Abstract

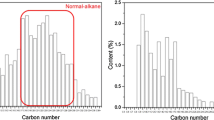

Studying phase behavior at high temperatures is always a challenge due to the risk of evaporation and losing fluid volume; however, we achieved it with our novel device with a high-pressure high-temperature (HPHT) cell, capable of reaching 300 °C without losing any fluid volume. Phase behavior has been investigated for viscoelastic surfactant (VES)/crude oil system and VES/squalene system to explore the effect of salinity, concentration, and temperature on the volume fraction phases and the solubilization ratios. The crude oil system is to mimic the real case in the oil field, while the squalene system is considered a reference model oil with known composition and properties. The results showed that in VES/crude oil system, the emulsion volume decreases with increase in salinity and surfactant concentration, while the temperature has a mixed effect on the emulsion volume, which decreased with increase in the temperature to its minimum volume at 90 °C and then increased again with increase in the temperature above 90 °C. Equal solubilization for each set was achieved at 75% Seawater (SW) salinity, 1.2% VES concentration, and approximately in the temperature range of 60 °C to 150 °C. In VES/squalene system, the lowest emulsion value was recorded for every set at 50% SW salinity, 90 °C temperature, and 1.25% VES concentration. Also, equal solubilization for each set was achieved at 0.5% and 1.25% VES concentration, and 90 °C temperature. However, no equal solubilization was noted for the salinity set. In both sets, no lower emulsion phase was noticed, it is either the middle phase or upper phase.

Similar content being viewed by others

References

Olajire, A.A.: Review of ASP EOR (alkaline surfactant polymer enhanced oil recovery) technology in the petroleum industry: prospects and challenges. Energy (2014). https://doi.org/10.1016/j.energy.2014.09.005

Gao, C.; Shi, J.; Zhao, F.: Successful polymer flooding and surfactant-polymer flooding projects at Shengli oilfield from 1992 to 2012. J. Petrol. Explor. Prod. Technol. (2014). https://doi.org/10.1007/s13202-013-0069-7

Mirchi, V.; Saraji, S.; Goual, L.; Piri, M.: Experimental investigation of surfactant flooding in shale oil reservoirs: dynamic interfacial tension, adsorption, and wettability. SPE Conf. (2014). https://doi.org/10.15530/urtec-2014-1913287

Feng, A.; Zhang, G.; Ge, J.; Jiang, P.; Pei, H.; Zhang, J.; Li, R.: Study of surfactant-polymer flooding in heavy oil reservoirs. SPE Heavy Oil Conf. Canada (2012). https://doi.org/10.2118/157621-MS

Shabani Afrapoli, M.; Alipour, S.; Torsaeter, O.: Effect of wettability and interfacial tension on microbial improved oil recovery with Rhodococcus Sp. 094. Proc. SPE Symp. Improved Oil Recovery 2010, 1 (2006). https://doi.org/10.2118/129707-ms

Afrapoli, M.S.; Alipour, S.; Torsaeter, O.: Analysis of microscopic displacement mechanisms of a MIOR process in porous media with different wettability. Transp. Porous Media 93(3), 705–719 (2012). https://doi.org/10.1007/s11242-012-9978-z

Kamal, M.S.; Sultan, A.S.; Al-Mubaiyedh, U.A.; Hussein, I.A.; Feng, Y.: Rheological properties of thermoviscosifying polymers in high-temperature and high-salinity environments. Can. J. Chem. Eng. 93(7), 1194–1200 (2015). https://doi.org/10.1002/cjce.22204

Gogoi, S.; Gogoi, S.B.: Review on microfluidic studies for EOR application. J. Petrol. Explor. Prod. Technol. (2019). https://doi.org/10.1007/s13202-019-0610-4

Sedaghat, M.H.; Hatampour, A.; Razmi, R.: Investigating the role of polymer type and dead end Pores’ distribution on oil recovery efficiency during ASP flooding. Egypt. J. Petrol. 22(2), 79 (2013). https://doi.org/10.1016/j.ejpe.2013.06.003

Han, D.-K.; Yang, C.-Z.; Zhang, Z.-Q.; Lou, Z.-H.; Chang, Y.-I.: Recent development of enhanced oil recovery in China. J. Pet. Sci. Eng. 22(1–3), 181–188 (1999). https://doi.org/10.1016/S0920-4105(98)00067-9

Clarke, A.; Howe, A.M.; Mitchell, J.; Staniland, J.; Hawkes, L.A.: How viscoelastic-polymer flooding enhances displacement efficiency. SPE J. 21, 675–687 (2016). https://doi.org/10.2118/174654-pa

Fang, Y.; Yang, E.; Guo, S.; Cui, C.; Zhou, C.: Study on micro remaining oil distribution of polymer flooding in class-II B oil layer of daqing oilfield. Energy 2022, 254 (2022). https://doi.org/10.1016/j.energy.2022.124479

Gu, H.; Duits, M.H.G.; Mugele, F.: Interfacial tension measurements with microfluidic tapered channels. Colloids Surf. A Physicochem. Eng. Asp. 389(1–3), 38–42 (2011). https://doi.org/10.1016/j.colsurfa.2011.08.054

Bennetzen, M. V.; Andersson, M.; Mogensen, K. Predicting interfacial tension of multiphase systems based on computational single-molecule quantum mechanics and thermodynamics applying four different physical models and COSMO-theory. In: Society of Petroleum Engineers-SPE EOR Conference at Oil and Gas West Asia 2014: Driving Integrated and Innovative EOR 2014, pp. 70–82. https://doi.org/10.2118/169663-ms.

Pal, N.; Saxena, N.; Divya Laxmi, K.V.; Mandal, A.: Interfacial behaviour, wettability alteration and emulsification characteristics of a novel surfactant: implications for enhanced oil recovery. Chem. Eng. Sci. 187, 200–212 (2018). https://doi.org/10.1016/j.ces.2018.04.062

Ghosh, P.; Mohanty, K.K.: Study of surfactant-polymer flooding in high-temperature and high-salinity carbonate rocks. Energy Fuels 33(5), 4130–4145 (2019). https://doi.org/10.1021/acs.energyfuels.9b00407

Ding, M.C.; Wang, Y.; Yuan, F.; Zhao, H.; Li, Z.: A comparative study of the mechanism and performance of surfactant- and alkali-polymer flooding in heavy-oil recovery. Chem. Eng. Sci. 219, 115603 (2020). https://doi.org/10.1016/j.ces.2020.115603

Hou, J.; Liu, Z.; Zhang, S.; Yue, X.; Yang, J.: The role of viscoelasticity of alkali/surfactant/polymer solutions in enhanced oil recovery. J Pet Sci Eng 47(3–4), 219–235 (2005). https://doi.org/10.1016/j.petrol.2005.04.001

Shuaib A, K.; Khaled A, E.; Kumar, S.; Abbas, G. Wettability alteration by new acid-alkali-surfactant-polymer formulation in high salinity carbonate reservoirs. In: Offshore Technology Conference Asia: Meeting the Challenges for Asia’s Growth, OTC ASIA 2014, vol. 1, pp. 595–602. https://doi.org/10.4043/24738-MS.

Mohammadi, H.; Delshad, M.; Pope, G.A.: Mechanistic modeling of alkaline/surfactant/polymer floods. Spe (2008). https://doi.org/10.2118/110212-PA

Riswati, S.S.; Bae, W.; Park, C.; Permadi, A.K.; Efriza, I.; Min, B.: Experimental analysis to design optimum phase type and salinity gradient of alkaline surfactant polymer flooding at low saline reservoir. J. Pet. Sci. Eng. 2019(173), 1005–1019 (2018). https://doi.org/10.1016/j.petrol.2018.09.087

Cheraghian, G.: Effects of titanium dioxide nanoparticles on the efficiency of surfactant flooding of heavy oil in a glass micromodel. Pet. Sci. Technol. 34(3), 260–267 (2016). https://doi.org/10.1080/10916466.2015.1132233

Cheraghian, G. Improved Heavy Oil Recovery by Nanofluid Surfactant Flooding - An Experimental Study. In: 78th EAGE Conference and Exhibition 2016; European Association of Geoscientists & Engineers, 2016; vol. 2016, pp. 1–5. https://doi.org/10.3997/2214-4609.201601509.

Adejare, O.O.; Nasralla, R.A.; Nasr-El-Din, H.A.: A procedure for measuring contact angles when surfactants reduce the interfacial tension and cause oil droplets to spread. SPE Reservoir Eval. Eng. 17(3), 365–372 (2014). https://doi.org/10.2118/160876-PA

Healy, R.N.; Reed, R.L.: Physiochemical aspects of microemulsion flooding. Soc. Pet. Eng. AIME J. (1974). https://doi.org/10.2118/4583-pa

Healy, R.N.; Reed, R.L.; Stenmark, D.G.: Multiphase microemulsion systems. Soc. Pet. Eng. AIME J. (1976). https://doi.org/10.2118/5565-pa

Green, D.W.; Willhite, G.P.: Enhanced oil recovery. Soc. Pet. Eng. 6, 143–154 (1998)

Huh, C.: Interfacial tensions and solubilizing ability of a microemulsion phase that coexists with oil and brine. J. Colloid Interface Sci. (1979). https://doi.org/10.1016/0021-9797(79)90249-2

Levitt, D. B.; Jackson, A. C.; Heinson, C.; Britton, L. N.; Malik, T.; Dwarakanath, V.; Pope, G. A. Identification and evaluation of high-performance EOR surfactants. In: SPE Reservoir Evaluation and Engineering; 2009; Vol. 12. https://doi.org/10.2118/100089-PA.

Fuseni, A.; Han, M.; Al-Mobith, A. Phase behavior and interfacial tension properties of an amphoteric surfactant for EOR application. In: Society of Petroleum Engineers - SPE Saudi Arabia Section Technical Symposium and Exhibition 2013; 2013. https://doi.org/10.2118/168104-ms.

Li, Y.; Zhang, W.; Kong, B.; Puerto, M.; Bao, X.; Sha, O.; Shen, Z.; Yang, Y.; Liu, Y.; Gu, S.; Miller, C.; Hirasaki, G. J. Mixtures of anionic-cationic surfactants: a new approach for enhanced oil recovery in low-salinity, high-temperature sandstone reservoir. In: SPE Improved Oil Recovery Symposium 2014, No. August, 1–19. https://doi.org/10.2118/169051-MS.

Xu, L.; Han, M.; Bu, X.; Almaskeen, L.: Phase Behavior and Interfacial Properties of an Amphoteric Surfactant for a High Temperature and High Salinity Reservoir. Springer, Singapore (2021) https://doi.org/10.1007/978-981-16-1123-0

Windsor, P.A.: Solvent Properties of Amphiphilic Compounds. Butterworth Scientific publication, London (1954)

Nelson, R.C.; Pope, G.A.: Phase relationships in chemical flooding. Soc. Pet. Eng. AIME J. 18(5), 85 (1978)

Bourrel, M.; Salager, J.L.; Schechter, R.S.; Wade, W.H.: A correlation for phase behavior of nonionic surfactants. J. Colloid Interface Sci. 75(2), 451–461 (1980). https://doi.org/10.1016/0021-9797(80)90470-1

Osterloh, W. T.; Jante, Jr. M. J. Surfactant-polymer flooding with anionic PO/EO surfactant microemulsions containing polyethylene glycol additives. In: SPE/DOE Enhanced Oil Recovery; 1992. https://doi.org/10.2118/24151-MS.

Glover, C.; Puerto, M.; Maerker, J.; Sandvik, E.: Surfactant phase behavior and retention in porous media. SPE J. 19(3), 183–193 (1979). https://doi.org/10.2118/7053-PA

Santanna, V.C.; Curbelo, F.D.S.; Castro Dantas, T.N.; Dantas Neto, A.A.; Albuquerque, H.S.; Garnica, A.I.C.: Microemulsion flooding for enhanced oil recovery. J. Pet. Sci. Eng. 66(3–4), 67 (2009). https://doi.org/10.1016/j.petrol.2009.01.009

Walker, D.; Britton, C.; Kim, D. H.; Dufour, S.; Weerasooriya, U.; Pope, G. A. The impact of microemulsion viscosity on oil recovery. In: SPE Improved Oil Recovery Symposium 2013, pp. 1–13. https://doi.org/10.2118/154275-MS.

Wang, Z.; Xu, Y.; Gan, Y.; Han, X.; Liu, W.; Xin, H.: Micromechanism of partially hydrolyzed polyacrylamide molecule agglomeration morphology and its impact on the stability of crude oil−water interfacial film. J. Pet. Sci. Eng. (2022). https://doi.org/10.1016/j.petrol.2022.110492

Acknowledgements

The authors would like to acknowledge the College of Petroleum Engineering and Geosciences, King Fahd University of Petroleum and Minerals, Saudi Arabia, for providing necessary laboratory facilities and KACST for providing financial support under NSTIP Project 14-OIL611-04. Special thanks are due to Mr. Ahmed Mahboob and Mr. Xianmin Zhou for their valuable support.

Author information

Authors and Affiliations

Contributions

The manuscript was prepared through the contributions of all authors. All authors have approved the final version of the manuscript.

Corresponding authors

Ethics declarations

Conflicts of interest

There are no conflicts of interest to declare.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ahmed, M.E., Sultan, A.S., Mahmoud, M. et al. Investigating the Phase Behavior of Viscoelastic Surfactant with Squalene and Crude Oil Systems at High Temperature. Arab J Sci Eng 48, 9505–9518 (2023). https://doi.org/10.1007/s13369-023-07671-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-023-07671-6