Abstract

Biodiesel and ethanol are known as the typical alternative and renewable fuels that can replace fossil and mineral fuels; however, they can affect combustion due to their undesirable innate traits. The investigation is a numerical attempt to compare the synthesized blended fuels of diesel–ethanol (DE) and diesel–biodiesel (DB) and pure diesel (D100) when combusted in a high-speed direct injection (HSDI) diesel engine. The blends are B10D90, B50D50, E05D95, E10D90, and E85D15. In the initial condition of the code, the fuel is defined as multi-component and the share of each component is determined. The results are indicative of lower ethanol-blended fuel’s mean spray droplet (SMD), thus lower CO2 and soot emissions although it is afflicted with low engine output in terms of power and efficiency. The interaction of SMDE85D15 = 2.5 µm and LHVE85D15 = 31,045.3 kJ/kg with the SMDB50D50 = 2.664 µm and LHVB50D50 = 40335 kJ/kg, droplet diameter is more efficient in emission reduction in better spraying, and on the other hand fuel’s intrinsic heat value is more significant for power generation.

Similar content being viewed by others

Abbreviations

- AHR:

-

Accumulated heat release (J)

- ATDC:

-

After top dead center

- BD:

-

Biodiesel–diesel

- B50D50:

-

50% Biodiesel, 50% diesel shares by volume

- CA:

-

Crank angle

- D100:

-

Pure diesel

- ECFM-3Z:

-

Extended coherent flame method-3 zone

- ED:

-

Ethanol–diesel

- EGR:

-

Exhaust gas recirculation

- EVO:

-

Exhaust valve opening

- HSDI:

-

High-speed direct injection

- IVC:

-

Injection valve closing

- LHV:

-

Lower heating value (MJ/kg)

- SMD:

-

Sauter mean diameter (m)

- TKE:

-

Turbulent kinetic energy (m2/s2)

- VGT:

-

Variable geometry turbocharging

- u :

-

Velocity component

- x :

-

Fuel’s volumetric ratio

- ∂cNO/∂t :

-

NO concentration variation

References

Qi, D.H.; Chen, H.; Geng, L.M.; Bian, Y.Z.: Effect of diethyl ether and ethanol additives on the combustion and emission characteristics of biodiesel–diesel blended fuel engine. Renew. Energy 36(4), 1252–1258 (2011)

Tan, P.Q.; Ruan, S.S.; Hu, Z.Y.; Lou, D.M.; Li, H.: Particle number emissions from a light-duty diesel engine with biodiesel fuels under transient-state operating conditions. Appl. Energy 113, 22–31 (2014)

Taghavifar, H.; Khalilarya, S.; Mirhasani, S.; Jafarmadar, S.: Numerical energetic and exergetic analysis of CI diesel engine performance for different fuels of hydrogen, dimethyl ether, and diesel under various engine speeds. Int. J. Hydrogen Energy 39(17), 9515–9526 (2014)

Kumar, S.; Cho, J.H.; Park, J.; Moon, I.: Advances in diesel–alcohol blends and their effects on the performance and emissions of diesel engines. Renew. Sustain. Energy Rev. 22, 46–72 (2013)

Yusri, I.M.; Mamat, R.; Najafi, G.; Razman, A.; Awad, O.I.; Azmi, W.H.; Ishak, W.F.W.; Shaiful, A.I.M.: Alcohol based automotive fuels from first four alcohol family in compression and spark ignition engine: a review on engine performance and exhaust emissions. Renew. Sustain. Energy Rev. 77, 169–181 (2017)

Union, E.: Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the promotion of the use of energy from renewable sources and amending and subsequently repealing Directives 2001/77/EC and 2003/30/EC. Off. J. Eur. Union 5, 2009 (2009)

Yang, K.; Wei, L.; Cheung, C.S.; Tang, C.; Huang, Z.: The effect of pentanol addition on the particulate emission characteristics of a biodiesel operated diesel engine. Fuel 209, 132–140 (2017)

Basso, G.L.; de Santoli, L.; Albo, A.; Nastasi, B.: H2NG (hydrogen-natural gas mixtures) effects on energy performances of a condensing micro-CHP (combined heat and power) for residential applications: an expeditious assessment of water condensation and experimental analysis. Energy 84, 397–418 (2015)

Asadi, A.; Kadijani, O.N.; Doranehgard, M.H.; Bozorg, M.V.; Xiong, Q.; Shadloo, M.S.; Li, L.K.: Numerical study on the application of biodiesel and bioethanol in a multiple injection diesel engine. Renew. Energy (2019). https://doi.org/10.1016/j.renene.2019.11.088

Biswal, A.; Kale, R.; Balusamy, S.; Banerjee, R.; Kolhe, P.: Lemon peel oil as an alternative fuel for GDI engines: a spray characterization perspective. Renew. Energy 142, 249–263 (2019)

Scholl, A.L.; Menegol, D.; Pitarelo, A.P.; Fontana, R.C.; Zandoná Filho, A.; Ramos, L.P.; Dillon, A.J.P.; Camassola, M.: Ethanol production from sugars obtained during enzymatic hydrolysis of elephant grass (Pennisetum purpureum, Schum.) pretreated by steam explosion. Biores. Technol. 192, 228–237 (2015)

Byrne, G.; O’Shaughnessy, S.M.: Performance characteristics and exhaust gas analysis of a diesel engine using biodiesel fuel blends. Biofuels (2017). https://doi.org/10.1080/17597269.2017.1358943

Kumar, P.; Rehman, A.: Bio-diesel in homogeneous charge compression ignition (HCCI) combustion. Renew. Sustain. Energy Rev. 56, 536–550 (2016)

Tutak, W.; Jamrozik, A.; Pyrc, M.; Sobiepański, M.: A comparative study of co-combustion process of diesel–ethanol and biodiesel–ethanol blends in the direct injection diesel engine. Appl. Therm. Eng. 117, 155–163 (2017)

Liu, H.; Ma, X.; Li, B.; Chen, L.; Wang, Z.; Wang, J.: Combustion and emission characteristics of a direct injection diesel engine fueled with biodiesel and PODE/biodiesel fuel blends. Fuel 209, 62–68 (2017)

Paul, A.; Panua, R.; Debroy, D.: An experimental study of combustion, performance, exergy and emission characteristics of a CI engine fueled by diesel–ethanol–biodiesel blends. Energy 141, 839–852 (2017)

Noorollahi, Y.; Azadbakht, M.; Ghobadian, B.: The effect of different diesterol (diesel–biodiesel–ethanol) blends on small air-cooled diesel engine performance and its exhaust gases. Energy 142, 196–200 (2018)

Alptekin, E.: Evaluation of ethanol and isopropanol as additives with diesel fuel in a CRDI diesel engine. Fuel 205, 161–172 (2017)

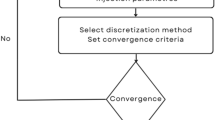

AVL FIRE ESE DIESEL user manual V2013.2

Han, Z.; Reitz, R.D.: A temperature wall function formulation for variable-density turbulent flows with application to engine convective heat transfer modeling. Int. J. Heat Mass Transf. 40(3), 613–625 (1997)

Hawley, J.G.; Wallace, F.J.; Cox, A.; Cumming, B.; Capon, G.: An experimental study of the application of variable-geometry turbocharging and high-pressure common rail to an automotive diesel engine. J. Inst. Energy 74(501), 124–133 (2001)

Hawley, J.G.; Wallace, F.J.; Khalil Arya, S.: A fully analytical treatment of heat release in diesel engines. J. Automob. Eng. Part D Inst. Mech. Eng. 217(8), 701–717 (2003)

Hanjalic, K.; Popovac, M.; Hadziabdic, M.: A robust near-wall elliptic-relaxation eddy-viscosity turbulence model for CFD. Int. J. Heat Fluid Flow 25, 1047–1051 (2004)

Yin, C.; Zhang, Z.; Sun, Y.; Sun, T.; Zhang, R.: Effect of the piston top contour on the tumble flow and combustion features of a GDI engine with a CMCV: a CFD study. Eng. Appl. Comput. Fluid Mech. 10(1), 311–329 (2016)

Fire, A.V.L.: Users Guide-ICE Physics & Chemistry. AVL LIST GmbH, Graz (2014)

McAllister, S.; Chen, J.Y.; Fernandez-Pello, A.C.: Fundamentals of Combustion Processes. Springer, New York (2011)

Author information

Authors and Affiliations

Corresponding author

Additional information

Finding The effect of spray disintegration mechanism in diesel engine for ethanol–diesel and biodiesel–diesel in NOx–soot emission is investigated.

Rights and permissions

About this article

Cite this article

Taghavifar, H., Anvari, S. An Insight into Diesel–Ethanol and Diesel–Biodiesel Blends Spraying and Co-combustion in HSDI Diesel Engine. Arab J Sci Eng 45, 5075–5085 (2020). https://doi.org/10.1007/s13369-020-04343-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-04343-7