Abstract

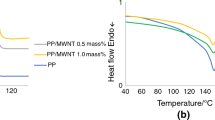

The extraordinary physical properties of multiwalled carbon nanotubes (MWCNTs) are yet to be fully realised in polyamide-6 (PA6) nanocomposites, due to difficulty in dispersion of MWCNTs within PA6 matrix, owing to high toughness of PA6 and agglomerating properties of MWCNTs. In this study, MWCNTs of high aspect ratio prepared by chemical vapour deposition (CVD) method are melt-mixed with 0.1–0.5 parts-per-hundred ratios (phr) into PA6 matrix by twin-screw extrusion. The high shearing force of co-rotating twin-screws and intermixing of the components along the back-flow channel of extruder assured uniformly dispersed MWCNTs within PA6 system. A 30.2% rise in yield strength and an 82.6% rise in Young’s modulus were noticed for 0.1 phr MWCNTs/PA6 tensile specimens over neat PA6 specimens during tensile testing. A strain hardening behaviour was shown by neat PA6, which was persistent in all its composites containing MWCNTs. A distinct trend in storage and loss behaviour, as well as 14 °C and 11 °C rise in glass transition temperatures (Tg) in loss modulus and loss factor curves, respectively, were observed for 0.5 phr MWCNTs’ reinforcement in dynamic mechanical analysis (DMA), which indicated an effective PA6–MWCNTs interaction. The improvements in crystallization and melting temperatures, as well as crystallinity values in differential scanning calorimetry (DSC) indicated nucleating effects of MWCNTs towards stable crystallization of PA6 molecules. The shifting and rise in intensity peaks in XRD and Raman spectroscopy curves supported the reinforcing effect of MWCNTs within PA6 matrix. These nanocomposites are beneficial for fabricating high mechanical and thermal stability-required components in automobiles, aerospace, and biomedicals.

Similar content being viewed by others

Data and code availability

Not applicable.

References

Abbasi S, Derdouri A, Carreau PJ (2011) Properties of microinjection molding of polymer multiwalled carbon nanotube conducting composites. Polym Eng Sci 51:992–1003. https://doi.org/10.1002/pen.21904

Brosse AC, Girault ST, Piccione PK, Leibler L (2008) Effect of multi-walled carbon nanotubes on the lamellae morphology of polyamide-6. Polymer 49:4680–4686. https://doi.org/10.1016/j.polymer.2008.08.003

Bureau M, Denault J, Cole K, Enright G (2002) The role of crystallinity and reinforcement in the mechanical behavior of polyamide-6/clay nanocomposites. Polym Eng Sci 42:1897–1906. https://doi.org/10.1002/pen.11082

Cavallo LGD, Alfonso GC, Portale G, Balzano L, Androsch R (2011) Effect of cooling rate on the crystal/mesophase polymorphism of polyamide 6. Colloid Polym Sci 289:1073–1079. https://doi.org/10.1007/s00396-011-2428-6

Clemente LA, Fonte XG, Abad MJ, Pernas AA (2018) Role of rheology in tunning thermal conductivity of polyamide 12/polyamide 6 composites with a segregated multiwalled carbon nanotube network. J Compos Mat 52:2549–2557. https://doi.org/10.1177/0021998317749715

de Melo CCN, Beatrice CAG, Pessan LA, de Oliveira AD, Machado FM (2018) Analysis of nonisothermal crystallization kinetics of graphene oxide-reinforced polyamide 6 nanocomposites. Thermochim Acta 667:111–121. https://doi.org/10.1016/j.tca.2018.07.014

Faridirad F, Ahmadi S, Barmar M (2017) Polyamide/carbon nanoparticles nanocomposites: a review. Polym Eng Sci 57:475–494. https://doi.org/10.1002/pen.24444

Feldman D (2017) Polyamide nanocomposites. J Macromol Sci Part A 54:255–262. https://doi.org/10.1080/10601325.2017.1282700

Francisco DL, Paiva LB, Aldeia W (2019) Advances in polyamide nanocomposites: a review. Polym Compos 40:851–870. https://doi.org/10.1002/pc.24837

Fried JR (2014) Polymer science and technology, Pearson Education.

Ghane N, Mazinani S, Gharehaghaji AA (2018) Fabrication and characterization of hollow nanofibrous PA6 yarn reinforced with CNTs. J Polym Res 25:1–12. https://doi.org/10.1007/s10965-018-1477-7

Gupta TK, Singh BP, Tripathi RK, Dhakate SR, Singh VN, Panwar O, Mathur RB (2015) Superior nano-mechanical properties of reduced graphene oxide reinforced polyurethane composites. RSC Adv 5:16921–16930. https://doi.org/10.1039/C4RA14223C

Hamester MRR, Dalmolin C, Becker D (2019) Role of π-π interactions and chain flexibility in dispersion and dynamic-mechanical properties of nanocomposites with multiple wall carbon nanotubes. J Appl Polym Sci 136:48195. https://doi.org/10.1002/app.48195

Han Z, Fina A (2011) Thermal conductivity of carbon nanotubes and their polymer nanocomposites: a review. Prog Polym Sci 36:914–944. https://doi.org/10.1016/j.progpolymsci.2010.11.004

Heflin DG, Mansson JAE (2022) Mechanisms for combining polyamide and epoxy and their effects on mechanical performance—a review. Polym Polym Compos 30:1–19. https://doi.org/10.1177/09673911221130120

Humeau C, Davies P, LeGac PY, Jacquemin F (2018) Influence of water on the short and long term mechanical behaviour of polyamide 6 (nylon) fibres and yarns. Multiscale Multidiscip Model, Exp Des 1:317–327. https://doi.org/10.1007/s41939-018-0036-6

Jyoti J, Singh BP (2022) A review on 3D graphene–carbon nanotube hybrid polymer nanocomposites. J Mater Sci 56:1–46. https://doi.org/10.1007/s10853-021-06370-7

Jyoti J, Singh BP, Arya AK, Dhakate SR (2016) Dynamic mechanical properties of multiwall carbon nanotube reinforced ABS composites and their correlation with entanglement density, adhesion, reinforcement and C factor. RSC Adv 6:3997–4006. https://doi.org/10.1039/C5RA25561A

Kausar A (2020) A review of high performance polymer nanocomposites for packaging applications in electronics and food industries. J Plast Film Sheeting 36:94–112. https://doi.org/10.1177/8756087919849459

Kazemi Y, Kakroodi AR, Mark LH, Filleter T, Park CB (2019) Effects of polymer-filler interactions on controlling the conductive network formation in polyamide 6/multi-Walled carbon nanotube composites. Polymer 178:121684. https://doi.org/10.1016/j.polymer.2019.121684

Kondo MY, Montagna LS, Morgado GFM, Castilho ALG et al (2022) Recent advances in the use of Polyamide-based materials for the automotive industry. Polimeros 32(2):e2022023. https://doi.org/10.1590/0104-1428.2022004

Kumar A, Sharma K, Dixit AR (2021) A review on the mechanical properties of polymer composites reinforced by carbon nanotubes and graphene. Carbon Lett 31:149–165. https://doi.org/10.1007/s42823-020-00161-x

Lee DK, Yoo J, Kim H, Kang BH, Park SH (2022) Electrical and thermal properties of carbon nanotube polymer composites with various aspect ratios. Materials 15(4):1356. https://doi.org/10.3390/ma15041356

Lei X, Liang M, Zou H, Zhou S (2023) Properties of polyamide 6/multiwalled carbon nanotubes composites: the influence of processing methods. J Appl Polym Sci 1–13:e53424. https://doi.org/10.1002/app.53424

Li J, Fang Z, Tong L, Gu A, Liu F (2006) Polymorphism of nylon-6 in multiwalled carbon nanotubes/nylon-6 composites. J Polym Sci Part b: Polym Phys 44:1499–1512. https://doi.org/10.1002/polb.20808

Li L, Li B, Hood MA, Li CY (2009) Carbon nanotube induced polymer crystallization: the formation of nanohybrid shish–kebabs. Polymer 50:953–965. https://doi.org/10.1016/j.polymer.2008.12.031

Liu T, Phang IY, Shen L, Chow SY, Zhang WD (2004) Morphology and mechanical properties of multiwalled carbon nanotubes reinforced nylon-6 composites. Macromolecules 37:7214–7222. https://doi.org/10.1021/ma049132t

Mathur RB, Chatterjee S, Singh BP (2008) Growth of carbon nanotubes on carbon fibre substrates to produce hybrid/phenolic composites with improved mechanical properties. Compos Sci Technol 68:1608–1615. https://doi.org/10.1016/j.compscitech.2008.02.020

Mei J, Lei X, Liang M, Wu H, Zhou S, Zou H, Chen Y (2021) Comparative study on the electrical, thermal, and mechanical properties of multiwalled carbon nanotubes filled polypropylene and polyamide 6 micromoldings. Appl Polym Sci 138:1–15. https://doi.org/10.1002/app.49984

Millot C, Fillot LA, Lame O, Sotta P, Seguela R (2015) Assessment of polyamide-6 crystallinity by DSC. J Therm Anal Calorim 122:307–314. https://doi.org/10.1007/s10973-015-4670-5

Murthy NS (2006) Hydrogen bonding, mobility, and structural transitions in aliphatic polyamides. J Polym Sci Part b: Polym Phys 44:1763–1782. https://doi.org/10.1002/polb.20833

Murthy NS, Kagan VA, Bray RG (2002) Effect of melt temperature and skin-core morphology on the mechanical performance of nylon 6. Polym Eng Sci 42:940–950. https://doi.org/10.1002/pen.11003

Nurazzi NM, Sabaruddin FA, Harussani MM, Kamarudin SH et al (2021) Mechanical performance and applications of CNTS reinforced polymer composites—a review. Nanoaterial 11:2186. https://doi.org/10.3390/nano11092186

Parodi E (2017) Structure properties relations for polyamide 6, Technische Universiteit Eindhoven, PhD Thesis

Pastukhov LV, Kanters MJ, Engels TA, Govaert LE (2021) Influence of fiber orientation, temperature and relative humidity on the long-term performance of short glass fiber reinforced polyamide 6. J Appl Polym Sci 138(50382):1–19. https://doi.org/10.1002/app.50382

Penel-Pierron L, Seguela R, Lefebvre JM, Miri V, Depecker C, Jutigny M, Pabiot J (2001) Structural and mechanical behavior of nylon-6 films. II Uniaxial and Biaxial Drawing. J Polym Sci Part b: Polym Phys 39:1224–1236. https://doi.org/10.1002/polb.1096

Petrény R, Mészáros L (2022) Moisture dependent tensile and creep behaviour of multi-wall carbon nanotube and carbon fibre reinforced, injection moulded polyamide 6 matrix multi-scale composites. J Mater Res Technol 16:689–699. https://doi.org/10.1016/j.jmrt.2021.12.030

Phang IY, Ma J, Shen L, Liu T, Zhang WD (2006) Crystallization and melting behavior of multi-walled carbon nanotube-reinforced nylon-6 composites. Polym Internat 55:71–79. https://doi.org/10.1002/pi.1920

Pothan LA, Oommen Z, Thomas S (2003) Dynamic mechanical analysis of banana fiber reinforced polyester composites. Compos Sci Technol 63:283–293. https://doi.org/10.1016/S0266-3538(02)00254-3

Roth MR, Pisani WA, Wedgeworth DN, Newman JK, Shukla MK (2022) Computational analysis on mechanical property reinforcement of nylon 6 polymer and nanofiller dispersion through addition of CNT/Graphene/CNT-Graphene nanofillers. J Polym Res 29:1–10. https://doi.org/10.1007/s10965-022-03147-7

Russo P, Cimino F, Tufano A, Fabbrocino F (2021) Thermal and quasi-static mechanical characterization of polyamide 6-graphene nanoplatelets composites. Nanomaterials 11:1454. https://doi.org/10.3390/nano11061454

Sehrawat M, Rani M, Bharadwaj S, Sharma S, Chauhan GS, Dhakate SR, Singh BP (2022) Glass transition temperature measurement of polycarbonate specimen by dynamic mechanical analyser towards the development of reference material. Mapan 37:517–527. https://doi.org/10.1007/s12647-022-00572-3

Sharma S, Pathak AK, Singh VN, Teotia S, Dhakate SR, Singh BP (2018) Excellent mechanical properties of long multiwalled carbon nanotube bridged Kevlar fabric. Carbon 137:104–117. https://doi.org/10.1016/j.carbon.2018.05.017

Sharma S, Sudhakara P, Omran AAB, Singh J, Ilyas R (2021) Recent trends and developments in conducting polymer nanocomposites for multifunctional applications. Polymers 13(2898):1–31. https://doi.org/10.3390/polym13172898

Singh BP, Saini PK, Choudhary V, Teotia S, Pande S, Mathur RB (2014) Effect of length of carbon nanotubes on electromagnetic interference shielding and mechanical properties of their reinforced epoxy composites. J Nanopart Res 16:1–11. https://doi.org/10.1007/s11051-013-2161-9

Taher F, Hardani H, Bakhshi S, Samadi MR, Ayaz M (2022) Enhancing the tensile properties of PA6/CNT nanocomposite in selective laser sintering process. Polym Compos. https://doi.org/10.1002/pc.27171

Tajik S, Beitollahi H, Nejad FG, Dourandish Z et al (2021) Recent developments in polymer nanocomposite-based electrochemical sensors for detecting environmental pollutants. Ind Eng Chem Res 60:1112–1136. https://doi.org/10.1021/acs.iecr.0c04952

Thabet A, Mubarak Y, Bakry M (2011) A review of nano-fillers effects on industrial polymers and their characteristics. J Eng Sci 39(2):377–403

Varghese M, Grinstaff MW (2022) Beyond nylon 6: polyamides via ring opening polymerization of designer lactam monomers for biomedical applications. Chem Soc Rev 51:8258–8275. https://doi.org/10.1039/d1cs00930c

Verma M, Dhawan SK, Choudhary V (2017) Graphene nanoplatelets/carbon nanotubes/polyurethane composites as efficient shield against electromagnetic polluting radiations. Compos Part B 120:118–127. https://doi.org/10.1016/j.compositesb.2017.03.068

Xanthos M (2005) Polymers and polymer composites, Functional fillers for plastics, 1–16. https://doi.org/10.1002/9783527629848.ch1

Yang C, Xie G, Kang J, Zhang L (2022) Research on polyamide based self-lubricating composites: a review. Polym Compos 43:5767–5782. https://doi.org/10.1002/pc.26926

Zhao C, Hu G, Justice R, Schaefer DW, Zhang S, Yang M, Han CC (2005) Synthesis and characterization of multi-walled carbon nanotubes reinforced polyamide 6 via in situ polymerization. Polymer 46:5125–5132. https://doi.org/10.1016/j.polymer.2005.04.065

Zhao B, Zhao C, Li R, Hamidinejad SM, Park CB (2017) Flexible, ultrathin, and high-efficiency electromagnetic shielding properties of poly (vinylidene fluoride)/carbon composite films. ACS Appl Mater Interfaces 9:20873–20884. https://doi.org/10.1021/acsami.7b04935

Zhou L, Liu H, Zhang X (2015) Graphene and carbon nanotubes for the synergistic reinforcement of polyamide 6 fibers. J Mater Sci 50:2797–2805. https://doi.org/10.1007/s10853-015-8837-z

Acknowledgements

The authors are grateful to Mr. R. K. Seth for DSC measurements, Mrs. Shaveta Sharma for Raman characterization and mechanical properties measurement, and Mr. Naval Kishore Upadhyay for XRD and SEM measurements. Sangita Tripathy is thankful to Council of Scientific and Industrial Research (CSIR) for the senior research fellowship (SRF) to carry out her research work.

Author information

Authors and Affiliations

Contributions

ST: conceptualization, formal analysis, writing—original draft, methodology, investigation, and writing—review and editing; SRD: methodology, and writing—review and editing; BPS: conceptualization, project administration, supervision, and writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they do not have any competing financial interests or personal relationships which could influence the work reported in this paper.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tripathy, S., Dhakate, S.R. & Singh, B.P. Effect of long-length carbon nanotubes on yield, ultimate, dynamic mechanical, and thermal properties of polyamide-6 composites prepared by twin-screw extrusion. Appl Nanosci 14, 465–475 (2024). https://doi.org/10.1007/s13204-023-02992-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-023-02992-2