Abstract

Tight sandstone reservoirs are significant sources of natural gas reserves. As traditional reserves become increasingly scarce and costly, optimizing the development of these reservoirs becomes crucial. This study introduces a novel two-phase gas–water flow model for single wells, incorporating both Darcy and non-Darcy flow equations. These equations are derived from mass conservation and momentum principles for both gas and water phases. Using data from a real tight gas well, our model, which includes stress-sensitive phases for gas and water, outperforms traditional Darcy flow models. Specifically, the average relative deviations in daily production rates were 0.1815% for gas and − 0.2677% for water, which are significantly smaller compared to traditional Darcy flow models. Further application of the non-Darcy flow model reveals strategies to enhance well performance. For example, mitigating liquid lock damage within a 2 m radius near the well could restore the permeability from 0.045 to 0.143 mD, thereby tripling the daily gas production. This non-Darcy flow model is easy to implement and shows significant potential in forecasting production yields in tight sandstone reservoirs, highlighting its importance in the petroleum and natural gas industry.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

As global efforts intensify to balance energy supply and demand, unconventional energy sources have gained increasing research interest. This is due to their substantial geological reserves and significant potential for development (Islam et al. 2014; Zhang H et al. 2017; Caineng et al. 2018; Jiao et al. 2019). Tight sandstone gas reservoirs, in particular, have shown promise. In their initial development stages, these reservoirs maintain significant pressure and energy. This ensures stable fluid extraction from the well bottom. However, problems arise as the reservoir develops. Its pressure decreases, leading to a reduction in gas production and a decline in the recovery rate. Most existing research in gas–water two-phase flow theory has focused on specific areas. These include gas–water two-phase flow equations, steady-state inflow dynamics in production wells, and the derivation of mathematical models for well tests and production analysis (Xiaoping and Birong 1999; Sun et al. 2018a; Wang W et al. 2019; Wang Q et al. 2020; Shi H et al. 2021; Mo et al. 2022; Yong et al. 2022). To accurately predict production behavior in tight sandstone gas reservoirs, it is ideal to integrate a geological model and develop a fully-calibrated, full-physics reservoir simulation model (Cheng et al. 2013; Jianlong et al. 2015; Guo et al. 2017; Sun et al. 2018b; Huang X et al. 2019; Luo H et al. 2019). However, numerical simulations carry limitations, including significant computational costs and time requirements (Zhang X et al. 2009; Song et al. 2017; Mutailipu et al. 2017, 2018). In contrast, the productivity equation, an analytical tool, can predict production and provide direct insights into the development of tight gas wells, making its development of great practical significance. Therefore, numerous scholars have made various improvements to the production model. For example, they have introduced new fluid flow models to explain the behavior of fluid transport at macro, micro, and meso scales (Aldhuhoori et al. 2021a, 2021b; Alkuwaiti et al. 2021; Belhaj et al. 2019). These improvements also include optimization of the traditional Darcy model to more accurately predict Darcy and non-Darcy flow characteristics in porous media (Belhaj et al. 2003a, 2003b, 2003c, 2003d; Al Hameli et al. 2022b). Some research has also introduced additional parameters into the existing theoretical models to more precisely simulate the complex fluid flow behavior in reservoirs (Nouri et al. 2003; Haroun et al. 2009; Belhaj et al. 2013; Shi S et al. 2018; Adegbite et al. 2021; Al Hameli et al. 2022a; Prempeh et al. 2022). However, these models generally face a challenge: they require a large amount of experimental data for validation and support in practical applications, which increases the difficulty of their implementation (Akilu et al. 2021).

This paper aims to provide a more scientific and rational theoretical foundation for the development planning of tight sandstone gas reservoirs. We propose a new two-phase flow production equation under pseudo-steady-state conditions. Additionally, we introduce a novel non-Darcy gas–water two-phase production prediction model that considers stress-sensitive conditions. Utilizing existing gas–water two-phase flow theory, the model can be solved using optimal fitting methods. By using only production data, it is possible to determine a single well's control reserves, relative permeability profiles, and formation pressure distribution, as well as to make predictions about the well's production. It also helps in understanding the variation of formation water saturation in gas wells. The findings from this study promise to be invaluable for predicting production and understanding the development of tight gas wells.

Gas–water two-phase flow model for a single well

Joshi suggested that during gas reservoir development, a single well can be approximated as a pseudo-Darcy flow (Joshi 1988). Based on this concept, the following assumptions have been made for the gas–water two-phase flow prediction model:

-

(1)

The reservoir fluid is assumed to be isothermal.

-

(2)

Only gas and water phases are present in the gas reservoir.

-

(3)

The impact of gravity and capillary forces has been neglected.

-

(4)

The slip effect and start-up pressure have not been considered in the gas–water two-phase flow model. These assumptions have been made to simplify the model and make it more practical to use for prediction and analysis purposes.

Motion equation for the gas–water two-phase flow

According to Darcy's law of percolation, the equation of motion of the gas and water phases can be expressed as follows:

Gas phase:

Water phase:

where vg, vw are gas-phase and water-phase percolation velocities, 10−3 m/s; μg, μw are gas-phase and water-phase viscosities, mPa·s; krg, krw are gas-phase and water-phase relative permeabilities; k is the absolute permeability, D; \(\nabla p\) is the pressure gradient, MPa/m.

Continuity equation for the gas–water two-phase flow

During the flow process, conservation of matter within the formation unit leads to the establishment of the continuity equation, which connects the inflow and outflow masses within a dt time frame. For the gas and water phases, the continuity equations can be represented as:

By dividing this equation by ρi and converting it to sub-surface volume, the gas–water two-phase continuity equation can be expressed using the Hamiltonian operator. This results in the following equation:

where ρi is the density of gas or water phase, kg/m3; Bi is the volume factor of gas or water phase, m3/m3; Si is the saturation of gas or water phase, decimal; φ is the porosity of rock, %.

State equation for the gas–water two-phase flow

The state equation for real gas can be formulated as:

where p is pressure, MPa; Vg is the molar volume of gas, cm3; n is Mole; Z is the gas compressibility factor; and R is the gas constant.

This state equation can be converted into a representation of subsurface volume as follows:

where γg is the relative density of the gas; and Mair is the relative molecular mass of air.

The saturation constraint equation can be expressed as:

where Sg and Sw are the gas and water saturation, respectively.

Production model for the gas–water two-phase Darcy flow

The gas–water two-phase Darcy flow model is used to calculate gas and water in tight sandstone reservoirs, excluding the influences of the oil phase, water-soluble gas, and condensate. The model assumes linear Darcy flow of the gas and water in the formation and considers the formation fluid to comprise two components: free gas and formation water.

Based on Eq. (1) and Eq. (2), the differential form of the subsurface production formula for radial flow in the gas and water planes can be expressed as follows:

where r is the plane radial flow radius, m; h is the reservoir thickness, m.

By integrating Eq. (8) and Eq. (9), assuming pseudo-steady flow in both the gas and water phases and taking into account the skin factor, we can obtain:

where Sa is the skin factor; rw is the radius of the bottom of the well, m; re is the flow radius, m; pr is the average reservoir pressure, MPa.

Defining the gas phase pseudo-pressure and water phase pseudo-pressure as follows:

Gas phase pseudo-pressure:

Water phase pseudo-pressure:

Concisely, Eq. (12) and Eq. (13) can be expressed as:

where C is the production coefficient, m3/d.

The ratio from Eq. (14) and Eq. (15) can be expressed as the production gas–water ratio:

where Rpgw is the production gas–water ratio, m3/m3.

By simplifying Eq. (16), it turns into:

Using Eq. (17), the effective permeability of the water and gas phases can be expressed as follows:

The preceding equations can be combined to yield the following system of equations:

The set of Eq. (20) represents a novel model for gas–water two-phase production under pseudo-steady-state conditions. This set of equations can be solved using the relative permeability of one phase and the production coefficient C to determine the relative permeability of the other phase.

Formation pressure distribution

By integrating the equations of motion, state, and continuity, we can construct the mathematical model for a gas–water two-phase stable flow as follows:

Substituting Eq. (12) into Eq. (21) yields:

Then the mathematical model Eqs. (23)–(25) can be simplified to the following form:

The differential equation for planar radial steady flow of gas–water two-phase can be expressed as follows:

The general solution of the differential equation is expressed as follows:

Substituting the boundary conditions yields:

After incorporating values of C1 and C2 into Eq. (28), we derive the following expression for the pressure function:

Phase relative permeability curve and water saturation

The flows of gas-phase and water-phase at r can be deduced from the gas–water two-phase flow production equations, as per Eq. (31) and Eq. (32):

The empirical equation for the phase relative permeability data is expressed as follows (Huang BG, 2004):

where \(\overline{S}_{w}\) is the average water saturation of the formation, decimal; D is the phase relative permeability coefficient.

Applying Eq. (33) and Eq. (34), krg/krw can be formulated as a function of water saturation Sw:

Jokhio (Jokhio and Tiab 2002) suggested a method to calculate each relative permeability ratio using the gas–water production ratio Rpgw. This approach allows the depiction of krg/krw as a function of Rpgw under gas–water two-phase flow conditions:

In Eq. (36), the ratio of gas-phase relative permeability to water-phase relative permeability, krg/krw, is represented as a function of average water saturation and pressure, inclusive of gas and water viscosities (μg and μw) and gas and water formation volume factors (Bg and Bw). Employing the formation pressure p and the production gas–water ratio Rpgw, the values of krg/krw, the average water saturation, and subsequently, the relative permeability of gas and water phases, krg and krw, can be determined. Merging Eq. (35) with Eq. (36) derives Eq. (37).

By uniting Eq. (37) and the pressure distribution function from Eq. (28), the water saturation function appears as follows:

Bottom-hole pressure in gas wells

The bottom-hole pressure in a gas well (Kidnay et al. 2019) can be estimated using Eq. (39):

where pwf is the bottom-hole pressure, MPa; pts is the tubing pressure, MPa; H is the depth in the middle of the reservoir, m; Tav is the average temperature in the middle of the reservoir, K; Zav is the gas compressibility factor at average reservoir pressure.

Average water saturation of the formation

In gas reservoirs where both gas and water occupy the pore spaces, the capacity of the reservoir can be described as follows:

where V is the total pore volume of gas reservoir, m3; G is the reservoir volume, m3; Swi is the original water saturation, decimal; Bgi is the original volume factor, m3/m3.

The volume of water bodies in the gas reservoir is expressed as:

Subsequently, the average water saturation in the gas reservoir at any time during production is given by:

where Wp is the total water production of gas reservoir, m3.

Single well control reserves

The material balance equation for a gas reservoir as follows:

where Cc is the expansion coefficient of the reservoir, MPa−1; We is the volume of water intrusion in the gas reservoir, m3; pi is the initial formation pressure, MPa; Zi is initial gas compressibility factor.

In gas reservoirs, the expansion of gas is considerably more prominent compared to the contributions from formation water and rock, allowing these latter factors to be neglected. Furthermore, the simplified equations do not account for the influx of water at the bottom edge, as the predominant source of water production in dense sandstone gas reservoirs is intra-formation water. Consequently, the equations can be simplified as follows:

The physical parameters of gas and water in the gas–water two-phase Darcy flow model include:

-

(1)

The volume factor of natural gas,

-

(2)

The viscosity of natural gas,

-

(3)

the compressibility factor of natural gas,

-

(4)

The volume factor of formation water.

The calculations primarily refer to the PR (Peng-Robinson) equation (Peng and Robinson 1976).

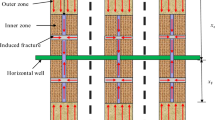

Non-Darcy flow model considering stress sensitivity for gas–water two-phase

Numerous laboratory experiments have unequivocally demonstrated that stress sensitivity has a significant impact on gas–water two-phase flow. Therefore, it becomes paramount to take into account stress sensitivity when formulating a gas–water two-phase flow production prediction model. An exponential relationship between the permeability of the porous medium and effective stress has been identified and can be articulated as follows (Xu et al. 2018; Huang X et al. 2021; Luo X et al. 2022):

where K0 is the absolute permeability of the reservoir rock at the initial state, D; β is the stress sensitivity coefficient of rock, MPa−1; peff is the effective stress of the formation, MPa.

Expanding the exponential term e−β(pi−p) to the first two terms of the Maclaurin series, we obtain:

Therefore, the equations of motion for the gas and water phases considering stress sensitivity are as follows:

The differential form of the radial flow in the gas phase plane for Eq. (47):

This calculation enables us to establish the gas production equation, taking into account stress sensitivity:

Defining the gas-phase proposed pressure function as follows:

Combining Eq. (12), Eq. (49), and Eq. (50) yields:

The water production equation considering stress sensitivity can be expressed as follows:

Similarly, the proposed pressure function for the water phase can be defined as:

Combining Eq. (13) and Eq. (53) yields the water production equation:

The equations for pressure, water saturation, production coefficient, and water and gas production for the gas and water phases are combined to derive the production equation that takes stress sensitivity into account.

Equation (55) signifies that the individual production equation for each phase in the gas–water system can be derived solely through the use of the gas phase relative permeability krg, water phase relative permeability krw, production coefficient C, and stress sensitivity coefficient β.

Solution of the model

Utilizing production data from a sample well located in the western region of the Sichuan Basin, China, the gas–water two-phase flow production model for a single well can be partitioned into two key sections: data fitting and production prediction.

Production data fit

The goal of the model is to fit the production coefficient C, phase relative permeability coefficient D, stress sensitivity coefficient β, and single well dynamic gas reserves G with the measured values. The optimal values of these parameters are obtained by seeking the best fit between theoretical and measured values, which can be expressed as follows:

where qgsci’ (C, D, βg, G), qwsci’ (C, D, βw, G) are the fitted gas production and water production, m3/d, respectively; qgsci’, qwsci’ are the actual gas production and water production, m3/d, respectively; E is the fitted objective function.

The above equation is a non-linear least squares problem, demanding an automatic fitting method to locate a set of optimal parameters that minimize the objective function. Figure 1 presents a block diagram of the gas–water two-phase non-Darcy flow model software.

The gas–water two-phase non-Darcy flow model can be calculated using the following steps:

-

(1)

Input key parameters such as original formation pressure, formation temperature, well depth, initial water saturation, oil pressure, actual gas production, actual water production, and gas components of the gas well.

-

(2)

Determine bottom-hole pressure pwf from the wellhead oil pressure.

-

(3)

Calculate total gas and water production from the actual production data, establish current formation pressure pr using Eq. (44), and compute formation fluid physical parameters.

-

(4)

Set initial values for production coefficient C, phase relative permeability coefficient D, stress sensitivity coefficient β, and dynamic gas reserves G, and compute the average water saturation of the formation based on the water saturation expression.

-

(5)

Determine the daily gas and water production of the gas well using Eq. (55).

-

(6)

Compare the model-predicted daily gas and water production with the actual production data, and calculate the deviation \(E_{{i^{\prime}}}\). Ascertain whether the total number of calculated deviations matches the production duration of the gas well. If not, return to step 5.

-

(7)

Change the current deviation \(\sum\nolimits_{{i^{\prime} = 1}}^{N} {E_{{i^{\prime}}}^{j - 1} }\) with the production coefficient C, stress sensitivity coefficient β, phase relative permeability coefficient D, and dynamic gas reserves G. If the current primary deviation \(\sum\nolimits_{{i^{\prime} = 1}}^{N} {E_{{i^{\prime}}}^{j} }\) is less than a specific deviation \(\left| {\sum\nolimits_{{i^{\prime} = 1}}^{N} {E_{{i^{\prime}}}^{j - 1} } - \sum\nolimits_{{i^{\prime} = 1}}^{N} {E_{{i^{\prime}}}^{j} } } \right| < error\), exit the cycle. Otherwise, adjust the value of C, D, G, β, and repeat step 4.

Production data forecasting

The steps for implementing the non-Darcy flow model are as follows:

-

(1)

Input the basic parameters. These should include the original formation pressure, formation temperature, well depth, original water saturation, oil pressure, actual water production, and gas components of gas wells.

-

(2)

Input the cumulative gas and water production. Subsequently, calculate the current formation pressure pr based on Eq. (44), and solve for the gas–water physical parameters.

-

(3)

Utilize historical fitting data to ascertain key coefficients and reserves. These include the production coefficient C, phase relative permeability coefficient D, stress sensitivity coefficient β, and dynamic gas reserves G for the gas well. Also, compute the average water saturation in the gas well based on the relevant water saturation expression.

-

(4)

Calculate the bottom-hole pressure pwf from the wellhead oil pressure using Eq. (39) for constant oil pressure production.

-

(5)

Evaluate the relative permeability for the gas and water phase using the relative permeability calculation expression, and calculate the gas and water production from the gas well for constant oil pressure production.

-

(6)

Export the final results.

Example calculation and analysis

The basic parameters of the sample wells are shown in Table 1.

The natural gas components are shown in Table 2.

The phase diagram of the sample can be obtained by solving the PR equation for the gas component parameters in Table 2, as shown in Fig. 2. The two-phase critical temperature of this sample is 200.003 K, the two-phase critical pressure is 5.351 MPa, the critical condensation pressure is 5.501 MPa, and the temperature at the critical condensation pressure is 203.442 K. These values classify this sample as a dry gas reservoir.

Based on the known formation parameters listed in Table 1, the pressure–volume-temperature (PVT) properties of the gas were calculated using the PR equation of state. The resulting p/Z, viscosity, compressibility factor, and volume factor curves of the sample gas, as a function of pressure, are depicted in Fig. 3.

The p/Z, viscosity, compressibility factor, and volume factor of the sample gas varied with pressure, as shown in Fig. 3. Production data from the sample wells were used to fit the stress-sensitive model. This fitting process determined the production coefficient C, the phase relative permeability coefficient D, and the dynamic gas reserves G for the sample wells. The results of the fitting, are shown in Table 3.

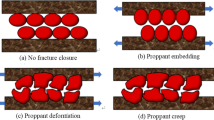

The Darcy flow model and non-Darcy flow model were used to fit and predict the daily and total gas and water production data of the sample wells, generating Fig. 4. The total gas and water production obtained with the Darcy flow model were 14.01844 million m3 and 3394.613 m3, respectively, with deviations of 0.0062% and 0.328%. The Darcy model assumes laminar flow within the reservoir, which may not always represent the complex flow dynamics, especially when considering high flow rates or low permeability regions. However, the Darcy flow model only provides an overall average view of well development, resulting in significant deviations in the daily production data. In contrast, the non-Darcy flow model incorporates stress-sensitive coefficients βg and βw. These coefficients consider the impact of turbulence and inertial effects, which become significant in high rate flows and near-wellbore regions, leading to non-linear flow behavior. By integrating these coefficients, the model can adapt to dynamic reservoir conditions and account for the deviations from the Darcy flow. This allows real-time revisions to be made during development. This model not only satisfies the total production (with deviations of 0.2396% and 0.2114% for total gas and water production, respectively) but also provides high accuracy for the daily production data (with an average absolute deviation of 22.8%, an average relative deviation of 0.1815%, and an average absolute deviation of daily production of 41.45% and average relative deviation of − 0.2677%). The current recovery level of the sample wells is 78.78%, and both models predict a higher recovery level after 1000 days of development, with the gas reservoir predicted to be 82.43% (Darcy flow model) and 88.40% (non-Darcy flow model). It's worth noting that these predictions, especially from the non-Darcy model, reflect a more realistic assessment of the reservoir's response over time by accounting for intricate flow mechanics. The average water saturation of the gas reservoir is currently 39.798%, and the two models predict a slightly lower saturation after 1,000 days of development, with average water saturation of 39.453% (Darcy flow model) and 39.281% (non-Darcy flow model). The simulation and analysis of the sample well's water intrusion distribution curve is shown in Fig. 4, based on the relevant results of the sample parameters.

Figure 5 shows the relationship between the lifting radius and the permeability recovery, indicating that as the lifting radius increases, the permeability recovery shows rapid growth initially, then levels off and stabilizes at around 2 m. Thus, it is recommended to remove the liquid lock damage at 2 m in the near-well zone, and this results in a permeability recovery of 0.143 mD, with an agent dosage of 0.911 m3 per unit layer thickness.

Based on the relevant sample parameters, daily gas production after removing the water intrusion damage in the near-well zone is simulated and analyzed, and Fig. 6 shows the results.

In Fig. 6, it is evident that the daily gas production can be restored to 4,484 m3/D after the removal of the liquid lock damage of 2 m in the near-well zone.

Conclusions

-

(1)

Based on the principles of the equation of motion and the continuity equation, we established two production models: the gas–water two-phase Darcy flow model and the gas–water two-phase non-Darcy flow model, which incorporates stress sensitivity. While the Darcy flow model, considering the production process as a pseudo-steady state flow, effectively fit the total production data with a deviation of less than 3%, it struggles with accurately fitting the daily production data.

-

(2)

Demonstrative calculations revealed that the non-Darcy flow model, taking into accounting stress sensitivity, maintains high precision in the total production data, with deviation of 0.2396% for total gas production and 0.2114% for total water production. Moreover, this model shows a high level of accuracy in predicting daily production data: the average absolute deviation of daily gas production is 22.8%, the average relative deviation is 0.1815%, and for daily water production, the average absolute and relative deviations are is 41.45% and − 0.2677%, respectively).

-

(3)

Utilizing the non-Darcy flow model, we simulated both the current water intrusion distribution curve and daily gas production recovery of the sample well. The results demonstrate that permeability can be restored from 0.045 to 0.143 mD, and daily gas production can increase from 1,458 to 4,484 m3/D following mitigation of liquid lock damage at 2 m distance from the well. In conclusion, our study highlights the effectiveness of the non-Darcy flow model with stress sensitivity in accurately predicting and analyzing production data in gas–water two-phase flow systems.

Abbreviations

- B g :

-

Volume factor of gas phase, m3/m3

- B w :

-

Volume factor of water phase, m3/m3

- C :

-

Production coefficient, m3/d

- C c :

-

Expansion coefficient of the reservoir, MPa−1

- D :

-

Phase relative permeability coefficient

- E :

-

Fitted objective function

- G :

-

Reservoir volume, m3

- H :

-

Is the depth in the middle of the reservoir, m

- K 0 :

-

Absolute permeability of the reservoir rock at the initial state, D

- M:

-

Relative molecular mass

- M air :

-

Relative Molecular mass of air

- N :

-

Number of production days

- R :

-

Gas constant, 8.3144 MPa·cm3·mol−1·K−1

- R pgw :

-

Production gas–water ratio, m3/m3

- S a :

-

Skin factor

- S g :

-

Saturation of gas phase, decimal

- S w :

-

Saturation of water phase, decimal

- \(\overline{S}_{w}\) :

-

Average water saturation of the formation, decimal

- S wi :

-

Initial water saturation, decimal

- T :

-

Formation temperature, K

- T av :

-

Average temperature in the middle of the reservoir, K

- T c :

-

Critical temperature, K

- V :

-

Total pore volume of gas reservoir, m3

- V g :

-

Molar volume of gas, cm3

- W :

-

Volume of water bodies in the gas reservoir, m3

- W e :

-

Volume of water intrusion in the gas reservoir, m3

- W p :

-

Total water production of gas reservoir, m3

- Z :

-

Gas compressibility factor

- Z av :

-

Gas compressibility factor at average reservoir pressure

- Z c :

-

Critical compressibility factor

- Z i :

-

Initial gas compressibility factor’

- h :

-

Reservoir thickness, m

- i’ :

-

Production data for day i’

- j :

-

Number of iterations of the model

- k :

-

Absolute permeability, D

- k g :

-

Gas-phase effective permeability, D

- k rg :

-

Gas-phase relative permeability

- k rw :

-

Water-phase relative permeability

- k w :

-

Water-phase effective permeability, D

- n :

-

Mole

- p :

-

Pressure, MPa

- p c :

-

Critical pressure, MPa

- p eff :

-

Effective stress of the formation, MPa

- p i :

-

Initial formation pressure, MPa

- p r :

-

Average reservoir pressure, MPa

- p ts :

-

Tubing pressure, MPa

- p wf :

-

Bottom-hole pressure, MPa

- q gsci’ :

-

Actual gas production, m3/d

- q wsci’ :

-

Actual water production, m3/d

- r :

-

Plane radial flow radius, m

- r e :

-

Flow radius, m

- r w :

-

Radius of the bottom of the well, m

- t :

-

Time, s

- v g :

-

Gas-phase percolation velocity, 10−3 m/s

- v w :

-

Water-phase percolation velocity, 10−3 m/s

- x :

-

X-axis in the Cartesian coordinate system

- y :

-

Y-axis in the Cartesian coordinate system

- z :

-

Z-axis in the Cartesian coordinate system

- β :

-

Stress sensitivity coefficient of rock, MPa−1

- β g :

-

Stress sensitivity coefficient of gas, MPa−1

- β w :

-

Stress sensitivity coefficient of water, MPa−1

- γ g :

-

Relative density of the gas

- \(\Delta m(p)_{g}\) :

-

Gas phase pseudo-pressure

- \(\Delta m(p)_{w}\) :

-

Water phase pseudo-pressure

- \(\Delta m(p)^{\prime}_{g}\) :

-

Pseudo-pressure for gas-phase additional pressure, MPa

- \(\Delta m(p)^{\prime}_{w}\) :

-

Pseudo-pressure for water-phase additional pressure, MPa

- μ g :

-

Gas-phase viscosity, mPa·s

- μ w :

-

Water-phase viscosity, mPa·s

- ρ g :

-

Density of gas phase, kg/m3

- ρ w :

-

Density of water phase, kg/m3

- φ :

-

Porosity of rock, %

- ω :

-

Acentric factor

- \(\nabla p\) :

-

Pressure gradient, MPa/m

References

Adegbite JO, Belhaj H, Bera A (2021) Investigations on the relationship among the porosity, permeability and pore throat size of transition zone samples in carbonate reservoirs using multiple regression analysis, artificial neural network and adaptive neuro-fuzzy interface system. Pet Res 6(4):321–332. https://doi.org/10.1016/j.ptlrs.2021.05.005

Akilu S, Padmanabhan E, Sun Z (2021) A review of transport mechanisms and models for unconventional tight shale gas reservoir systems. Int J Heat Mass Transfer 175:121125. https://doi.org/10.1016/j.ijheatmasstransfer.2021.121125

Al Hameli F, Belhaj H, Al Dhuhoori M (2022a) CO2 sequestration overview in geological formations: trapping mechanisms matrix assessment. Energies 15(20):7805. https://doi.org/10.3390/en15207805

Al Hameli F, Suboyin A, Al Kobaisi M, Rahman MM, Haroun M (2022b) Modeling fracture propagation in a dual-porosity system: pseudo-3d-carter-dual-porosity model. Energies 15(18):6779. https://doi.org/10.3390/en15186779

Aldhuhoori MA, Belhaj H, Ghosh B, Fernandes R, Alkuwaiti H, Qaddoura R (2021a) A unique approach in modelling flow in tight oil unconventional reservoirs with viscous, inertial and diffusion forces contributions. Int Conf Offshore Mech Arctic Eng. https://doi.org/10.1115/OMAE2021-62957

Aldhuhoori MA, Belhaj H, Alkuwaiti HK, Ghosh B, Fernandes R, Qaddoura R (2021b) Role of viscous, diffusion and inertial mechanisms in modeling fluid flow through unconventional reservoir. J Petrol Sci Eng 205:108772. https://doi.org/10.1016/j.petrol.2021.108772

Alkuwaiti H, Belhaj H, Aldhuhoori M, Ghosh B, Fernandes R (2021) An extensive study on desorption models generated based on langmuir and knudsen diffusion. Energies 14(19):6435. https://doi.org/10.3390/en14196435

Belhaj H, Agha K, Butt S, Islam M (2003a) A comprehensive numerical simulation model for non-Darcy flow including viscous, inertial and convective contributions. SPE Nigeria Annual Int Conf Exhibition. https://doi.org/10.2118/85678-MS

Belhaj H, Agha K, Butt S, Islam M (2003b) Simulation of non-Darcy flow in porous media including viscous, inertial and frictional effects. SPE Int Improv Oil Recovery Conf in Asia Pacific. https://doi.org/10.2118/84879-MS

Belhaj H, Agha K, Nouri A, Butt S, Islam M (2003c) Numerical and experimental modeling of non-Darcy flow in porous media. SPE Latin Am Caribb Petrol Eng Conf. https://doi.org/10.2118/81037-MS

Belhaj H, Agha K, Nouri A, Butt S, Vaziri H, Islam M (2003d) Numerical modeling of forchheimer’s equation to describe Darcy and non-Darcy flow in porous media. SPE Asia Pacific Oil and Gas Conf Exhib. https://doi.org/10.2118/80440-MS

Belhaj H, Khalifeh HA, Javid K (2013) Potential of nitrogen gas miscible injection in South East assets, Abu Dhabi. North Africa technical conference and exhibition. https://doi.org/10.2118/164774-MS

Belhaj H, Qaddoura R, Ghosh B, Saqer R (2019) Modeling fluid flow in tight unconventional reservoirs: nano scale mobility/trapability mechanistic approach! SPE Gas & Oil Technol Showc Conf. https://doi.org/10.2118/198676-MS

Caineng Z, Zhi Y, Dongbo H, Yunsheng W, Jian L, Ailin J, Jianjun C, Qun Z, Yilong L, Jun L (2018) Theory, technology and prospects of conventional and unconventional natural gas. Pet Explor Dev 45(4):604–618. https://doi.org/10.1016/S1876-3804(18)30066-1

Cheng Y, Li L, Yuan Z, Wu L, Mahmood S (2013) Finite element simulation for fluid–solid coupling effect on depressurization-induced gas production from gas hydrate reservoirs. J Nat Gas Sci Eng 10:1–7. https://doi.org/10.1016/j.jngse.2012.10.001

Guo J, Xie R (2017) Numerical simulation and parameter analysis of NMR T2–D distributions of tight sandstone saturated with a gas–water two-phase fluid. J Nat Gas Sci Eng 37:502–511. https://doi.org/10.1016/j.jngse.2016.12.005

Haroun MR, Chilingar GV, Pamukcu S, Wittle J, Belhaj H, Al Bloushi MN (2009) Optimizing electroosmotic flow potential for electrically enhanced oil recovery (EEORTM) in carbonate rock formations of Abu Dhabi based on rock properties and composition. Int Petrol Technol Conf. https://doi.org/10.2523/IPTC-13812-MS

Huang BG (2004) Reservoir Engineering and Dynamic Analysis Methods [In Chinese]. Petroleum Industry Press, Bei Jing, pp 25–30

Huang X, Guo X, Zhou X, Lu X, Shen C, Qi Z, Li J (2019) Productivity model for water-producing gas well in a dipping gas reservoir with an aquifer considering stress-sensitive effect. J Energy Res Technol. Doi 10(1115/1):4041741

Huang X, Qi Z, Zhang H, Yan W, Yan C, Li S, Li J (2021) Effect of stress-sensitive permeability and porosity on production performance in water-soluble gas reservoirs. J Energy Res Technol doi 10(1115/1):4049586

Islam MR (2014) Unconventional gas reservoirs: evaluation, appraisal, and development. Elsevier

Jianlong F, Ping G, Xiangjiao X, Jianfen D, Chao D, Xiong Y, Fang L (2015) Gas-water relative permeability measurement of high temperature and high pressure tight gas reservoirs. Pet Explor Dev 42(1):92–96. https://doi.org/10.1016/S1876-3804(15)60010-6

Jiao F (2019) Re-recognition of “unconventional” in unconventional oil and gas. Pet Explor Dev 46(5):847–855. https://doi.org/10.1016/S1876-3804(19)60244-2

Jokhio SA, Tiab D (2002) Establishing Inflow performance relationship (ipr) for gas condensate wells. SPE Gas Technology Symposium. https://doi.org/10.2118/75503-MS

Joshi SD (1988) Augmentation of well productivity with slant and horizontal wells (includes associated papers 24547 and 25308). J Petrol Technol 40(06):729–739. https://doi.org/10.2118/15375-PA

Kidnay AJ, Parrish WR, McCartney DG (2019) Fundamentals of natural gas processing. CRC Press

Luo H, Li H, Zhou X, Li Y, Li Y, Zhu X (2019) Modeling temperature behavior of multistage fractured horizontal well with two-phase flow in low-permeability gas reservoirs. J Petrol Sci Eng 173:1187–1209. https://doi.org/10.1016/j.petrol.2018.10.015

Luo X, Wang X, Wu Z, He T, Qiu X, Yuan F, Tan C (2022) Study on stress sensitivity of ultra-low permeability sandstone reservoir considering starting pressure gradient. Front Earth Sci. https://doi.org/10.3389/feart.2022.890084

Mo C, Zhang G, Zhang Z, Yuan Y, Yang S (2022) Productivity calculation model for fractured horizontal wells considering phase variation. J Petrol Sci Eng 209:109811. https://doi.org/10.1016/j.petrol.2021.109811

Mutailipu M, Liu Y, Wu B, Song Y, Wang D, Ai L (2017) Gas-water two phase flow simulation based on pore network model for reservoir rocks. Energy Procedia 142:3214–3219. https://doi.org/10.1016/j.egypro.2017.12.493

Mutailipu M, Liu Y, Wu B, Song Y, Wang D (2018) Simulation of wettability effects on gas-water flow in porous media. Int Heat Trans Conf Digit Libr. https://doi.org/10.1615/IHTC16.cat.023191

Nouri A, Vaziri H, Belhaj H, Islam R (2003) Effect of volumetric failure on sand production in Oil-wellbores. SPE Asia Pacific Oil Gas Conf Exhib. https://doi.org/10.2118/80448-MS

Peng DY, Robinson DB (1976) A new two-constant equation of state. Ind Eng Chem Fundam 15(1):59–64. https://doi.org/10.1021/i160057a011

Prempeh KOK, Parker-Lamptey G, Martin H, Amoako-Yirenkyi P (2022) Boltzmann transformation of radial two-phase black oil model for tight oil reservoirs. J Pet Explor Prod Technol 12(12):3409–3424. https://doi.org/10.1007/s13202-022-01528-8

Shi S, Belhaj H, Bera A (2018) Capillary pressure and relative permeability correlations for transition zones of carbonate reservoirs. J Pet Explor Prod Technol 8:767–784. https://doi.org/10.1007/s13202-017-0384-5

Shi H, Lai F, Shi G, Liang Y, Dai Y (2021) Dynamic prediction and influencing factors analysis of gas and water co-production stage in tight sandstone reservoir. J Nat Gas Sci Eng 96:104327. https://doi.org/10.1016/j.jngse.2021.104327

Song W, Yao J, Ma J, Couples G, Li Y (2017) Assessing relative contributions of transport mechanisms and real gas properties to gas flow in nanoscale organic pores in shales by pore network modelling. Int J Heat Mass Transfer 113:524–537. https://doi.org/10.1016/j.ijheatmasstransfer.2017.05.109

Sun Z, Shi J, Wu K, Miao Y, Zhang T, Feng D, Xiao Z, Wu N, Lin W, Li X (2018a) A fully-coupled gas-water two phase productivity equations for low-permeability CBM wells. J Petrol Sci Eng 166:611–620. https://doi.org/10.1016/j.petrol.2018.03.084

Sun Z, Shi J, Wang K, Miao Y, Zhang T, Feng D, Sun F, Wang S, Han S, Li X (2018b) The gas-water two phase flow behavior in low-permeability CBM reservoirs with multiple mechanisms coupling. J Nat Gas Sci Eng 52:82–93. https://doi.org/10.1016/j.jngse.2018.01.027

Wang W, Fan D, Sheng G, Chen Z, Su Y (2019) A review of analytical and semi-analytical fluid flow models for ultra-tight hydrocarbon reservoirs. Fuel 256:115737. https://doi.org/10.1016/j.fuel.2019.115737

Wang Q, Wan J, Mu L, Shen R, Jurado MJ, Ye Y (2020) An analytical solution for transient productivity prediction of multi-fractured horizontal wells in tight gas reservoirs considering nonlinear porous flow mechanisms. Energies 13(5):1066. https://doi.org/10.3390/en13051066

Xiaoping L, Birong Z (1999) A new IPR curve of gas-water well in gas reservoirs undergoing simultaneous water production. Techn Meet petrol Conf South Saskatchewan Section. https://doi.org/10.2118/99-120

Xu C, Lin C, Kang Y, You L (2018) An experimental study on porosity and permeability stress-sensitive behavior of sandstone under hydrostatic compression: characteristics, mechanisms and controlling factors. Rock Mech Rock Eng 51(8):2321–2338. https://doi.org/10.1007/s00603-018-1481-6

Yong H, Jianjun W, Xiaoqing H, Yue D, Xiang L, Wenshu Z, Daolun L (2022) Investigation of low water recovery based on gas-water two-phase low-velocity Non-Darcy flow model for hydraulically fractured horizontal wells in shale. Petroleum. https://doi.org/10.1016/j.petlm.2022.03.005

Zhang XM, Tong DK, Xue LL (2009) Numerical simulation of gas-water leakage flow in a two layered coalbed system. J Hydrodyn 21(5):692–698. https://doi.org/10.1016/S1001-6058(08)60201-2

Zhang H, Lei W, Xinguang W, Wei Z, Xiaoming Z, Changwei L, Nan Z, Laichao W, Xinbin W, Wentao W (2017) Productivity analysis method for gas-water wells in abnormal overpressure gas reservoirs. Pet Explor Dev 44(2):280–285. https://doi.org/10.1016/S1876-3804(17)30031-9

Funding

The study was supported by the National Natural Science Foundation of China (51504202).

Author information

Authors and Affiliations

Contributions

The manuscript was written through contributions of all authors. All authors have given approval to the final version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mo, C., Zhang, G., Tang, Y. et al. Multi-parameter modeling for prediction of gas–water production in tight sandstone reservoirs. J Petrol Explor Prod Technol (2024). https://doi.org/10.1007/s13202-024-01822-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13202-024-01822-7