Abstract

Temporary plugging diversion fracturing in multistage horizontal well is normally used to improve stimulation efficiency and increase production in unconventional reservoirs. Temporary plugging agent plays an important role in diversion fracturing. A strongly resilient temporary plugging diversion agent can improve the effectiveness of fracturing diversion. Therefore, a novel organosilicon temporary plugging diversion agent (QBZU) was developed through micellar copolymerization method. Self-synthesized strongly resilient temporary plugging diversion agent (QBZU gel) was prepared by using acrylamide, N, N′-methylene bisacrylamide, surfactants, organosilicon, ammonium persulfate and sodium bisulfite as chemical raw materials. The micellar copolymerization is investigated to overcome the incompatibility of hydrophobic organosilicon and water-soluble monomer by adding some appropriate surfactants. The experimental results indicated that the combination of sodium dodecyl sulphonate and Tween 80 provided excellent copolymerization results. The characteristics of compressive resistance, salt resistance, shearing resistance, resilience and degradation are superior compared with traditional rigid granular temporary plugging agent widely used in oilfields (QG hydrogel). According to the experimental evaluation results of QBZU, its pressure-bearing capacity can reach 56.3MPa, shearing strength can reach 410N, elastic modulus can reach 80MPa, and Poisson ratio can reach 0.48. Meanwhile, the main synthetic factors affecting the resilient performance of QBZU were investigated, including polymer concentration, organosilicon concentration and the types of surfactant. Based on the fracturing pressure curve and microseismic monitoring results, the plugging and fracture diversion effectiveness was further confirmed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

At present, the direction of global petroleum exploration and development has been shifted from conventional reservoirs to low permeability and unconventional reservoirs, and from shallow reservoirs to deep and ultra-deep reservoirs. In recent years, unconventional oil and gas resources have gradually become a major component of our reserve growth. Up to 2019, the production of tight oil and shale oil in China has reached 1413 × 104 t, which is accounting for 7.4% of total crude oil production. In addition, the production of tight gas and shale gas has reached 635 × 108 m3, accounting for 36.5% of the total natural gas production. As a result, China has fully entered the era of unconventional oil and gas (Li et al. 2022a; Zhou et al. 2015).

Fracturing was an essential technique for the economic exploitation of unconventional reservoirs characterized by microscopic and nanoscale Darcy-scale permeability. A series of horizontal well volumetric fracturing techniques, such as long-horizontal completion, multi-cluster perforation, and multi-cluster temporary plugging fracturing, have become the major force in the exploration of unconventional oil and gas in China (Bin et al. 2021; Zheng et al. 2022). As the targets and conditions of exploration and development became more complex, the industry’s demand for re-fracturing and increasing the volume was increasingly enhanced. Based on theoretical analyses and experiments, the applications of chemical plugging fracturing and reproduction have demonstrated the feasibility of reconstructing new fractures. It involved in vertical wells with different orientations in a single layer, in different layers, and in different perforation clusters (Muther et al. 2021; Zhang et al. 2020b). At the same time, field applications demonstrated the fact that it was able to enhance oil recovery (EOR) (Weng et al. 2013). Moreover, multiple clusters (5–12 clusters) are perforated in a single horizontal section under the condition of shortening the perforating cluster interspacing, which was beneficial for increasing the number of artificial fractures (Talgat et al. 2023). Significantly, the homogeneous initiation of perforated clusters was a critical factor to ensure the effectiveness of multiple fracturing clusters in a single horizontal section. If the perforated clusters are not completely initiated and propagated, stimulation will be greatly influenced. Therefore, in order to improve the efficiency of artificial fracture initiation and propagation, high-strength water-soluble temporary plugging agents were pumped into the intended layer several times. Since the fluid always flows in the direction of minimum resistance, the temporary plugging diversion particles preferentially entered into the pre-existing initiated fractures or high permeability layers (Jianye et al. 2018). When the bridge plugging phenomenon appeared in the initiated fractures or high permeability layers, the subsequent fracturing fluid cannot flow into initiated fracture or high permeability layers. As a result, the fracturing fluid was forced to flow into layers with higher stress or lower permeability. Therefore, a sharp rise in wellbore pressure or net pressure within the fracture resulted in the fact that subsequent pumping pressure was transferred to an unexpected location rather than the initial orientations of the fractures. Meaningfully, new fractures or activate natural fractures will be generated, greatly improving fracture-controlled reserves and oil and gas fluidity. After achieving the above objectives, the temporary plugging agent will flow back efficiently. This process was repeated several times, and eventually a complex fracture network was obtained in a single horizontal section. This stimulation method was known as temporary plugging fracturing (Wang et al. 2021a; Zhang et al. 2020b; Li et al. 2022b). In addition, horizontal wells were always segmented and fractured using bridge plugs. However, approximately 30% of horizontal well casings were damaged during the fracturing processes of shale gas or other unconventional reservoir. Consequently, the combination operation of bridge plug pumping and perforating cannot be performed safely and effectively. In this case, temporary plugging and diversion technology can be used to achieve successful fracturing in such complex wells and improve the production rate of high-quality reservoir (Wang et al. 2021b; Lishan et al. 2022).

Temporary plugging fracturing was an effective technique to enhance the fracture complexities and increase the stimulated reservoir volume (SRV) of unconventional reservoirs (Vanessa et al. 2016). Importantly, the performance of temporary plugging agent was the key point to determine the success rate of temporary plugging (Shun et al. 2020; Ali and Daneshy 2019). Currently, the dominating temporary plugging diversion agents were used for fracturing, including temporary plugging ball, oil-soluble resin, fiber, water-soluble granules, and other novel temporary plugging agents (Wang et al. 2021b; Lu 2020; Yang et al. 2019; Xia 2019; Zhang et al. 2020a; Shi et al. 2015; Suleimenova et al. 2016). The temporary plugging balls were easily soluble in formation-water and fracturing fluid with low formation-damage, strong pressure-resistance, easy on-site construction, and low cost. Generally, due to the higher density of the temporary plugging balls, some of the balls would be fallen off to cause a failure after the fracturing truck pumped off (Wang et al. 2021b). Oil-soluble resin was suitable for low water-cut-oil wells because of its special solubility requirements (Xia 2019). As the formation temperature increasing, the fibers gradually degraded and flew back. However, the fibrous temporary blocking agent cannot function effectively as a single agent, and its mechanical and plugging performance were also limited (Chen et al. 2019; Yang et al. 2019; Zhang et al.2019; Zhao et al. 2019; Talgat et al. 2023; Zhang et al. 2020c). Therefore, it was not suitable for plugging wide fractures. Granular cross-linked temporary plugging agent was the most widely used for plugging perforations or initial fracture in fracturing treatment. It is prepared by cross-linked gel, which involves several processes, including cutting, granulation and drying.

In recent years, to increase the degradation ability, decrease reservoir damage, and enhance oil and gas recovery, several novel temporary plugging agents have been developed, such as polyanhydrides, aliphatic polyesters, polyamides, modified starches, resin nanoparticles, and microorganisms (Oladoyin et al. 2021; Zhang et al. 2020a).

A self-degrading hydrogel (TDJ) was developed using ethoxylated trimethylolpropane triacrylate (ETPTA) as a cross-linking agent. TDJ mainly was used in acid-fracturing operations. Due to the loss of cross-linking, TDJ will be transformed into a low molecular weight polymer solution resulting in self-degradation (Zhao et al. 2022).

What is the process of microbial temporary plugging? That is, bacteria are initially pumped to propagate and grow in the reservoir before temporary plugging fracturing operation. Then, a large number of microorganisms were used to temporarily plug the reservoir with the high-permeability or the pre-existent fractures for achieving uniform propagation of the fracture (Ana et al. 2018). The microbial temporary plugging agents mainly included glucose-13 coccus and sulfate-reducing bacteria (Xue et al. 2018; Wang et al. 2021b; Zhao et al. 2022; Gao 2016; Oladoyin et al. 2021; Ana et al. 2018). Firstly, a researcher named Xue Yafei has applied the velvet pouches as a temporary plugging agent in tight reservoirs fracturing (Xue et al. 2018). The pressure resistance of the velvet pouches was about 25 MPa, causing very low reservoir damage. The permeability of the reservoir can recover to above 85% after temporary plugging fracturing by the velvet pouches. However, the temporary plugging mechanism of velvet pouches was generally not properly defined, and the fracture propagation was also difficult to predict (Xue et al. 2018; Ruxin et al. 2020). Furthermore, it is verified that the schizophyllan can maintain an excellent viscosity at high salinity and high temperature (Gao 2016). Additionally, the biogeomechanical can alter near-wellbore properties of shale gas reservoirs on hydrocarbon recovery from shale gas reservoirs, such as weakening the mechanical integrity, altering the mineralogical and microstructural properties, reducing the mechanical cohesion, increasing the porosity and permeability (Oladoyin et al. 2021).

Of course, it is well known that the most widely used plugging agents were still granular polymer. Most of rigid granular temporary plugging agents exihibited high viscosity, strong pressure-bearing capacity (compressive resistance of above 40 MPa), no deformation, no resilience, and no adhesion (Zhao et al. 2018; Zhao et al. 2022; Yang et al. 2019; Lu 2020; Xia 2019). The poor elasticity lead to the fact that the stress cannot be forced to transfer to the desired positions, rather than automatically transferring in the direction of the initial fracturing orientation to open new fractures. Thus, this is undoubtedly one of the key points to the current ineffectiveness of fracture diversion for granular temporary plugging agents (Shun et al. 2020).

Furthermore, the shearing and salt resistance performances of traditional rigid granular temporary plugging agents were also poor (Gao 2013). During the process of fracturing operation, the bottom-hole pressure can reach as high as 60 MPa or above (calculated by the fractured extension pressure gradient of 0.02 MPa/m and the vertical burial depth of 3500 m). Some rigid particles will inevitably be crushed at such high closure-stress. Then, as the perforated tunnels cannot be perfectly filled with those rigid particles, therefore, some water-expandable particles, fibers, and other materials were used to match the different sizes and shapes of perforated tunnel. However, the traditional water-expandable materials can maintain mechanical stability only at the low water content, and the mechanical strength decreased sharply once water content exceeded 40%. Sequentially, as the structure of the material was damaged, the plugging effectiveness will be significantly decreased.

In this study, in order to improve the poor resiliency of current granular temporary plugging agent, a strongly resilient hydrogel was synthesized by introducing organosilicon monomers with micellar polymerization. By adding an appropriate concentration of surfactant, the organosilicon hydrophobic monomer is easily dispersed into the water solution. Therefore, the copolymerization of acrylamide and organosilicon with micellar copolymerization method was successfully completed.

After the gels were cut, granulated and dried, the strongly resilient water-expandable temporary plugging particles and powders with different sizes and shapes were obtained. The organosilicon monomers self-polymerized into nanoscale particles, which then dispersed into the organic polymer hydrogel. The organosilicon monomer combined the rigidity and dimensional stability of nanomaterials with the moisturizing performance of hydrogels, resulting in particularly excellent properties of resilient and deformation recovery. It’s worth noting that it can avoid the disadvantage of dehydration and do not suffer structural damage even under high pressure.

This paper focuses on investigating a strongly resilient water-expandable temporary plugging diversion agent. This new product is called QBZU in this paper. As shown in Fig. 1, the experimental flow chart was included the following steps: Materials, Preparation, Characterization, Performance evaluation, and Application.

Experimental materials and methods

Materials

Acrylamide [CH2 = CHCONH2], Ammonium persulfate [(NH4)2S2O8], Sodium bisulfite [NaHSO3], N,N′- methylenebisacrylamide [(CH2 = CHCONH)2CH2], Anionic surfactants, Nonionic surfactants and Organosilicon were all provided by Sichuan Kelong Chemical Reagent Factory. All reagents were analytical grade without further purification before use. QBZU was self-synthesized in the laboratory. QG was provided by the oil field site.

Instruments

A multi-functional chemical flooding physical simulation system was used to test plugging performance. The mechanical uniaxial stress testing system was used to test mechanical parameter. The self-machined visual aging tanks were used to test the high temperature degradation performance at 200 ℃. Fourier Transform Infrared Spectrometer (FTIR) (Nicolet 6700) was used to analyze the functional groups of the sample. EDAX GENSIS (EDS) was used to analyze the elements of the sample and the mass fraction of each element.

Methods and principles

Preparation of QBZU hydrogel

The solution was prepared by dissolving 8–10 g acrylamide into 89 g distilled water under continuous magnetic stirring. Then, the 0.2 mL of N, N-methylene bisacrylamide solution (1%wt) was slowly dripped into the solution. Surfactants and other additives were slowly added into the above solution under continuous stirring. After that, the 2 g of organic silicon was also added into the solution under stirring and properly mixed. Finally, 0.02 g of ammonium persulfate and 0.02 g of sodium bisulfite were added evenly into the mixed solution under stirring. After the above mixed gel solution was placed in an oven at 60–70 ℃ for 10–12 h, the QBZU hydrogel with high elasticity and strong deformation was finally obtained.

Granulation and drying of QBZU

The QBZU hydrogel was granulated into different sizes as shown in Fig. 2a. The QBZU particles (3–10 mm) were obtained after drying as shown in Fig. 2b. Then, the QBZU particles were crushed into powders (100–200 meshes), as shown in Fig. 2c.

Characterization of QBZU

The dried QBZU particles (1–2 mg) were grinded into powders in an agate mortar, and then mixed evenly with 100 mg dried potassium bromide (KBr, AR grade) powders. FTIR absorption spectra of QBZU was recorded by FTIR (Nicolet 6700), which is provided by Thermo Fisher Scientific Corporation (USA). Elementary analysis of QBZU was investigated by EDS, which was provided by EDAX (USA).

Compressive strength evaluation of QBZU

The pressure-bearing capacity was evaluated by multi-functional chemical flooding physical simulation system at 90 ℃. The sand-packed tube with a diameter of 25 mm and a height of 35 mm was used as the experimental model. First of all, 20 g of quartz sands (70–140 meshes) and 2–3 drops of water were filled into the sand-packed tube every time, and a lifting jack was used for compaction. A compaction pressure of 25 MPa was maintained for about 20 min, and the sand packed height was 5 cm. The QBZU particles, powders and fibers were fully mixed and filled into the sand-packed tube until it was completely filled. Then, the sand- packed tube was placed into the core holder. The filling materials were displaced with clean water at a flow rate of 0.2–0.5 mL/min. With the continuous injection of clean water, the QBZU particles and powders absorbed water and expanded continually until they filled the whole tube. Meanwhile, the discharged fluid was collected and weighted with a balance, and the data of displacement pressure and permeability were real-time recorded.

Deformability evaluation of QBZU

The QBZU gel was synthesized in a cylindrical container with a diameter of 25 mm and a height of 35 mm. The bottom and top of gel were leveled and polished so that the base surface deviation was less than 2.5% and the ratio of length to diameter was greater than 1.5. After that, uniaxial compression experiments were carried out and stress–strain curves of QBZU gel were recorded. Based on the stress–strain curves in the elastic deformation stage, the main mechanical parameters were characterized, including Young's modulus, Poisson ratio, tensile strength and recovery rate.

Shearing, salt, and high-temperature-resistance evaluation of QBZU

The samples were immersed into an aqueous solution at the desired temperature and salinity. The samples were then taken out for further use. A required quantity of hydrogels was placed into the water-expandable shearing strength instrument. Next, the tensile strength and shearing resistance of the hydrogel were measured and analyzed.

Water-expansion evaluation of QBZU

A few QBZU particles were immersed into clean water at a required temperature, and the volume of QBZU particles was periodically measured at given regular intervals.

High temperature degradation evaluation of QBZU

QBZU particles (m1) were weighed and placed into an aging tank at high temperature and high pressure. Then, the broken fracturing fluid was added to the aging tank. After being respectively heated for different times at 90 ℃ and 120 ℃, QBZU particles were taken out from the aging tank and dried in a high-temperature oven at 95 ℃ until the weight of m2 remained constant. Finally, the degradation rate η was calculated based on the following Eq. (1).

Results and discussion

This section provides and analyzes the results obtained from the following experiments.

Synthesis and characterization of QBZU

Polymer, organosilicon, crosslinking agent, initiator and polymerization condition can greatly influence the success or failure in the polymerization and the performance of QBZU. The most important polymerization factors, such as polymer concentration, polymerization method and organosilicon optimization, will significantly influence the performance of QBZU. Therefore, it is necessary to optimize the synthesis conditions to optimize the engineering performance of QBZU. In the following paper, we will analyze the synthesis factors which influence the polymerization and the performances of QBZU in detail, including polymer concentration, surfactant, organosilicon concentration, deformation resistance, compressive strength, water-expandable rate, salt resistance and heat-degradation, etc.

Optimization of acrylamide concentration

Not only is good plugging resistance required, but rapid degradation after fracturing is also critical for temporary plugging diversion agents used in fracturing (Ahmed et al. 2016; Mohammed and Fragachan 2023). The concentration of acrylamide will directly influence the heat-degradation and water-expandable rate.

Fracturing field experience demonstrates that QBZU particles are required to expand rapidly as they are pumped into the wellbore. And at the same time, QBZU particles are required to degrade rapidly as soon as possible after the completion of fracturing. In addition, field experience also suggests that the degradation is more important than water expansion rate between these two contradictory factors, due to the safety of fracturing tools and formation damage, as detailed later.

The increase of acrylamide concentration would significantly improve the rigidity and compressive resistance. On the contrary, it will also greatly increase the difficulty of heat-degradation at the same temperature. Therefore, it is extremely necessary to decrease acrylamide concentration as much as possible to avoid formation-damage. Of course, in order to further improve the resilient performance, it is required to introduce appropriate functional monomers to compensate for the loss of rigidity, resulted from the decrease of acrylamide concentration. Therefore, organosilicon monomer was determined to add to the polymer.

The water-absorbed expansion rate was plotted against the variation of acrylamide concentration in Fig. 3. Obviously, the expansion rate of water absorption increased with the enhancement of acrylamide concentration. However, when the concentration of acrylamide was higher than 10%, the increase in expansion rate of water absorption gradually slowed down.

Meanwhile, as shown in Fig. 4, the required degradation time increased continually with the acrylamide concentration increases. The slope of the degradation time increased significantly with the concentration above 8–10%. Based on these two contradictory influencing factors and a greater focus on the degradation time, the optimal concentration of acrylamide was determined to be 8–10%.

Optimization of organosilicon concentration

Organosilicon compounds were semi-inorganic and semi-organic macromolecular compounds, with many excellent physical and chemical properties, such as elasticity, low surface energy, high temperature resistance, and strong hydrophobicity, etc.

Organosilicon can effectively improve the compressive strength and mechanical properties of hydrogel.

As shown in Fig. 5, the water absorption expansion rate decreased with the increase of organosilicon concentration, while the mechanical strength increased significantly. As the soaking time in clean water increased, the expansion multiple of QBZU hydrogel also gradually increased. When the soaking time was above 20 min, the increase in expansion multiple of QBZU hydrogel tended to be slow. The mechanical strength was generally characterized by the shearing resistance.

Figure 6 shows the shearing strength of QBZU hydrogel with different organosilicon concentrations after being soaked in clean water for 20 min. Also, it is shown that the shearing strength increased with the increase of organosilicon concentration. The increase of organosilicon concentration was able to reduce the water-absorbed expansion rate and strengthen hydrophobicity. Thus, the shearing strength was improved. Clearly, when the organosilicon concentration was more than 2%, the increasing trend of shearing strength gradually slowed down. Due to the high price of organosilicon, it is inevitable to solve the contradiction between low cost and great compressive resistance. As a result, 2% of organosilicon concentration was used for synthesizing QBZU hydrogel.

Optimization of surfactant

As a kind of new material, organosilicon has been widely used in many industrial fields due to its unique physical and chemical properties. The chemical modification of polyacrylamide copolymer with hydrophobic organosilicon monomer can overcome the current poor elasticity and poor shearing stability problems of rigid temporary plugging diversion agent. Although hydrophobic associating polymer has many excellent properties, it was difficult to synthesize it due to the difficulty to fully mix oil-soluble monomer with water-soluble monomer. However, there were three copolymerization methods involving in inhomogeneous copolymerization, homogeneous copolymerization, and micellar copolymerization to solve the difficulty. In the copolymerization reaction with very low hydrophobic monomer concentration, the inhomogeneous copolymerization reaction may eventually become homogeneous. However, when the concentration of hydrophobic monomer was high, the conversion rate of hydrophobic monomer was very low. Replacing water with a single solvent or mixed solvent (such as alcohols, ethers and ketones) was the simplest method to overcome the incompatibilities of hydrophobic monomers and water-soluble monomers. This method can also solve the incompatibility of hydrophobic monomer and water-soluble monomer. However, the problem of insoluble copolymers in solvent often occurred. The random copolymer was obtained by homogeneous copolymerization method, generally resulting in no obvious hydrophobic association effect in aqueous solution. Micellar copolymerization was an important method to prepare hydrophobic associating water-soluble polymers. The hydrophobic monomers was dissolved in water solution by adding appropriate surfactants and then copolymerized with water-soluble monomers. Micellar copolymerization was essentially a microscopic inhomogeneous process. Table 1 analyzed the influence of different surfactants on the micellar copolymerization reaction.

As shown in Table 1, the experimental results indicated that the combination of sodium dodecyl sulphonate and Tween 80 provided better copolymerization results than that of single Tween 80 alone. This phenomenon can be explained as follows: Firstly, non-ionic surfactants were aggregated to form adsorption layer on the surface of polymer, preventing polymer molecules from colliding with each other. Thus, the dispersion stability and chemical stability of the polymer were improved. Non-ionic surfactant was also insensitive to pH value, electrolyte and other chemical influencing factors, so the polymerization reaction rate was difficult to control. It would result in precipitation and coagulation in the polymer gel. On the other hand, anionic surfactants can change the surface of the polymer particles with negative charges, so that the polymer particles repelled with each other. It would reduce particle size and improve the dispersion-stability. However, anionic surfactants have poor chemical stability and are easily influenced by pH value, metal ions, and salinity, which could lead to a failure of polymerization reaction. As shown in Fig. 7, it was demonstrated the QBZU hydrogel in the initial state and different stretched states, firmly indicating the excellent resilience and deformation of QBZU hydrogel. Therefore, the successful introduction of organosilicon can significantly increase the success-rate of temporary plugging diversion fracturing due to the improvement of the poor resilience and deformation, which is a critical factor for the success of fracturing diversion.

Structural characterization of QBZU

Infrared spectral structural characterization

The structure of QBZU was confirmed by FTIR as illustrated in Fig. 8. The strong absorption peak at 3426.3 cm−1 was attributed to the –NH2 bond in the amide group (–CONH2). The absorption peak at 1651.8 cm−1 caused by amide I band and II band. The absorption peaks at 1046.6 cm−1 and 1116.2 cm−1 are stretching vibration peaks of Si–O–Si or Si-OR. The absorption peak at 3207.5 cm−1 indicated the stretching vibration of the Si–OH band. As expected, the FTIR spectrum confirmed the presence of organosilicon in QBZU.

Chemical element analysis

The chemical element distribution of QBZU was further investigated by EDS, as shown in Table 2. In the 400 × magnification microscopic view, it showed that the mass fraction of silicon (Si), carbon (C), nitrogen (N) and oxygen (O) were 2.1%, 51.13%, 18.92%, and 27.84% respectively, indicating the presence of organosilicon in QBZU. In addition, the distribution of elements in QBZU has slightly difference from that of the desired one.

Engineering performance evaluation of QBZU

Compressive performance

Interlayer (cluster) temporary plugging diversion fracturing was widely used to plug the perforation tunnels. The composite temporary plugging diversion agents which mixed in the linear gel were pumped into the desired zone, temporarily plugging the perforations tunnels and forcing new artificial fractures to initiate and propagate. In general, the average perforation tunnel diameter was 7–12mm and the perforation density was 16 holes per meter. Therefore, the compressive capability was a key parameter to evaluate the temporary plugging and diverting performance.

The breakthrough pressure was given in Table 3 under different proportions of temporary plugging agent and different sand packed thickness. There was no pressure rise when only rigid particle was used. After the addition of some fibers, the rigid particles were entangled and stacked together by the soft and easily curled polymer fibers, resulting in a pressure rise.

When the ratio of rigid particles to fibers was 3:1, the plugging effect was improved. The displacement pressure increased with the increase of sand packed thickness.

The displacement pressure can increase to 20.3 MPa when the ratio of rigid particles to fibers was 3:1 and the sand packed thickness was 5 cm. Fortunately, QBZU particles still had excellent pressure-bearing capacity (35.6 MPa), which was derived from the good elasticity, water absorption expansion, and adhesion of QBZU particles.

Figure 9 demonstrated that the maximum pressure-bearing capacity was up to 56.3 MPa, when the ratio of QBZU particles/fibers/QBZU powders was 5:1:1. Therefore, the ratio of QBZU particles /fibers/QBZU powders (5:1:1) was recommended as the optimal compound temporary plugging diversion agent.

This experimental phenomenon can be explained as follows. (1) There are many gaps among rigid particles when they were stacked together, because they did not have water absorption and expansion ability. Although the fibers can be wrapped around each other to fill part of the gap, they can never fill the whole space. Since there were so many gaps, the stress will be transmitted through them, resulting in a decline in the displacement pressure. (2) Although rigid particles have the advantage of strong rigidity, they were inelastic and were not able to generate a reactive force. (3) QBZU can fully fill a limited space until there was no gap, due to its excellent water absorption and expansion performance. (4) When the stress acts on QBZU, a reaction force will be generated immediately to withstand the mechanical stress because of its strong deformability resistance and elasticity.

It is worth mentioning that no matter from the aspects of lithology, permeability, formation heterogeneity or temporary plugging agent structure, the core experimental method and numerical analysis have high requirements for the natural core and the accuracy of model (Hongtao et al. 2022; Jesus et al. 2017; Youwei et al. 2020; Zhang et al. 2020a).

The influencing factors of permeability, lithology, and natural fractures frequency on the performance of QBZU were briefly investigated. The reservoir was quite tight, with a lower permeability, a higher closure stress, requiring a higher compressive resistance and proportion of QBZU particles and the organsilicon concentration. Therefore, due to the different reservoirs, further optimization of QBZU synthesis formula and particles proportion should be required.

Most of reservoirs were geologically complex and heterogeneous due to various distributions of porosity and permeability, deposition, and natural fractures. Because of the strong heterogeneity, some reservoirs have many natural fractures. Based on the width and angle of natural fractures, it is necessary to optimize the size, shapes, and concentration of QBZU particles in order to perfectly match various natural fractures. Furthermore, increasing the proportion of fibers can improve the bridging effect and thus increase the plugging efficiency (Lufeng et al. 2019; Meng et al. 2021; Li et al. 2019; Shi et al. 2022).

Based on the above analysis, it was very essential that the shape of QBZU can be further processed, depending on the reservoir properties and the requirements of the nature fracture shape. Moreover, the QBZU gel has excellent resilient ability and compressive resistance. Because of those, the QBZU gel can be combined with proppant to plug the initial fractures in the heterogeneous reservoir, which will substantially increase pressure. However, the presence of natural fractures or pre-existing fractures seriously affected the formation of the plugging structure. Hence, the direction of the fracture diversion and the amount of temporary plugging agent need to be further discussed.

Salt resistance

QBZU and QG were both immersed into sodium chloride solutions with different salinity. After the water absorption and expansion of QBZU and QG particles, the shearing resistance was measured in Fig. 10.

Figure 10 demonstrated that the shearing resistance of hydrogel decreased with the increase of sodium chloride concentration. When the salinity is less than 35,000 mg/L, the shear resistance rate of QBZU is more than 80%, while the shear resistance rate of QG is only about 50%. The main chain of QG was only acrylamide, resulting in its relatively simple molecular structure of QG. In general, the molecular structure of QG was primarily based on a long linear main chain, and its branched chains were very few, resulting in poor salt resistance of QG. Additionally, due to the hydrophobic association of organosilicon group, the salt resistance of QBZU hydrogel improved.

High-temperature and shearing resistance

A desired quantity of QBZU hydrogels and QG hydrogels were gradually placed in the container of the water-expandable shearing instrument at different temperatures, and the experimental data were recorded when the tension was steady, as shown in Fig. 11.

As shown in Fig. 11, the shearing strength of QBZU hydrogel was 410 N at 25℃, while the shearing strength of QG hydrogel was only 154 N, indicating that QBZU hydrogel has better-shearing resistance. The presence of organosilicon within the acrylamide main chain may explain the excellent shearing resistance of QBZU hydrogel. The presence of organosilicon not only can greatly improve the resilience and deformation, but also keep the rigidity of the original polymeric main chain. Therefore, the effective enhancement of the shearing resistance was successful.

Deformation performance

Based on the stress–strain curve, the Elastic modulus and Poisson's ratio of QBZU gel were calculated by simultaneous Eqs. (2) and (3).

where Es was the Elastic modulus, MPa; μs was the Poisson’s ratio; Δσ was the axial stress increment, MPa; Δε1 was the axial strain increment; Δε2 was the transverse strain increment.

Table 4 demonstrated the uniaxial mechanical parameters of QBZU hydrogel. Elastic modulus was the ratio of the stress in a body to the equivalent strain, characterizing the difficulty of elastic deformation. The greater the elastic modulus was, the greater the stress required for the desired elastic deformation. In other words, under the same stress, the greater the material rigidity was, the weaker the elastic deformation was. The ratio of transverse strain to axial strain was called Poisson's ratio (μ), also known as the transverse deformation coefficient, which was an elastic constant characterizing the transverse deformation of materials. No material can have a Poisson ratio greater than 0.5, which was the maximum value of the Poisson ratio. Table 4 showed that the Elastic modulus was only 80 MPa and the Poisson's ratio was as high as 0.48, indicating that the compressibility and elasticity of QBZU were very excellent. Once the stress was relieved, QBZU hydrogel can completely recover to its original appearance without any cracks in the gel, even with compression of up to 60%.

Degradation performance

Good plugging and diverting resistance were essential for the temporary plugging diverting agents used in fracturing. The rapid degradation after fracturing was also critical. Since layers (clusters) temporary plugging diversion fracturing was intended to increase longitudinal layers (clusters) fracture production, it usually needed to be used with mechanical packers. During the process of pumping temporary plugging diversion agents to the intended interval, it was inevitable that the temporary plugging diversion agents will get stuck in the packer, hydraulic anchor and other related mechanical tools. As a result, the oil tube could not be successfully pulled out, leading to construction accidents. On the one hand, the easily degradable temporary plugging diversion agent can greatly reduce construction risk and improve field operation possibility. On the other hand, the formation-damage was not generated. Therefore, it was of great significance for the popularization and application in the temporary plugging fracturing.

The degradation rate of QBUZ at different temperatures and different time was in Fig. 12. The longer the degradation time was, the higher the degradation rate was at the same temperature. Moreover, the higher the temperature was, the higher the degradation rate was, and the shorter the degradation time was. The apparent viscosity of degraded QBZU was 1.52 mPa s and pH value was 7–8.

Optimization of on-site pumping process

The QBZU diversion agents have been successfully applied in more than eight wells, including three horizontal wells and eight vertical wells. In the past, when clear water was used to carry QG rigid large particles, the pump efficiency of fracturing truck often reduced. The plunger pump got stuck, and even the fracturing truck could not work normally. Some service providers can essentially solve this problem by refitting the fractured trucks. However, the cost of refitting special fractured trucks and removing equipment to different places was too high, significantly increasing the cost and the difficulty of popularization and application.

Based on the optimization of pumping equipment procedure, a set of on-site pumping process of large particle temporary plugging agents was developed. First, 1.5 m3 of carrying fluid was loaded into the small tank of a separate fracturing blender truck, which was directly connected to a fracturing truck. This fractured truck was then directly connected to the wellhead, which was independent of the high and low pressure manifold. The polyvinyl alcohol fiber (30 kg) was added to the small tank while stirring continuously for about 60 min. After the fibers were completely dispersed and swollen, QBZU powders (30 kg) were also added to the small tank. After that, QBZU particles (150 kg) were added into the tank under stirring for above 10 min. Finally, the whole mixture (1.5 m3) in the tank was totally pumped into the desired layer at a rate of 0.8–1.5 m3/min. Both pumping pressure and displacement were very stable during the pumping process, indicating that the large particles passed through the plunger pump easily without decreasing the pump efficiency or leading to getting stuck, as shown in Fig. 13.

Field application

The field test of the QBZU temporary plugging diversion agent was applied with a 100% success rate in field construction. The average depth of the reservoir was 3500–4000 m, and the reservoir temperature was 130–140℃. In the pumping process of temporary plugging agents, there was no phenomenon of stuck plunger pump or reduced pump efficiency. Specifically, (1) When the proportion of larger QBZU particles was high, the temporary plugging pressure between clusters or layers increased significantly. Therefore, it was especially important to successfully add larger particles. (2) The pressure was higher with a lower pump displacement of the temporary plugging agent, and the optimal pump displacement was about 1–2 m3/min. (3) When the temporary plugging agents were pumped into the intended layer, the pump displacement should be immediately increased to more than 4 m3/ min in order to clean the residual temporary plugging agents as far as possible in the pipeline. It would completely avoid the problem of unstable subsequent fracturing fluid supply. (4) The temporary plugging agent with good heat-degradation and water solubility can significantly reduce the construction risk, especially in the case of multiple packer staged fracturing in oil tube, which can avoid the risk of stuck pipe string. (5) The professional fracturing blender truck needed to be clean after pumping larger particles, especially for sand containers, pipelines, etc.

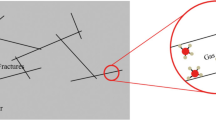

The QBZU temporary plugging diversion agents were used in multi-cluster and multi-stage fracturing for horizontal wells. There were usually 2–3 cluster-perforations in a single fracturing stage. During one stage of fracturing, a temporary plugging diversion fracturing between clusters was implemented. The QBZU temporary plugging agents (225 kg) were pumped into the intended layer with a displacement of 1.8 m3/ min. Figure 14 demonstrated that the pressure immediately increased 14–16 MPa as soon as the temporary plugging diversion agents reached the intended layer. Both the breakdown pressure and the pump-off pressure between the two clusters were very different during the two fracturing curves of XX horizontal well. In terms of breakdown pressure in Fig. 14, the A point was 62.37 MPa, while the B point was 65.88 MPa. Similar to the breakdown pressure, the pump-off pressure was 47.12 MPa and 50.94 MPa for point C point D, respectively. Therefore, it was concluded that the temporary plugging diversion fracturing between clusters was effective, both from the fracturing curve and hydraulic fracture microseismogram. Microseismic monitoring method was an essential technique for monitoring the dynamic changes of hydraulic fracture. As shown in Fig. 15, microseismic monitoring captured signals in real-time during the initiation and propagation of hydraulic fracture. The red marks were the points where the fracture propagation occurred before temporarily plugging diversion fracturing. However, the green marks were the points where fracture propagation occurred after temporarily plugging diversion fracturing. From Fig. 15, it is visualized that the fracture volume after temporary plugging diversion fracturing was much larger than that before fracturing.

The fractured well opened on December 17, 2019. The surface wellhead pressure was 36 MPa and the average daily production was 44 m3 at the stage of initial production. The first oil productive time was 7 days after fracturing. The flow back was only 5.8% at that time. In the initial stage of oil production, the average daily production of oil and gas was 21.1 tons and 1.2*104 m3, respectively. In addition, cumulative oil production was 4100 tons up to now. Therefore, the stimulation result of multi-stage and multi-cluster horizontal well fracturing was better than that of conventional fracturing in the same fault block.

Conclusions

Based on the investigation and analysis of experimental materials, methods, and chemical temporary plugging diverting agent characteristics, a novel strongly resilient organosilicon temporary plugging diversion agent has been developed to improve the current poor resilience, poor deformation recovery, and poor salt resistance. Hence, the effectiveness of fracturing diversion significantly increased. There are some conclusions that can be drawn from this study:

-

Most of current temporary plugging diversion agents are still rigid particles with poor resilience and poor deformation recovery. When the stress acts on the rigid particles, the stress cannot be transferred to anywhere else effectively, resulting in poor effectiveness of fracturing diversion. We successfully developed a novel strongly resilient temporary plugging diversion agent named QBZU gel.

-

Because organosilicon is insoluble in water, water-soluble copolymerization is inappropriate to use. The micellar copolymerization is investigated to overcome the incompatibility of hydrophobic organosilicon and water-soluble monomer by adding proper concentration of sodium dodecyl sulphonate and Tween 80.

-

Experimental results show that the successful introduction of organosilicon can significantly improve the current poor resilience and deformation. Moreover, it plays a critical role in the success of diversion fracturing. Based on the experimental evaluation results, pressure-bearing capacity, shearing strength, elastic modulus, and Poisson ratio of QBZU gel was up to 56.3 MPa, 410 N, 80 MPa, and 0.48.

-

Based on the fracturing pressure curve and microseismic monitoring results, the effectiveness of plugging and fracture diversion was further confirmed.

Data availability

The figures and field data used to support the findings of this study are included within the article. The figures and field data used in this study are available from the corresponding author upon request.

Abbreviations

- EDS:

-

EDAX GENSIS

- ETPTA:

-

Ethoxylated trimethylolpropane triacrylate

- FTIR:

-

Fourier transform infrared spectrometer

- QBZU:

-

Self-synthesized strongly resilient temporary plugging diversion agent in the laboratory

- QG:

-

Traditional rigid granular temporary plugging agent widely used in the oilfield

- E s :

-

Elastic modulus

- μ s :

-

Poisson's ratio

- Δσ :

-

Axial stress increment (MPa)

- Δε 1 :

-

Axial strain increment

- Δε 2 :

-

Transverse strain increment

- η :

-

Degradation rate (%)

References

Ahmed M, Gomaa, Andrea NP, Dorianne C et al (2016) Experimental Investigation of Particulate Diverter Used to Enhance Fracture Complexity.In:SPE International Conference and Exhibition on Formation Damage Control. SPE-178983-MS

Ali D, Daneshy CI (2019) Mechanics & Effectiveness of Different Types of Diversion in Horizontal Well Fracturing. In: SPE Annual Technical Conference and Exhibition. SPE-195926-MS

Ana G, Sebastián MG, Lourdes U et al (2018) Nanocomposites of microbial polyglutamic acid and nanoclays compatibilized by organophosphonium surfactants. Macromol Chem Phys 219:180–183. https://doi.org/10.1002/macp.201800083

Bin C, Beatriz RB, Yanan S et al (2021) A review of hydraulic fracturing simulation. Arch Comput Methods Eng 29:2113–2170. https://doi.org/10.1007/s11831-021-09653-z

Chen Y, Fujian Z, Wei F et al (2019) Plugging mechanism of fibers and particulates in hydraulic fracture. J Pet Sci Eng 176:396–402. https://doi.org/10.1016/j.petrol.2019.01.084

Gao CH (2013) Viscosity of partially hydrolyzed polyacrylamide under shearing and heat. J Pet Explor Prod Technol 3:203–206. https://doi.org/10.1007/s13202-013-0051-4

Gao CH (2016) Application of a novel biopolymer to enhance oil recovery. J Pet Explor Prod Technol 6:749–753. https://doi.org/10.1007/s13202-015-0213-7

Hongtao Z, Xiaotong W, Zongxiao S et al (2022) A review on mechanism and adaptive materials of temporary plugging agent for chemical diverting fracturing. J Petrol Sci Eng 212:1–12. https://doi.org/10.1016/J.PETROL.2022.110256

Jesus B, Christian C, Matthew C. Jones et al (2017) Increased Cluster Efficiency and Fracture Network Complexity Using Degradable Diverter Particulates to Increase Production: Permian Basin Wolfcamp Shale Case Study. In: SPE Annual Technical Conference and Exhibition. SPE-187218-MS

Jianye M, Xuezhi H, Lei W (2018) Experimental Investigation on Tool-Free Multi-Stage Acid Fracturing of Open-Hole Horizontal Wells by Using Diversion Agents. In: SPE International Hydraulic Fracturing Technology Conference and Exhibition. SPE-191415-18IHFT-MS

Li W, Zhao H, Pu H et al (2019) Study on the mechanisms of refracturing technology featuring temporary plug for fracturing fluid diversion in tight sandstone reservoirs. Energy Sci Eng 7:88–97. https://doi.org/10.1002/ese3.259

Li GX, Lei ZD, Dong HW et al (2022a) Progress challenges and key issues of unconventional oil and gas development of CNPC. China Pet Explor 27(1):1–13. https://doi.org/10.3969/j.issn.1672-7703.2022.01.001

Li MH, Zhou FJ, Liu JJ et al (2022b) Quantitative investigation of multi-fracture morphology during TPDF through true tri-axial fracturing experiments and CT scanning. Pet Sci 19:1700–1717. https://doi.org/10.1016/j.petsci.2022.03.017

Lishan Y, Fujian Z, Minghui L et al (2022) Experimental Study on Diverter Transport Through Perforations in Multicluster Fracturing of Horizontal Well. In: SPE International Conference and Exhibition on Formation Damage Control. SPE-208606-PA

Lu Z (2020) Research progress and prospect of temporary plugging agent for diverting fracturing. Sci Technol Eng 20(31):12692–12701

Lufeng Z, Fujian Z, Jianye M et al (2019) Large-scale true tri-axial fracturing experimental investigation on diversion behavior of fiber using 3D printing model of rock formation. J Pet Sci Eng 181:106171. https://doi.org/10.1016/j.petrol.2019.06.035

Meng W, Mingguang C, Guangyao W et al (2021) Optimization Approach for Determination of the Dosage of Diversion Agents in Temporarily Plugging Fracturing of Shale Using 3D Printing Fractures. In: SPE Europec featured at 82nd EAGE Conference and Exhibition. SPE-205135-MS

Mohammed O, Francisco E. Fragachan (2023) Using Advance Modelling Techniques to Design Diversion for Acidizing, Fracturing & Re-Fracturing. In: SPE Argentina Exploration and Production of Unconventional Resources Symposium. SPE-212415-MS

Muther T, Syed FI, Dahaghi AK et al (2021) Socio-inspired multi-cohort intelligence and teaching-learning-based optimization for hydraulic fracturing parameters design in tight formations. J Energy Res Technol 144:073201. https://doi.org/10.1115/1.4052182

Oladoyin K, Ion I, Mallika K, Katelyn H (2021) Biogeomechanical alteration of near-wellbore properties: Implications for hydrocarbon recovery. J Nat Gas Sci Eng 94:1–14. https://doi.org/10.1016/J.JNGSE.2021.104055

Ruxin Z, Bing H, Peng T et al (2020) Hydraulic fracture propagation behavior and diversion characteristic in shale formation by temporary plugging fracturing. J Pet Sci Eng 190:1–5. https://doi.org/10.1016/j.petrol.2020.107063

Shi SZ, Cheng F, Wang MX et al (2022) Hydrofracture plugging mechanisms and evaluation methods during temporary plugging and diverting fracturing. Energy Sci Eng 10:790–799. https://doi.org/10.1002/ese3.1054

Shi Y, Yang X, Zhou F et al (2015) No-damage Stimulation Based on Residual-free Diverting Fluid for Carbonate Reservoir. In: Abu Dhabi International Petroleum Exhibition and Conference. SPE-177495-MS

Shun L, Guo TK, Rui ZH, Li KG (2020) Performance evaluation of degradable temporary plugging agent in laboratory experiment. J Energy Res Technol 142:123002–123012. https://doi.org/10.1115/1.4047311

Suleimenova A, Wang X, Zhu D et al (2016) Comparative Study of Acid Fracturing and Propped Hydraulic Fracturing for a Tight Carbonate Formation. In: SPE Europec featured at 78th EAGE Conference and Exhibition. SPE-180114-MS

Talgat S, John O, David P et al (2023) Integration of Fracturing Pressure Diagnostics with Multi-Well Smart Tracer Program for Hydraulic Fracturing Stimulation and Diversion Efficiency Assessment. In: SPE Hydraulic Fracturing Technology Conference and Exhibition. SPE-212319-MS

Vanessa W, Elizabeth MC, Andrea NP et al (2016) Far-Field Diversion in Hydraulic Fracturing and Acid Fracturing: Using Solid Particulates to Improve Stimulation Efficiency. In: SPE Asia Pacific Hydraulic Fracturing Conference. SPE-181845-MS

Wang L, Sheng ZM, Zhao ZX et al (2021a) Large-stage multi-cluster fracturing technology in the Jimsar shale horizontal well. Oil Drill Technol 49:106–108. https://doi.org/10.11911/syztjs.2021091

Wang JW, Kang YZ, Zhang DW et al (2021b) Application progress of temporary plugging agents in unconventional reservoir fracturing. Special Oil Gas Reserv 28:1–9. https://doi.org/10.3969/j.issn.1006-6535.2021.05.001

Weng DW, Lei Q, Li DX et al (2013) The field exploration of network fracturing technology. Oil Drill Prod Technol 35:59–62. https://doi.org/10.13639/j.odpt.2013.01.016

Xia PX (2019) New progress of temporary plugging agent for diversion fracturing technology. Appl Petrochem 38(10):1–5. https://doi.org/10.3969/j.issn.1673-5285.2019.10.001

Xue YP, Weng ZH, Shen YB et al (2018) Analysis of the diversion ability & mechanical mechanism of wool bursa temporarily plugging diversion fracture. Oil drill Prod Skills 40:633–640. https://doi.org/10.13639/j.odpt.2018.05.016

Yang C, Zhou FJ, Feng W, Tian ZD, Yuan LS, Gao LY (2019) Plugging mechanism of fibers and particulates in hydraulic fracture. J Petrol Sci Eng 176:396–402. https://doi.org/10.1016/j.petrol.2019.01.084

Youwei H, Jianchun G, Yong T et al (2020) Interwell fracturing interference evaluation of multi-well pads in shale gas reservoirs: a case study in WY Basin. In: SPE annual technical conference & exhibition. SPE-201694-MS

Zhang LF, Zhou FJ, Mou JY et al (2019) Large-scale true tri-axial fracturing experimental investigation on diversion behavior of fiber using 3D printing model of rock formation. J Petrol Sci Eng 181:106171. https://doi.org/10.1016/j.petrol.2019.06.035

Zhang RX, Hou B, Peng T et al (2020a) Hydraulic fracture propagation behavior and diversion characteristic in shale formation by temporary plugging fracturing. J Petrol Sci Eng 190:107063. https://doi.org/10.1016/j.petrol.2020.107063

Zhang X, Wang XZ, Guo TK et al (2020) Evaluation experiment of transient plugging agent for fracture diversion in Shunbei oilfield. Lithol Oil-Gas Reserv 32:170–176. https://doi.org/10.12108/yxyqc.20200518

Zhang YY, Wen QZ, Zhang DX (2020) A novel targeted plugging and fracture-adaptable gel used as a diverting agent in fracturing. Energy Sci Eng 8:116–133. https://doi.org/10.1002/ese3.513

Zhao MW, Gao ZB, Dan CL et al (2018) Research progress of temporary plugging agents for diversion fracturing in oil field. Oil Field Chem 35:538–544. https://doi.org/10.19346/j.cnki.1000-4092.2018.03.030

Zhao RH, Liu WZ, Zhou JM et al (2019) Application of compound temporary plugging and diversion acidification fracturing technology in Tahe oilfield. Special Oil Gas Reserv 26:146–150. https://doi.org/10.3969/j.issn.1006-6535.2019.06.027

Zhao ZF, Ye L, Li MR et al (2022) Preparation and evaluation of self-degrading granular temporary plugging agent for acid fracturing. Synth Chem 30:167–174. https://doi.org/10.15952/j.cnki.cjsc.1005-1511.21300

Zheng XQ, He CM, Yang NY et al (2022) The technology and development recommendations of volumetric fracturing 2.0 technology for unconventional reservoirs. Pet Sci Technol Forum 41(3):1–4. https://doi.org/10.3969/j.issn.1002-302x.2022.03.001

Zhou CN, Dong DZ, Wang YM et al (2015) Characteristics, challenges and prospects (I). Pet Explor Dev 42:689–701. https://doi.org/10.11698/PED.2015.06.01

Funding

This work was funded by the Research and Field Testing on Improving Refracturing Stimulation Effect of Vertical and Directional Wells in Old Oilfield (2022KT1704).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Liu, Y., Chen, R., Liu, J. et al. Development and field application of strongly resilient temporary plugging diversion agent for fracturing. J Petrol Explor Prod Technol 14, 2073–2088 (2024). https://doi.org/10.1007/s13202-024-01814-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-024-01814-7