Abstract

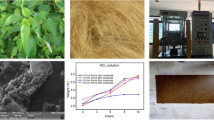

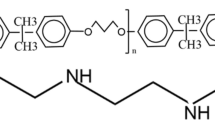

The aim of this study was to determine the mechanical and thermomechanical properties of nettle fibre-reinforced polymethylmethacrylate composites. The polymethylmethacrylate composites reinforced with nettle fibres were manufactured using nettle fibres obtained using the natural methods. The nettle fibre contents were 0, 2.5, 5, 7.5, and 10 Vf %. The composites so formed were characterized in terms of their mechanical and thermomechanical properties. The mechanical properties of nettle-reinforced composites were characterized in terms of bending stress, bending modulus, impact strength, and fracture toughness tests, whilst their behaviour was determined by heat deviation temperature and Vicat softening temperature. The micro-mechanisms underlying the toughening and fracture processes were observed in the light of studies of the microstructure of fractures. From the mechanical properties of composites reinforced with 10% nettle fibres, an increase of 75% in bending stress, 40% in impact strength, and 106% in fracture toughness was recorded. The findings show that nettle fibres can be used as an important reinforcement material for environmentally friendly composite applications.

Similar content being viewed by others

References

Avual, M.R.: A novel facial composite adsorbent for enhanced copper(II) detection and removal from wastewater. Chem. Eng. J. 266, 368–375 (2015). https://doi.org/10.1016/j.cej.2014.12.094

Avual, M.R.; Hasan, M.M.; Shahat, A.; Naushad, M.; Shiwaku, H.; Yaita, T.: Investigation of ligand immobilized nano-composite adsorbent for efficient cerium(III) detection and recovery. Chem. Eng. J. 265, 210–218 (2015). https://doi.org/10.1016/j.cej.2014.12.052

Avual, M.R.: Novel nanocomposite materials for efficient and selective mercury ions capturing from wastewater. Chem. Eng. J. 307, 456–465 (2017). https://doi.org/10.1016/j.cej.2016.08.108

Shahata, A.; Hassana, H.M.A.; El-Shahatc, M.F.; Shahawyd, O.E.; Avual, M.R.: Visual nickel(II) ions treatment in petroleum samples using a mesoporous composite adsorbent. Chem. Eng. J. 334(15), 957–967 (2018). https://doi.org/10.1016/j.cej.2017.10.105

Avual, M.R.: Innovative composite material for efficient and highly selective Pb(II) ion capturing from wastewater. J. Mol. Liq. 284, 502–510 (2019)

Kiruthika, A.V.: A review on physico-mechanical properties of bast fibre reinforced polymer composites. J. Build. Eng. 9, 91–99 (2017)

Low, İ.M.; McGrath, M.; Lawrence, D.; Schmidt, P.: Mechanical and fracture properties of cellulose-fibre-reinforced epoxy laminates. Compos. A Appl. Sci. Manuf. 38, 963–974 (2007)

Hassan, F.; Zulkifli, R.; Ghazali, M.J.; Azhari, C.H.: Kenaf fiber composite in automotive industry: an overview. Int. J. Adv. Sci. Eng. Inf. Technol. 7(1), 315–321 (2017)

Campilho, R.D.S.G.: Natural Fiber Composites. CRC Press, Boca Raton (2016)

George, M.; Chae, M.; Bressler, D.C.: Composite materials with bast fibres: structural, technical, and environmental properties. Prog. Mater. Sci. 83, 1–23 (2016)

Mohanty, A.K.; Misra, M.; Drzal, L.T.: Surface modifications of natural fibers and performance of the resulting biocomposites: an overview. Compos. Interfaces 8, 313–343 (2001)

Kroehong, W.; Jaturapitakkul, C.; Pothisiri, T.; Chindaprasirt, P.: Effect of oil palm fiber content on the physical and mechanical properties and microstructure of high-calcium fly ash geopolymer paste. Arab. J. Sci. Eng. (2018). https://doi.org/10.1007/s13369-017-3059-0

Sahin, A.; Tasdemir, H.M.; Karabulut, A.F.; Gürü, M.: Mechanical and thermal properties of particleboard manufactured from waste Peachnut shell with glass powder. Arab. J. Sci. Eng. 42, 1559–1568 (2017). https://doi.org/10.1007/s13369-017-2427-0

Hepworth, D.G.; Hobson, R.N.; Bruce, D.M.: The use of unretted hemp fibre in composite manufacture. Compos. A Appl. Sci. Manuf. 31, 1279–1283 (2000)

Fuqua, M.A.; Huo, S.; Chad, A.: Ulven natural fibre reinforced composites. Polym. Rev. 52, 259–320 (2012)

Sahu, P.; Gupta, M.K.: Sisal (Agave sisalana) fibre and its polymer-based composites: a review on current developments. J. Reinf. Plast. Compos. 36(24), 1759–1780 (2017)

Yan, L.; Chouw, N.; Jayaraman, K.: Flax fibre and its composites—a review. Compos. Part B: Eng. 56, 296–317 (2014)

Akil, H.; Zamri, M.H.; Osman, M.R.: The use of kenaf fibers as reinforcements in composites. Biofiber Reinf. Compos. Mater. (2015). https://doi.org/10.1533/9781782421276.1.138138-161

Low, I.M.; Schmidt, P.; Lane, J.: Properties of rubber-modified cellulose-fiber-epoxy laminate. J. Appl. Polym. Sci. 54, 2191–2193 (1994)

Karnani, R.; Krishnan, M.; Narayan, R.: Biofiber-reinforced polypropylene composite. Polym. Eng. Sci. 37, 476–483 (1997)

Ali, A.; Shaker, Z.R.; Khalina, A.: Development of anti-ballistic board from ramie fiber. Polym. Plast. Technol. Eng. 50, 622–634 (2011)

Paukszta, D.; Mańkowski, J.; Kołodziej, J.: Polypropylene (PP) composites reinforced with stinging nettle (Utrica dioica L.) Fiber. J. Nat. Fibers 10, 147–158 (2013)

Bajpai, P.K.; Meena, D.; Vatsa, S.: Tensile behavior of nettle fiber composites exposed to various environments. J. Nat. Fibers 10, 244–256 (2013)

Lanzilao, G.; Goswami, P.; Blackburn, R.S.: Study of the morphological characteristics and physical properties of Himalayan giant nettle (Girardinia diversifolia L.) fibre in comparison with European nettle (Urtica dioica L.) fibre. Mater. Lett. 181, 200–203 (2016)

Bodros, E.; Baley, C.: Study of the tensile properties of stinging nettle fibres (Urtica dioica). Mater. Lett. 62, 2143–2145 (2008)

Zhang, X.; Sun, Z.; Hu, X.: Low temperature fracture toughness of PMMA and crack-tip conditions under flat-tipped cylindrical indenter. Polym. Test. 38, 57–63 (2014)

Marshall, G.P.; Coutts, L.H.; Williams, J.G.: Temperature effects in the fracture of PMMA. J. Mater. Sci. 9, 1409–1419 (1974)

Low, I.M.; Schmidt, P.; Lane, J.: Synthesis and properties of cellulose-fibre/epoxy laminates. J. Mater. Sci. Lett. 14, 170–172 (1995)

Atkins, A.G.; Mai, Y.W.: Elastic and plastic fracture: metals, polymers, ceramics, composites, biological materials. Halsted Press, Ellis Horwood (1985)

Roe, P.J.; Ansell, M.P.: Jute-reinforced polyester composites. J. Mater. Sci. 20, 4015–4020 (1985)

Hughes, M.; Hill, C.A.S.; Hague, J.R.B.: The fracture toughness of bast fibre reinforced polyester composites Part 1 Evaluation and analysis. J. Mater. Sci. 37(21), 4669–4676 (2002)

Roncero, M.B.; Torres, A.L.; Colom, J.F.: The effect of xylanase on lignocellulosic components during the bleaching of wood pulps. Biores. Technol. 96, 21–30 (2005)

Shahat, A.; Hassan, H.M.A.; Azzazy, H.M.E.; El-Sharkawy, E.A.; Abdou, H.M.; Awual, M.R.: Novel hierarchical composite adsorbent for selective lead(II) ions capturing from wastewater samples. Chem. Eng. J. 332, 377–386 (2018). https://doi.org/10.1016/j.cej.2017.09.040

Mazrouaa, A.M.; Mansour, N.A.; Abed, M.Y.; Youssif, M.A.; Shenashen, M.A.; Awual, M.R.: Nano-composite multi-wall carbon nanotubes using poly(p-phenylene terephthalamide) for enhanced electric conductivity. J. Environ. Chem. Eng. 7(2), 103002 (2019). https://doi.org/10.1016/j.jece.2019.103002

Joonobi, M.; Harun, J.; Tahir, P.M.: Characteristic of nanofibers extracted from kenaf core. BioResources 5, 2556–2566 (2010)

Rong, M.Z.; Zhang, M.Q.; Liu, Y.: The effect of fiber treatment on the mechanical properties of unidirectional sisal-reinforced epoxy composites. Compos. Sci. Technol. 61, 1437–1447 (2001)

Usta, M.; Gümüşkaya, E.; Odabaş, S.Z.: Characterization of the crystalline structure in cotton linters cellulose. Cellul. Chem. Technol. J. 37(1–2), 7–18 (2003)

Harby, E.A.; Fragiskos, N.K.: Preliminary notes on using lipase enzyme to remove oil dirty in textile conservation. In: Proceeding 4th International Congress on the Science and Technology for the Safeguard of Cultural Heritage in the Mediterranean Basin, Cairo Egypt

Fan, M.; Fu, F.: Advanced High Strength Natural Fibre Composites in Construction, Bölüm 1/3 Physical and Mechanical Properties of Natural Fibers. Woodhead Publishing, Sawston (2017)

Kumar, N.; Das, D.: Alkali treatment on nettle fibers part II: design of experiment and desirability function approach to study enhancement of tensile properties. J. Text. Inst. 108(8), 1468–1475 (2017). https://doi.org/10.1080/00405000.2016.1257347

Büyükkaya, K.: Investigation of mechanical behavior of nettle filled hybrid composites of nettle fiber-hazelnut shell. Gazi Üniversitesi Fen Bilimleri Dergisi Part C: Tasarım ve Teknoloji 5(4), 133–144 (2017)

Joseph, S.; Sreekalab, M.S.; Oommena, Z.; Koshyc, P.; Thomas, S.: A comparison of the mechanical properties of phenol formaldehyde composites reinforced with banana fibres and glass fibres. Compos. Sci. Technol. 62, 1857–1868 (2002)

Athijayamani, A.; Thiruchitrambalam, M.; Manikandan, V.; Pazhanivel, B.: Mechanical properties of natural fibers reinforced polyester hybrid composite. Int. J. Plast. Technol. 14, 101–116 (2010)

Yan, L.; Chouw, N.; Yuan, X.: Improving the mechanical properties of natural fibre fabric reinforced epoxy composites by alkali treatment. J. Reinf. Plast. Compos. 31(6), 425–437 (2012)

Liu, Q.; Hughes, M.: The fracture behaviour and toughness of woven flax fibre reinforced epoxy. Compos. Part A: Appl. Sci. Manuf. 39(10), 1644–1652 (2008). https://doi.org/10.1016/j.compositesa.2008.07.008

Ku, H.; Wang, H.; Pattarachaiyakoop, N.: A review on the tensile properties of natural fiber reinforced polymer composite. Compos. Part B: Eng. 42, 856–873 (2011)

Malkapuram, R.; Kumar, V.; Negi, Y.S.: Recent development in natural fiber reinforced polypropylene composites. J. Reinf. Plast. Compos. 28, 1169–1189 (2009)

Ahmad, I.; Baharum, A.; Abdullah, I.: Effect of extrusion rate and fiber loading on mechanical properties of Twaron fiber-thermoplastic natural rubber (TPNR) composite. J. Reinf. Plast. Compos. 25, 957–965 (2006)

Gümüskaya, E.; Usta, M.; Kirci, H.: The effects of various pulping conditions on crystalline structure of cellulose in cotton linters. Polym. Degrad. Stab. 81, 559–564 (2003)

Gan, Y.: Effect of interface structure on mechanical properties of advanced composite materials. Int. J. Mol. Sci. 10(12), 5115–5134 (2009). https://doi.org/10.3390/ijms10125115

Bueno, M.A.; Aneja, A.P.; Renner, M.: Influence of the shape of fiber cross section on fabric surface characteristics. J. Mater. Sci. 39(2), 557–564 (2004). https://doi.org/10.1023/b:jmsc.0000011511.66614.48

Ornaghi, H.L.; Poletto, M.; Zattera, A.J.: Correlation of the thermal stability and the decomposition kinetics of six different vegetal fibers. Cellulose 21, 177–188 (2014)

Poletto, M.; Zattera, A.J.; Santana, R.: Structural differences between wood species: evidence from chemical composition, FTIR spectroscopy, and thermogravimetric analysis. J. Appl. Polym. Sci. 126, E337–E344 (2012)

Bergfjord, C.; Holst, B.: A procedure for identifying textile bast fibres using microscopy: flax, nettle/ramie, hemp and jut. Ultramicroscopy 110, 1192–1197 (2010)

Herzog, A.: Mikrophotographischer Atlas der Technisch Wichtigen Pflanzenfasern. Akademie-Verlag, Berlin (1955)

Fidelis, M.E.A.; Pereira, T.V.C.; Gomes, O.D.F.M.: The effect of fiber morphology on the tensile strength of natural fibers. J. Mater. Res. Technol. 2, 149–157 (2013)

Rao, S.; Bhattacharyya, D.K.; Jayaraman, K.; Fernyhough, A.: Manufacturing and recycling of sisal-polypropylene composites. Polym. Polym. Compos. 17(8), 467–479 (2009)

Bensadoun, F.; Depuydt, D.; Baets, J.; Verpoest, I.; van Vuure, A.V.: Low velocity impact properties of flax composites. Compos. Struct. 176, 933–944 (2017). https://doi.org/10.1016/j.compstruct.2017.05.005

Thomason, J.L.: The influence of fibre length, diameter and concentration on the impact performance of long glass-fibre reinforced polyamide 6, 6. Compos. A. Appl. Sci. Manuf. 40, 114–124 (2009). https://doi.org/10.1016/j.compositesa.2008.10.013

Bax, B.; Müssig, J.: Impact and tensile properties of PLA/Cordenka and PLA/flax composites. Compos. Sci. Technol. 68, 1601–1607 (2008). https://doi.org/10.1016/j.compscitech.2008

Huda, M.S.; Drzal, L.T.; Mohanty, A.K.: Effect of fiber surface-treatments on the properties of laminated biocomposites from poly (lactic acid)(PLA) and kenaf fibers. Compos. Sci. Technol. 68, 424–432 (2008)

Perelló, B.D.; Garcia-Sanoguera, D.; Gimeno, F.O.Á.; Boronat, T.; Gimeno, B.R.A.: Use of eco-friendly epoxy resins from renewable resources as potential substitutes of petrochemical epoxy resins for ambient cured composites with flax reinforcements. Polym. Compos. 33(5), 683–692 (2012)

Guo, C.; Ma, L.C.; Sun, C.; Liping Li, L.: Influence of high loaded wood flour and coupling agent (m-TMI-g-PP) content on properties of wood flour/polypropylene. J. Adhes. Sci. Technol. 27(8), 912–923 (2013)

Acknowledgements

We would like to acknowledge the support of Giresun University’s Scientific Research Projects Office (FEN-BAP-A-250414-76).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Büyükkaya, K., Demirer, H. Examining the Mechanical and Thermomechanical Properties of Polymethylmethacrylate Composites Reinforced with Nettle Fibres. Arab J Sci Eng 45, 665–674 (2020). https://doi.org/10.1007/s13369-019-04136-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-019-04136-7