Abstract

Oil and gas pipelines are often threatened by mechanical degradation and corrosion damage. This mechanical degradation is attributable to the aging of the carbon steel, and corrosion damage results from the level of environmental aggressiveness combined with the material's metallurgical characteristics. Unfortunately, studying the natural aging of steel in in-service pipelines is difficult because many tests are destructive. For this reason, the present study used isothermal artificial aging to simulate the mechanical degradation of pipeline steel. Charpy energy tests were carried out to assess the changes in the material's ductility. It was found that this energy exhibited random behavior. Our findings indicate that, on average, the aged material exhibited lower Charpy fracture energy and a much higher variance. This evidence will help experts select the correct material properties while considering its degradation over time. In addition, according to the fractographic study, it was confirmed that the aged pipeline steel tended to be more brittle than the unaged material. Moreover, the dominant corrosion mechanism observed during electrochemical tests for aged and unaged steel was analyzed. We concluded that a moderate chloride ion content is insufficient to stimulate pitting corrosion. Corrosion rates with three different electrochemical techniques (LPR, EIS, and ENA) were obtained, showing that the unaged material tended to be more vulnerable to corrosion effects.

Similar content being viewed by others

Notes

Localized corrosion is a phenomenon that is characterized as exhibiting stochastic behavior. It has been modeled by many researchers using advanced statistics techniques [22].

The solutions used in the present research were chosen to have chloride ion contents of 5246 and 9952 ppm because these were the maximum and the average values found in Mexican oilfield produced waters according to the study presented by J.C. Velázquez et al. [28].

The corrosion rate estimations are presented in a later subsection in this paper.

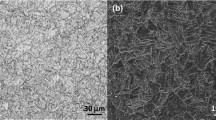

The unaged API 5L grade B steel specimens exhibited a finer grain size than their aged specimens counterparts [20]

References

International energy agency (IEA): Oil market report - April 2022, https://www.iea.org/reports/world-energy-outlook-2020

Kutlu, O.: Global oil production down in Dec 2019, https://www.aa.com.tr/en/energy/international-organization/global-oil-production-down-in-december-2019/28086

Omonbude, E.J.: The economics of transit oil and gas pipelines: a review of the fundamentals. OPEC Energy Rev. 33, 125–139 (2009). https://doi.org/10.1111/j.1753-0237.2009.00163.x

Belvederesi, C.; Dann, M.R.: Statistical analysis of failure consequences for oil and gas pipelines. Int. J. Saf. Secur. Eng. 7, 103–112 (2017). https://doi.org/10.2495/SAFE-V7-N2-103-112

Lu, H.; Iseley, T.; Behbahani, S.; Fu, L.: Leakage detection techniques for oil and gas pipelines: state-of-the-art. Tunn. Undergr. Sp. Technol. 98, 103249 (2020)

Caleyo, F.; Alfonso, L.; Alcántara, J.; Hallen, J.M.: On the estimation of failure rates of multiple pipeline systems. J. Press. Vessel Technol. (2008). https://doi.org/10.1115/1.2894292

Farh, H.M.H.; Ben Seghier, M.E.A.; Zayed, T.: A comprehensive review of corrosion protection and control techniques for metallic pipelines. Eng Fail Anal 143, 06885 (2023)

Seghier, M.E.; Keshtegar, B.; Tee, K.F.; Zayed, T.; Abbassi, R.; Trung, N.T.: Prediction of maximum pitting corrosion depth in oil and gas pipelines. Eng Failure Anal 1(112), 104505 (2020). https://doi.org/10.1016/j.engfailanal.2020.104505

Seghier, M.E.; Höche, D.; Zheludkevich, M.: Prediction of the internal corrosion rate for oil and gas pipeline: implementation of ensemble learning techniques. J. Nat. Gas Sci. Eng. 99, 104425 (2022)

Seghier, M.E.; Höche, D.; Zheludkevich, M.: Prediction of the internal corrosion rate for oil and gas pipeline: implementation of ensemble learning techniques. J. Nat. Gas Sci. Eng. 1(99), 104425 (2022)

Mahdi, E.; Eltai, E.: Development of cost-effective composite repair system for oil/gas pipelines. Compos. Struct. 202, 802–806 (2018). https://doi.org/10.1016/j.compstruct.2018.04.025

Kotrechko, S.O.; Krasowsky, A.Y.; Meshkov, Y.Y.; Torop, V.M.: Effect of long-term service on the tensile properties and capability of pipeline steel 17GS to resist cleavage fracture. Int. J. Press. Vessel. Pip. 81, 337–344 (2004). https://doi.org/10.1016/j.ijpvp.2004.02.015

Wang, Y.; Wang, W.; Zhang, B.; Zhao, Y.; Li, C.Q.: Fracture resistance of naturally corroded steel after service for 128 years. Eng. Fract. Mech. 265, 108367 (2022)

Vargas-Arista, B.; Albiter, A.; García-Vázquez, F.; Mendoza-Camargo, Ó.; Manuel, H.J.: Effect of natural aging on the microstructural regions, mechanical properties, corrosion resistance and fracture in welded joints on API5L X52 steel pipeline. Rev. Metal. 50(3), e024 (2014). https://doi.org/10.3989/revmetalm.024

Vargas-Arista, B.; Hallen, J.M.; Albiter, A.; Angeles-Chavez, C.: Effect of artificial aging time on the mechanical properties of weldment on API 5L X-52 line pipe steel. Metall. Mater. Trans. A. 37, 2683–2690 (2006). https://doi.org/10.1007/BF02586102

Vargas-Arista, B.; Hallen, J.M.; Albiter, A.: Effect of artificial aging on the microstructure of weldment on API 5L X-52 steel pipe. Mater. Charact. 58, 721–729 (2007). https://doi.org/10.1016/j.matchar.2006.11.004

Vargas-Arista, B.; Angeles-Chavez, C.; Albiter, A.; Hallen, J.M.: Metallurgical investigation of the aging process on tensile fracture welded joints in pipeline steel. Mater. Charact. 60, 1561–1568 (2009). https://doi.org/10.1016/j.matchar.2009.09.007

Korda, A.A.; Hidayat, R.; Suriana, S.: Kinetics of strain aging behavior of API 5L X65 and API 5L B Steel types on long-term operations. Int J Tech 7(3), 500–508 (2016)

Vargas-Arista, B.; Hallen, J.M.; Albiter, A.; Ángeles-Chávez, C.: Degradation of impact fracture during accelerated ageing of weld metal on microalloyed steel. Weld. Int. 24, 315–320 (2010). https://doi.org/10.1080/09507110903568760

González-Arévalo, N.E.; Velázquez, J.C.; Díaz-Cruz, M.; Cervantes-Tobón, A.; Terán, G.; Hernández-Sanchez, E.; Capula-Colindres, S.: Influence of aging steel on pipeline burst pressure prediction and its impact on failure probability estimation. Eng. Fail. Anal. (2021). https://doi.org/10.1016/j.engfailanal.2020.104950

Castillo, E.; Hadi, A.S.; Balakrishnan, N.; Sarabia, J.M.: Extreme Value and Related Models with Applications in Engineering and Science. Wiley, New Jersey (2004)

Velázquez, J.C.; Hernández-Sánchez, E.; Terán, G.; Capula-Colindres, S.; Diaz-Cruz, M.; Cervantes-Tobón, A.: Probabilistic and statistical techniques to study the impact of localized corrosion defects in oil and gas pipelines: a review. Metals (Basel) 12, 576 (2022). https://doi.org/10.3390/met12040576

Velázquez, J.C.; González-Arévalo, N.E.; Díaz-Cruz, M.; Cervantes-Tobón, A.; Herrera-Hernández, H.; Hernández-Sánchez, E.: Failure pressure estimation for an aged and corroded oil and gas pipeline: a finite element study. J. Nat. Gas Sci. Eng. 101, 104532 (2022)

Vargas-Arista, B.; Solis Romero, J.; Angeles-Chavez, C.; Albiter, A.; Hallen, J.M.: Deterioration of the corrosion resistance of welded joints in API5L X52 steel isothermally aged. Int. J. Electrochem. Sci. 2011, 367–378 (2011)

Saba, N.; Jawaid, M.; Sultan, M.T.H.: An overview of mechanical and physical testing of composite materials. In: Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites. pp. 1–12. Elsevier (2019)

González-Velázquez, J.L.: Mechanical Behavior and Fracture of Engineering Materials. Springer International Publishing, Cham (2020)

ASTM INTERNATIONAL: ASTM E23 Standard Test Methods for Notched Bar Impact Testing of Metallic Materials, (2016)

Velázquez, J.C.; Cruz-Ramirez, J.C.; Valor, A.; Venegas, V.; Caleyo, F.; Hallen, J.M.: Modeling localized corrosion of pipeline steels in oilfield produced water environments. Eng. Fail. Anal. 79, 216–231 (2017). https://doi.org/10.1016/j.engfailanal.2017.04.027

AMETEK scientific instruments: VersaSTAT 4 Potentiostat Galvanostat, https://www.ameteksi.com/products/potentiostats/single-channel/versastat-series/versastat4

AMETEK scientific instruments: PARSTAT 4000A Potentiostat Galvanostat, https://www.ameteksi.com/products/potentiostats/single-channel/parstat-series/parstat4000a

AMETEK scientific instruments: VersaStudio software, https://www.ameteksi.com/products/software/versastudio-software

Mansfeld, F.: Tafel slopes and corrosion rates from polarization resistance measurements. Corrosion 29(10), 397–402 (1973)

ASTM INTERNATIONAL: ASTM G102–89 standard practice for calculation of corrosion rates and related information from electrochemical measurements, (1999)

Yang, L.: Techniques for Corrosion Monitoring. Elsevier, USA (2021)

Kelly, R.G.; Scully, J.R.; Shoesmith, D.; Buchheit, R.G.: Electrochemical Techniques in Corrosion Science and Engineering. CRC Press, USA (2002)

Capula-Colindres, S.; Terán, G.; Angeles-Herrera, D.; Velázquez, J.C.; Torres-Santillán, E.: Determination of fracture toughness and KIC-CVN correlations for BM, HAZ, and WB in API 5L X60 pipeline. Arab. J. Sci. Eng. 46, 7461–7469 (2021). https://doi.org/10.1007/s13369-021-05451-8

Guillal, A.; Seghier, M.E.; Nourddine, A.; Correia, J.A.; Mustaffa, Z.B.; Trung, N.T.: Probabilistic investigation on the reliability assessment of mid-and high-strength pipelines under corrosion and fracture conditions. Eng. Failure Anal. 118, 104891 (2020)

Ghelloudj, O.; Zelmati, D.; Berdjane, D.; Gharbi, A.; Achouri, S.; Ramoul, C.E.; Bouhamla, K.: Reliability estimation of cracked API 5L X70 pipeline Steel. J. Phys. Conf. Ser. 1818, 012164 (2021)

Peabody, A.W.: Peabody’s Control of Pipeline Corrosion. NACE International (2001)

Barsom, J.M.; Rolfe, S.T.: Fracture and fatigue control in structures: applications of fracture mechanics. Am Soc Test Materials (1999)

Askeland, D.R.; Fulay, P.P., Wright, W.J.: The science and engineering of materials. Cengage Learning (2010)

Callister, W.D.; Rethwisch, D.: Materials Science and Engineering an Introduction. , New Jersey, USA (2009)

Dieter, G.E.: Mechanical Metallurgy SI Metric. McGraw-Hill Book Company, USA (1988)

Herrera Hernández, H.; M. Ruiz Reynoso, A.; C. Trinidad González, J.; O. González Morán, C.; G. Miranda Hernández, J.; Mandujano Ruiz, A.; Morales Hernández, J.; Orozco Cruz, R.: Electrochemical Impedance Spectroscopy (EIS): A Review Study of Basic Aspects of the Corrosion Mechanism Applied to Steels. In: Electrochemical Impedance Spectroscopy. IntechOpen (2020)

Herrera Hernández H; González Díaz F; Fajardo San Miguel GD; Velázquez Altamirano JC; González Morán CO; Morales Hernández J. Electrochemical impedance spectroscopy as a practical tool for monitoring the carbonation process on reinforced concrete structures. Arab J Sci Eng 2019;44(12):10087-103

Soleimani, M.; Mirzadeh, H.; Dehghanian, C.: Effect of grain size on the corrosion resistance of low carbon steel. Mater. Res. Express. 7, 016522 (2020). https://doi.org/10.1088/2053-1591/ab62fa

Al-rubaiey, S.I.; Anoon, E.A.; Hanoon, M.M.: The influence of microstructure on the corrosion rate of carbon steels. Eng. Technol. J. 31, 1825–1836 (2013)

Akeer, E.S.: Effect of Carbon steel composition and microstructure on CO2 corrosion, https://www.ohio.edu/engineering/sites/ohio.edu.engineering/files/sites/engineering/Effect-of-Carbon-Steel-Composition-and-Microstructure-on-CO2-Corrosion_E-Akeer_2014_-PhD.pdf, (2014)

Mandujano Ruiz, A.: Desarrollo de Mapas de Corrosión a Través del Análisis de las Señales de Ruido Electroquímico presentes en un acero AISI 304 en diferentes medios, CIDETEQ (2018). http://cideteq.repositorioinstitucional.mx/jspui/handle/1021/253

Dugstad, A.; Hemmer, H.; Seiersten, M.: Effect of steel microstructure on corrosion rate and protective iron carbonate film formation. Corrosion 57, 369–378 (2001). https://doi.org/10.5006/1.3290361

Clover, D.; Kinsella, B.; Pejcic, B.; De Marco, R.: The influence of microstructure on the corrosion rate of various carbon steels. J. Appl. Electrochem. 35, 139–149 (2005). https://doi.org/10.1007/s10800-004-6207-7

Zhao, Y.; Zhou, E.; Liu, Y.; Liao, S.; Li, Z.; Xu, D.; Zhang, T.; Gu, T.: Comparison of different electrochemical techniques for continuous monitoring of the microbiologically influenced corrosion of 2205 duplex stainless steel by marine Pseudomonas aeruginosa biofilm. Corros. Sci. 126, 142–151 (2017). https://doi.org/10.1016/j.corsci.2017.06.024

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Díaz-Cruz, M., Velázquez, J.C., González-Arévalo, N.E. et al. Study of the Effect of Isothermal Aging on API 5L Grade B Steel Through Charpy Energy Testing and Electrochemical Evaluation. Arab J Sci Eng 48, 16607–16622 (2023). https://doi.org/10.1007/s13369-023-07804-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-023-07804-x