Abstract

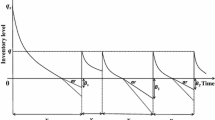

Managers always want to decrease the cost of the inventory system and increase the customers’ satisfaction. To access to the mentioned aim they should notice the different aspects of their inventory system to become successful in today competitive global marketing. In this research we model the periodic review inventory system by considering some important aspects of the system that are improving quality, reduction of setup cost, partial backordering and inspection process. The provided model is the first one that includes all of the mentioned aspects simultaneously. Finally, we provide the numerical result according to the certain algorithm and show how the sensitive parameters affect the total cost. We compare the total cost in two cases: at first, we consider setup cost and the probability of the production that results in producing defective items as parameters and in the second case we consider them as variables.

Similar content being viewed by others

References

Alfares HK, Elmorra HH (2005) The distribution free newsboy problem: extension to the shortage penalty case. Int J Prod Econ 93–94:465–477

Ben-Daya M, Rauf A (1994) Inventory models involving lead-time as a decision variable. J Oper Res Soc 45:579–582

Chuang BR, Ouyang LY, Chuang KW (2004) A note on periodic review inventory model with controllable setup cost and lead time. Comput Oper Res 31:549–561

Cobb BR (2013) Mixture distributions for modelling demand during lead time. J Oper Res Soc 64:217–228

Gallego G, Moon I (1993) The distribution free newsboy problem: review and extensions. J Oper Res Soc 45:579–582

Glock CH (2012) Lead time reduction strategies in a single-vendor-single-buyer integrated inventory model with lot size-dependent lead times and stochastic demand. Int J Prod Econ 136:37–44

Hariga M, Ben-Daya M (1999) Some stochastic inventory models with deterministic variable lead time. Eur J Oper Res 113:42–51

Kim M, Sarkar B (2017a) Multi-stage cleaner production process with quality improvement and lead time dependent ordering cost. J Clean Prod 144:572–590

Kim SJ, Sarkar B (2017b) Supply chain model with stochastic lead time, trade-credit financing, and transportation discounts. Math Probl Eng:6465912. https://doi.org/10.1155/2017/6465912

Kono H (2012) Safer zone analysis for multiple investment alternatives on the total cost unit cost domain. Ind Eng Manag Syst 11(1):11–17

Liao CJ, Shyu CH (1991) An analytical determination of lead time with normal demand. Int J Oper Prod Manag 11:72–78

Majumder A, Guchhait R, Sarkar B (2017a) Manufacturing quality improvement and setup cost reduction in an integrated vendor-buyer supply chain model. Eur J Ind Eng. In Press. https://doi.org/10.1504/EJIE.2017.087678

Majumder A, Jaggi CK, Sarkar B (2017b) A multi-retailer supply chain model with backorder and variable production cost. Rairo Oper Res. In Press. https://doi.org/10.1051/ro/2017013

Moon I, Choi S (1998) A note on lead time and distributional assumptions in continuous review inventory models. Comput Oper Res 25:1007–1012

Moon I, Shin E, Sarkar B (2014) Min max distribution free continuous-review model with a service level constraint and variable lead time. Appl Math Comput 229:310–315

Nagasawa K, Irohara T, Matoba Y, Liu S (2012) Selecting ordering policy and items classification based on canonical correlation and cluster analysis. Ind Eng Manage Syst 11(2):134–141

Ouyang LY, Wu KS (1998) A minimax distribution free procedure for mixed inventory model with variable lead time. Int J Prod Econ 56–57:511–516

Ouyang LY, Chen CK, Chang HC (2002) Quality improvement, setup cost and lead-time reductions in lot size reorder point models with an imperfect production process. Comput Oper Res 29:1701–1717

Ouyang LY, Wu KS, Ho CH (2004) Integrated vendor-buyer cooperative models with stochastic demand in controllable lead time. Int J Prod Econ 92:255–266

Ouyang LY, Chuang BR, Lin YJ (2005) Periodic review inventory models with controllable lead time and lost sales rate reduction. J Chin Inst Ind Eng 22:355–368

Ouyang LY, Wu KS, Ho CH (2007) An integrated vendor-buyer inventory model with quality improvement and lead time reduction. Int J Prod Econ 108:349–358

Park C (2007) An analysis of the lead time demand distribution derivation in stochastic inventory systems. Int J Prod Econ 105:263–272

Porteus EL (1986) Optimal lot sizing, process quality improvement, and setup cost reduction. Oper Res 34:137–144

Sarkar B (2013) A production-inventory model with probabilistic deterioration in two-echelon supply chain management. Appl Math Model 37:3138–3151

Sarkar B (2016) Supply chain coordination with variable backorder, inspections, and discount policy for fixed lifetime products. Mathe Probl Eng 2016:6318737 14 pages

Sarkar B, Majumder A (2013) Integrated vendor-buyer supply chain model with vendors setup cost reduction. Appl Math Comput 224:362–371

Sarkar B, Mandal P, Sarkar S (2014) An EMQ model with price and time dependent demand under the effect of reliability and inflation. Appl Math Comput 231:414–421

Sarkar B, Mandal B, Sarkar S (2015) Quality improvement and backorder price discount under controllable lead time in an inventory model. J Manuf Syst 35:26–36

Sarkar B, Majumder A, Sarkar M, Dey BK, Roy G (2017) Two-echelon supply chain model with manufacturing quality improvement and setup cost reduction. J Ind Manag Optim 13(2):1085–1104

Scarf H (1958) A min-max solution of an inventory problem. Stanford University Press, Redwood City

Shin D, Guchhait R, Sarkar B, Mittal M (2016) Controllable lead time, service level constraint, and transportation discount in a continuous review inventory model. RAIRO Oper Res (SCIE) 50:921–934

Silver EA (1992) Changing the givens in modelling inventory problems: the example of just in time systems. Int J Prod Econ 26:347–351

Soni H, Sarkar B, Majumder A, Majumder S (2017) Lost sales reduction and quality improvement with variable lead time and fuzzy costs in an imperfect production system. Rairo Oper Res. In Press. https://doi.org/10.1051/ro/2016075

Taleizadeh AA (2014) An Economic Order Quantity Model with Partial Backordering and Advance Payments for an Evaporating Item. Int J Prod Econ 155:185–193

Taleizadeh AA, Nematollahi MR (2014) An inventory control problem for deteriorating items with backordering and financial engineering considerations. Appl Math Model 38:93–109

Taleizadeh AA, Pentico DW (2013) An economic order quantity model with known price increase and partial backordering. Eur J Oper Res 28(3):516–525

Taleizadeh AA, Pentico DW (2014) An economic order quantity model with partial backordering and all-units discount. Int J Prod Econ 155:172–184

Taleizadeh AA, Aryanezhad MB, Niaki STA (2008a) Optimizing multi-products multi-constraints inventory control systems with stochastic replenishments. J Appl Sci 6(1):1–1

Taleizadeh AA, Niaki ST, Aryanezhad MB (2008b) Multi-product multi-constraint inventory control systems with stochastic replenishment and discount under fuzzy purchasing price and holding costs. Am J Appl Sci 8(7):1228–1234

Taleizadeh AA, Moghadasi H, Niaki STA, Eftekhari AK (2009) An EOQ-joint replenishment policy to supply expensive imported raw materials with payment in advance. J Appl Sci 8(23):4263–4273

Taleizadeh AA, Niaki STA, Aryanezhad MB, Fallah-Tafti A (2010) A genetic algorithm to optimize multi-product multi-constraint inventory control systems with stochastic replenishments and discount. Int J Adv Manuf Technol 51(1–4):311–323

Taleizadeh AA, Barzinpour F, Wee HM (2011) Meta-heuristic algorithms to solve the fuzzy single period problem. Math Comput Model 54(5–6):1273–1285

Taleizadeh AA, Pentico DW, Jabalameli MS, Aryanezhad MB (2013a) An economic order quantity model with multiple partial prepayments and partial backordering. Math Comput Model 57(3–4):311–323

Taleizadeh AA, Wee HM, Jalali-Naini SGR (2013b) economic production quantity model with repair failure and limited capacity. Appl Math Model 37(5):2765–2774

Taleizadeh AA, Wee HM, Jolai F. (2013c) Revisiting fuzzy rough economic order quantity model for deteriorating items considering quantity discount and prepayment. Math Comput Model 57(5–6):1466–1479

Taleizadeh AA, Cardenas-Barron LE, Mohammadi B (2014) Multi product single machine epq model with backordering, scraped products, rework and interruption in manufacturing process. Int J Prod Econ 150:9–27

Tersine RJ (1982) Principles of inventory and materials management, vol 15. North Holland, New York

Vidalis M, Vrisagotis V, Varlas G (2014) Performance evaluation of a two-echelon supply chain with stochastic demand, lost sales, and Coxian-2 phase replenishment times. Int Trans Oper Res 21:649–671

Wu KS, Ouyang LY (2001) (Q, r, L) inventory model with defective items. Comput Ind Eng 39:173–185

Yang JS, Pan JC (2004) An integrated inventory model involving deterministic variable lead time and quality improvement investment. Int J Prod Res 42:853–863

Acknowledgements

The first author would like to thank the financial support of University of Tehran for this research under grant number 30015-1-04.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

The expected number of defective items is calculated as below according to the article that Porteus [23] has provided:

As \( \overset{\sim }{\phi }=1-\phi \cong 1 \) we use the Taylor series expansion of \( \overset{\sim }{\phi^{DT}} \) until 2nd order as ϕ is very small and we obtain:

And the expected annual cost for defective items is computed as below:

Rights and permissions

About this article

Cite this article

Taleizadeh, A.A., Zamani-Dehkordi, N. Optimizing setup cost in (R, T) inventory system model with imperfect production process, quality improvement, and partial backordering. Jnl Remanufactur 7, 199–215 (2017). https://doi.org/10.1007/s13243-017-0040-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13243-017-0040-8