Abstract

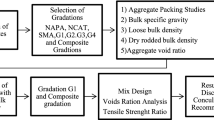

Targeting the midline of aggregate gradation envelope alone does not guarantee packing of aggregates. Source and consensus properties of aggregates need to be considered while developing a gradation for asphalt mixtures. This paper presents a research study to improve the packing characteristic of an aggregate gradation using Bailey method. Experimental program composed of proposing criteria for limiting values of aggregate gradation with different sizes for a specific quarry. Second phase of the study targets two aggregate gradations at same nominal maximum particle size, one prepared with conventional method and other improved by using Bailey method. Asphalt mixtures were prepared using both the gradations. Performance tests were conducted on the asphalt mixtures to ascertain the rutting, permanent deformation, fatigue characteristics, and asphalt mixture compatibility. The study revealed that Bailey method can successfully be used for the preparation of different aggregate gradations by keeping the limiting criteria within the defined ratios. Also, mixtures prepared using a Bailey method performed better than a mixture with conventional gradation. Optimizing the aggregate gradation using bulk specific gravity and voids in coarse aggregate better control aggregate volumetric than targeting the midline of gradation envelop.

Similar content being viewed by others

References

Hafeez, I.; Ozer, H.; Al-Qadi, I.L.: Performance characterization of hot in-place recycled mixtures. J. Transp. Eng. 140(8), 04014029 (2014). doi:10.1061/(ASCE)TE.1943-5436.0000679

Transportation Research Board: A mix design manual for hot-mix asphalt. NCHRP Rep. No. 673, National Research Council, Washington (2009)

Vavrik, W.R.; Huber, G.; Pine, W.J.; Carpenter, S.H.; Bailey, R.: Bailey method for gradation selection in hot-mix asphalt mixture design. Transportation research E-circular, report No: E-C044. (2002)

Smith, R.W.; Rice, J.M.; Spelman, S.R.: Design of open-graded asphalt friction courses. Federal Highway Administration report No. FHWA-RD-74-2 (1974)

Roberts, F.L.; Kandhal, P.S.; Brown, E.R.; Lee, D.Y.; Kennedy, T.W.: Hot Mix-Asphalt Materials, Mixture Design, and Construction, 2nd edition. NAPA Research and Education Foundation (1996)

Lanham M.D., Shen S., Yu H.: Analysis of aggregate gradation and packing for easy estimation of hot-mix-asphalt voids in mineral aggregate. J. Mater. Civ. Eng. 23, 664–672 (2011)

Hafeez I., Kamal M.A., Waseem M.W.: Evaluation of rutting in HMA mixtures using uniaxial repeated creep and wheel tracker tests. Pak. J. Eng. Appl. Sci. 7((2010), 55–64 (2010)

Anthony, D.S.; Bahia, H.U.: The effect of fine aggregate angularity, asphalt content and performance graded asphalts on hot mix asphalt performance. WisDOT Highway research study Rep. No. 0092-45-98. University of Wisconsin, Madison (2003)

Haritonovs V., Zaumanis M., Brencis G., Smirnovs J.: Performance of asphalt concrete with dolomite sand waste and basic oxygen furnace steel slag aggregate. Baltic J. Road Bridge Eng. 8(2), 91–97 (2013). doi:10.3846/bjrbe.2013.12

Vasconcelos K.L., Bhasin A., Little D.N., Lytton R.L.: Experimental measurement of water diffusion through fine aggregate mixtures. J. Mater. Civ. Eng. 23(4), 445–452 (2011). doi:10.1061/(ASCE)MT.1943-5533.0000190

Mishra D., Tutumuler E.: Aggregate physical properties affecting modulus and deformation characteristics of unsurfaced pavement. J. Mater. Civ. Eng. 24(9), 1144–1152 (2012). doi:10.1061/(ASCE)MT.1943-5533.0000498

Transportation Research Board: Bailey method for gradation selection in hot-mix asphalt mixture design. Transportation Research Circular No. E-C044, Washington (2002)

Mitchell, M.; Link, R.; Punith, V.; Raju, S.; Kumar, K.K.; Boes, S.; Veeraragaven, A.: Laboratory evaluation of stone matrix asphalt mixtures with polyethylene and cellulose stabilizers. J. Test. Eval. 102919 (2011). doi:10.1520/JTE102919

Al-Qadi, I.L; Son, S.; Zehr, T.: Development of an economical, thin, quiet, long-lasting, high friction surface layer, volum-I: mix design and lab performance testing Rep. No. FHWA-ICT-13-001. Illinois centre for transportation. Univ. of Illinois at Urbana-Champaign, Rantoul (2013)

Shang G.T., Takahashi O., Maekawa R.: Recommended combination of the bailey parameters in Superpave gradation design for Japanese airfield pavements. Int. J. Pavement Res. Technol. 6(6), 704–713 (2013). doi:10.6135/ijprt.org.tw/2013.6(6).704

NegaA.;GhadimiB.; Nikraz H.: Developing master curves, binder viscosity and predicting dynamic modulus of polymer-modified. IACSIT Int. J. Eng. Technol. 7(3), 190 (2015)

BS EN 12697-22.: Test Methods for Hot Mix Asphalt, Part-22, Wheel Tracking. European Standard, UK (2002)

Li J., Zofka A., Yut I.: Evaluation of dynamic modulus of typical asphalt mixtures in Northeast US region. J. Road Mater. Pavement Des. 13(2), 249–265 (2012)

Yan, J.; Zhang, Z.; Charmot, S.; Ding, W.; Li, F.: Investigation and prediction model for the dynamic modulus of asphalt emulsion cold recycled mixtures. J. Mater. Civ. Eng. 04014113 (2014). doi:10.1061/(ASCE)MT.1943-5533.0001048

Biligiri, K.; Said, S.: Prediction of the remaining fatigue life of flexible pavements using laboratory and field correlations. J. Mater. Civ. Eng. 04014201 (2014). doi:10.1061/(ASCE)MT.1943-5533.0001161

Daniel J., Kim Y.: Laboratory evaluation of fatigue damage and healing of asphalt mixtures. J. Mater. Civ. Eng. 13(6), 434–440 (2001)

AASHTO TP 62: Standard method of test for determining dynamic modulus of hot mix asphalt (HMA). American Association of State Highway and Transportation Officials, DC (2009)

Hafeez, I.; Kamal, M.A.; Mirza. M.W.: An experimental study to select aggregate gradation of stone mastic asphalt. J. Chin. Inst. Eng. (2014). doi:10.1080/02533839.2014.953242.1-8

Zhu H., Sun L., Yang J., Chen Z., Gu W.: Developing master curves and predicting dynamic modulus of polymer-modified asphalt mixtures. J. Mater. Civ. Eng. 23(2), 131–137 (2011)

Singh, D.; Zaman, M.; Commuri, S.: Inclusion of aggregate angularity, texture, and form in estimating dynamic modulus of asphalt mixes. Road Mater. Pavement Des. 327–344 (2012). doi:10.1080/14680629.2011.650088

Hafeez I., Kamal M.A., Mirza M.W., Bilal S.: Laboratory fatigue performance evaluation of different field laid asphalt mixtures. J. Constr. Build. Mater. 44(2013), 792–797 (2013). doi:10.1016/j.conbuildmat.2013.03.083

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hafeez, I., Kamal, M.A., Ishaq, M.A. et al. A Laboratory-Based Research Study to Investigate the Aggregate Packing Characteristics and Its Influence on Asphaltic Mixtureʼs Performance. Arab J Sci Eng 40, 3119–3134 (2015). https://doi.org/10.1007/s13369-015-1804-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-015-1804-9