Abstract

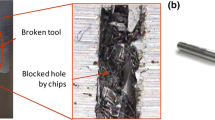

Stainless steels are considered to be difficult to machine due to specific properties such as high toughness, work-hardening, and low heat conductivity. Built-up edge and irregular wear situations are often faced in the machining of stainless steel parts. In addition, various problems such as low surface roughness and breakage of drill tool occurred in the drilling of these materials. In this study, \({{{\rm nACo}}^{\circledR}}\) nanocomposite-coated and uncoated Tungsten Carbide (WC) tools were compared to specify the performance of nanocomposite coating in the drilling of AISI 304L stainless steel workpieces. The breakages and damages of \({{{\rm nACo}}^{\circledR}}\) nanocomposite-coated and uncoated WC drill tools were presented when the stainless steel parts were drilled. Drill tool tip damages were investigated by microscope, and surface roughness values of the drilled holes were measured. \({{{\rm nACo}}^{\circledR}}\)-coated WC drill tools were less damaged than uncoated WC drill tools due to the fact that \({{{\rm nACo}}^{\circledR}}\) coating reduced the drill tool–workpiece friction and increased the wear resistance. The surface roughness of the drilled holes with \({{{\rm nACo}}^{\circledR}}\)-coated WC drill tools was better than that of the drilled holes with the uncoated WC drill tools.

Similar content being viewed by others

References

Selinder T.I., Sjöstrand M.E., Nordin N., Larsson M., Hogmark Å., Hogmark S.: Performance of PVD TiN/TaN and TiN/NbN superlattice coated cemented carbide tools in stainless steel machining. Surf. Coat. Tech. 105, 51–55 (1998)

Chen W.C., Liu X.D.: Study on the various coated twist drills for stainless steels drilling. J. Mater. Process. Tech. 99, 226–230 (2000)

Lin T.S.: Cutting behavior of a TiN-coated carbide drill with curved cutting edges during the high-speed machining of stainless steel. J. Mater. Process. Tech. 127, 8–16 (2002)

Liew W.Y.H., Ngoi B.K.A., Lu Y.G.: Wear characteristics of PCBN tools in the ultra-precision machining of stainless steel at low speeds. Wear 254, 265–277 (2003)

Dolinšek S.: Work-hardening in the drilling of austenitic stainless steels. J. Mater. Process. Tech. 133, 63–70 (2003)

Korkut I., Kasap M., Ciftci I., Seker U.: Determination of optimum cutting parameters during machining of AISI 304 austenitic stainless steel. Mater. Design 25, 303–305 (2004)

Paro J.A., Gustafsson T.E., Koskinen J.: Drilling of X2CrNi 19 11 stainless steel with hiped NiTi coating. J. Mater. Process. Tech. 150, 309–316 (2004)

Paro J.A., Gustafsson T.E., Koskinen J.: Drilling of conventional cast stainless steel with HIPed NiTi coating. J. Mater. Process. Tech. 153–154, 622–629 (2004)

Ciftci I.: Machining of austenitic stainless steels using CVD multi-layer coated cemented carbide tools. Tribol. Int. 39, 565–569 (2006)

Endrino J.L., Fox-Rabinovich G.S., Gey C.: Hard AlTiN, AlCrN PVD coatings for machining of austenitic stainless steel. Surf. Coat. Tech. 200, 6840–6845 (2006)

Xavior M.A., Adithan M.: Determining the influence of cutting fluids on tool wear and surface roughness during turning of AISI 304 austenitic stainless steel. J. Mater. Process. Tech. 209, 900–909 (2009)

Lee S.M., Chow H.M., Huang F.Y., Yan B.H.: Friction drilling of austenitic stainless steel by uncoated and PVD AlCrN- and TiAlN-coated tungsten carbide tools. Int. J. Mach. Tools Manuf. 49, 81–88 (2009)

Jurko J., Panda A.: Identification the tool wear mechanisms and forms at drilling of a new stainless steels. AASRI Procedia. 3, 127–132 (2012)

Kıvak T., Samtaş G., Çiçek A.: Taguchi method based optimization of drilling parameters in drilling of AISI 316 steel with PVD monolayer and multilayer coated HSS drills. Measurement 45, 1547–1557 (2012)

Nomani J., Pramanik A., Hilditch T., Littlefair G.: Machinability study of first generation duplex (2205), second generation duplex (2507) and austenite stainless steel during drilling process. Wear 304, 20–28 (2013)

Hagarovà M., Blàhovà O., Savkovà J.: Structure and properties of PVD coatings deposited by ARC and LARC technology. Acta Metall. Slov. 15, 221–227 (2009)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Uysal, A. A Study on Drilling of AISI 304L Stainless Steel with Nanocomposite-Coated Drill Tools. Arab J Sci Eng 39, 8279–8285 (2014). https://doi.org/10.1007/s13369-014-1379-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-014-1379-x