Abstract

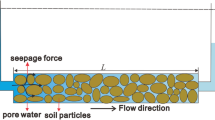

Due to different pore or layer structures in different directions, reservoir rocks are often anisotropic in permeability, causing permeability tests to differ between vertical and radial permeability. Except for the anisotropy of rock mass, the seepage test direction may also have an impact on the connection between stress and permeability tests. In order to illustrate the reasons for the difference between vertical and horizontal permeability test results, this article comparatively analyses the simulation results between the vertical and horizontal direction, using the discrete element method with an isotropic model. A further permeability stress test experiment was carried out in a different direction with an improved multi-functional outburst research rig. The results show that the horizontal contact hydraulic aperture had a higher sensitivity to axial stress than the vertical contact, which made the axial permeability more sensitive to the confining stress than radial permeability. In contrast to the axial stress, as the confining stress increased, the vertical contact hydraulic aperture gradually decreased, while the horizontal contact hydraulic aperture only changed a small amount. This meant that the radial permeability was more sensitive to axial stress than axial permeability. Additionally, the reducing speed of the axial permeability was very slow or even zero, with the axial stress increasing when the axial stress was less than the confining stress. In general, the seepage test direction was a very important factor, and it should be considered in the study of the relationship between stress and permeability.

Similar content being viewed by others

References

Barrash W., Clemo T., Fox J.J., Johnson T.C.: Field, laboratory, and modeling investigation of the skin effect at wells with slotted casing, Boise Hydrogeophysical Research Site. J. Hydrol. 326(1), 181–198 (2006)

Baptiste N., Chapuis R.P.: What maximum permeability can be measured with a monitoring well?. Eng. Geol. 184, 111–118 (2015)

Palchik V.: Formation of fractured zones in overburden due to longwall mining. Environ. Geol. 44(1), 28–38 (2003)

Zhang, C.; Tu, S.; Zhang, L.;Bai,Q.;Yuan,Y.;Wang, F.:Amethodology for determining the evolution law of gob permeability and its distributions in longwall coal mines. J. Geophys. Eng. 13(2), 181–193 (2016)

Adhikary D.P., Guo H.: Modelling of longwall mining-induced strata permeability change. Rock Mech. Rock Eng. 48(1), 345–359 (2015)

Zhang C., Tu S., Bai Q., Yang G., Zhang L.: Evaluating pressure-relief mining performances based on surface gas venthole extraction data in longwall coal mines. J. Nat. Gas Sci. Eng. 24, 431–440 (2015)

Lv Y.: Test studies of gas flow in rock and coal surrounding a mined coal seam. Int. J. Min. Sci. Technol. 22(4), 499–502 (2012)

Yin G., Jiang C., Wang J.G., Xu J.: Geomechanical and flow properties of coal from loading axial stress and unloading confining pressure tests. Int. J. Rock Mech. Min. Sci. 76, 155–161 (2015)

Li B., Wei J., Wang K., Li P., Wang K.: A method of determining the permeability coefficient of coal seam based on the permeability of loaded coal. Int. J. Rock Mech. Min. Sci. 24(5), 637–641 (2014)

Sereshki, F.: Improving coal mine safety by identifying factors that influence the sudden release of gases in outburst prone zones. Doctoral dissertation, University of Wollongong (2005)

Cui X., Bustin R.M.: Volumetric strain associated with methane desorption and its impact on coalbed gas production from deep coal seams. AAPG Bull. 89(9), 1181–1202 (2005)

Palmer, I.; Mavor, M.; Gunter, B.: Permeability changes in coal seams during production and injection. In: International Coalbed Methane Symposium, University of Alabama, Tuscaloosa, Alabama (0713) (2007)

Palmer I.: Permeability changes in coal: analytical modeling. Int. J. Coal Geol. 77(1), 119–126 (2009)

Shi J.Q., Durucan S.: A model for changes in coalbed permeability during primary and enhanced methane recovery. SPE Reserv. Eval. Eng. 8(4), 291–299 (2005)

Shi J.Q., Durucan S.: Modelling laboratory horizontal stress and coal permeability data using S&D permeability model. Int. J. Coal Geol. 131, 172–176 (2014)

Gu F., Chalaturnyk R.: Permeability and porosity models considering anisotropy and discontinuity of coalbeds and application in coupled simulation. J. Pet. Sci. Eng. 74(3), 113–131 (2010)

Pan Z., Ma Y., Connell L.D., Down D.I., Camilleri M.: Measuring anisotropic permeability using a cubic shale sample in a triaxial cell. J. Nat. Gas Sci. Eng. 26, 336–344 (2015)

Ren F., Ma G., Fu G., Zhang K.: Investigation of the permeability anisotropy of 2D fractured rock masses. Eng. Geol. 196, 171–182 (2015)

Zhang L., Ren T., Aziz N., Tu S.: Triaxial permeability testing and microstructure study of hard-to-drain coal from Sydney Basin, Australia. Int. J. Oil Gas Coal Technol. 8(4), 432–448 (2014)

Baghbanan A., Jing L.: Stress effects on permeability in a fractured rock mass with correlated fracture length and aperture. Int. J. Rock Mech. Min. Sci. 45(8), 1320–1334 (2008)

Min K.B., Jing L.R.: Numerical determination of the equivalent elastic compliance tensor for fractured rockmasses using the distinct element method. Int. J. Rock Mech. Min. Sci. 40(6), 795–816 (2003)

Itasca Consulting Group Inc.: UDEC: Universal Distinct Element Code, Version 5.0. ICG, Minneapolis, MN (2011)

Li H., Li K., Subhash G., Kecskes L.J., Dowding R.J.: Micromechanical modeling of tungsten-based bulk metallic glass matrix composites. Mater. Sci. Eng. A 429, 115–123 (2006)

Nygards M., Gudmundson P.: Micromechanical modeling of ferritic/pearlitic steels. Mater. Sci. Eng. A 325, 435–443 (2002)

Zhang K.S., Wu M.S., Feng R.: Simulation of microplasticity-induced deformation in uniaxially strained ceramics by 3-D Voronoi polycrystal modeling. Int. J. Plast. 21(4), 801–834 (2005)

Kazerani T., Zhao J.: . Int. J. Numer. Anal. Methods Geomech. 34(18), 1877–1895 (2010)

Ren, T.X.; Edwards, J.S.: Goaf gas modeling techniques to maximize methane capture from surface gob wells. In: De Sauza, E. (eds.): Mine Ventilation, pp. 279–286 (2002)

Singh K.K., Singh D.N., Ranjith P.G.: Laboratory simulation of flow through single fractured granite. Rock Mech. Rock Eng. 48(3), 987–1000 (2015)

Zhang, L.; Zhang, C.; Tu, S.; Tu, H.; Wang, C.: A study of directional permeability and gas injection to flush coal seam gas testing apparatus and method. Transp. Porous Media 111(3), 573–589 (2016)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, C., Tu, S., Zhang, L. et al. A Study on Effect of Seepage Direction on Permeability Stress Test. Arab J Sci Eng 41, 4583–4596 (2016). https://doi.org/10.1007/s13369-016-2215-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-016-2215-2