Abstract

Bentonite suspension in water-based drilling fluid is susceptible to deterioration in high-temperature environments, hence requiring a deflocculant to stabilize the solid particles. Considering the use of highly toxic chrome-based deflocculant in the industry, Rhizophora spp. tannin-lignosulfonate (RTLS) was synthesized in this study as an alternative deflocculant. A viscometer was used to study the rheological properties, and the filtration performance was evaluated using low-pressure low-temperature and high-pressure high-temperature filter press in accordance with the American Petroleum Institute standard procedure. The addition of 0.5 wt% RTLS to water-based drilling fluid (WBDF) was effective in a significant reduction of the plastic viscosity (PV) and yield point (YP) of WBDF at elevated temperatures. As the amount of RTLS added to the suspension exceeds 0.5 wt%, the effect on PV and YP becomes negligible. A higher fluid loss of 13 mL was observed in the WBDF without RTLS aged at 177 °C. The addition of 2.0 wt% RTLS reduced the fluid loss to 10.7 mL. This suggests that RTLS is an effective deflocculant that can be used to improve the filtration properties of WBDF at high temperatures. The morphology of RTLS filter cakes was examined using field emission scanning electron microscopy with energy-dispersive X-ray spectroscopy (FESEM-EDX). The interlayer between clay particles was identified as RTLS, a natural additive that plays a vital role in enhancing filtration while minimizing fluid loss. The outcomes of this research are promising, and this non-toxic deflocculant has the potential to replace chrome-based deflocculants that are still in use for borehole drilling.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Drilling fluid, also known as circulation fluid, is vital in drilling rig systems as the fluid allows the systems to execute different functions throughout the drilling operation (Apaleke et al. 2012; Li et al. 2018; Lyu et al. 2019; Zhou et al. 2021). This mixture of natural and synthetic chemical compounds with the base fluid is used to clean the bottom hole, transport the cutting to the surface, cool and lubricate the drilling string, prevent the formation of fluid inflow, and preserve the stability of the wellbore (Jones and Hughes 1996; Lyu et al. 2019). The systems can be classified as pneumatic or mist systems, water-based systems, and non-aqueous systems, which include oil- and synthetic-based systems. Generally, water-based drilling fluid (WBDF) is often preferred owing to its ecological friendliness and lower cost of operation, but it is very susceptible to the well problems. Due to the difficulties encountered during drilling, such as high-pressure high-temperature (HPHT) and heaving shale, researchers have attempted to improve the performance of WBDF.

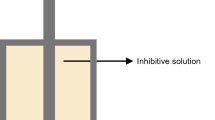

Clay mineral, such as bentonite, is a vital element in WBDF as it has the ability to enhance viscosity and reduce fluid loss (Temraz and Hassanien 2016; Zheng et al. 2020). Bentonite is primarily composed of montmorillonite and other chemical compounds, such as illite, quartz, calcite, iron oxide, and pyrite (Al-Risheq et al. 2021b, 2021a; Yamagata and Miyamoto 2021). Bentonite has a high surface area with a negative zeta potential, resulting in a highly stable colloid suspension when dispersed in water (Al-Risheq et al. 2021b). Nevertheless, in high-temperature environments, WBDF with water-bentonite slurries is prone to flocculation. Flocculation is a common occurrence when the WBDF contains a high concentration of solids and electrolytes, such as salt. The rheology of drilling fluid is influenced by this phenomenon, as evidenced by its rheology and filtration properties. Kelessidis et al. (2007) found that water-bentonite suspensions thicken significantly when exposed to high temperatures and develop high yield stress, with little effect on plastic viscosity (PV). Vryzas et al. (2017) observed that the yield point (YP) increased linearly with the temperature at low shear rates, whereas the PV decreased linearly with temperature. Li et al. (2020) highlighted that bentonite dehydrates and aggregates at high temperatures, resulting in larger bentonite particle size, lower viscosity of the bentonite dispersion, and thicker filter cake with higher fluid loss. Without any intervention, shear stress at low shear rates is projected to increase with increasing temperature, thus increasing yield stress and causing a slight reduction in PV in high-temperature conditions. Higher fluid loss in the filtration properties can lead to the formation of a permeable and thick filter cake, which can increase the cost of drilling operations (Al-Darweesh et al. 2023). To retain the system deflocculated, the repulsive force needs to be increased by adding a deflocculant with negative charges to neutralize the positive sites on the edge, as shown in Fig. 1. Deflocculant can be very effective at low concentrations due to the size of the edge surface area in comparison to the total surface area.

Deflocculant is an anionic chemical thinner, capable of deflocculating a clay suspension by counteracting the positive edge charges on a clay platelet. Additionally, it helps to reduce fluid loss caused by the open network structure due to flocculation. Chromium-modified lignosulfonate, as well as mixed-metal lignosulfonate of chromium and iron, have been proven to be effective at reducing viscosity and lowering yield point and gel strength (GS). It has high salt tolerance and excellent thermal stability up to 177 °C. Given that chromium is potentially toxic, numerous researchers have constantly looked for the alternatives (Hafshejani et al. 2016; Moslemizadeh et al. 2019, 2017; Zhang et al. 2014, 2012). Kök & Bal (2019) proved through their research that the use of chrome-free deflocculant in WBDF could reduce the fluid loss, and Pérez et al. (2017) highlighted that the use of bio-based deflocculant is more efficient than heavy metals commercially modified tannins. Apart from that, Bagum et al. (2022) and Moslemizadeh et al. (2019) emphasized that environmental challenges led to the introduction of natural sources to develop drilling fluid additives with low environmental impact and cost-effective. Several studies have been conducted to investigate the potential of natural resources as drilling fluid additives, specifically aloe vera (Bagum et al. 2022); mulberry leaf extract (Moslemizadeh et al. 2019); henna extract (Moslemizadeh et al. 2015); dividivi tannin (Pérez et al. 2017); wild jujube pit powder (Zhou et al. 2021), pomegranate peel powder and Prosopis farcta plant powder (Ali et al. 2022); cross-linking of corn starch, tea polyphenols, and sodium lignosulfonate (Li et al. 2021); oak seed extract (Hafshejani et al. 2016), and tea polyphenols (Li et al. 2020). The search was exhaustive because the potential replacement must meet both of the following criteria: thermal stability and non-toxicity to the environment.

This study evaluated a newly synthesized material, Rhizophora spp. Tannin-Lignosulfonate (RTLS) as a bentonite deflocculant in WBDF and compared it to the currently used chrome-based deflocculant in the industry. The thermal stability of RTLS was assessed by thermogravimetric analysis (TGA), which demonstrated exceptional thermal stability of more than 250 °C (Ghazali et al. 2018). The pre-hydrated bentonite was kept hydrated for 24 h prior to aging at 80, 93, 121, 149, and 177 °C. The low-pressure low-temperature (LPLT) and in situ rheology and filtration properties were measured with a rotational viscometer and a filter press according to the American Petroleum Institute (API) standard method. The rheological properties were fitted to the Herschel–Bulkley model, and the morphology of the filter cake was determined by using FESEM-EDX.

Materials and methods

Materials

Bentonite or sodium montmorillonite (Na-Mt), barite (barium sulfate), caustic soda (NaOH), and soda ash (Na2CO3) were obtained from Telnite Co., Ltd. (Sakata, Japan). A new cross-linked biopolymer as an anti-flocculant, RTLS, was synthesized in the laboratory by adding a covalent bond with the aid of formaldehyde as a cross-linker (Ghazali et al. 2018). In this study, RTLS with a 45–55 ratio of calcium lignosulfonate to Rhizophora spp. tannin was used, as it exhibits excellent thermal degradation. Figures 16, 17 and 18 show the chemical-physical composition and properties of RTLS. RTLS has a homogeneous size distribution ranging from 2 to 150 µm after 1-h grinding as shown in Fig. 16. FTIR spectra in Fig. 17 confirm the RTLS sample exhibited absorption band of hydroxyl groups, C–H stretching vibrations of CH2 and CH3, aromatic skeleton vibrations and Fe–O stretching vibrations. RTLS samples also demonstrated high thermal stability, as evidenced by the low degradation between 200 and 350 °C in the TGA shown in Fig. 18. In addition, an industrial chrome-based deflocculant (ICD) was used to compare the performance of RTLS. In this study, X-ray diffraction (XRD) was used to characterize bentonite. The clay is predominantly composed of montmorillonite, as shown in Fig. 2 with intense peaks at 2θ = 5.96°. Other peaks are related to quartz and feldspar impurities.

Methods

Preparation of drilling fluid

In developing the WBDF system, a pre-hydrated bentonite slurry was prepared by mixing 8 wt% of Na-Mt into deionized water. According to Vipulanandan and Mohammed (2014), more than 70% of past research used up to 8 wt% bentonite in their bentonite colloid system. The bentonite slurry was kept hydrated at room temperature for 24 h. Afterward, WBDF was formulated by adding barite to the bentonite slurry as a weighting material and adjusting the density to 9.0 ppg or 1,078 kg/m3. Later, deflocculants were added to the respective samples, as shown in the experimental protocols summarized in Table 1. The pH of the samples was adjusted by adding NaOH and Na2CO3 to improve the hardness. Drilling fluid samples prepared in this manner were aged for 16 h in a rolling oven at the designated temperature before measuring rheological and filtration properties. Thermal aging by rolling oven simulates the extreme conditions of the downhole environment that could be encountered by drilling fluids.

Measurement of rheology and filtration properties

Once aged, the drilling fluid samples were cooled to room temperature. Prior to rheological measurement, the samples were stirred for 10 min to create similar conditions for all samples to obtain similar shear history (Vryzas et al. 2019). The rheological properties of the samples before hot rolling (BHR) and after hot rolling (AHR) were determined using a Fann 35A viscometer at room temperature. The dial readings were recorded for six rotational speeds of 600, 300, 200, 100, 6, and 3 rpm that corresponded to shear rates of 1,022, 511, 341, 170.3, 10.22, and 5.11 s−1, respectively. All parameters were measured and calculated according to the recommended practice (American Petroleum Institute 2009). Figure 3 shows a flowchart of the process for rheology and filtration analysis of WBDF. The plastic viscosity (PV) and yield point (YP) were described according to the Bingham fluid model as follows:

Specifically, θ600 refers to the dial reading at 600 rpm, and θ300 refers to the dial reading at 300 rpm. The early GS (10 s) and 10 min GS were determined by recording the maximum deflection of the dial reading right before the gel broke.

WBDF samples with RTLS were tested using an HPHT Fann 50SL rheometer. Test conditions were pressure of 250 psi (1,723 kPa), shear rate of 60 rpm (102.2 s− 1), and elevated temperatures from 27 to 120 °C. The low shear rate reflects the normal shear rate of drilling fluid in the annulus and drill pipe. A multiple unit Fann API low-pressure low-temperature (LPLT) filter press was used to measure the filtration according to API standard procedure. The filtrate was collected in a graduated cylinder, and the thickness of the filter cake collected on the filter paper was measured. The HPHT filtration was tested for ten samples aged at 80 and 121 °C. The same temperature was set for the Fann HPHT filter press with an operating pressure of 500 psi (3447 kPa). The morphology of the filter cake was examined using a field emission scanning electron microscope (FESEM) coupled to EDX. The microstructures were studied under 15 kV of electron accelerating voltage with 1000 × magnification of platinum-coated dried filter cake.

Results and discussion

Drilling fluid properties: rheology and filtration

Shear stress and shear strain have a great influence on the design of drilling fluid formulation in the presence of bentonite. Bentonite is preferred over other types of clay due to its exceptional swelling capacity and excellent rheological properties, in which a high concentration is required to provide ideal rheological and filtration properties (Li et al. 2015).

Bingham PV is a primary function of viscosity measured at high shear stress that is used in drilling activities to give a direct indicator of fluid behavior around the bit (Annis and Smith 1996; Vryzas et al. 2017). Figure 4a and b presents the PV of drilling fluid with increasing RTLS and ICD concentration, respectively. The PV of BHR samples was recorded before aging, while the PV of other samples was measured after 16 h of aging at 80, 90, 121, 149, and 177 °C. Without any chemical treatment, all samples produced relatively higher PV after being exposed to a high-temperature environment. This phenomenon can be explained by the flocculation due to edge-to-edge (E-E) or edge-to-face (E–F) association that induced the increase of PV at elevated temperatures (Annis 1967; Kelessidis et al. 2007). The addition of 0.5 wt% RTLS to bentonite suspension remarkably reduced the PV before becoming constant as the RTLS concentration increased. The PV of the sample aged at 177 °C increased by 10 mPa·s in the presence of 1.0 wt% RTLS. The PV of the samples aged at 149, 121, and 80 °C dropped by 10 and 12 mPa·s in the presence of 0.25 and 0.5 wt% RTLS, respectively. The increment of RTLS concentration beyond 0.5 wt% did not influence the PV directly. A similar trend was observed for ICD samples, but the PV was significantly lower when more than 1.0 wt% ICD was added. Annis (1967) observed that rheology of WBDF is frequently related to high shear thinning of bentonite suspension at high temperatures, resulting in low PV readings.

The effects of deflocculant concentration on YP are presented in Fig. 5a and b for RTLS and ICD, respectively. In general, exposing WBDF to a high-temperature environment will increase the Bingham YP (Ahmad et al. 2018; Annis and Smith 1996; Hafshejani et al. 2016; Moslemizadeh et al. 2015; Vryzas et al. 2019, 2017). The YP of WBDF at 93 °C doubled the YP of the BHR sample before the values increased significantly to 30.1, 35.8, and 46 Pa for 121, 149, and 177 °C, respectively. The effectiveness of RTLS as a deflocculant could be clearly observed with 0.5 wt% concentration for the WBDF, similar to ICD. Further increment of RTLS concentration did not influence the reduction of YP. Theoretically, there are two circumstances that influence the yield point of drilling fluid. The first factor is the electrical interaction between solid particles, which can be controlled by deflocculants via chemical treatment. The electrical interaction between clay platelets induces the linking of E-E and E–F, hence increasing the yield point. Another factor is the mechanical interaction controlled by the amount of solid particles and/or the presence of polymer (Annis and Smith 1996). Treating WBDF with deflocculant will reduce the YP by neutralizing the clay platelet until it reaches the optimum condition. Then, the YP is no longer influenced by chemical treatment. Proper solid removal is required for further reduction of YP.

Figures 6 and 7 show the effect of RTLS and ICD concentration on early GS and 10 min GS, respectively. The GS of the drilling fluid recorded the maximum dial deflection after 10 s and 10 min by using a Fann 35A viscometer. Both early GS and 10 min GS of 8 wt% bentonite increase slightly with the increase in temperature. A satisfactory reduction of GS was achieved at higher RTLS concentration. An increase in GS indicates the beginning of flocculation, whereas a decrease in GS indicates that clay particles are being deflocculated by chemical treatment (deflocculant). Barite settlement is represented by the magnitude of GS. If a deflocculant does not reduce the GS, this indicates an excessively high colloid solid content, or possible chemical contamination.

The situation is called complete deflocculation when the YP is equal to 0, which was achieved by 2.0 wt% ICD aged at 121, 149, and 177 °C. Zero GS is a signal that barite is fully settled in the slurries. It is impractical for drilling fluid to have zero GS as it needs to have a carrying capacity to carry the cutting and weighting material.

Aside from being a good thinner, deflocculants also aid in the effectiveness of reducing filtration and enhancing the quality of filter cake. LPLT filtration analysis conducted at room temperature (~ 25 °C) and 100 psi (690 kPa) supports this statement, as can be seen in Fig. 8. Additionally, this finding is in accordance with the TGA results, which show that thermal stability is consistent at temperatures up to 250 °C (Ghazali et al. 2018). The WBDF with RTLS aged at 80, 90, 121, 149, and 177 °C revealed a reduction in filtrate volume and filter cake thickness. Without any deflocculant, a higher fluid loss of 13 mL was found in the WBDF aged at 177 °C. The fluid loss volume decreased to 10.7 mL in the presence of 2.0 wt% RTLS. As fluid loss additives are often subjected to degradation at elevated temperatures, this finding demonstrates the ability of RTLS to perform under this condition.

High-temperature drilling fluid properties: high temperature rheology

A Fann 50SL rheometer was used to determine the effective viscosity under dynamic temperature conditions to imitate actual drilling conditions. The heating process in the rheometer, using an oil bath, decreased the fluid viscosity with increasing temperature. The viscosity reached a constant value before increasing. This phenomenon is identified as drilling fluid gelation due to thermal degradation in the physicochemical structure immediately after the viscosity increases (Santoyo et al. 2001). Figure 9 shows that the sample with 8 wt% bentonite reached the gelation point at 63 °C. The gel formation was delayed by the addition of 0.25 wt% RTLS. Other samples reached the gelation point at lower temperatures of 53, 61, and 58 °C for 0.5, 1.0, and 2.0 wt% RTLS, respectively. A slightly different trend emerged after aging the drilling fluid sample at 121 °C, as shown in Fig. 10. The gelation of 8 wt% bentonite began at 79 °C, but the addition of 2.0 wt% RTLS retarded the gelation process, which was achieved at 84 °C. Other samples attained gelation at 52, 60, and 63 °C for 0.25, 0.5, and 1.0 wt% RTLS, respectively. As a result, it demonstrates that RTLS may retard the gelation of the water-bentonite suspension at elevated temperatures.

High-temperature drilling fluid properties: HPHT filtration

HPHT filtration tests were conducted at 80 and 121 °C with an operating pressure of 500 psi (3447 kPa). The filtrate volume and thickness of the filter cake were recorded after 30 min, as shown in Figs. 11 and 12. As for untreated WBDF, about 8.2 mm of filter cake was measured at 121 °C, which was twice the thickness of the WBDF filter cake examined at 80 °C. The addition of 0.25 wt% RTLS resulted in a significant reduction in the filtrate for the samples tested at 121 °C. Filtrate volume and filter cake thickness were reduced by 3.6 mL and 3.05 mm, respectively, after the addition of 2.0 wt% RTLS. This result demonstrated that RTLS can produce an effective filter cake while decreasing filtration volume. An excellent filter cake should be thin and permeable to reduce fluid loss and avoid stuck pipes.

Drilling fluid properties: rheogram and model fitting

The Herschel–Bulkley model is among the most effective models in explaining the behavior of flocculated suspension in relation to the applied shear rate. At low shear rates, bentonite suspension exhibited initial yield stress and shear-thinning behavior at increasing shear rates (Al-Risheq et al. 2021b). All experimental data were fitted to the Herschel–Bulkley fluid model using the OriginLab® software, as shown in Figs. 13 and 14. The mathematical equation of the Herschel–Bulkley fluid model is described as follows:

where τ represents the yield stress, while K and n indicate the consistency coefficient and flow characteristic exponential, respectively. The effectiveness of the experimental data fitted to the polynomial model was measured by means of coefficient of determination, R2. An ideal fitting is when the R2 and adjusted R2 are closer to the unity (Al-Risheq et al. 2021a; Du et al. 2018; Zheng et al. 2020).

As shown in Tables 2 and 3, all data sets have a good linear relationship as all the R2 values are greater than 0.99, indicating that the model fits the experimental data well. The fluids behave like pseudoplastic with a low value of n, as can be seen in all RTLS samples. In Table 3, for WBDF with 2.0 wt% ICD aged at 149 °C, the fluid behaved like a Newtonian fluid as the flow characters are equal to 1.02. A lower magnitude of flow characteristic indicates more non-Newtonian behavior, and the fluid is said to belong to the Newtonian fluid when n is equal to 1 and \(\tau_{{\text{y}}}\) is equal to 0.

On the other hand, K; an increase in the magnitudes implies an increase in annular viscosity, which also increases the hole-cleaning capacity. Additionally, it is always subjected to an increase in the amount of small-size cutting. Higher concentration of cutting influences the particle–particle interaction, hence increasing the viscosity (Du et al. 2018).

Morphology of filter cake

The morphology of filter cake was studied using FESEM-EDX. Both filter cakes from WBDF without deflocculant and WBDF with RTLS were dried at room temperature prior to analysis. The LPLT filtration test was performed on WBDF aged at 121 °C, as shown in Fig. 15a for the filter cake from WBDF and (b) for the filter cake from WBDF with RTLS. The addition of RTLS to bentonite resulted in a less porous structure and a smoother morphology with no visible fracture. These morphology analyses confirmed that the newly synthesized RTLS reduced the fluid loss by reducing the open network caused by flocculation. The presence of aluminum (Al) and silicon (Si) was detected in EDX because the bentonite structure is a natural smectite clay formed from the octahedral layer of these two elements. Table 4 shows that the percentage of carbon (C) in WBDF with RTLS is 20.68%, whereas the percentage of C in WBDF is only 8.69%. The increase in the percentage of element C is caused by the association of RTLS with the bentonite structure. This suggests that RTLS plays an important role in improving rheology and reducing fluid loss.

Conclusions

In high-temperature environments, the presence of a deflocculant is necessary to stabilize the solid particles in the water-based drilling fluid (WBDF) containing bentonite suspension, as it tends to decrease. Given the industry’s reliance on toxic chrome-based deflocculants, this study developed a novel additive as an alternative. The newly synthesized Rhizophora spp. Tannin-Lignosulfonate (RTLS) in the WBDF was investigated for its thinning ability, and its performance was compared to the industrial chrome-based deflocculant (ICD). Laboratory drilling fluids were aged at 177, 149, 121, 93, and 80 °C to imitate the high-temperature environment. The conclusions are as follows:

-

1.

The RTLS improves the rheology and filtration properties of WBDF, which outperforms ICD.

-

2.

Adding 0.5 wt% RTLS to WBDF significantly reduces its plastic viscosity (PV) and yield point (YP) at elevated temperatures. However, the effect on PV and YP becomes negligible when more than 0.5 wt% RTLS is added to the suspension. Reducing the plastic viscosity (PV) and yield point (YP) at elevated temperatures will minimize friction in the drill pipe and enhance pumpability. Since the pressure drop across the drill pipe during drilling fluid circulation is directly proportional to its viscosity, reducing the fluid's viscosity translates into lower power consumption and overall drilling costs.

-

3.

In a WBDF without RTLS aged at 177 °C, a higher fluid loss of 13 mL was observed. However, the addition of 2.0 wt% RTLS reduced the fluid loss to 10.7 mL. RTLS is able to reduce filtration in both static and dynamic conditions. Additionally, the addition of RTLS retarded the gelation of drilling fluid, even with the addition of 0.25 wt% RTLS.

-

4.

The morphology analysis on filter cake using Field emission scanning electron microscopy with energy-dispersive X-ray spectroscopy (FESEM-EDX) confirmed that the RTLS effectively produced a smooth morphology with less porous filter cake.

-

5.

RTLS, a natural-based and sustainable deflocculant, has the potential to replace chrome-based deflocculants in oil well drilling.

Abbreviations

- θ 600 :

-

Dial readings at 600 (rpm)

- θ 300 :

-

Dial readings at 300 (rpm)

- τ :

-

Sheer stress (Pa)

- \(\tau_{{\text{y}}}\) :

-

Yield stress or yield strength (Pa)

- γ :

-

Shear rate, per second (s−1)

- K :

-

Consistency coefficient (Pa·sn)

- n :

-

Flow characteristic exponential

- AHR:

-

After hot rolling

- API:

-

The American petroleum institute

- BHR:

-

Before hot rolling

- FESEM-EDX:

-

Field emission scanning electron microscopy (FESEM) with energy-dispersive X-ray spectroscopy (EDX)

- GS:

-

Gel strength

- HPHT:

-

High-pressure high-temperature

- ICD:

-

Industrial chrome-based deflocculant

- LPLT:

-

Low-pressure low-temperature

- Na-Mt:

-

Sodium montmorillonite

- NaOH:

-

Sodium hydroxide

- Na2CO3 :

-

Soda ash

- PV:

-

Plastic viscosity

- RT:

-

Rhizophora Spp. tannin

- RTLS:

-

Rhizophora Spp. Tannin-Lignosulfonate

- TGA:

-

Thermogravimetric analysis

- WBDF:

-

Water-based drilling fluid

- XRD:

-

X-ray diffraction

- YP:

-

Yield point

References

Ahmad HM, Kamal MS, Al-Harthi MA (2018) Effect of thermal aging and electrolyte on bentonite dispersions: rheology and morphological properties. J Mol Liq 269:278–286. https://doi.org/10.1016/j.molliq.2018.08.058

Al-Darweesh J, Aljawad MS, Al-Ramadan M, Elkatatny S, Mahmoud M, Patil S (2023) Review of underbalanced drilling techniques highlighting the advancement of foamed drilling fluids. J Pet Explor Prod Technol. https://doi.org/10.1007/s13202-022-01596-w

Ali JA, Ahmed RN, Abdullah AD, Ali NH, Kalhury AM, Sabir AN, Khaksar Manshad A, Keshavarz A, Mohammadi AH (2022) Development of a nanobiodegradable drilling fluid using prosopis farcta plant and pomegranate peel powders with metal oxide nanoparticles. ACS Omega. https://doi.org/10.1021/acsomega.2c03492

Al-Risheq DIM, Nasser MS, Qiblawey H, Ba-Abbad MM, Benamor A, Hussein IA (2021a) Destabilization of stable bentonite colloidal suspension using choline chloride based deep eutectic solvent: optimization study. Journal of Water Process Engineering 40:101885. https://doi.org/10.1016/j.jwpe.2020.101885

Al-Risheq DIM, Nasser MS, Qiblawey H, Hussein IA, Al-Ghouti MA (2021b) Influence of choline chloride based natural deep eutectic solvent on the separation and rheological behavior of stable bentonite suspension. Sep Purif Technol 270:118799. https://doi.org/10.1016/j.seppur.2021.118799

American Petroleum Institute, 2009. Recommended practice for field testing of water-based drilling fluids API 13B-1(RP 13B-1).

Annis MR (1967) High-Temperature flow properties of water-base drilling fluids. J Petrol Technol 19:1074–1080. https://doi.org/10.2118/1698-pa

Annis MR, Smith MV (1996) Drilling fluids technology. EXXON Company, USA, p 366

Apaleke, A.S., Al-Majed, A., Hossain, M.E., 2012. Drilling fluid: state of the art and future trend. Society of petroleum engineers - North Africa Technical Conference and Exhibition 2012, NATC 2012: Managing Hydrocarbon Resources in a Changing Environment. 1, 101–113. doi https://doi.org/10.2118/149555-ms

Bagum M, Ahammad JM, Husain T, Hossain ME (2022) An experimental study to develop an environmental friendly mud additive of drilling fluid using aloe vera. J Petrol Sci Eng 211:110135. https://doi.org/10.1016/j.petrol.2022.110135

Du H, Wang G, Deng G, Cao C (2018) Modelling the effect of mudstone cuttings on rheological properties of KCl/Polymer water-based drilling fluid. J Pet Sci Eng 170:422–429. https://doi.org/10.1016/j.petrol.2018.06.071

Ghazali, N.A., Naganawa, S., Masuda, Y., 2018. Development of modified Rhizophora spp. Tannin biopolymer additive in drilling fluid system for high temperature well applications, In: Proceedings of the IADC/SPE Asia Pacific Drilling Technology Conference, APDT. pp. 1–8.

Hafshejani KS, Moslemizadeh A, Shahbazi K (2016) A novel bio-based deflocculant for bentonite drilling mud. Appl Clay Sci 127–128:23–34. https://doi.org/10.1016/j.clay.2016.03.037

Jones, T.G.J., Hughes, T.L., 1996. Drilling fluid suspensions. Suspensions: fundamentals and applications in the petroleum industry. 251, 463–564.https://doi.org/10.1021/ba-1996-0251.ch010

Kelessidis VC, Christidis G, Makri P, Hadjistamou V, Tsamantaki C, Mihalakis A, Papanicolaou C, Foscolos A (2007) Gelation of water-bentonite suspensions at high temperatures and rheological control with lignite addition. Appl Clay Sci. https://doi.org/10.1016/j.clay.2006.09.010

Kök MV, Bal B (2019) Effects of silica nanoparticles on the performance of water-based drilling fluids. J Pet Sci Eng 180:605–614. https://doi.org/10.1016/j.petrol.2019.05.069

Li MC, Wu Q, Song K, Qing Y, Wu Y (2015) Cellulose nanoparticles as modifiers for rheology and fluid loss in bentonite water-based fluids. ACS Appl Mater Interfaces 7:5009–5016. https://doi.org/10.1021/acsami.5b00498

Li MC, Ren S, Zhang X, Dong L, Lei T, Lee S, Wu Q (2018) Surface-chemistry-tuned cellulose nanocrystals in a bentonite suspension for water-based drilling fluids. ACS Appl Nano Mater 1:7039–7051. https://doi.org/10.1021/acsanm.8b01830

Li X, Jiang G, Shen X, Li G (2020) Application of tea polyphenols as a biodegradable fluid loss additive and study of the filtration mechanism. ACS Omega 5:3453–3461. https://doi.org/10.1021/acsomega.9b03712

Li X, Jiang G, He Y, Chen G (2021) Novel starch composite fluid loss additives and their applications in environmentally friendly water-based drilling fluids. Energy Fuels 35:2506–2513. https://doi.org/10.1021/acs.energyfuels.0c03258

Lyu S, Wang S, Chen X, Shah SM, Li R, Xiao Y, Dong Q, Gu Y (2019) Experimental study of a degradable polymer drilling fluid system for coalbed methane well. J Pet Sci Eng 178:678–690. https://doi.org/10.1016/j.petrol.2019.03.065

Moslemizadeh A, Shadizadeh SR, Moomenie M (2015) Experimental investigation of the effect of henna extract on the swelling of sodium bentonite in aqueous solution. Appl Clay Sci 105–106:78–88. https://doi.org/10.1016/j.clay.2014.12.025

Moslemizadeh A, Khezerloo-ye Aghdam S, Shahbazi K, Zendehboudi S (2017) A triterpenoid saponin as an environmental friendly and biodegradable clay swelling inhibitor. J Mol Liq 247:269–280. https://doi.org/10.1016/j.molliq.2017.10.003

Moslemizadeh A, Samadzadeh Hafshejani K, Shahbazi K, Zaravi Dezfuli M, Zendehboudi S (2019) A biosurfactant for inhibiting clay hydration in aqueous solutions: applications to petroleum industry. Can J Chem Eng 97:384–394. https://doi.org/10.1002/cjce.23172

Pérez MA, Rengifo R, Pereira C, Hernández V (2017) Dividivi tannins: an ecological product for water-based drilling fluids. Environ Dev Sustain 19:1815–1829. https://doi.org/10.1007/s10668-016-9829-0

Santoyo E, Santoyo-Gutiérrez S, García A, Espinosa G, Moya SL (2001) Rheological property measurement of drilling fluids used in geothermal wells. Appl Therm Eng 21:283–302. https://doi.org/10.1016/S1359-4311(00)00003-X

Temraz MG, Hassanien I (2016) Mineralogy and rheological properties of some Egyptian bentonite for drilling fluids. J Nat Gas Sci Eng 31:791–799. https://doi.org/10.1016/j.jngse.2016.03.072

Vipulanandan C, Mohammed AS (2014) Hyperbolic rheological model with shear stress limit for acrylamide polymer modified bentonite drilling muds. J Pet Sci Eng 122:38–47. https://doi.org/10.1016/j.petrol.2014.08.004

Vryzas Z, Kelessidis VC, Nalbantian L, Zaspalis V, Gerogiorgis DI, Wubulikasimu Y (2017) Effect of temperature on the rheological properties of neat aqueous Wyoming sodium bentonite dispersions. Appl Clay Sci 136:26–36. https://doi.org/10.1016/j.clay.2016.11.007

Vryzas Z, Nalbandian L, Zaspalis VT, Kelessidis VC (2019) How different nanoparticles affect the rheological properties of aqueous Wyoming sodium bentonite suspensions. J Pet Sci Eng 173:941–954. https://doi.org/10.1016/j.petrol.2018.10.099

Yamagata Y, Miyamoto K (2021) Gel formation and its relaxation mechanism of shear-induced aqueous suspensions comprised of bentonite and heptaethylene oleyl ether. Colloids Surf A Physicochem Eng Asp 624:126786. https://doi.org/10.1016/j.colsurfa.2021.126786

Zhang J, Chen G, Yang NW (2012) Development of a new drilling fluid additive from lignosulfonate. Adv Mat Res 524–527:1157–1160. https://doi.org/10.4028/www.scientific.net/AMR.524-527.1157

Zhang J, Chen G, Yang NW, Wang YG (2014) Preparation of nitration-oxidation lignosulfonate as an eco-friendly drilling fluid additive. Pet Sci Technol 32:1661–1668. https://doi.org/10.1080/10916466.2011.652334

Zheng W, Wu X, Huang Y (2020) Impact of polymer addition, electrolyte, clay and antioxidant on rheological properties of polymer fluid at high temperature and high pressure. J Pet Explor Prod Technol 10:663–671. https://doi.org/10.1007/s13202-019-0732-8

Zhou G, Qiu Z, Zhong H, Zhao X, Kong X (2021) Study of environmentally friendly wild jujube pit powder as a water-based drilling fluid additive. ACS Omega 6:1436–1444. https://doi.org/10.1021/acsomega.0c05108

Acknowledgements

This paper is based on the outcomes derived from a project commissioned by the New Energy and Industrial Technology Development Organisation (NEDO), Japan. The study was supported by the JSPS KAKENHI Grant-in-Aid for Scientific Research (C) Number 26420842. N.A.G. would like to thank the Malaysia Ministry of Higher Education and Universiti Teknologi MARA for the financial support under the Sustainable Research Collaboration grant with the grant number 600-RMC/SRC/5/3 (028/2020). The authors would like to acknowledge Telnite Co., Ltd (Japan) for the facilities and technical assistance.

Funding

Funding for this research was provided by The Japan Society for the Promotion of Science (JSPS) through their research grant (26420842) and Malaysia Ministry of Higher Education (Universiti Teknologi MARA) with the grant number 600-RMC/SRC/5/3 (028/2020).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declare(s) that there is no conflict of interest regarding the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ghazali, N.A., Naganawa, S. & Masuda, Y. The effect of high-temperature environment on the rheology and filtration properties of Rhizophora spp. tannin-lignosulfonate as bio-based additive in water-based drilling fluid. J Petrol Explor Prod Technol 14, 727–743 (2024). https://doi.org/10.1007/s13202-023-01740-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-023-01740-0