Appl Clay Sci 118, 171–177 (2015). https://doi.org/10.1016/J.CLAY.2015.09.012

Weng, C.H.; Lin, D.F.; Chiang, P.C.: Utilization of sludge as brick materials. Adv. Environ. Res. 7, 679–685 (2003). https://doi.org/10.1016/S1093-0191(02)00037-0

Wolff, E.; Schwabe, W.K.; Conceição, S.V.: Utilization of water treatment plant sludge in structural ceramics. J Clean Prod 96, 282–289 (2015). https://doi.org/10.1016/J.JCLEPRO.2014.06.018

Lemougna, P.N.; Yliniemi, J.; Nguyen, H., et al.: Utilisation of glass wool waste and mine tailings in high performance building ceramics. J Build Eng 31, 101383 (2020). https://doi.org/10.1016/J.JOBE.2020.101383

Phonphuak, N.: Effects of Additive on the Physical and Thermal Conductivity of Fired Clay Brick Types of waste, properties, and durability of pore-forming waste-based fired masonry bricks View project Effects of Additive on the Physical and Thermal Conductivity of Fired Clay Brick. J Chem Sci Technol 2, 95–99 (2013)

Aouba, L.; Bories, C.; Coutand, M., et al.: Properties of fired clay bricks with incorporated biomasses: Cases of olive stone flour and wheat straw residues. Constr Build Mater 102, 7–13 (2016). https://doi.org/10.1016/J.CONBUILDMAT.2015.10.040

ASTM C373–88: ASTM C373 - 88(2006) Standard test method for water absorption, bulk density, apparent porosity, and apparent specific gravity of fired whiteware products. https://www.astm.org/DATABASE.CART/HISTORICAL/C373-88R06.htm. (2006) Accessed 18 Sep 2021

El-Din, B.; Hegazy, E.; Fouad, H.A.; Hassanain, A.M.: Incorporation of water sludge, silica fume, and rice husk ash in brick making. Adv. Environ. Res. 1, 83–96 (2012)

Lingling, X.; Wei, G.; Tao, W.; Nanru, Y.: Study on fired bricks with replacing clay by fly ash in high volume ratio. Constr Build Mater 19, 243–247 (2005). https://doi.org/10.1016/J.CONBUILDMAT.2004.05.017

More AS, Tarade A, Anant A: Assessment of suitability of Fly Ash and Rice Husk Ash burnt clay bricks. Int. J. Sci. Res. Public. 4 (2014)

Gencel, O.; Sutcu, M.; Erdogmus, E., et al.: Properties of bricks with waste ferrochromium slag and zeolite. J Clean Prod 59, 111–119 (2013). https://doi.org/10.1016/J.JCLEPRO.2013.06.055

Koksal, F.; Gencel, O.; Kaya, M.: Combined effect of silica fume and expanded vermiculite on properties of lightweight mortars at ambient and elevated temperatures. Constr Build Mater 88, 175–187 (2015). https://doi.org/10.1016/J.CONBUILDMAT.2015.04.021

Stazi, F.: Experimental methods to compare building component alternatives. Adv Build Env Compon (2019). https://doi.org/10.1016/B978-0-12-816921-6.00004-4

Heaney, D.F.: Handbook of metal injection molding. Woodhead Publishing (2012)

Mandili, B.; Taqi, M.; Chakir, H., et al.: Development of new construction material for thermal insulation of building based on aggregate of waste paper and cement. Heat Mass Transfer/Waerme- und Stoffuebertragung 56, 1753–1765 (2020). https://doi.org/10.1007/S00231-020-02811-2

Bonet-Martínez, E.; Pérez-Villarejo, L.; Eliche-Quesada, D.; Castro, E.: Manufacture of sustainable clay bricks using waste from secondary aluminum recycling as raw material. Materials (2018). https://doi.org/10.3390/MA11122439

Gualtieri, M.L.; Gualtieri, A.F.; Gagliardi, S., et al.: Thermal conductivity of fired clays: Effects of mineralogical and physical properties of the raw materials. Appl Clay Sci 49, 269–275 (2010). https://doi.org/10.1016/J.CLAY.2010.06.002

Dondi M, Mazzanti F, Principi P, et al: Thermal conductivity of clay bricks. core.ac.uk pp. 8–14 (2004)

Emrullahoglu Abi, C.B.: Effect of borogypsum on brick properties. Constr Build Mater 59, 195–203 (2014). https://doi.org/10.1016/J.CONBUILDMAT.2014.02.012

Gong, L.; Wang, Y.; Cheng, X., et al.: Thermal conductivity of highly porous mullite materials. Int J Heat Mass Transf 67, 253–259 (2013). https://doi.org/10.1016/J.IJHEATMASSTRANSFER.2013.08.008

TS EN 771–1/T1: Specification for masonry units–part 1: clay masonry units (2005)

Kandymov, N.; Fazilah, N.; Hashim, M., et al.: Derivation of empirical relationships to predict Cambodian masonry strength. Materials (2022). https://doi.org/10.3390/MA15145030

Kandymov N, Masha A, Durdyev S, Yardim Y: Construction materials’ properties: Investigation of unreinforced masonry buildings in the cities of Tirana, Durres and Elbasan. Case Studies in Construction Materials 13 (2020)

ASTM C62: Standard Specification for Building Brick (Solid Masonry Units Made From Clay or Shale). pp. 19428–2959 (2012)

Acknowledgements

This research paper was financed by the Economic Society “Dowletli-Dowran”.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest that are relevant to the content of this article.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kandymov, N., Korpayev, S., Bayramov, M. et al. Sustainable Use of Raw Sand Residue in Production of Fired Clay Bricks. Arab J Sci Eng 49, 4729–4743 (2024). https://doi.org/10.1007/s13369-023-08208-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-023-08208-7