Abstract

Rubber concrete has been proposed to address the environmental challenges caused by waste tires and the shortage of natural aggregates worldwide; however, its strength and elastic modulus reduction hinder its wide application in structure members. This study proposes filling corrugated steel tubes with rubber concrete (RuCFCST) and using the non-uniform confinement provided by corrugated steel tubes (CSTs) to compensate for the loss in strength and elastic modulus of rubber concrete. We conducted monotonic axial compression tests on 12 tubular specimens to evaluate the effects of the steel tube type, loading mode, diameter-to-thickness ratio, and rubber concrete strength on the axial shortening behavior and strength. The test results confirmed the effectiveness of CST confinement in strengthening the axial behavior of rubber concrete and CST had a higher confinement efficiency than plain straight steel tubes. The strength and ductility indices of the specimens increased by 10% and 30%, respectively; however, the strength of the concrete core decreased by 38.4% owing to the incorporation of rubber particles. These results suggest that such columns can be used in infrastructure, such as in seismic bridge piers, mine roadway supports, and underground structural columns, where load-bearing capacity and ductility are required. The current specifications lack consistency in predicting the axial strength of RuCFCST columns and the results of our proposed modified formulas were in good agreement with the experimental data, and the formulas predicted the axial strength of piers well.

Similar content being viewed by others

References

Abendeh, R., Ahmad, H. S., & Hunaiti, Y. M. (2016). Experimental studies on the behavior of concrete-filled steel tubes incorporating crumb rubber. Journal of Constructional Steel Research, 122, 251–260. https://doi.org/10.1016/j.jcsr.2016.03.022

Alkhatib, S. E., Tarlochan, F., & Eyvazian, A. (2017). Collapse behavior of thin-walled corrugated tapered tubes. Engineering Structures, 150, 674–692. https://doi.org/10.1016/j.engstruct.2017.07.081

American Institute of Steel Construction (AISC). (2010). AISC 360-10: Specification for structural steel buildings. AISC.

Architectural Institute of Japan (AIJ). (2008). Recommendations for design and construction of concrete filled steel tubular structures. AIJ.

Avci-Karatas, C. (2019). Prediction of ultimate load capacity of concrete-filled steel tube columns using multivariate adaptive regression splines (MARS). Steel and Composite Structures, 33(4), 583–594. https://doi.org/10.12989/scs.2019.33.4.583

Avci-Karatas, C. (2021). Modeling approach for estimation of ultimate load capacity of concrete-filled steel tube composite stub columns based on relevance vector machine. Ömer Halisdemir Üniversitesi Mühendislik Bilimleri Dergisi. https://doi.org/10.28948/ngumuh.759297

Avci-Karatas, C. (2022). Application of machine learning in prediction of shear capacity of headed steel studs in steel-concrete composite structures. International Journal of Steel Structures, 22(2), 539–556. https://doi.org/10.1007/s13296-022-00589-z

Chellapandian, M., Prakash, S. S., & Sharma, A. (2017). Strength and ductility of innovative hybrid NSM reinforced and FRP confined short RC columns under axial compression. Composite Structures, 176, 205–216. https://doi.org/10.1016/j.compstruct.2017.05.033

Chen, D. H., & Ozaki, S. (2009). Numerical study of axially crushed cylindrical tubes with corrugated surface. Thin-Walled Structures, 47(11), 1387–1396. https://doi.org/10.1016/j.tws.2008.12.008

Chen, Z. P., Xu, J. J., Xue, J. Y., & Su, Y. S. (2014). Performance and calculations of recycled aggregate concrete-filled steel tubular (RACFST) short columns under axial compression. International Journal of Steel Structures, 14(1), 31–42. https://doi.org/10.1007/s13296-014-1005-5

Chung, K. S., Kim, J. H., & Yoo, J. H. (2012). Prediction of hysteretic behavior of high-strength square concrete-filled steel tubular columns subjected to eccentric loading. International Journal of Steel Structures, 12(2), 243–252. https://doi.org/10.1007/s13296-012-2008-8

Duarte, A. P. C., Silva, B. A., Silvestre, N., de Brito, J., Julio, E., & Castro, J. M. (2016). Tests and design of short steel tubes filled with rubberised concrete. Engineering Structures, 112, 274–286. https://doi.org/10.1016/j.engstruct.2016.01.018

Eldin, N. N., & Senouci, A. B. (1993). Rubber-tire particles as concrete aggregate. Journal of Materials in Civil Engineering, 5(4), 478–496.

Elgalai, A. M., Mahdi, E., Hamouda, A. M. S., & Sahari, B. S. (2004). Crushing response of composite corrugated tubes to quasi-static axial loading. Composite Structures, 66(1–4), 665–671. https://doi.org/10.1016/j.compstruct.2004.06.002

Eurocode 4 (EC4): EN 1994-1-1. (2004) (English) Design of composite steel and concrete structure-Part 1–1: General rules and rules for buildings (p. 117). CEN, Brussels: European Committee for Standardization. Authority: The European Union per Regulation 305/2011, Directive 98/34/EC, Directive 2004/18/EC]. https://eurocodes.jrc.ec.europa.eu/EN-Eurocodes/eurocode-4-design-composite-steel-and-concrete-structures?id=134

Eyvazian, A., Tran, T. N., & Hamouda, A. M. (2018). Experimental and theoretical studies on axially crushed corrugated metal tubes. International Journal of Non-Linear Mechanics, 101, 86–94. https://doi.org/10.1016/j.ijnonlinmec.2018.02.009

Fattuhi, N. I., & Clark, L. A. (1996). Cement-based materials containing shredded scrap truck tyre rubber. Construction and Building Materials, 10(4), 229–236. https://doi.org/10.1016/0950-0618(96)00004-9

Gholampour, A., Ozbakkaloglu, T., & Hassanli, R. (2017). Behavior of rubberized concrete under active confinement. Construction and Building Materials, 138, 372–382. https://doi.org/10.1016/j.conbuildmat.2017.01.105

Gintautas, S., Audrius, G., & Kestutis, M. (2009). Damping properties of concrete with rubber waste additives. Materials Science, 15, 266–272.

Guneyisi, E. M., Gultekin, A., & Mermerdas, K. (2016). Ultimate capacity prediction of axially loaded CFST short columns. International Journal of Steel Structures, 16(1), 99–114. https://doi.org/10.1007/s13296-016-3009-9

Hameed, A. S., & Shashikala, A. P. (2016). Suitability of rubber concrete for railway sleepers. Perspectives in Science, 8(C), 32–35.

Han, T. H., Stallings, J. M., & Kang, Y. J. (2010). Nonlinear concrete model for double-skinned composite tubular columns. Construction and Building Materials, 24(12), 2542–2553. https://doi.org/10.1016/j.conbuildmat.2010.06.001

Hassanli, R., Youssf, O., & Mills, J. E. (2017). Experimental investigations of reinforced rubberized concrete structural members. Journal of Building Engineering, 10, 149–165. https://doi.org/10.1016/j.jobe.2017.03.006

Hossain, K. M. A., & Chu, K. (2019). Confinement of six different concretes in CFST columns having different shapes and slenderness. International Journal of Advanced Structural Engineering, 11(2), 255–270. https://doi.org/10.1007/s40091-019-0228-2

Khatib, Z. K., & Bayomy, F. M. (1999). Rubberized Portland cement concrete. Journal of Materials in Civil Engineering, 11(3), 206–213. https://doi.org/10.1061/(ASCE)0899-1561(1999)11:3(206)

Li, G. Q., Pang, S. S., & Ibekwe, S. I. (2011). FRP tube encased rubberized concrete cylinders. Materials and Structures, 44(1), 233–243. https://doi.org/10.1617/s11527-010-9622-8

Liang, J. F., Jiang, L. Z., Wu, H. Y., & Gu, L. S. (2017). Experimental study on mechanical properties of rubber concrete filled steel tube column under axial compression. Journal of Guangxi University (natural Science Edition), 42, 142–149.

Liu, Y. H., Bai, Y. K., & Jiang, G. H. (2011). Analytical behavior of rubber concrete-filled steel tubular columns under cyclic loading. Applied Mechanics and Materials [Advances in structural engineering, pts 1–3]. International conference on civil engineering and transportation (ICCET 2011), Jinan, Peoples Republic of China.

Liu, B., Zhang, L., Sun, H., Feng, M., & Dou, K. (2022). Side shear strength and load-transfer mechanism of corrugated steel column-foundation socket connection. Case Studies in Construction Materials. https://doi.org/10.1016/j.cscm.2022.e01377

Liu, B. D., Zhang, Z. N., Zhang, M. Q., & Wang, X. X. (2019). Experimental study of the mechanical performance of corrugated steel plate-concrete composite structures. International Journal of Steel Structures, 19(3), 733–746. https://doi.org/10.1007/s13296-018-0158-z

Ministry of Housing and Urban-Rural Development of the People’s Republic of China (MOHURD). (2014). GB50936-2014: Code for design of concrete filled steel tubular structures. China Architecture & Building Press. https://www.chinesestandard.net/PDF/English.aspx/GB50936-2014?Redirect=YES

Mujdeci, A., Bompa, D. V., & Elghazouli, A. Y. (2021). Confinement effects for rubberised concrete in tubular steel cross-sections under combined loading. Archives of Civil and Mechanical Engineering, 21(2), 20. https://doi.org/10.1007/s43452-021-00204-8

Nematzadeh, M., Karimi, A., & Gholampour, A. (2020). Pre- and post-heating behavior of concrete-filled steel tube stub columns containing steel fiber and tire rubber. Structures, 27, 2346–2364. https://doi.org/10.1016/j.istruc.2020.07.034

Shen, M. Y., Huang, W., Liu, J. L., & Zhou, Z. (2022). Axial compressive behavior of rubberized concrete-filled steel tube short columns. Case Studies in Construction Materials, 16(11), e00851. https://doi.org/10.1016/j.cscm.2021.e00851

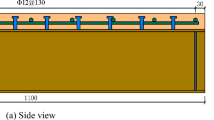

Su, R., Li, X., Zhong, T., & Zhou, T. (2021). Axial behavior of novel CFDST columns with outer welded corrugated steel tubes. Structures, 34, 2708–2720. https://doi.org/10.1016/j.istruc.2021.09.039

Topçu, I. B. (1995). The properties of rubberized concretes. Cement and Concrete Research, 25(2), 304–310. https://doi.org/10.1016/0008-8846(95)00014-3

Wang, Y. Y., Chen, J., & Geng, Y. (2015). Testing and analysis of axially loaded normal-strength recycled aggregate concrete filled steel tubular stub columns. Engineering Structures, 86, 192–212. https://doi.org/10.1016/j.engstruct.2015.01.007

Wang, Y. Y., Yang, L. G., Yang, H., & Liu, C. Y. (2019). Behaviour of concrete-filled corrugated steel tubes under axial compression. Engineering Structures, 183, 475–495. https://doi.org/10.1016/j.engstruct.2018.12.093

Xu, P. Z., Li, H. W., Yan, H. S., & Zhu, Y. G. (2019). Effect of rubber content on mechanical properties of round rubber concrete-filled steel tubular short columns. Building Structures, 495(03), 71–75.

Yang, Y. F., & Han, L. H. (2006). Compressive and flexural behaviour of recycled aggregate concrete filled steel tubes (RACFST) under short-term loadings. Steel and Composite Structures, 6(3), 257–284. https://doi.org/10.12989/scs.2006.6.3.257

Yoshida, A. (1966). The stress in a helical corrugated tube under axial tension. Bulletin of JSME, 9(36), 654–666. https://doi.org/10.1299/jsme1958.9.654

Zhang, S. M., Guo, L. H., Ye, Z. L., & Wang, Y. Y. (2005). Behavior of steel tube and confined high strength concrete for concrete-filled RHS tubes. Advances in Structural Engineering, 8(2), 101–116. https://doi.org/10.1260/1369433054037976

Acknowledgements

The research leading to these results received funding from the National Natural Science Foundation of China under Grant Agreement No. 51478030 and the Qilu Transportation Technology Project under Grant Agreement No. KJ-2019-QLJTJT-01. At the same time, Hengshui Yitong Pipe Industry Co., Ltd. provided sites and equipment to help in the testing process. The author is deeply grateful for that.

Author information

Authors and Affiliations

Contributions

BL: Conceptualization, Writing—Review & Editing, Funding acquisition, Project administration, Resources. LZ: Methodology, Visualization, Software, Writing—Original Draft. MF: Validation, Software, Writing—Review & Editing, Supervision. HS: Project administration. YC: Investigation, Writing—Review & Editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, B., Zhang, L., Feng, M. et al. Experimental Study of Rubber-Concrete-Filled CST Composite Column Under Axial Compression. Int J Steel Struct 23, 247–262 (2023). https://doi.org/10.1007/s13296-022-00692-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13296-022-00692-1