Abstract

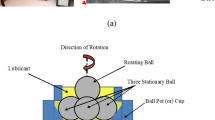

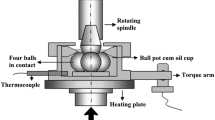

Plant-based oil is a better alternative for replacing petroleum-based oil on account of its good lubricity, biodegradability, availability and low manufacturing cost. The methyl esters obtained from plant-based oils could be used as potential biolubricants in diverse applications, based on their fatty acid profile and properties. The present research investigates the influence of fatty acid composition of three different methyl esters on the physicochemical, thermal and tribological characteristics. Jatropha, Karanja and Cottonseed methyl esters are chosen and important properties viz. fatty acid profile, viscosity, density, TAN and flashpoint are measured. Using a reciprocating wear tester, a sliding contact pair is established between AISI E52100 steel and SS-301. The tribo-tests are carried out under different loads (50, 75 and 100 N) and sliding frequencies (15 and 30 Hz) while keeping the contact pair at 160 °C, simulating the boundary lubrication regime. The output responses such as frictional force, coefficient of friction and wear scar diameter are measured at the end of every trial. The relationship between the fatty acid composition of all investigated methyl esters to their tribological behaviour is deduced and pictorially presented. The test results revealed the supremacy of Jatropha methyl ester over Cottonseed and Karanja. A maximum reduction of about 31% in frictional force and 39% in wear scar diameter are observed with Jatropha methyl ester. The results are substantiated by the microscopic examination of the worn-out surfaces.

Similar content being viewed by others

Data Availability

Can be provided on request.

References

Nowak, P.; Kucharska, K.; Kamiński, M.: Ecological and health effects of lubricant oils emitted into the environment. Int. J. Environ. Res. Public Health 16, 1–13 (2019). https://doi.org/10.3390/ijerph16163002

Zhou, Y.; Zhao, W.; Lai, Y.; Zhang, B.; Zhang, D.: Edible plant oil: global status, health issues, and perspectives. Front. Plant Sci. 11, 1–16 (2020). https://doi.org/10.3389/fpls.2020.01315

Shaah, M.A.H.; Hossain, M.S.; Allafi, F.A.S.; Alsaedi, A.; Ismail, N.; Ab Kadir, M.O.; Ahmad, M.I.: A review on non-edible oil as a potential feedstock for biodiesel: physicochemical properties and production technologies. RSC Adv. 11(40), 25018–25037 (2021)

Jain, S.; Sharma, M.P.: Prospects of biodiesel from Jatropha in India: a review. Renew. Sustain. Energy Rev 14(2), 763–771 (2010)

Heikal, E.K.; Elmelawy, M.S.; Khalil, S.A.; Elbasuny, N.M.: Manufacturing of environment friendly biolubricants from vegetable oils. Egypt. J. Pet 26, 53–59 (2017). https://doi.org/10.1016/j.ejpe.2016.03.003

Matiliunaite, M.; Paulauskiene, T.: From concept to practice: manufacturing of bio-lubricants from renewable resources. Biomass Convers. Biorefinery 9, 353–361 (2019). https://doi.org/10.1007/s13399-018-0356-0

Reeves, C.J.; Siddaiah, A.; Menezes, P.L.: A review on the science and technology of natural and synthetic biolubricants. J. Bio Tribo-Corros. 3, 1–27 (2017). https://doi.org/10.1007/s40735-016-0069-5

Salih, N.; Salimon, J.: A review on eco-friendly green biolubricants from renewable and sustainable plant oil sources. Biointerface Res. Appl. Chem. 11, 13303–13327 (2021). https://doi.org/10.33263/BRIAC115.1330313327

Hussain, M.M.; Pratap, A.P.; Gaval, V.R.: Study of vegetable oil based biolubricants and its hydrodynamic journal bearing application: a review. Tribol. Ind. 43, 511–523 (2021). https://doi.org/10.24874/ti.979.10.20.02

Karmakar, G.; Ghosh, P.; Sharma, B.K.: Chemically modifying vegetable oils to prepare green lubricants. Lubricants 5, 1–17 (2017). https://doi.org/10.3390/lubricants5040044

Kalhapure, A.; Bajaj, D.; Mhaske, V.: Performance evaluation of tribological properties of cotton seed oil for multi-cylinder engine. In: International Journal of Innovation in Engineering, Research and Technology [IJIERT], pp. 1–7 (2015)

Nair, S.S.; Nair, K.P.; Rajendrakumar, P.K.: Evaluation of physicochemical, thermal and tribological properties of sesame oil (Sesamum indicum L.): a potential agricultural crop base stock for eco-friendly industrial lubricants. Int. J. Agric. Resour. Gov. Ecol. 13, 77–90 (2017). https://doi.org/10.1504/IJARGE.2017.084037

Golshokouh, I.; Syahrullail, S.; Golshokouh, M.: Tribology evaluation of jatropha as a new environmental source of lubricant. Eur. Online J. Nat. Soc. Sci 3, 343–348 (2014)

Wang, Z.; Ren, R.; Song, H.; Jia, X.: Improved tribological properties of the synthesized copper/carbon nanotube nanocomposites for rapeseed oil-based additives. Appl. Surf. Sci. 428, 630–639 (2017). https://doi.org/10.1016/j.apsusc.2017.09.207

Sajeeb, A.; Rajendrakumar, P.K.: Comparative evaluation of lubricant properties of biodegradable blend of coconut and mustard oil. J. Clean. Prod. 240, 118255 (2019). https://doi.org/10.1016/j.jclepro.2019.118255

Ruggiero, A.; D’Amato, R.; Merola, M.; Valašek, P.; Müller, M.: Tribological characterization of vegetal lubricants: comparative experimental investigation on Jatropha curcas L. oil, rapeseed methyl ester oil hydrotreated rapeseed oil. Tribol. Int. 109, 529–540 (2017). https://doi.org/10.1016/j.triboint.2017.01.030

Prasannakumar, P.; Edla, S.; Thampi, A.D.; Arif, M.; Santhakumari, R.: A comparative study on the lubricant properties of chemically modified Calophyllum inophyllum oils for bio-lubricant applications. J. Clean. Prod. 339, 130733 (2021). https://doi.org/10.1016/j.jclepro.2022.130733

Woma, T.Y.; Lawal, S.A.; Abdulrahman, A.S.; Olutoye, M.A.: Nigeria Jatropha oil as suitable basestock for biolubricant production. J. Tribol. 23, 97–112 (2020)

Ewunie, G.A.; Morken, J.; Lekang, O.I.; Yigezu, Z.D.: Factors affecting the potential of Jatropha curcas for sustainable biodiesel production: a critical review. Renew. Sustain. Energy Rev. 137, 110500 (2020). https://doi.org/10.1016/j.rser.2020.110500

Kumbhar, V.; Pandey, A.; Sonawane, C.R.; El-Shafay, A.S.; Panchal, H.; Chamkha, A.J.: Statistical analysis on prediction of biodiesel properties from its fatty acid composition. Case Stud. Therm. Eng. 30, 101775 (2022). https://doi.org/10.1016/j.csite.2022.101775

Farfan-Cabrera, L.I.; Gallardo-Hernández, E.A.; Pérez-González, J.; Marín-Santibáñez, B.M.; Lewis, R.: Effects of Jatropha lubricant thermo-oxidation on the tribological behaviour of engine cylinder liners as measured by a reciprocating friction test. Wear 426–427, 910–918 (2019). https://doi.org/10.1016/j.wear.2019.02.028

Sharma, U.C.; Sachan, S.: Friction and wear behavior of karanja oil derived biolubricant base oil. SN Appl. Sci. 1, 668 (2019). https://doi.org/10.1007/s42452-019-0706-y

Amruth, E.; Sudev, L.J.: Characterization of biodiesels produced using mixed base catalyst by gas chromatography and FTIR spetroscopy. Int. J. Innov. Technol. Explor. Eng. 9, 668–672 (2020). https://doi.org/10.35940/ijitee.d1767.069820

Lamba, B.Y.; Joshi, G.; Rawat, D.S.; Jain, S.; Kumar, S.: Study of oxidation behavior of Jatropha oil methyl esters and Karanja oil methyl esters blends with EURO-IV high speed diesel. Renew. Energy Focus 27, 59–66 (2018). https://doi.org/10.1016/j.ref.2018.09.002

Liu, Z.; Li, F.; Shen, J.; Wang, H.: Effect of oxidation of Jatropha curcas-derived biodiesel on its lubricating properties. Energy Sustain. Dev. 52, 33–39 (2019). https://doi.org/10.1016/j.esd.2019.06.003

Knothe, G.; Krahl, J.; Van Gerpen, J. (eds): Biodiesel production. In: Biodiesel Handbook, 2nd edn, pp. 31–96 (2010). https://doi.org/10.1016/B978-1-893997-62-2.50009-7

Kumar, V.; Wani, M.F.; Mannekote, J.K.; Kailas, S.V.: Tribological properties of some fatty acids. J. Phys. Conf. Ser. 1240, 012133 (2019). https://doi.org/10.1088/1742-6596/1240/1/012133

Venkatesan, H.; John, G.; Sivamani, S.: Cotton seed biodiesel as alternative fuel: production and its characterization analysis using spectroscopic studies. Int. J. Renew. Energy Res. 7, 1333–1339 (2017). https://doi.org/10.20508/ijrer.v7i3.6085.g7166

Suh, A.Y.; Polycarpou, A.A.; Conry, T.F.: Detailed surface roughness characterization of engineering surfaces undergoing tribological testing leading to scuffing. Wear 255, 556–568 (2003). https://doi.org/10.1016/S0043-1648(03)00224-2

Vorburger, T.V.; Rhee, H.G.; Renegar, T.B.; Song, J.F.; Zheng, A.: Comparison of optical and stylus methods for measurement of surface texture. Int. J. Adv. Manuf. Technol. 33, 110–118 (2007). https://doi.org/10.1007/s00170-007-0953-8

Farhanah, A.N.; Syahrullail, S.: Evaluation of lubrication performance of RBD palm stearin and its formulation under different applied loads. J. Tribol. 10, 1–15 (2016)

Quinchia, L.A.; Delgado, M.A.; Reddyhoff, T.; Gallegos, C.; Spikes, H.A.: Tribological studies of potential vegetable oil-based lubricants containing environmentally friendly viscosity modifiers. Tribol. Int. 69, 110–117 (2014). https://doi.org/10.1016/j.triboint.2013.08.016

Zulhanafi, P.; Syahrullail, S.; AbdulHamid, M.K.; Chong, W.W.F.: The effect of saturated and unsaturated fatty acid composition in bio-based lubricant to the tribological performances using four-ball tribotester. J. Oil. Palm. Res. 33, 653–667 (2021)

Verdier, S.; Coutinho, J.A.; Silva, A.M.; Alkilde, O.F.; Hansen, J.A.: A critical approach to viscosity index. Fuel 88(11), 2199–2206 (2009)

Kalam, M.A.; Masjuki, H.H.; Shahabuddin, M.; Mofijur, M.: Tribological characteristics of amine phosphate and octylated/butylated diphenylamine additives infused bio-lubricant. Energy Educ. Sci. Technol. Part A Energy Sci. Res. 30(1), 123–136 (2012)

Wadumesthrige, K.; Ara, M.; Salley, S.O.; Ng, K.Y.S.: Investigation of lubricity characteristics of biodiesel in petroleum and synthetic fuel. Energy Fuels 23, 2229–2234 (2009). https://doi.org/10.1021/ef800887y

Hamdan, S.H.; Chong, W.W.F.; Ng, J.H.; Ghazali, M.J.; Wood, R.J.K.: Influence of fatty acid methyl ester composition on tribological properties of vegetable oils and duck fat derived biodiesel. Tribol. Int. 113, 76–82 (2017). https://doi.org/10.1016/j.triboint.2016.12.008

Zainal, N.A.; Zulkifli, N.W.M.; Gulzar, M.; Masjuki, H.H.: A review on the chemistry, production, and technological potential of bio-based lubricants. Renew. Sustain. Energy Rev. 82, 80–102 (2018). https://doi.org/10.1016/j.rser.2017.09.004

Acknowledgements

The authors would like to thank the management of the Vellore Institute of Technology, Vellore for the facilities provided during the execution of this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interests.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rajasozhaperumal, G., Kannan, C. Influence of Fatty Acid Composition on the Tribological Performance of Methyl Esters Under Boundary Lubrication Regime. Arab J Sci Eng 48, 3581–3597 (2023). https://doi.org/10.1007/s13369-022-07232-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-07232-3