Abstract

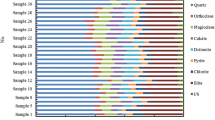

Shale resources contain a significant quantity of clay minerals and organic matter. These material components influence the evolution of intra- and inter-granular pore features. This study investigates the role of clay’s elemental concentration, purity and types on its pore attributes. Four samples; illite, chlorite, montmorillonite, and kaolinite-rich clay samples were studied. Clay elemental composition, purity, pore shape, and structural parameters were determined. X-ray fluorescence and diffraction techniques were used to compute the elemental and mineralogical compositions of clay samples, respectively. Rock surfaces were mapped using the energy dispersive x-ray spectroscopy and scanning electron microscopy to confirm the distribution of elements and clay homogeneity, respectively in the four phyllosilicate materials. Total organic content analysis confirms the quantity of organic matter. N2 adsorption/desorption experiment at 77 K and over a relative pressure range up to 0.995 was executed with a surface area and porosity analyzer, to extract information regarding the pore shape, and determine the pore volume and specific surface area. The interrelation of the purity and computed pore structure properties was established. Mineralogy and elemental analyses showed that the studied samples with clay purities of 60–98% have a combined 80–96 wt.% of Aluminum (Al), Silicon (Si), and Iron (Fe). The adsorption–desorption curve at \( p/p^{o} < 0.04\) and carbon content analysis indicate that clays accommodate negligible micropores. The type III and IV isotherms combined with H1, H2, and H3 hysteresis loop implied that clay had connected complex pores with plate-like, uniform cylindrical, and inkbottle shapes. Capillary condensation and evaporation curves revealed more mesopores and macropores of 2-50 nm and > 50 nm, respectively. The pore distribution plateaued around an average of 100 nm, which confirmed the suitability of the Barrett-Joyner-Halenda technique to characterize clay mesopores. Kaolinite has the highest capacity (74.43 \({\text{cm}}^{{3}} {\text{/g}}\)) to host N2 gas at a standard temperature and pressure followed by montmorillonite (65.08 \({\text{cm}}^{{3}} {\text{/g}}\)), chlorite (21.01 \({\text{cm}}^{{3}} {\text{/g}}\)) and illite (16.59 \({\text{cm}}^{{3}} {\text{/g}}\)) in that order. The capacity of the pores to store fluid and their average size follow a similar pattern and increase with aluminum and clay contents. A specific surface area of the non-micropores is directly related to silicon concentration. The study provides an insight regarding the potential of kaolinite (with the highest aluminum concentration of 39.5 wt.%) as a good catalytic material required to speed up the esterification reaction. In addition, it can serve as a waste repository and a material for the treatment of phosphorus-containing contaminants in polluted areas. This research confirms that montmorillonite with the largest specific surface area in non-micropores and silicon content of 63.9 wt.% promotes reactivity and cation exchange interaction. However, this high basal spacing attribute of the material means that swelling will occur in the presence of water.

Similar content being viewed by others

Abbreviations

- \(A_{{\text{m}}} = 0.162\;{\text{ nm}}^{{2}}\) :

-

Is nitrogen molecule surface area at 77 K

- \(c_{{{\text{BET}}}}\) :

-

BET isotherm fitting constant

- \(N_{{\text{A}}}\) :

-

Avogadro’s number \(\left( {6.022 \times 10^{22} \frac{{{\text{number}}}}{{{\text{mol}}}}} \right)\)

- \(p^{o}\) :

-

Standard pressure of \({\text{N}}_{2} {\text{ gas}}\) \(\sim 1.02{\text{ bar at }}77.4{\text{ K}}\)

- \(p/p^{o}\) :

-

Relative pressure of \({\text{N}}_{2} {\text{ gas}}\) between 0.001 and 0.995 and 77.4 K

- \(r\) :

-

Pore radius (m)

- \(R = 8.314{\text{ J}}/{\text{Kmol}}\) :

-

Is universal gas constant

- \(s_{{{\text{BET}}}} \) :

-

Total specific surface area (m2/g)

- \(S_{{{\text{ext}}}} { }\) :

-

Non-micropores specific surface area

- \(S_{{{\text{mic}}}}\) :

-

Micropores specific surface area

- \(t_{{{\text{ads}}}}\) :

-

Statistical thickness of adsorbed layer (Å)

- \(T\) :

-

Temperature (\(K\))

- \({\text{V}}_{{{\text{ads}}}} { }\) :

-

Total volume of adsorbed N2 gas at p⁄po = 0.001–0.995 and 77.4 K (m3/kg)

- \(V_{{\text{m}}}\) :

-

Monolayer adsorption capacity (cm3/g)

- \(V_{{{\text{mic}}}}\) :

-

Micropore filling volume

- \(V_{{{\text{mol}}}}\) :

-

Molar volume (m3/mol)

- \(\alpha\) :

-

Shape factor of the gas/liquid interface during adsorption

- \(\Delta H_{{\text{m}}}\) :

-

Heat of gas condensation

- \(\gamma\) :

-

Surface tension of liquid nitrogen (N/m)

- AFM:

-

Atomic force microscopy

- APM:

-

Areal porosity method

- BET:

-

Brunauer, Emmett and Teller

- BJH:

-

Barrett, Joyner and Halenda

- BSE:

-

Backscatter electron

- DRIFTs:

-

Diffuse reflectance Fourier transform infrared spectroscopy

- EBSD:

-

Electron backscatter diffraction

- EDX:

-

Energy-dispersive X-Ray spectroscopy

- EGME:

-

Ethylene glycol monoethyl ether

- HCPC:

-

Hierarchical clustering of principal components

- IUPAC:

-

International union of pure and applied chemistry

- LEED:

-

Low energy electron diffraction

- LOD:

-

Limit of detection

- MIP:

-

Mercury injection porosimetry

- NDIR:

-

Non-destructive infrared

- NMR:

-

Nuclei magnetic resonance

- QEMSCAN:

-

Quantitative evaluation of minerals by scanning electron microscopy

- SANS:

-

Small angle neutron scattering

- SAXS:

-

Small angle X-ray scattering

- SEM:

-

Scanning electron microscopy

- SSA:

-

Specific Surface Area

- SSM:

-

Solid sample measurements

- STP:

-

Standard temperature and pressure

- 3D-SIMS:

-

Three-dimensional secondary ion mass spectroscopy

- TEM:

-

Transmission electron microscopy

- TOC:

-

Total organic content

- XRD:

-

X-ray diffraction

- µXRF:

-

Micro- X-ray fluorescence

References

Yaalon, D.H.: Mineral composition of the average shale. Clay Miner. (1962). https://doi.org/10.1180/claymin.1962.5.27.05

Ambrose, R.J.; Hartman, R.C.; Diaz-Campos, M.; Akkutlu, I.Y.; Sondergeld, C.H.: Shale gas-in-place calculations. Part I: new pore-scale considerations. SPE J. 17, 219–229 (2012). https://doi.org/10.2118/131772-PA

Afagwu, C.; Abubakar, I.; Kalam, S.; Al-Afnan, S.F.; Awotunde, A.A.: Pressure-transient analysis in shale gas reservoirs: a review. J. Nat. Gas Sci. Eng. 78, 103319 (2020). https://doi.org/10.1016/j.jngse.2020.103319

Jin, Z.; Firoozabadi, A.: Methane and carbon dioxide adsorption in clay-like slit pores by Monte Carlo simulations. Fluid Phase Equilib. 360, 456–465 (2013). https://doi.org/10.1016/j.fluid.2013.09.047

Ross, D.J.K.; Marc-Bustin, R.: The importance of shale composition and pore structure upon gas storage potential of shale gas reservoirs. Mar. Pet. Geol. 26, 916–927 (2009). https://doi.org/10.1016/j.marpetgeo.2008.06.004

Yuan, Y.; Rezaee, R.: Comparative porosity and pore structure assessment in shales: measurement techniques, influencing factors and implications for reservoir characterization. Energies 12, 7–9 (2019). https://doi.org/10.3390/en12112094

Zhang, Y.; Shao, D.; Yan, J.; Jia, X.; Li, Y.; Yu, P.; Zhang, T.: The pore size distribution and its relationship with shale gas capacity in organic-rich mudstone of Wufeng-Longmaxi Formations, Sichuan Basin, China. J. Nat. Gas Geosci. 1, 213–220 (2016). https://doi.org/10.1016/j.jnggs.2016.08.002

El Ouahabi, M.; Daoudi, L.; Fagel, N.: Mineralogical and geotechnical characterization of clays from northern Morocco for their potential use in the ceramic industry. Clay Miner. (2014). https://doi.org/10.1180/claymin.2014.049.1.04

Hubert, F.; Caner, L.; Meunier, A.; Lanson, B.: Advances in characterization of soil clay mineralogy using X-ray diffraction: from decomposition to profile fitting. Eur. J. Soil Sci. 60, 1093–1105 (2009). https://doi.org/10.1111/j.1365-2389.2009.01194.x

Środoń, J.: Chapter 12.2 identification and quantitative analysis of clay minerals. Dev. Clay Sci. 1, 765–787 (2006). https://doi.org/10.1016/S1572-4352(05)01028-7

Mattioli, M.; Giardini, L.; Roselli, C.; Desideri, D.: Mineralogical characterization of commercial clays used in cosmetics and possible risk for health. Appl. Clay Sci. 119, 449–454 (2016). https://doi.org/10.1016/j.clay.2015.10.023

Zhong, H.; Yang, T.; Yin, H.; Lu, J.; Zhang, K.; Fu, C.: Role of Alkali type in chemical loss and ASP-flooding enhanced oil recovery in Sandstone formations. SPE Reserv. Eval. Eng. 23, 431–445 (2020). https://doi.org/10.2118/191545-PA

Zhao, Y.; Han, C.; Sun, Y.; Danesh, N.N.; Liu, T.; Gao, Y.: Nano- to micro-pore characterization by synchrotron radiation SAXS and nano-CT for bituminous coals. Front. Earth Sci. 15, 189–201 (2021). https://doi.org/10.1007/s11707-021-0889-6

Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Jarvie, D.M.: Morphology, genesis, and distribution of nanometer-scale pores in siliceous mudstones of the Mississippian Barnett Shale. J. Sediment. Res. 79, 848–861 (2009). https://doi.org/10.2110/jsr.2009.092

Tang, Y.; Hou, C.; He, Y.; Wang, Y.; Chen, Y.; Rui, Z.: Review on pore structure characterization and microscopic flow mechanism of CO2 flooding in porous media. Energy Technol. 2021, 9 (2021). https://doi.org/10.1002/ente.202000787

Aringhieri, R.: Nanoporosity characteristics of some natural clay minerals and soils. Clays Clay Miner. (2004). https://doi.org/10.1346/CCMN.2004.0520604

Luo, P.; Zhong, N.; Khan, I.; Wang, X.; Wang, H.; Luo, Q.; Guo, Z.: Effects of pore structure and wettability on methane adsorption capacity of mud rock: insights from mixture of organic matter and clay minerals. Fuel 251, 551–561 (2019). https://doi.org/10.1016/j.fuel.2019.04.072

Kuila, U.; Prasad, M.: Specific surface area and pore-size distribution in clays and shales. Geophys. Prospect. (2013). https://doi.org/10.1111/1365-2478.12028

Tompsett, G.A.; Krogh, L.; Griffin, D.W.; Conner, W.C.: Hysteresis and scanning behavior of mesoporous molecular sieves. Langmuir 21, 8214–8225 (2005). https://doi.org/10.1021/la050068y

Wang, X.; Cheng, H.; Chai, P.; Bian, J.; Wang, X.; Liu, Y.; Yin, X.; Pan, S.; Pan, Z.: Pore characterization of different clay minerals and its impact on methane adsorption capacity. Energy Fuels 34, 12204–12214 (2020). https://doi.org/10.1021/acs.energyfuels.0c01922

Sayed Hassan, M.; Villieras, F.; Gaboriaud, F.; Razafitianamaharavo, A.: AFM and low-pressure argon adsorption analysis of geometrical properties of phyllosilicates. J. Colloid Interface Sci. 296, 614–623 (2006). https://doi.org/10.1016/j.jcis.2005.09.028

Macht, F.; Eusterhues, K.; Pronk, G.J.; Totsche, K.U.: Specific surface area of clay minerals: comparison between atomic force microscopy measurements and bulk-gas (N2) and -liquid (EGME) adsorption methods. Appl. Clay Sci. 53, 20–26 (2011). https://doi.org/10.1016/j.clay.2011.04.006

Kariem, H.; Kiefer, T.; Hellmich, C.; Gaggl, W.; Steiger-Thirsfeld, A.; Füssl, J.: EDX/XRD-based identification of micrometer-sized domains in scanning electron micrographs of fired clay. Mater. Struct. Constr. 2020, 53 (2020). https://doi.org/10.1617/s11527-020-01531-7

Ochieng, O.: Characterization and classification of clay minerals for potential applications in Rugi Ward, Kenya. Afr. J. Environ. Sci. Technol. (2016). https://doi.org/10.5897/ajest2016.2184

Adeniyi, F.I.; Ogundiran, M.B.; Hemalatha, T.; Hanumantrai, B.B.: Characterization of raw and thermally treated Nigerian kaolinite-containing clays using instrumental techniques. SN Appl. Sci. 2, 1–14 (2020). https://doi.org/10.1007/s42452-020-2610-x

Chen, J.J.; Sorelli, L.; Vandamme, M.; Ulm, F.J.; Chanvillard, G.: A coupled nanoindentation/SEM-EDS study on low water/cement ratio portland cement paste: evidence for C-S-H/Ca(OH)2 nanocomposites. J. Am. Ceram. Soc. 93, 1484–1493 (2010). https://doi.org/10.1111/j.1551-2916.2009.03599.x

Boulingui, J.E.; Nkoumbou, C.; Njoya, D.; Thomas, F.; Yvon, J.: Characterization of clays from Mezafe and Mengono (Ne-Libreville, Gabon) for potential uses in fired products. Appl. Clay Sci. 115, 132–144 (2015). https://doi.org/10.1016/j.clay.2015.07.029

Zaffar, M.; Lu, S.G.: Pore size distribution of clayey soils and its correlation with soil organic matter. Pedosphere 25, 240–249 (2015). https://doi.org/10.1016/S1002-0160(15)60009-1

Li, W.; Lu, S.; Xue, H.; Zhang, P.; Hu, Y.: Microscopic pore structure in shale reservoir in the argillaceous dolomite from the Jianghan Basin. Fuel 181, 1041–1049 (2016). https://doi.org/10.1016/j.fuel.2016.04.140

Wilson, W.; Sorelli, L.; Tagnit-Hamou, A.: Automated coupling of NanoIndentation and quantitative energy-dispersive spectroscopy (NI-QEDS): a comprehensive method to disclose the micro-chemo-mechanical properties of cement pastes. Cem. Concr. Res. 103, 49–65 (2018). https://doi.org/10.1016/j.cemconres.2017.08.016

Elgamouz, A.; Tijani, N.; Shehadi, I.; Hasan, K.; Al-Farooq Kawam, M.: Characterization of the firing behaviour of an illite-kaolinite clay mineral and its potential use as membrane support. Heliyon. 5, e02281 (2019). https://doi.org/10.1016/j.heliyon.2019.e02281

Qian, G.; Li, Y.; Gerson, A.R.: Applications of surface analytical techniques in earth sciences (2015)

Lei, Q.; Zhang, L.; Tang, H.; Zhao, Y.; Chen, M.; Xie, C.: Describing the full pore size distribution of tight sandstone and analyzing the impact of clay type on pore size distribution. Geofluids (2020). https://doi.org/10.1155/2020/5208129

Kamal, M.S.; Mahmoud, M.; Hanfi, M.; Elkatatny, S.; Hussein, I.: Clay minerals damage quantification in sandstone rocks using core flooding and NMR. J. Pet. Explor. Prod. Technol. 9, 593–603 (2019). https://doi.org/10.1007/s13202-018-0507-7

Takbiri-Borujeni, A.; Kazemi, M.; Sun, T.; Mansouri-Boroujeni, M.: Effect of kerogen type and maturity on performance of carbon dioxide storage in shale. In: Proc. SPE Annu. Tech. Conf. Exhib. 2040 (2017). https://doi.org/10.2118/187360-ms

Obliger, A.; Ulm, F.J.; Pellenq, R.: Impact of nanoporosity on hydrocarbon transport in shales’ organic matter. Nano Lett. 18, 832–837 (2018). https://doi.org/10.1021/acs.nanolett.7b04079

Vandenbroucke, M.; Largeau, C.: Kerogen origin, evolution and structure. Org. Geochem. 38, 719–833 (2007). https://doi.org/10.1016/j.orggeochem.2007.01.001

Okiongbo, K.S.; Aplin, A.C.; Larter, S.R.: Changes in type II Kerogen density as a function of maturity: evidence from the Kimmeridge clay formation. Energy Fuels 19, 2495–2499 (2005). https://doi.org/10.1021/ef050194+

Ji, L.; Zhang, T.; Milliken, K.L.; Qu, J.; Zhang, X.: Experimental investigation of main controls to methane adsorption in clay-rich rocks. Appl. Geochem. 27, 2533–2545 (2012). https://doi.org/10.1016/j.apgeochem.2012.08.027

Dang, W.; Zhang, J.; Wei, X.; Tang, X.; Chen, Q.; Li, Z.; Zhang, M.; Liu, J.: Geological controls on methane adsorption capacity of Lower Permian transitional black shales in the Southern North China Basin, Central China: experimental results and geological implications. J. Pet. Sci. Eng. 152, 456–470 (2017). https://doi.org/10.1016/j.petrol.2017.03.017

Amao, A.O.; Al-Ramadan, K.; Koeshidayatullah, A.: Automated mineralogical methodology to study carbonate grain microstructure: an example from oncoids. Environ. Earth Sci. 75, 1–11 (2016). https://doi.org/10.1007/s12665-016-5492-x

Afagwu, C.; Mahmoud, M.A.; Alafnan, S.; Patil, S.: Multiscale storage and transport modeling in unconventional shale gas: a review. J. Pet. Sci. Eng. 2021, 109518 (2021). https://doi.org/10.1016/j.petrol.2021.109518

Brunauer, S.; Emmett, P.H.; Teller, E.: Adsorption of gases in multimolecular layers. J. Am. Chem. Soc. 60, 309–319 (1938). https://doi.org/10.1021/ja01269a023

Sing, K.: The use of nitrogen adsorption for the characterisation of porous materials. Colloids Surfaces A Physicochem. Eng. Asp. 187–188, 3–9 (2001). https://doi.org/10.1016/S0927-7757(01)00612-4

Mohammed, I.; Afagwu, C.C.; Adjei, S.; Kadafur, I.B.; Jamal, M.S.; Awotunde, A.A.: A review on polymer, gas, surfactant and nanoparticle adsorption modeling in porous media. Oil Gas Sci. Technol. 2020, 75 (2020). https://doi.org/10.2516/ogst/2020063

Tian, H.; Pan, L.; Zhang, T.; Xiao, X.; Meng, Z.; Huang, B.: Pore characterization of organic-rich Lower Cambrian shales in Qiannan Depression of Guizhou Province, Southwest China. Mar. Pet. Geol. 62, 28–43 (2015). https://doi.org/10.1016/j.marpetgeo.2015.01.004

Rouquerol, J.; Llewellyn, P.; Rouquerol, F.: Is the BET equation applicable to microporous adsorbents? Stud. Surf. Sci. Catal. (2007). https://doi.org/10.1016/s0167-2991(07)80008-5

de Boer, J.H.; Lippens, B.C.; Linsen, B.G.; Broekhoff, J.C.P.; van den Heuvel, A.; Osinga, T.J.: Thet-curve of multimolecular N2-adsorption. J. Colloid Interface Sci. 21, 405–414 (1966). https://doi.org/10.1016/0095-8522(66)90006-7

Coasne, B.; Gubbins, K.E.; Pellenq, R.J.M.: A Grand Canonical Monte Carlo study of adsorption and capillary phenomena in nanopores of various morphologies and topologies: testing the BET and BJH characterization methods. Part. Part. Syst. Charact. 21, 149–160 (2004). https://doi.org/10.1002/ppsc.200400928

Sing, K.S.W.: Reporting physisorption data for gas/solid systems. Presented at the (1984)

Xiong, J.; Liu, X.; Liang, L.; Zeng, Q.: Adsorption of methane in organic-rich shale nanopores: an experimental and molecular simulation study. Fuel 200, 299–315 (2017). https://doi.org/10.1016/j.fuel.2017.03.083

Barsotti, E.; Tan, S.P.; Piri, M.; Chen, J.H.: Capillary-condensation hysteresis in naturally-occurring nanoporous media. Fuel 2020, 263 (2020). https://doi.org/10.1016/j.fuel.2019.116441

Groen, J.C.; Peffer, L.A.A.; Pérez-Ramírez, J.: Pore size determination in modified micro- and mesoporous materials. Pitfalls and limitations in gas adsorption data analysis. Microporous Mesoporous Mater. 60, 1–17 (2003). https://doi.org/10.1016/S1387-1811(03)00339-1

Barrett, E.P.; Joyner, L.G.; Halenda, P.P.: The determination of pore volume and area distributions in porous substances. I. Computations from nitrogen isotherms. J. Am. Chem. Soc. (1951). https://doi.org/10.1021/ja01145a126

Hwang, J.; Pini, R.: Supercritical CO2 and CH4 uptake by illite-smectite clay minerals. Environ. Sci. Technol. 53, 11588–11596 (2019). https://doi.org/10.1021/acs.est.9b03638

Li, T.; Tian, H.; Chen, J.; Cheng, L.: Application of low pressure gas adsorption to the characterization of pore size distribution of shales: an example from Southeastern Chongqing area, China. J. Nat. Gas Geosci. 1, 221–230 (2016). https://doi.org/10.1016/j.jnggs.2016.07.001

Tian, H.; Li, T.; Zhang, T.; Xiao, X.: Characterization of methane adsorption on overmature Lower Silurian-Upper Ordovician shales in Sichuan Basin, southwest China: experimental results and geological implications. Int. J. Coal Geol. 156, 36–49 (2016). https://doi.org/10.1016/j.coal.2016.01.013

Tournassat, C.; Bourg, I.C.; Steefel, C.I.; Bergaya, F.: Surface properties of clay minerals. Dev. Clay Sci. 6, 5–31 (2015)

Muhammed, N.S.; Olayiwola, T.; Elkatatny, S.; Haq, B.; Patil, S.: Journal of Natural Gas Science and Engineering Insights into the application of surfactants and nanomaterials as shale inhibitors for water-based drilling fluid: a review. J. Nat. Gas Sci. Eng. 92, 103987 (2021). https://doi.org/10.1016/j.jngse.2021.103987

Fatimah, I.; Narsito, W.K.: Effect of aluminium content in aluminium pillared montmorillonite on its surface acidity properties. ITB J. Sci. 43(A), 123–138 (2011). https://doi.org/10.5614/itbj.sci.2011.43.2.5

Yang, H.; He, K.; Lu, D.; Wang, J.; Xu, D.; Jin, Z.; Yang, M.; Chen, J.: Removal of phosphate by aluminum-modified clay in a heavily polluted lake, Southwest China: effectiveness and ecological risks. Sci. Total Environ. 705, 135850 (2020). https://doi.org/10.1016/j.scitotenv.2019.135850

Wang, J.; Chen, J.; Chen, Q.; Yang, H.; Zeng, Y.; Yu, P.; Jin, Z.: Assessment on the effects of aluminum-modified clay in inactivating internal phosphorus in deep eutrophic reservoirs. Chemosphere 215, 657–667 (2019). https://doi.org/10.1016/j.chemosphere.2018.10.095

Roshan, H.; Lv, A.; Aghighi, M.A.; Sarmadivaleh, M.; Siddiqui, M.A.Q.; van As, D.; Ehsani, S.: Stabilization of clay-rich interburdens using silica nanoparticles. J. Pet. Sci. Eng. 211, 110126 (2022). https://doi.org/10.1016/j.petrol.2022.110126

Sadek, O.M.; Reda, S.M.; Al-Bilali, R.K.: Preparation and characterization of silica and clay-silica core-shell nanoparticles using sol-gel method. Adv. Nanoparticl. (2013). https://doi.org/10.4236/anp.2013.22025

Alperovitch, N.; Shainberg, I.; Keren, R.; Singer, M.J.: Effect of clay mineralogy and aluminium and iron oxides on the hydraulic conductivity of clay-sand mixtures. Clays Clay Miner. (1985). https://doi.org/10.1346/ccmn.1985.0330511

Muhammed, N.S.; Olayiwola, T.; Elkatatny, S.: A review on clay chemistry, characterization and shale inhibitors for water-based drilling fluids. J. Pet. Sci. Eng. 206, 109043 (2021)

Acknowledgements

The authors acknowledge the provision of experimental equipment by the College of Petroleum Engineering and Geosciences (CPG) and the Research Institute at King Fahd University of Petroleum and Minerals, Dhahran, Saudi Arabia. A special appreciation to Dr. Abduljamiu Olalekan Amao, Mr. Bandar Al-Otaibi, Ms. Mashaer Alfaraj, and Mr. Nadeem Syed for their assistance in CPG laboratory analyses. The authors thank Mr. Reynante Balmes Pagcaliwagan for his cooperation in using the Surface Area and Porosity analyzer Micromeritics ASAP2020 model for the N2 adsorption experiment. The authors also thank anonymous reviewers for providing comments, which improve the manuscript’s quality.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Rights and permissions

About this article

Cite this article

Afagwu, C., Mahmoud, M., Alafnan, S. et al. Pore Volume Characteristics of Clay-Rich Shale: Critical Insight into the Role of Clay Types, Aluminum and Silicon Concentration. Arab J Sci Eng 47, 12013–12029 (2022). https://doi.org/10.1007/s13369-022-06720-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-06720-w