Abstract

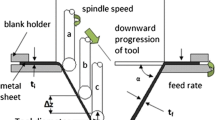

Single Point Incremental Forming (SPIF) is an emerging sheet metal forming process which has been used in the prototype production of complex geometries. The geometric inaccuracies and quality of formed parts are the major obstructions in commercialization of SPIF process. The aim of presented work is to study this hindrance using experimental and numerical investigation on Aluminum Alloy 2210-O. Parametric optimization is done using Response Surface Methodology (RSM) for quality factor (surface roughness) and geometric accuracy (Maximum wall angle) while minimizing thickness reduction and forming time. For this purpose, three experimental setups were designed in this study, using tool types and tool paths. During investigation, the interaction and main effects of process parameters, viz. feed rate, spindle speed, and step increment are evaluated on surface roughness (Ra), maximum wall angle \(({\alpha }_{\mathrm{max}})\), % thickness reduction (% TR), and forming time (T) using ANOVA method. Results showed that among all the parameters of SPIF process, step increment is the most significant parameter for both forming paths using ball end and flat end tool. The comparative analysis of this study suggested that the ball end tool using the bidirectional path was better than the other setups. Furthermore, the results revealed that the ball end tool using a spiral path was better in desirability achievement (73%) as compared to the flat end tool using a spiral path (71.2%). The findings of this study are beneficial in paving a path for optimization of the SPIF process for an industrial-scale production of Al alloy AA 2219-O with desired characteristics.

Similar content being viewed by others

Availability of data and material

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Code availability (software application or custom code)

Not applicable.

References

Park, J.-J.; Kim, Y.-H.: Fundamental studies on the incremental sheet metal forming technique. J. Mater. Process. Technol. 140(1–3), 447–453 (2003)

Emmens, W.; van den Boogaard, A.H.: An overview of stabilizing deformation mechanisms in incremental sheet forming. J. Mater. Process. Technol. 209(8), 3688–3695 (2009)

Dai, K.; Wang, Z.; Fang, Y.: CNC incremental sheet forming of an axially symmetric specimen and the locus of optimization. J. Mater. Process. Technol. 102(1–3), 164–167 (2000)

Wang, Z.; Cai, S.; Chen, J.: Experimental investigations on friction stir assisted single point incremental forming of low-ductility aluminum alloy sheet for higher formability with reasonable surface quality. J. Mater. Process. Technol. 277, 116488 (2020). https://doi.org/10.1016/j.jmatprotec.2019.116488

Shrivastava, P.; Tandon, P.: Microstructure and texture based analysis of forming behavior and deformation mechanism of AA1050 sheet during single point incremental forming. J. Mater. Process. Technol. 266, 292–310 (2019)

Zhang, Q.; Xiao, F.; Guo, H.; Li, C.; Gao, L.; Guo, X.; Han, W.; Bondarev, A.: Warm negative incremental forming of magnesium alloy AZ31 sheet: new lubricating method. J. Mater. Process. Technol. 210(2), 323–329 (2010)

Hussain, G.; Gao, L.; Hayat, N.; Cui, Z.; Pang, Y.; Dar, N.: Tool and lubrication for negative incremental forming of a commercially pure titanium sheet. J. Mater. Process. Technol. 203(1–3), 193–201 (2008)

Franzen, V.; Kwiatkowski, L.; Martins, P.; Tekkaya, A.: Single point incremental forming of PVC. J. Mater. Process. Technol. 209(1), 462–469 (2009)

McAnulty, T.; Jeswiet, J.; Doolan, M.: Formability in single point incremental forming: a comparative analysis of the state of the art. CIRP J. Manuf. Sci. Technol. 16, 43–54 (2017)

Centeno, G.; Bagudanch, I.; Martínez-Donaire, A.J.; Garcia-Romeu, M.L.; Vallellano, C.: Critical analysis of necking and fracture limit strains and forming forces in single-point incremental forming. Mater. Des. 63, 20–29 (2014)

Duflou, J.R.; Habraken, A.-M.; Cao, J.; Malhotra, R.; Bambach, M.; Adams, D.; Vanhove, H.; Mohammadi, A.; Jeswiet, J.: Single point incremental forming: state-of-the-art and prospects. Int. J. Mater. Form. 11(6), 743–773 (2018)

Prashant M, Bhavik P, Vaibhav M, Anukr V.: Single point incremental sheet forming by CNC vertical milling machine. Imp. J. Interdiscip. Res. 2(11) (2016)

Ziran, X.; Gao, L.; Hussain, G.; Cui, Z.: The performance of flat end and hemispherical end tools in single-point incremental forming. Int. J. Adv. Manuf. Technol. 46(9–12), 1113–1118 (2010)

Silva, M.; Skjødt, M.; Atkins, A.; Bay, N.; Martins, P.: Single-point incremental forming and formability—failure diagrams. J. Strain Anal. Eng. 43(1), 15–35 (2008)

Malwad, D.; Nandedkar, V.: Deformation mechanism analysis of single point incremental sheet metal forming. Procedia Mater. Sci. 6, 1505–1510 (2014)

Jagtap, R.; Kashid, S.; Kumar, S.; Hussein, H.: An experimental study on the influence of tool path, tool diameter and pitch in single point incremental forming (SPIF). Adv. Mater. Process. Technol. 1(3–4), 465–473 (2015)

Rattanachan, K.; Chungchoo, C.: The effected of single point incremental forming process parameters on the formed part surface roughness. Adv. Mater. Res. 979, 335–338 (2014)

Cavaler, L.; Schaeffer, L.; Rocha, A.; Peruch, F.: Surface roughness in the incremental forming of AISI 304L stainless steel sheets. J Mechan Eng Phys 1(2), 87–98 (2010)

Bagudanch, I.; Sabater, M.; Garcia-Romeu, M.L.: Single point versus two point incremental forming of thermoplastic materials. Adv. Mater. Process. Technol. 3(1), 135–144 (2017)

Davidson, M.J.; Balasubramanian, K.; Tagore, G.: Surface roughness prediction of flow-formed AA6061 alloy by design of experiments. J. Mater. Process. Technol. 202(1–3), 41–46 (2008)

Mulay, A.; Ben, S.; Ismail, S.; Kocanda, A.: Experimental investigations into the effects of SPIF forming conditions on surface roughness and formability by design of experiments. J. Braz. Soc. Mech. Sci. Eng. 39(10), 3997–4010 (2017)

Kopac, J.; Kampus, Z.: Incremental sheet metal forming on CNC milling machine-tool. J. Mater. Process. Technol. 162, 622–628 (2005)

Cui, Z.; Gao, L.: Studies on hole-flanging process using multistage incremental forming. CIRP J. Manuf. Sci. Technol. 2(2), 124–128 (2010)

Lu, B.; Chen, J.; Ou, H.; Cao, J.: Feature-based tool path generation approach for incremental sheet forming process. J. Mater. Process. Technol. 213(7), 1221–1233 (2013)

Ambrogio, G.; Filice, L.; Manco, G.: Improving process performance in incremental sheet forming (ISF). AIP Conf. Proc. 1315(1), 613–618 (2011)

Cawley, B.; Adams, D.; Jeswiet, J.: Examining tool shapes in single point incremental forming. Proc NAMRI/SME 26, 201–206 (2012)

Adams, D.W.: Improvements on Single Point Incremental Forming Through Electrically Assisted Forming, Contact Area Prediction and Tool Development. Queen’s University, Canada (2014)

Maan, H.Y.: Determining the effect of process parameters on surface roughness in two point incremental sheet metal forming process using the Taguchi method. Eng. Technol. J. 33(7), 1569–1582 (2015)

Shah, H.; Chaudhary, S.: Optimization of process parameters for incremental sheet forming process. Int. J. Technol. Res. Eng. 3(7), 2347–4718 (2016)

Uttarwar P, Raini S.: Study of effect of process parameters on hardness during incremental sheet metal forming. Int. J. Eng. Sci. 3799 (2016)

Chinnaiyan, P.; Jeevanantham, A.: Multi-objective optimization of single point incremental sheet forming of AA5052 using Taguchi based grey relational analysis coupled with principal component analysis. Int. J. Precis. Eng. Manuf. 15(11), 2309–2316 (2014)

Majagi, S.D.; Chandramohan, G.: Optimization of incremental sheet metal forming parameters by design of experiments. In: Applied Mechanics and Materials, pp. 111–116. Trans Tech Publ (2014)

Majagi, S.D.; Chandramohan, G.; Kumar, M.S.: Effect of incremental forming process parameters on aluminum alloy using experimental studies. In: Advanced Materials Research, pp. 633–639. Trans Tech Publ (2015)

Pandivelan, C.; Jeevanantham, A.: Formability evaluation of AA 6061 alloy sheets on single point incremental forming using CNC vertical milling machine. J. Mater. Environ. Sci. 6(5), 1343–1353p (2015)

Mugendiran, V.; Gnanavelbabu, A.; Ramadoss, R.: Parameter optimization for surface roughness and wall thickness on AA5052 Aluminium alloy by incremental forming using response surface methodology. Procedia Eng. 97, 1991–2000 (2014)

Suriyaprakan P.: Single Point Incremental Forming and Multi-Stage Incremental Forming on Aluminium Alloy 1050. Thammasat University (2013)

Chang, Z.; Chen, J.: Mechanism of the twisting in incremental sheet forming process. J. Mater. Process. Technol. 276, 116396 (2020)

Echrif, S.B.; Hrairi, M.: Significant parameters for the surface roughness in incremental forming process. Mater. Manuf. Process. 29(6), 697–703 (2014)

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

UK was involved in methodology, resources collection, investigation, data curation and formal analysis. MHA was involved in conceptualization, supervision and project administration. SQ was involved in software, writing—original draft and visualization. KM was involved in validation and writing—review and editing.

Corresponding author

Ethics declarations

Conflicts of interest

The authors have no conflict of interests. The authors also state that they have full control of all primary data and that they agree to allow the journal to review their data if requested.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Khalil, U., Aziz, M.H., Qamar, S. et al. Parametric Optimization on Single Point Incremental Forming of Aluminum Alloy AA 2219-O using Response Surface Methodology. Arab J Sci Eng 48, 4025–4044 (2023). https://doi.org/10.1007/s13369-022-07333-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-07333-z