Abstract

Identifying the optimal azimuth and inclination for wellbore drilling in sandy formations can be considered a valuable aid in reducing sand production risks, lost time, and decreasing drilling costs in the petroleum industry. Therefore, a numerical systematic approach was provided to predict sand production in wellbore SDX-5, drilled in a deep-water sandstone reservoir in the Shah-Deniz gas field (South Caspian Basin), which has never been done previously. Additionally, this systematic approach uses geomechanical and geodynamical criteria, along with petrophysical information (density and sonic log) and tectonic characteristics of the study area, which are influenced by the active tectonic stresses of the Apsheron-Balkhan zone. The subsurface data sources employed are more eco-friendly, available, and continuous than experimental tests. The computations conducted achieved azimuth, inclination, polar, and depth profile plots for the Lower Balakhany Formation. The calculations reveal that the optimum azimuth for the wellbore drilling trajectories is parallel to SHmax and oblique drilling to near horizontal is the result of optimum inclination. Polar plots showed optimum azimuth, inclination, and effect of wellbore trajectory on critical collapse pressure and collapse drawdown pressure with pressure values simultaneously, which identify safer alternatives for achieving higher petroleum production rates without sanding. Depth profile plots provide a simultaneous overview of the values of critical collapse pressure, critical sanding pressure for instantaneous drawdown, and optimum wellbore production pressure during drilling and production operations. Moreover, optimum reservoir fluid production (maximum discharge) rates can be identified and imposed as upper limits to prevent sand production.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Two key problems are commonly encountered when drilling oil and gas boreholes into poorly consolidated, clastic reservoir formations: (1) wellbore instability, caving, and partial collapse of the wellbore walls during drilling and subsequent fracturing and failure of the rock formations surrounding the wellbore during production; and (2) sand (solid particle) production derived from the failed formations during fluid flow into the wellbore. Sand production occurs in a three-step sequence in the subsurface section of a wellbore: a) constituent fragmentation of the formation; b) erosion of separate sand (mineral or rock) grains caused by fluid flow, and c) sand migration (Pham 2017). It is, therefore, appropriate to study the mechanisms that lead to sand production from specific reservoir formations over time and to develop models to quantify it (Papamichos et al. 2000). Two generic mechanisms tend to contribute to wellbore sand production: 1) mechanical failure of the reservoir formations; and 2) hydrodynamic erosion (Wu and Tan 2002; Xue and Yuan 2004, 2007; Younessi et al. 2013). If allowed to progress, sand production can cause wellbore fluid production to deteriorate substantially over time (Oyama et al. 2010; Kurihara et al. 2010; Li et al. 2016). Furthermore, other problems that sand production causes include wellbore and production liner blocking, failure and/or collapse of sections of poorly consolidated formations in the wellbore wall, environmental impacts incurring extra costs associated with remedial and clean-up operations, sand deposition inside flowlines and pipelines leading to fluid-flow blockages, and erosion and degradation of surface and downhole facilities and equipment (Bol et al. 1994; Al-Awad et al. 1999; Willson et al. 2002; Wan and Wang 2004; Rahmati et al. 2013; Guo et al. 2014).

The Caspian Sea is well known as a petroliferous basin containing substantial oil and gas reserves and resources (Jones and Simmons 1997; Reynolds et al. 1998; Devlin et al. 1999; Kalyuzhnova et al. 2002). The southern portion of the Caspian Sea Basin extends to Azerbaijan in the west, Turkmenistan in the east, and Iran in the south. This area is a deep basin and drilling for petroleum extraction purposes is more problematic compared to shallow basins. The giant Shah-Deniz gas field lies within the Azerbaijan portion of the basin and is considered one of the strategic natural gas supply fields for Europe.

A wide range of studies have been conducted focusing mainly on the prediction, mitigation, and control of wellbore sand production (Weingarten and Perkins 1995; Burton et al. 2005; Younessi et al. 2013; Pham 2017; Javani et al. 2017; Salehi et al. 2019; Shabdirova et al. 2019). Multiple studies have developed analytical or numerical models and systematic approaches to predict the onset of sand production in specific subsurface conditions (Vaziri et al. 2002; Nouri et al. 2006; Isehunwa and Olanrewaju 2010; Aadnoy and Kaarstad 2010; Rahman et al. 2010; Volonté et al. 2013; Khamehchi et al. 2014; Gui et al. 2016; Gharagheizi et al. 2017; Subbiah et al. 2021; Lu et al. 2021; Shahsavari et al. 2021).

This study is the first to quantify sand production risk, identify the optimal drilling azimuth and inclination and determine the values of critical sanding collapse pressure and critical sanding pressure for instantaneous drawdown simultaneously in the South Caspian Basin, particularly in the Shah-Deniz gas field, to minimise or avoid sand production. As the study area is affected by the Apsheron-Balkhan active tectonic zone (Apsheron-Balkhan sill), (Jackson et al. 2002), therefore, providing information related to field stress in the reservoir management process of the oil and gas fields provides prominent knowledge about sand production and stability issues. In these circumstances, values of magnitude and stress direction and the significant influence of tectonic stresses have considerable importance for the sand production problems of the wellbore. The proposed method integrates tectonics (stress measurements) and rock mechanics to predict sand production risks from drilled reservoir formations. Indeed, sand grains can be easily restrained in shallow reservoirs. However, since the study area is one of the deep-water sandstone reservoirs and also due to the high-pressure condition of the reservoir rock and the unconsolidated nature of the middle-Pliocene sands in this region, the control and management of sandy formations is difficult. So, this area is unique. The unconsolidated nature of the formations means that sand grains tend to be rapidly produced during drilling if a formation’s critical collapse pressure is exceeded. Thus, determining the critical collapse pressure and fluid production rate profiles from the direction and magnitude of in situ stresses is important for selecting well trajectories that minimise the risk of sand production.

One of the most available alternative indirect methods in the absence of direct approaches for obtaining stresses is using subsurface techniques, such as well-logging data and equations to calculate the properties of stresses. This approach leads to a more continuous distribution over a larger depth interval than experimental methods. Also, direct methods are precarious, overpriced, time-consuming, and belong only to certain depth ranges. Therefore, the developed method can be applied rapidly and at a low cost, making it a useful field development tool for the cases with poorly consolidated reservoirs that are prone to sand production. Moreover, due to the loose nature of the study area formations, a lack of other beneficial data, such as core data, is prevalent. Investigating the risks of sand production issues in such conditions as those mentioned above has never been done in other South Caspian Basin fields.

The objectives of this study are to quantitatively predict sand production from reservoirs penetrated by the SDX-5 well in the Shah-Deniz gas field using petrophysical well log data. Well-logging data derived from approximately 6000 m of drilling (density log (RHOB), P (DTco), and S (DTs) wave transit times) were exploited to calculate formation geomechanical and physical properties and also stress magnitudes for sand production prediction in this study. To determine the direction of stresses, the world stress map, numerical methods, and earthquake focal mechanisms from previous works were used. Overall, the values of critical sanding collapse pressure and critical sanding pressure for instantaneous drawdown were obtained simultaneously during drilling and production operations. Furthermore, in situ stresses around the borehole were assessed, and the wellbore’s optimum azimuth and inclination (to prevent sand production risks) were determined considering drilling issues for all wellbore depth intervals (all contained formations). Optimum hydrocarbon discharge rates and safe production pressures without sanding were finally achieved. The obtained results play a crucial role in reducing sand production risks and can have numerous positive aspects for future well and field development programs. The workflow of this study is illustrated in detail in Fig. 1.

Geological setting

The study area (Fig. 2) is tectonically active and complicated, and it has a band of significant earthquakes (Apsheron-Balkhan zone) that are located parallel to the normal faults, in a collision zone. In addition, the earthquakes of thrust faulting focal mechanisms can be seen along the same area. Some of these earthquakes have unusually deep epicentres, 30 km or more (Jackson et al. 2002). Additionally, the Shah-Deniz field (Fig. 2) is one of the largest natural gas fields in the Caspian Sea Basin (Javanshir et al. 2015). The reservoir is constrained within a prominent four-way-dip-closed anticlinal trap, with its core axis trending approximately northwest-southeast. The structure lies about 70 km southeast of Baku and incorporates 1.8 km of vertical dip closure (Fowler et al. 2000). The Shah-Deniz reservoirs are undergoing staged development with multiple wells drilled, with ten exploration, appraisal, and development wells drilled to date. One of these wells is SDX-5, drilled to appraise the "known reservoirs" in the south-eastern part of the field.

(Modified from Javanshir et al. 2015)

Location details of the Shah-Deniz gas field and its position within the Caspian Sea Basin. a The location of the Caspian Sea and its neighbouring countries; b Oil and gas fields are displayed in the vicinity of the Shah-Deniz field, including the large, predominantly oil-bearing Azeri–Chirag–Gunashli field (ACG); and c The location of the SDX-5 well in relation to the Shah-Deniz structure

The constituent formations and related lithologies, ages, depths, and thicknesses of the geological section associated with the Shah-Deniz field are summarised in Table 1. The thick Productive Series (Pliocene age), deposited over a relatively short time interval (about 1–2 my), constitutes the primary gas and oil reservoir rocks in the basin (Reynolds et al. 1998).

Materials and methods

Mohr–Coulomb failure criterion

Shear-failure criterion related to sub-surface rock formations can be expressed by mathematical functions to determine the triaxial stress field within which shear-compressive failure occurs. The failure criterion that is most commonly used for sand production prediction studies is the linearised Mohr–Coulomb failure criterion (Javani et al. 2017; Aadnoy and Looyeh 2019). Based on this criterion in production conditions, the shear stress of the rock (\(\tau_{{{\text{Mohr}}}}\)) and the maximum applied shear stress (\(\tau_{{{\text{Max}}}}\)) are expressed by Eqs. (1) and (2):

where C is cohesion and φ is the internal friction angle. Furthermore, σ1 and σ3 are the maximum and minimum principal effective stresses and Pw is the internal wellbore pressure. Sand is produced when the τmax exceeds the τmohr.

The failures resulting in sand production are often caused by shear failures in the reservoir formations (Al-Awad et al. 1999). If the reservoir rocks are consolidated and intact, the stresses mutually generate a resilient response inhibiting rock failure. However, when the reservoir rock is weak and unconsolidated, failure occurs, resulting in small and large solid particles forming as the formation fragments, and the structural integrity of the failure plane is annihilated. This type of failure is predictable using Mohr–Coulomb's failure criterion (Mohr 1900; Xianjie 2003; Vásárhelyi 2009), as expressed in Eq. (3).

where τ is the shear stress, C is the cohesion strength, σn is the normal stress, and φ is the friction angle.

Sand production

In sand production, sand grains become detached from the bulk of the reservoir formation and migrate, under pressure, towards the direction of maximum stress. Sand production most commonly occurs in unconsolidated, shallow sand or sandstone formations, but in some circumstances, it also occurs in deep formations (Al-Awad et al. 1999; Talaghat and Bahmani 2017; Elhaddad and Reddy 2019; Ben Mahmud et al. 2019). Numerous factors influence sand production. These include:

-

Properties of reservoir fluids (oil and gas) and water cut (Renpu 2011),

-

Fluid flow rates and variations in those rates (Xiong et al. 2018),

-

Rock strength properties (Ben Mahmud et al. 2019),

-

Formation properties such as moisture and clay-mineral contents (Bruno et al. 1996; Ranjith et al. 2013),

-

Effective stresses (Clearly et al. 1979; Palmer and Mansoori 1998),

-

Reservoir-operating attributes such as injection pressure (Tippie and Kohlhaas 1973),

-

Well-bore diameter (Fattahpour et al. 2012),

-

Cementation material properties and initial drag force caused by production (Nouri et al. 2006; Rahmati et al. 2013),

-

Viscosity of the liquid, rate of fluid production (Ranjith et al. 2013),

-

Formation particle dimensions and density (Isehunwa and Olanrewaju 2010),

-

Formation’s compressive strength (Perera et al. 2017).

Smoothing

During their recording, well-log data are influenced to a varying degree by environmental noise, caused by environmental factors and downhole conditions such as stresses and turbulence of wellbore fluids (Aftab and Moghadam 2022). Such noise is a stochastic phenomenon and can influence the geological interpretation and analysis of the recorded data. To eliminate such noise, smoothing was applied to the entire dataset before analysis. Once the well-log data have been compiled from the wellbore of interest, the raw recorded data obtained from the sonic logs consisting of compressive (P) and shear (S) wave transit times and bulk density log data were smoothed by applying the mean method (Fig. 3). In this method, several value intervals are defined to determine each smooth window in the x (width) and y (length) directions. The values of x and y were considered 1 and 6 for RHOB, 1 and 5 for DTco, and 1 and 6 for DTs, respectively.

Cohesion and internal friction angle

Due to the unconsolidated nature of sedimentary formations in the South Caspian Sea, their mechanical behaviour exhibits moderate cohesion, somewhere between soil and rock. In the absence of data from laboratory experiments (e.g. triaxial compressive strength test), Zoback's peak cohesion values were applied. These values were estimated by Zoback (2007) for loose (unconsolidated) and soft sediments based on various tests (Table 2).

Also, due to the absence of triaxial compressive strength test data, Lal and Weingarten's formulas were used to determine the internal friction angle (Weingarten and Perkins 1995; Lal 1999). They developed a series of experimentally derived formulas for calculating the internal friction angle using measured geophysical logs based on the type of rock. Equation (4) displays their empirical equation for shales (Lal 1999):

where \(V_{{\text{p}}}\) is the compressional wave velocity expressed in units of m/s. There is no single value for the internal friction angle for each generic rock type. However, some laboratory tests suggest that, for example, shales with a high Young’s modulus often tend to have a high internal friction angle (Lama and Vutukuri 1978).

Wingartan and Perkins proposed Eq. (5) for sandstones (Weingarten and Perkins 1995) is as:

where \(\emptyset\) is the porosity, which is obtained from the compressional sonic log data using Eq. (6).

where ∆tp is the P wave transit time in μs/ft.

The mechanical behaviour of mudstone and claystone tends to be similar to that of shale (Zoback 2007). Therefore, Eq. (4) for shale was used in this study for claystone and mudstone formations. The results of the internal friction angle are given for each formation penetrated by the SDX-5 wellbore in Table 2.

Physical and mechanical parameters of rock formation

Compressional and shear wave velocities

Computing reservoir parameters improves the accuracy of various reservoir properties calculated (Gholami Vijouyeh et al. 2022; Nasrnia et al. 2023). Vp is derived by applying Eq. 7.

where Δtp is the P wave transit time (microseconds per foot).

Shear-wave well log data were only recorded over certain depth sections, so shear-wave velocity (Vs) could only be calculated directly for those recorded depths. Therefore, considering the compressional wave velocity to shear wave velocity ratio (Vp/Vs) for those recorded depths, a formulaic relationship was established (Eq. (8)) and applied to estimate Vs for the depth sections lacking recorded shear-wave sonic data.

where Vs is the shear wave velocity (kilometre per seconds).

Missing density log recorded values were computed by applying the widely used Gardner's Eq. (9) (Gardner et al. 1974).

where ∝ and β are constants. According to the Gardner approach, β is considered to be 0.25 and ∝ depends on the Vp units involved. If the Vp unit is m/s, ∝ should be 0.23, whereas if the Vp unit is km/s, ∝ should be 1.74 (Gardner et al. 1974). Formation water density for the depth interval 0 to 550 m in wellbore SDX-5 was assumed to be 1.1 (Zoback 2007).

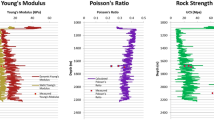

Elastic moduli

The mechanical properties of the rock formations can be measured directly from laboratory and downhole tests (Fjaer et al. 2008). Laboratory tests on recovered core material from different wellbore depths provide direct measurements of strength metrics and static elastic behaviour. However, it is possible to determine dynamic elastic rock properties from continuous measurements of Vp and Vs using downhole well log data. Such downhole measurement methods derived from sonic-log recorded data provided a more continuous distribution of elastic properties over a larger depth interval than those which can typically be derived experimentally from core data. Due to the lack of core data and the loose (unconsolidated) nature of the sandstone formations in the studied area, it was not possible to measure static laboratory geomechanical data. Thus, establishing a correlation between static and dynamic data for this geomechanical study was not possible. Therefore, Eqs. (10), (11), (12), and (13) were applied to calculate Poisson ratio (ν), Young's modulus (E), shear modulus (G), and bulk modulus (K), respectively (Zoback 2007; Nauroy 2011; Schön 2011; Alipour Tabrizy and Mirzaahmadian 2012; Saxena et al. 2018):

Poisson's ratio is a dimensionless coefficient, reaching values as high as 0.2 for most sandstone samples. However, for other rock types, ν can vary from 0.3 to 0.35, depending on the prevailing temperature and pressure conditions of the reservoir (Zoback 2007).

where ρ is the density in gr/cm3, Vp and Vs are the P and S wave velocities (km/s), respectively. Δtp and Δts are P and S waves transit times in μs/ft and 1.34 × 1010 is a conversion factor for the units to be expressed in pounds per square inch (psi). To calculate uniaxial compressive strength (UCS), several equations are recommended for a range of rock types (Yasar and Erdogan 2003; Tercan et al. 2005; Kılıç and Teymen 2008; Moradian and Behnia 2009; Diamantis et al. 2009; Altindag 2012). In this study, based on reservoir rock lithology, Eq. 14 (Kahraman 2001) was employed.

Pore pressure (Pp)

The Eaton method (Eaton 1969) was applied to estimate pore pressure values in this study. Based on Eq. (15), there is a relation between pore pressure and sonic wave transit time. Pore pressure leads to the prediction of hazard factors of well drilling such as sand production, wellbore stability, hydrocarbon migration and formation fluid migration.

where \(S_{{\text{g}}}\) is the overburden pressure gradient, Png is the hydrostatics pore pressure gradient, Δto is the observed sonic-wave transit time, Δtn is the sonic-wave transit time for shale in normal pressure conditions, and x is a constant exponent, which is set to 3 based on Eaton’s results (Eaton 1969).

The orientation and magnitude of stress in wellbore SDX-5

Anderson’s theory

Local stresses around a wellbore before reservoir development and production outset are referred to as "in situ" stresses. To specify the total in situ stress tensor, the magnitude and orientations of the principal stresses are required. One of those principal stresses is oriented approximately vertically (Sv), with its value determined by the weight of the overlying rocks (sediments in this case) plus that of the formation fluids present. Due to the orthogonal relationships between the principal stresses, the two other principal stresses (maximum horizontal stress (SHmax) and minimum horizontal stress (Shmin)) are positioned at right angles to each other on a horizontal plane, both being at right angles to Sv. The Anderson classification scheme (Anderson 1951) considers the relative magnitudes of the three principal tectonic stresses at depth (Sv (vertical stress), SHmax, and Shmin). Those relationships can be used to establish the orientations and types of faults likely to form (normal, strike-slip, and reverse) in different stress regimes.

Fault stress regime in wellbore SDX-5

Regional-scale geological tectonic movements generated by large-scale plate tectonic interactions influence rock mechanic stress directions at specific locations (Amadei and Stephansson 1997; Hudson and Harrison 1997; Fairhurst 2003; Zang and Stephansson 2010; Hudson 2012; Stephansson and Zang 2012). Determining the direction and magnitude of in situ stresses provides important information for planning and conducting drilling and wellbore completions (Zoback 2007; Aadnoy and Looyeh 2011). For sand-production predictions, the orientations and magnitudes of in situ stresses need to be determined. For this purpose, data recorded by various methods, such as leak-off tests, extended leak-off tests (Raaen et al. 2006; Zoback 2007; Zhang and Roegiers 2010), mini-fracture tests (Haimson and Cornet 2003), micro-fracture tests, dipole shear imager (well log), and full-bore formation micro imager (well log), can be utilised. As the rock mechanical laboratory tests were not conducted for wellbore SDX-5, the pro-elastic equations (Eqs. 16 to 18) were used as an alternative to determine the magnitude of principal stresses (Abdideh and Hamid 2019). Two reverse faults have been previously identified crossing the Shah-Deniz structure, leading to the conclusion that the predominant stress regime is compressive (Fowler et al. 2000). The reverse fault on the west flank limb of the structure has resulted in strong folding of the productive series present. On the other hand, the Shah-Deniz structure is also affected by a deep thrust fault within the pre-Oligocene section. Nevertheless, these two fault systems do not appear to be directly connected (Fowler et al. 2000) (Fig. 4).

A schematic cross section of the Shah-Deniz structure displaying structural influences from deep thrust faulting and shallow reverse faulting (after Fowler et al. 2000)

Orientation of in situ stresses in the study area

Information from the World Stress Map (Heidbach et al. 2018) and Bonini's studies was used to determine the stress orientations in wellbore SDX-5 (Bonini and Mazzarini 2010; Bonini 2012). In these studies, the near-surface mud volcanoes of the Shah-Deniz structure were investigated. The in situ stress orientations were obtained through their association with the shortening and elongating of mud volcano calderas (Bonini 2012) (Fig. 5). Thus, SHmax axis cumulative analysis revealed the principal preferential direction to be oriented in the interval N20°–40°E with a central frequency peak close to N30°E (Bonini and Mazzarini 2010; Bonini 2012). The azimuth of N30°E expresses the orientation azimuth of the maximum horizontal stress (SHmax). According to the rose diagrams presented in Bonini’s study, a secondary cluster (with 10° tolerance) was identified with a ~ N 110°–120°E trend from mud-volcano analysis and the World Stress Map. That secondary orientation cluster represents the azimuth of the minimum horizontal stress (Shmin) (Heidbach et al. 2010, 2018; Bonini and Mazzarini 2010; Bonini 2012) (Fig. 6).

(Adapted from Moffat and Randle 2009)

The position of the SDX-5 well with reverse faulting on the tectonic structure of Shah-Deniz

A satellite image of the Shah-Deniz field location in relation to the Azerbaijan coastline. The stereonet circle centre is accurately placed on the position of the SDX-5 wellbore to clearly illustrate the maximum horizontal stress (SHmax) and minimum horizontal stress (Shmin) orientations associated with the reservoirs in that wellbore

The magnitude of in situ stresses in SDX-5

The magnitude of vertical stress in offshore areas can be derived by applying Eq. (16) (Zoback 2007):

where ρ(z) is the density log readings (as a function of TVD), ρw is the density of sea water, zw is water depth, g is the gravitational acceleration of the earth and \(\overline{\rho }\) is the overburden density average (Jaeger and Cook 1971; Zoback 2007). Furthermore, the magnitudes of SHmax and Shmin can be derived by applying Eqs. (17) and (18), respectively (Zoback 2007). To calculate Shmin, the average of the vertical stress and the maximum horizontal stress was used.

where α is the Biot coefficient, ν is the Poisson's ratio, Pp is the pore pressure, E is the static Young's modulus, and εh and εH are the strains in the direction of Shmin and SHmax, respectively. In the absence of direct methods to measure strain, such as wellbore leak-off tests, the strain values are typically estimated using trial-and-error methods. To this end, the strain values determined for SDX-5 using a trial-and-error method were selected as those that best corroborated the response of the compressive stress regime and Anderson's theory applied to the wellbore data. The x and y strain values determined in this way are 0.00782329 and 0.0000999, respectively. Based on theoretical considerations and trial-and-error analysis, a Biot coefficient of 1 was applied (Biot 1941, 1962; Zhang 2011). The determined value trends of maximum and minimum horizontal stress magnitudes, vertical stress, and pore pressure (all expressed in psi units) are displayed relative to true vertical depth in Fig. 7.

Maximum and minimum horizontal stresses, vertical stress, and pore pressure (psi) values versus true vertical depth in metres for wellbore SDX-5. SHmax values are greater than Shmin. Also, Shmin values are greater than the vertical stress. According to Anderson's theory, the stress regime impacting SDX-5 is therefore interpreted to be compressive

A synopsis of the computed geomechanical variables applying the mentioned methods to the SDX-5 wellbore data is presented in Table 3. The gradient of each parameter was determined by Eq. (19).

where x represents the parameter for which the gradient was calculated.

Results

Geomechanical and physical parameters were calculated using the mentioned equations, which are demonstrated in Table 3. Each calculated value of a formation’s geomechanical parameter in Table 3 is the average value of all depth intervals in that formation. In other words, these geomechanical parameters were determined for each depth interval, and the average value was computed. As regards physical parameters, the gradient values (Eq. 19) of all depth intervals were obtained (Table 3).

Sand production begins when the critical collapse pressure exceeds the pore pressure (Aadnoy and Looyeh 2011). Also, the fundamental factor that influences gas and/or oil production into the wellbore from the reservoir formation is the drawdown pressure. Hence, a pressure difference between the reservoir formation and the wellbore must exist for flow from the formation to occur. Assuming that the reservoir is large, and the pressure of the reservoir is supported, it can be considered approximately invariant. On the other hand, the wellbore can be considered a pressure-evacuated environment. These conditions lead to the natural flow of formation fluids from the relatively high-pressure reservoir into the wellbore at a much lower pressure. However, good field operational management prevents the effective drawdown pressure (i.e. reservoir pressure minus flowing wellbore pressure) from becoming too high to minimise formation damage and adjusts it so that the pressure difference between the wellbore and the reservoir is not too high.

The formation collapse pressure, or maximum sand-free drawdown pressure (MSFDDP), is the critical pressure of formation fluid production into a wellbore. Indeed, when fluid production pressure is equal to or higher than the critical collapse pressure, even though for a time it would lead to an increase in the amount of fluid flow from the reservoir into the wellbore, sand particles from the reservoir formation would likely also be produced into the well simultaneously. When the formation collapse pressure is low, the production pressure applied should be maintained below it to prevent sand production. However, when the production pressure exceeds the collapse pressure, sand will enter the fluid flow stream in the wellbore. On the other hand, when the formation collapse pressure is high, a fluid production pressure can be applied just below that collapse pressure without sand production into the wellbore. Hence, by carefully managing drawdown pressure to maintain fluid production pressure below the formation’s collapse pressure, sand production into a wellbore can be minimised. A formation’s collapse pressure value typically exists somewhere between the formation’s pore pressure and its maximum horizontal stress value.

All the graphical trends presented in the following figures relate to the prediction of sand production from the Balakhany formation in wellbore SDX-5 (i.e. depth interval 4879.23 m to 5769.5 m). The Balakhany formation is one of the most productive reservoir formations (Yilmaz and Isaksen 2007) in the Shah-Deniz field.

Azimuth plot

The azimuth plot (Fig. 8) is used to demonstrate the highest and lowest probability of sand production for different wellbore azimuths (trajectory orientations). The horizontal and vertical axes indicate the azimuth values (from 0 to 360 degrees) and collapse pressure (psi), respectively. Every point on the stratigraphic column (depth column) in the azimuth plot can present a specific azimuth for each formation. This study focuses on the Lower Balakhany formation, and, as an example, the derived azimuth plot relating to the depth of 18,825 ft (TVD) of this formation is displayed in Fig. 8.

Azimuth plot for the lower Balakhany Formation (mostly sandstone) at the depth of 18,825 ft (TVD) in wellbore SDX-5. TVD refers to true vertical depth, MD refers to measured depth, and Cp and φp are the cohesion and internal friction angle values, respectively. E is the static Young's modulus (psi), v is the Poisson’s ratio, A is the Biot coefficient, and Pr grad is the pore-pressure gradient. Field observation data of sand production related to stress orientation would provide the most definitive analysis. However, as direct field observation data were lacking, the default base case considers well azimuth information instead

Inclination plot

The inclination plot (Fig. 9) illustrates the optimum inclination for wellbore drilling to prevent sand production. The vertical axis shows collapse pressure values (psi), and the horizontal axis displays the wellbore inclination angles from zero to 90°. The wellbore inclination is the angle of the wellbore trajectory relative to the vertical position of the well. In other words, this angle is the value of the deviated angle from the upright state of a well. An inclination angle of zero° in Fig. 9 represents a vertical well, whereas a 90° inclination angle represents a horizontal well. Every point on the stratigraphic column in the inclination plot can present a specific inclination for each of the formations. The obtained inclination plot is related to the depth of 18,825 ft (TVD) of this formation.

Inclination plot for the lower Balakhany Formation in wellbore SDX-5. TVD refers to true vertical depth, MD is measured depth, Cp is the cohesion value, and φp is the internal friction angle. E is the static Young's modulus (psi), V is Poisson’s ratio, A is the Biot coefficient, and Pr grad is the pore-pressure gradient. The base case shows the stability of the well with respect to sand production at this point. It indicates the optimal inclination for well drilling to prevent sand production. However, due to a lack of field observation data, the default base case related to well inclination was considered the base case for this research

Polar plots for collapse pressure and drawdown pressure

Polar plots combine inclination and azimuth with colour-contoured pressure data (critical points for sand production). They are applied to illustrate risk values for various wellbore trajectories and stereographic projections of poles to discontinuities. The centre of the polar plot represents a 0° wellbore trajectory inclination angle relative to the vertical position. Each of the circles displayed on the polar plot (from the centre to the outside) represents a 30-degree change in the inclination of the well. The outermost circle represents a 90° inclination to the vertical position (i.e. a horizontal wellbore trajectory). The top of the polar plot is marked with an N (North) and displays a zero-degree azimuth. Each radial line (from N = 0° to 360° rotation) presents a 30-degree variation in the azimuth. Each point with various colours on this plot shows the critical pressure for sand production. As explained, the fluid production pressure should not exceed these critical pressure values. If it does, sand will be produced into the wellbore. Moreover, polar plots are capable of indicating the azimuth and inclination of any specific depth (either true vertical depth or measured depth) on the depth column (shown to the left of each plot) simultaneously. Indeed, each point on the depth column (stratigraphic column) shows the collapse pressure values simultaneously with the inclination and azimuth specific to that depth (for each formation).

The polar plots for drawdown pressure (Fig. 10b and d) are expressed as negative pressure values. These values indicate the pressure difference between the reservoir pressure and the bottom hole pressure of the wellbore to flow fluids from the reservoir into the wellbore.

Polar plots showing the effect of wellbore trajectory on collapse pressure and collapse drawdown pressure for the lower Balakhany formation (a, b) and the upper Balakhany formation (c, d) wellbore SDX-5. The collapse and collapse drawdown pressures are expressed in psi units. The direction of minimum horizontal in situ stress is indicated by an arrow (↑)

Depth profile graphs

The depth profile graphs (Figs. 11 and 12) display pressure and risk of sand production in terms of wellbore depths expressed as TVD (ft). The horizontal axis of these graphs indicates the values of collapse pressure (psi). The vertical axis also demonstrates the depths of all formations with a true vertical depth scale expressed in feet.

Depth profile graph of instantaneous drawdown pressure (x axis) for all formations penetrated by wellbore SDX-5. The red curve indicates the borehole collapse pressure. The wellbore inclination changed significantly as the wellbore progressed through the Surakhany Anhydrite into the Upper Surakhany Formation, as shown on the right side of the graph

Depth profile of critical sanding collapse pressure

Since all existing pressures are related to the fluid column pressure of the Caspian Sea Sedimentary Basin, the in situ stress values should be greater than the pore pressure values, which is the case in Figs. 11 and 12. On the right side of Figs. 11 and 12, the wellbore inclination variations of the SDX-5 well are illustrated in TVD terms. It is apparent that the wellbore inclination increased rapidly as it penetrated the Surakhany anhydrite formation, reaching 34 degrees by the time it entered the Upper Surakhany formation.

Depth profile of critical sanding in terms of instantaneous drawdown pressure

Figure 12 displays the instantaneous drawdown pressure (red curve) versus depth for the SDX-5 wellbore. This pressure represents the instantaneous drawdown pressure required to generate sand production from the formations. From a well-bore shut-in condition, the enhancement of reservoir flow should be induced slowly by gradually introducing pressure drawdown, taking care not to exceed the red curve displayed in Fig. 12.

Discussion

The South Caspian Basin is one of the largest basins of petroleum resources in the world. However, this basin involves difficult conditions for oil and gas exploitation due to deeper water conditions compared to the North Caspian Basin. As a result, the drilling and exploitation of petroleum resources are more costly and problematic. The Shah-Deniz field is strategically important because it supplies substantial quantities of natural gas to Europe. Nevertheless, studies of sand production and stability problems in the South Caspian basin have not been conducted, introducing substantial uncertainty regarding optimum well designs. The presence of unconsolidated sediments and formations, together with the activity along the Apsheron-Balkhan active fault zone, have magnified drilling and production problems. Moreover, due to substantial water depths (more than 500 m), the presence of calcareous oozes in the upper formations, and the deep-water unconsolidated sandstone reservoir of the Shah-Deniz structure, the possibility of rock failure and sand production increases during the drilling and production. Therefore, based on the results of the mechanical earth model (including magnitudes, orientations of stresses, pore pressure, and elastic modulus) and the application of the failure criterion, a series of plots for sand production analysis were generated. These plots make it possible to identify the optimum drilling azimuth and inclination, critical collapse pressures, and fluid discharge rates.

The azimuth plot generated for the lower Balakhany Formation (Fig. 8) reveals that for 120 and 300-degree azimuths (i.e. parallel to Shmin), the collapse pressure reaches its lowest value (25,825 psi). Hence, the possibility of producing sand is most likely to occur if wellbores are drilled with trajectories following those azimuths. However, for wellbore azimuths of 30 and 210 degrees (i.e. parallel to SHmax), the collapse pressure reaches its maximum value (26,500 psi) and leads to the lowest probability of producing sand (Fig. 8). From the inclination plot (Fig. 9), at a 0° inclination angle (the vertical well through the SDX-5 reservoir), the collapse pressure reaches its lowest level (25,525 psi). Therefore, the potential for sand production is high. However, as the inclination of the wellbore increases, the collapse pressure also increases, and the potential for sand production decreases.

Considering the polar plots in terms of collapse pressure, following azimuths of 120° and 300° (parallel to Shmin), a well trajectory with an inclination angle of 0° to 45° relative to the vertical position of the well shows the lowest collapse pressure value (the trajectory most likely to experience sand production). On the other hand, following azimuths of 30 and 210 degrees (parallel to SHmax), a well trajectory with an inclination angle of 75 to 90 degrees relative to the vertical position displays the highest collapse pressure value (the trajectory least likely to experience sand production) (Fig. 10a). The polar plots reveal that for wellbore trajectories of any azimuth, if the inclination of the wellbore is approximately vertical or close to vertical (parts marked in blue), collapse pressure is low, and the probability of sand production is high. On the other hand, increasing the well inclination towards the horizontal acts to reduce the sand production risk due to the enhancement in the collapse pressure values. As regards azimuth, the most favourable azimuth to prevent or minimise the risk of sand production at the Wellbore SDX-5 location is the azimuth of N30E due to the relatively high collapse pressure values associated with that trajectory. The blue ellipsoid on the polar plots (parallel to Shmin) highlights the azimuth with the highest potential for sand production. Every point in the blue ellipsoid has high sand production potential. On the other hand, zones on the polar plots displaying red colours are those with the highest collapse pressure values (about 29,177 psi for the lower Balakhany formation and 33,305 psi for the upper Balakhany formation, at the SDX-5 location), have low sand production potential. Generally, each point on the polar plot is considered a critical pressure in analysing the potential of sand production. For the Balakhany formation at the SDX-5 location, if the wellbore is vertical, the production pressure value (to avoid or minimise sand production) should not exceed 25,549 psi for the lower Balakhany and 28,719 psi for the upper Balakhany. If the production pressure exceeds these values, sand will be produced simultaneously with fluid production into the wellbore. For horizontal well trajectories, production pressure values (to avoid or minimise sand production) should not exceed 29,177 psi for the lower Balakhany formation and 33,305 psi for the upper Balakhany formation (Fig. 10a and c).

The polar diagrams constructed in terms of collapse drawdown pressure related to the lower Balakhany formation show that for a vertical wellbore trajectory, the drawdown pressure of the wellbore should be 15,795 psi less than the reservoir pressure to flow fluid from the reservoir into the well (Fig. 10b). On the other hand, for a horizontal well trajectory, the drawdown pressure should be 19,365 psi lower than the reservoir pressure to produce the hydrocarbon from the formation to the well (Fig. 10b). With respect to the Upper Balakhany formation, it is apparent that the collapse pressure values are lowest for wellbore trajectories with azimuths of 120° and 300° (parallel to Shmin) and 0° (vertical) to 50° inclination. On the other hand, wellbore trajectories following azimuths of 30° and 210° (parallel to the direction of SHmax) with inclinations of 0° (vertical) to 15° have the highest probability of sand production for such trajectories, whereas wellbore inclinations close to 90° (horizontal) have the lowest probability of sand production (Fig. 10c). The more the well inclination deviates from the vertical position and becomes inclined towards the horizontal, the more the risk of sand production decreases. From the polar plot for drawdown pressure for the Upper Balakhany formation, for vertical and horizontal well trajectories, the drawdown pressure should be 20,825 and 25,334 psi less than the reservoir pressure to flow fluid from the reservoir into the well, respectively (Fig. 10d).

According to the depth profile of critical sanding collapse pressure, the formation pressure values (orange curve, Fig. 11) are intrinsically less than the magnitude of Sv (green curve). Moreover, the Shmin values (blue curve) are higher than the Sv values, and the SHmax values (black curve) are higher than the Shmin values. These relationships are consistent with the compressional stress regime impacting wellbore SDX-5. Considering the collapse pressure curve (red curve), when the reservoir fluid flow pressure values are lower than the collapse pressure curve, reservoir fluid production occurs without the production of sand. However, by increasing the pressure drawdown and crossing the red curve, sand grains would be produced in the wellbore along with reservoir fluids (Fig. 11). Furthermore, the depth profile of critical sanding pressure (instantaneous drawdown pressure) indicates that the risk of sand production is high for the Upper and Lower Balakhany formations in the SDX-5 well (low instantaneous drawdown pressure values). Therefore, it is prudent not to increase pressure drawdown beyond those values in order to avoid sand production. Indeed, increasing the drawdown pressure should be performed slowly (Fig. 12).

By determining the orientation and magnitude of the in situ stresses, strains, physical and mechanical rock formation parameters, and other required factors, the optimum drilling azimuth and inclination, the critical sanding collapse pressure, the production pressure, the optimum discharge rate of produced clean hydrocarbon (without sand), the collapse drawdown pressure, and the instantaneous drawdown pressure can be determined. Therefore, the method can be applied to optimise the trajectories of future development wells in the Shah-Deniz gas field to minimise sand production. Moreover, the method described can be applied to plan development wells in other fields based on a rigorous analysis of the prevailing stress regime.

A complete set of well-log data were available for the studied SDX-5 well, making it possible to conduct the analysis in the absence of core data. It is impossible to recover cores from the poorly consolidated sands making up the reservoir section of the Shah-Deniz field. This lack of core data means that static versus dynamic relationships could not be established for several of the geomechanical variables derived. Nevertheless, the method applied generated more accurate results. Future studies are required for other fields with both core and well-log data available to identify whether the geomechanical variable values measured from cores and calculated from well-logs provide consistent results in terms of sand production potential.

The models generated could be further improved with additional measurements and experimental data. For example, components of the coherence and angle of internal friction obtained through three-axis compression tests would provide valuable information to further refine the geomechanical numerical approach. Also, FMI image log data, non-catastrophic failures during drilling (e.g. breakouts), hydraulic fracturing data, leak-off tests, and pressure while drilling data would all assist in verifying the stress orientation calculations. However, in most fields, such data are only available for some of the wells and formations.

Conclusions

The determination of optimum azimuth and inclination along with the quantification of the values of various critical collapse pressures show that the risks of sand production can be reduced considerably during drilling and production operations by applying the Mohr–Coulomb failure criterion to unconsolidated formations in the Shah-Deniz field. According to the calculated results of the mechanical earth model (rock mechanical and physical parameters), the proposed numerical systematic approach adopted in this study predicted most of the significant factors to prevent these prevalent issues in oil and gas fields. It can, therefore, be applied in future development programs of this well or other fields. Also, the results obtained highlight that the direction and magnitude of tectonic stresses around the borehole represent the most important parameters for predicting the sand production potential, especially those that are located in active tectonic zones. The key conclusions drawn are:

-

1.

The magnitude of SHmax values is larger than Shmin values and is also larger than Sv values. Therefore, the Shah-Deniz gas field is affected by a compressional stress regime, and this result confirms the recent deformation of the region and seismic activities based on various studies that have identified a prevailing reverse fault regime.

-

2.

Obtaining information about the azimuth and inclination of stresses using sub-surface data recording methods such as well-logging data can be more reliable and affordable and provide continuous results than experimental/laboratory measurement on limited core and well-test data, particularly for reservoirs composed of unconsolidated formations.

-

3.

The optimum drilling azimuth to reduce wellbore failure potential and sand production risks in the wellbore SDX-5 location of the Shah-Deniz gas field, offshore Azerbaijan, was determined to be parallel to the direction of maximum horizontal stress in order to produce clean, sand-free petroleum (the azimuth of 30 and 210 degrees).

-

4.

Vertically oriented wellbores tend to produce more sand than high-angled wellbores. For highly deviated wellbores, the risk of sand production is much reduced due to the high collapse pressure values. As a result, near-vertical well designs are sub-optimal for drilling in the Shah-Deniz field.

-

5.

Polar plots (collapse pressures) can provide simultaneous results for critical collapse pressure values and optimal (safe) wellbore azimuth (parallel to SHmax) and inclination (typically high-angle / near-horizontal) for drilling designs. The results show that high collapse pressures provide safer drilling conditions more likely to result in high fluid production rates and low sand production risks.

-

6.

Polar plots (critical collapse drawdown pressure) are also useful for expressing the difference between the wellbore drawdown pressure and reservoir pressure assisting in the prevention of sand production during petroleum production. These values are most usefully expressed as negative numerical values for each formation and indicate how much drawdown pressure must be lower than reservoir pressure to flow petroleum effectively from the reservoir into the well. By knowing the critical collapse drawdown pressure, it is possible to plan drilling strategies that control wellbore sand production during drilling and production processes.

-

7.

Simultaneous determination of critical sanding collapse pressure and critical sanding pressure for instantaneous drawdown values of all formations suggests that wellbore flow pressure values should not exceed the limiting pressure values revealed by interpreting the borehole collapse pressure curve. If that occurs, sand will be produced during drilling and production operations. Moreover, it is possible to establish optimum reservoir fluid production (maximum discharge) rates to impose as upper limits in order to prevent sand production into the wellbore. In addition, the impacts of changes in instantaneous wellbore pressure suggest that any increases to production flow pressure should be applied gradually during wellbore production.

Abbreviations

- ACG:

-

Azeri–Chirag–Gunashli

- C :

-

Cohesion (psi)

- Dtco :

-

P wave transit time (μs/ft)

- Dts :

-

S wave transit time (μs/ft)

- E :

-

Young's modulus (psi)

- FMI:

-

Electrical Micro Imager

- \(g\) :

-

Gravitational acceleration of earth (m/s2)

- G :

-

Shear modulus (psi)

- K :

-

Bulk modulus (psi)

- KS:

-

Kirmaky Suite

- MA:

-

One-million years

- MPa:

-

Mega pascal

- MSFDDP:

-

Maximum sand-free drawdown pressure

- NKG:

-

Above-Kirmaky Shale

- NKP:

-

Above-Kirmaky Sandstone

- PK:

-

Under-Kirmaky Suite

- P ng :

-

Hydrostatics pore pressure gradient (psi/ft)

- P p :

-

Pore pressure (psi)

- P pg :

-

Formation pressure gradient (psi/ft)

- psi:

-

Pounds per square inch

- P w :

-

Internal wellbore pressure (psi)

- RHOB:

-

Density log (gr/cm3)

- S g :

-

Overburden pressure gradient (psi/ft)

- SHmax :

-

Maximum horizontal stress (psi)

- SHmin :

-

Minimum horizontal stress (psi)

- S v :

-

Vertical stress (psi)

- TVD:

-

True vertical depth (m)

- UCS:

-

Uniaxial compressive strength (MPa)

- V p :

-

Compressional wave velocity (km/s)

- V s :

-

Shear wave velocity (km/s)

- x :

-

Constant exponent (Eaton’s equation) = 3

- Z :

-

Depth (m)

- Z w :

-

Water depth (m)

- ∝ :

-

Experimental constant component (Gardner's equation) = 1.74

- α :

-

Biot coefficient

- Β :

-

Experimental constant component (Gardner's equation) = 0.25

- Δt o :

-

Observed sonic wave transit time (μs/ft)

- Δt n :

-

Sonic waves transit time for shale in normal pressure conditions (μs/ft)

- Δt p :

-

P wave transit time (μs/ft)

- Δt s :

-

S wave transit time (μs/ft)

- ε H :

-

Strain in the direction of SHmax (m)

- ε h :

-

Strain in the direction of Shmin (m)

- μs/ft:

-

Microseconds per foot

- ν :

-

Poisson ratio

- ρ :

-

Density (gr/cm3)

- \(\overline{\rho }\) :

-

Overburden density average (gr/cm3)

- ρ w :

-

Density of water (gr/cm3)

- ρ (z) :

-

Density (as a function of the true vertical depth) (gr/cm3)

- σ 1 :

-

Maximum principal effective stress (psi)

- σ 3 :

-

Minimum principal effective stress (psi)

- σ n :

-

Normal stress (psi)

- τ :

-

Shear stress (psi)

- τ max :

-

Used shear stress (psi)

- τ mohr :

-

Shear stress of the rock (psi)

- φ :

-

Internal friction angle (degrees)

- \(\emptyset\) :

-

Porosity

References

Aadnoy B, Looyeh R (2019) Petroleum rock mechanics: drilling operations and well design. 2nd edn. Gulf Professional Publishing. https://doi.org/10.1016/C2017-0-03371-2

Aadnoy B, Looyeh R (2011) Petroleum rock mechanics: drilling operations and well design. 1st edn. Gulf Professional Publishing. https://doi.org/10.1016/C2009-0-64677-8

Aadnoy BS, Kaarstad E (2010) Elliptical geometry model for sand production during depletion. In: IADC/SPE Asia pacific drilling technology conference and exhibition. Society of Petroleum Engineers, Ho Chi Minh City, Vietnam, Accessed 1–3 November. https://doi.org/10.2118/132689-MS

Abdideh M, Hamid Y (2019) An evaluation of rock integrity and fault reactivation in the cap rock and reservoir rock due to pressure variations. Iran J Oil Gas Sci Technol 8:18–39

Abreu V, Nummedal D (2007) Miocene to quaternary sequence stratigraphy of the south and central caspian basins. In: Yilmaz PO, Isaksen GH (eds) Oil and gas of the greater caspian area. American Association of Petroleum Geologists, pp 1–22. https://doi.org/10.1306/1205845St553000

Aftab S, Moghadam RH (2022) Robust data smoothing algorithms and wavelet filter for denoising sonic log signals. J Appl Geophys 206:104836. https://doi.org/10.1016/j.jappgeo.2022.104836

Al-Awad MNJ, El-Sayed A-AH, Desouky SE-DM (1999) Factors affecting sand production from unconsolidated sandstone saudi oil and gas reservoir. J King Saud Univ - Eng Sci 11:151–172. https://doi.org/10.1016/S1018-3639(18)30995-4

Alipour Tabrizy V, Mirzaahmadian Y (2012) Investigation of sand production onset: a new approach based on petrophysical logs. In: SPE international symposium and exhibition on formation damage control. Society of Petroleum Engineers, Lafayette, Louisiana, USA, Accessed 15–17 February. https://doi.org/10.2118/150529-MS

Altindag R (2012) Correlation between P-wave velocity and some mechanical properties for sedimentary rocks. J South Afr Inst Min Metall 112:229–237

Amadei B, Stephansson O (1997) Rock stress and its measurement, 1st edn. Springer, Dordrecht

Anderson EM (1951) The dynamics of faulting and dyke formation with applications to Britain. 2nd edn. Edinburgh, Oliver and Boyd

Ben Mahmud H, Leong VH, Lestariono Y (2019) Sand production: a smart control framework for risk mitigation. Petroleum. https://doi.org/10.1016/j.petlm.2019.04.002

Biot MA (1962) Mechanics of deformation and acoustic propagation in porous media. J Appl Phys 33:1482–1498. https://doi.org/10.1063/1.1728759

Biot MA (1941) General theory of three-dimensional consolidation. J Appl Phys 12:155–164. https://doi.org/10.1063/1.1712886

Bol GM, Wong S-W, Davidson CJ, Woodland DC (1994) Borehole stability in shales. SPE Drill Complet 9:87–94. https://doi.org/10.2118/24975-PA

Bonini M (2012) Mud volcanoes: indicators of stress orientation and tectonic controls. Earth-Sci Rev 115:121–152. https://doi.org/10.1016/j.earscirev.2012.09.002

Bonini M, Mazzarini F (2010) Mud volcanoes as potential indicators of regional stress and pressurized layer depth. Tectonophysics 494:32–47. https://doi.org/10.1016/j.tecto.2010.08.006

Bruno MS, Bovberg CA, Meyer RF (1996) Some influences of saturation and fluid flow on sand production: laboratory and discrete element model investigations. In: SPE annual technical conference and exhibition. society of petroleum engineers, Denver, Colorado, Accessed 6–9 October. https://doi.org/10.2118/36534-MS

Burton RC, Chin L, Davis ER, et al (2005) North slope heavy-oil sand-control strategy: detailed case study of sand-production predictions and field measurements for alaskan heavy-oil-multi-lateral field developments. In: SPE annual technical conference and exhibition. society of petroleum engineers, Dallas, Texas, Accessed 9–12 October. https://doi.org/10.2118/97279-MS

Clearly MP, Melvan JJ, Kohlhaas CA (1979) The effect of confining stress and fluid properties on arch stability in unconsolidated sands. In: SPE annual technical conference and exhibition. society of petroleum engineers, Las Vegas, Nevada, Accessed 23–26 September. https://doi.org/10.2118/8426-MS

Devlin WJ, Cogswell JM, Gaskins GM, et al (1999) The south caspian basin – young, cool, and full of promise. In: Second Wallace E. Pratt memorial conference “ petroleum provinces of the 21st century.” GSA Today, San Diego- California, pp 1–9, Accessed 11 December.

Diamantis K, Gartzos E, Migiros G (2009) Study on uniaxial compressive strength, point load strength index, dynamic and physical properties of serpentinites from Central Greece: test results and empirical relations. Eng Geol 108:199–207. https://doi.org/10.1016/j.enggeo.2009.07.002

Eaton BA (1969) Fracture gradient prediction and its application in oilfield operations. J Pet Technol 21:1353–1360

Elhaddad EEA, Reddy MM (2019) Formation of sand production control in an oil field, Libya. Int J Adv Res Eng Technol 2:81–85

Fairhurst C (2003) Stress estimation in rock: a brief history and review. Int J Rock Mech Min Sci 40:957–973. https://doi.org/10.1016/j.ijrmms.2003.07.002

Fattahpour V, Moosavi M, Mehranpour M (2012) An experimental investigation on the effect of rock strength and perforation size on sand production. J Pet Sci Eng 86–87:172–189. https://doi.org/10.1016/j.petrol.2012.03.023

Fjær E, Holt RM, Horsrud P, et al (2008) Mechanical properties and stress data from laboratory analysis. In: Fjær E, Holt RM, Horsrud P, et al (eds) Petroleum related rock mechanics, 2nd edn. Elsevier Science, pp 251–287. https://doi.org/10.1016/S0376-7361(07)53007-4

Fowler S, Mildenhall J, Zalova S et al (2000) Mud volcanoes and structural development on Shah-Deniz. J Pet Sci Eng 28:189–206. https://doi.org/10.1016/S0920-4105(00)00078-4

Gardner GHF, Gardner LW, Gregory AR (1974) Formation velocity and density; the diagnostic basics for stratigraphic traps. Geophysics 39:770–780. https://doi.org/10.1190/1.1440465

Gharagheizi F, Mohammadi AH, Arabloo M, Shokrollahi A (2017) Prediction of sand production onset in petroleum reservoirs using a reliable classification approach. Petroleum 3:280–285. https://doi.org/10.1016/j.petlm.2016.02.001

Gholami Vijouyeh A, Kadkhodaie A, Sedghi MH, Gholami Vijouyeh H (2022) A committee machine with intelligent experts (CMIE) for estimation of fast and slow shear wave velocities utilizing petrophysical logs. Comput Geosci 165:105149. https://doi.org/10.1016/j.cageo.2022.105149

Gui F, Khaksar A, Zee WV, Cadogan P (2016) Improving the sanding evaluation accuracy by integrating core tests, field observations and numerical simulation. In: SPE asia pacific oil & gas conference and exhibition. society of petroleum engineers, Perth, Australia, Accessed 25–27 October. https://doi.org/10.2118/182499-MS

Guo B, Song S, Ghalambor A, Lin TR (2014) General design information. In: Guo B, Song S, Ghalambor A, Lin TR (eds) Offshore pipelines - design, installation, and maintenance, 2nd edn. Gulf Professional Publishing, pp 13–20

Haimson BC, Cornet FH (2003) ISRM Suggested Methods for rock stress estimation—Part 3: hydraulic fracturing (HF) and/or hydraulic testing of pre-existing fractures (HTPF). Int J Rock Mech Min Sci 40:1011–1020. https://doi.org/10.1016/j.ijrmms.2003.08.002

Heidbach O, Rajabi M, Cui X et al (2018) The world stress map database release 2016: crustal stress pattern across scales. Tectonophysics 744:484–498. https://doi.org/10.1016/j.tecto.2018.07.007

Heidbach O, Tingay M, Barth A et al (2010) Global crustal stress pattern based on the World Stress Map database release 2008. Tectonophysics 482:3–15. https://doi.org/10.1016/j.tecto.2009.07.023

Hudson JA (2012) Design methodology for the safety of underground rock engineering. J Rock Mech Geotech Eng 4:205–214. https://doi.org/10.3724/SP.J.1235.2012.00205

Hudson JA, Harrison JP (1997) Engineering rock mechanics: an introduction to the principles, 1st edn. Elsevier Science, Oxford. https://doi.org/10.1016/B978-0-08-043864-1.X5000-9

Isehunwa SO, Olanrewaju O (2010) A simple analytical model for predicting sand production in a Niger Delta oil field. Int J Eng Sci Technol 2:4379–4387

Jackson J, Priestley K, Allen M, Berberian M (2002) Active tectonics of the South Caspian Basin. Geophys J Int 148:214–245. https://doi.org/10.1046/j.1365-246X.2002.01588.x

Jaeger JC, Cook NGW (1971) Fundamentals of rock mechanics. Chapman & Hall Ltd. & Science Paperbacks, Ex Library

Javani D, Aadnoy B, Rastegarnia M et al (2017) Failure criterion effect on solid production prediction and selection of completion solution. J Rock Mech Geotech Eng 9:1123–1130. https://doi.org/10.1016/j.jrmge.2017.07.004

Javanshir RJ, Riley GW, Duppenbecker SJ, Abdullayev N (2015) Validation of lateral fluid flow in an overpressured sand-shale sequence during development of Azeri-Chirag-Gunashli oil field and Shah-Deniz gas field: South Caspian Basin, Azerbaijan. Mar Pet Geol 59:593–610. https://doi.org/10.1016/j.marpetgeo.2014.07.019

Jones RW, Simmons MD (1997) A review of the stratigraphy of eastern paratethys (Oligocene—Holocene), with particular emphasis on the black sea. In: Robinson AG (ed) Regional and petroleum geology of the black sea and surrounding region. American Association of Petroleum Geologists, pp 39–51. https://doi.org/10.1306/M68612C4

Kahraman S (2001) Evaluation of simple methods for assessing the uniaxial compressive strength of rock. Int J Rock Mech Min Sci 38:981–994. https://doi.org/10.1016/S1365-1609(01)00039-9

Kalyuzhnova Y, Jaffe AM, Lynch D, Sickles RC (2002) Energy in the Caspian region: present and future. Palgrave Macmillan UK, London. https://doi.org/10.1057/9780230501225

Khamehchi E, Rahimzadeh Kivi I, Akbari M (2014) A novel approach to sand production prediction using artificial intelligence. J Pet Sci Eng 123:147–154. https://doi.org/10.1016/j.petrol.2014.07.033

Kılıç A, Teymen A (2008) Determination of mechanical properties of rocks using simple methods. Bull Eng Geol Environ 67:237–244. https://doi.org/10.1007/s10064-008-0128-3

Kurihara M, Sato A, Funatsu K, et al (2010) Analysis of production data for 2007/2008 Mallik gas hydrate production tests in Canada. In: International oil and gas conference and exhibition in China, IOGCEC. Society of Petroleum Engineers, Beijing, pp 2908–2931, Accessed 8–10 June. https://doi.org/10.2118/132155-MS

Lal M (1999) Shale stability: drilling fluid interaction and shale strength. In: SPE asia pacific oil and gas conference and exhibition. Society of Petroleum Engineers, Jakarta, Indonesia, Accessed 20–23 April. https://doi.org/10.2118/54356-MS

Lama RD, Vutukuri VS (1978) Handbook on mechanical properties of rocks: testing techniques and results, vol 2, 1st edn. Trans Tech Publications, Clausthal-zellerfieL

Li X-S, Xu C-G, Zhang Y et al (2016) Investigation into gas production from natural gas hydrate: a review. Appl Energy 172:286–322. https://doi.org/10.1016/j.apenergy.2016.03.101

Lu Y, Xue C, Liu T et al (2021) Predicting the critical drawdown pressure of sanding onset for perforated wells in ultra-deep reservoirs with high temperature and high pressure. Energy Sci Eng 9:1517–1529. https://doi.org/10.1002/ese3.922

Moffat A, Randle S (2009) Final well report, Shah-Deniz SDX-5/SDX-5Z/SDX-5Y, Geology and Mudlogging, by British Petroleum Ltd.

Mohr O (1900) Welche umstände bedingen die elastizitätsgrenze und den bruch eines materials (in German). Zeitschrift Des Vereines Dtsch Ingenieure 46:1524–1530

Moradian ZA, Behnia M (2009) Predicting the uniaxial compressive strength and static young’s modulus of intact sedimentary rocks using the ultrasonic test. Int J Geomech 9:14–19. https://doi.org/10.1061/(ASCE)1532-3641(2009)9:1(14)

Nasrnia B, Falahat R, Kadkhodaie A, Vijouyeh AG (2023) A committee machine-based estimation of shear velocity log by combining intelligent systems and rock-physics model using metaheuristic algorithms. Eng Appl Artif Intell 126:106821. https://doi.org/10.1016/j.engappai.2023.106821

Nauroy JF (2011) Geomechanics applied to the petroleum industry, 1st edn. Editions Technips / IFP Energies Nouvelles publications, Paris

Nouri A, Vaziri H, Kuru E, Islam R (2006) A comparison of two sanding criteria in physical and numerical modeling of sand production. J Pet Sci Eng 50:55–70. https://doi.org/10.1016/j.petrol.2005.10.003

Oyama H, Nagao J, Suzuki K, Narita H (2010) Experimental analysis of sand production from methane hydrate bearing sediments applying depressurization method. J MMIJ 126:497–502. https://doi.org/10.2473/journalofmmij.126.497

Palmer I, Mansoori J (1998) How permeability depends on stress and pore pressure in coalbeds: a new model. SPE Reserv Eval Eng 1:539–544. https://doi.org/10.2118/52607-PA

Papamichos E, Skjærstein A, Tronvoll J (2000) A volumetric sand production experiment. In: 4th North American rock mechanics symposium. American Rock Mechanics Association, Seattle, Washington, Accessed 31 July–3 August. Paper Number: ARMA-2000–0303

Perera MSA, Ranjith PG, Rathnaweera TD et al (2017) An experimental study to quantify sand production during oil recovery from unconsolidated quicksand formations. Pet Explor Dev 44:860–865. https://doi.org/10.1016/S1876-3804(17)30097-6

Pham ST (2017) Estimation of sand production rate using geomechanical and hydromechanical models. Adv Mater Sci Eng 2017:1–10. https://doi.org/10.1155/2017/2195404

Raaen AM, Horsrud P, Kjørholt H, Økland D (2006) Improved routine estimation of the minimum horizontal stress component from extended leak-off tests. Int J Rock Mech Min Sci 43:37–48. https://doi.org/10.1016/j.ijrmms.2005.04.005

Rahman K, Khaksar A, Kayes TJ (2010) An integrated geomechanical and passive sand-control approach to minimizing sanding risk from openhole and cased-and-perforated wells. SPE Drill Complet 25:155–167. https://doi.org/10.2118/116633-PA

Rahmati H, Jafarpour M, Azadbakht S et al (2013) Review of sand production prediction models. J Pet Eng 2013:1–16. https://doi.org/10.1155/2013/864981

Ranjith PG, Perera MSA, Perera WKG et al (2013) Effective parameters for sand production in unconsolidated formations: An experimental study. J Pet Sci Eng 105:34–42. https://doi.org/10.1016/j.petrol.2013.03.023

Renpu W (2011) Basis of well completion engineering. In: Renpu W (ed) Advanced well completion engineering, 3rd edn. Gulf Professional Publishing, pp 1–74. https://doi.org/10.1016/B978-0-12-385868-9.00001-4

Reynolds AD, Simmons MD, Bowman MBJ et al (1998) Implications of outcrop geology for reservoirs in the neogene productive series: Apsheron Peninsula, Azerbaijan. Am Assoc Pet Geol Bull 82:25–49. https://doi.org/10.1306/1D9BC38B-172D-11D7-8645000102C1865D

Salehi MB, Moghadam AM, Marandi SZ (2019) Polyacrylamide hydrogel application in sand control with compressive strength testing. Pet Sci 16:94–104. https://doi.org/10.1007/s12182-018-0255-9

Saxena V, Krief M, Adam L (2018) Rock strength and stress analysis. In: Saxena V, Krief M, Adam L (eds) Handbook of borehole acoustics and rock physics for reservoir characterization. Elsevier, pp 281–325. https://doi.org/10.1016/B978-0-12-812204-4.00008-3

Schön JH (2011) Elastic Properties (wave velocities, vp/vs-ratio and AVO parameters, fluid substitution, anisotropy). In: Schön JH (ed) Handbook of petroleum exploration and production: physical properties of rocks, Volume 8, 1st edn. Elsevier Science & Technology, pp 149–243. https://doi.org/10.1016/S1567-8032(11)08006-2

Shabdirova A, Minh NH, Zhao Y (2019) A sand production prediction model for weak sandstone reservoir in Kazakhstan. J Rock Mech Geotech Eng 11:760–769. https://doi.org/10.1016/j.jrmge.2018.12.015

Shahsavari MH, Khamehchi E, Fattahpour V, Molladavoodi H (2021) Investigation of sand production prediction shortcomings in terms of numerical uncertainties and experimental simplifications. J Pet Sci Eng 207:109147. https://doi.org/10.1016/j.petrol.2021.109147

Stephansson O, Zang A (2012) ISRM suggested methods for rock stress estimation—Part 5: establishing a model for the in situ stress at a given site. Rock Mech Rock Eng 45:955–969. https://doi.org/10.1007/s00603-012-0270-x

Subbiah SK, Samsuri A, Mohamad-Hussein A et al (2021) Root cause of sand production and methodologies for prediction. Petroleum 7:263–271. https://doi.org/10.1016/j.petlm.2020.09.007

Talaghat MR, Bahmani AR (2017) Sand production control in sandstone reservoirs using a modified urea-formaldehyde Re. Iran J Oil Gas Sci Technol 6:33–45. https://doi.org/10.22050/IJOGST.2017.47418

Tercan AE, Unver B, Tiryaki B, Özbilgin DA (2005) Study of relationships among mechanical, index and petrographic properties of some sandstones using canonical correlation analysis (in Turkish). Min 44:3–14

Tippie DB, Kohlhaas CA (1973) Effect of flow rate on stability of unconsolidated producing sands. In: Fall meeting of the society of petroleum engineers of AIME. Society of Petroleum Engineers, Las Vegas, Nevada, Accessed 30 September-3 October. https://doi.org/10.2118/4533-MS

Vásárhelyi B (2009) A possible method for estimating the Poisson’s rate values of the rock masses. Acta Geod Geophys Hungarica 44:313–322. https://doi.org/10.1556/AGeod.44.2009.3.4

Vaziri H, Xiao Y, Palmer I (2002) Assessment of several sand prediction models with particular reference To HPHT wells. In: SPE/ISRM rock mechanics conference. Society of Petroleum Engineers, Irving, Texas, Accessed 20–23 October. https://doi.org/10.2118/78235-MS

Volonté G, Scarfato F, Brignoli M (2013) Sand prediction: a practical finite-element 3D approach for real field applications. SPE Prod Oper 28:95–108. https://doi.org/10.2118/134464-PA

Wan RG, Wang J (2004) Analysis of sand production in unconsolidated oil sand using a coupled erosional-stress-deformation model. J Can Pet Technol. https://doi.org/10.2118/04-02-04

Weingarten JS, Perkins TK (1995) Prediction of sand production in gas wells: methods and Gulf of Mexico case studies. J Pet Technol 47:596–600. https://doi.org/10.2118/24797-PA

Willson SM, Moschovidis ZA, Cameron JR, Palmer ID (2002) New model for predicting the rate of sand production. In: SPE/ISRM rock mechanics conference. Society of petroleum engineers, Texas, USA, pp 152–160, Accessed 20–23 October. https://doi.org/10.2118/78168-MS

Wu B, Tan CP (2002) Sand production prediction of gas field - methodology and field application. In: SPE/ISRM rock mechanics conference. Society of Petroleum Engineers, Irving, Texas, Accessed 20–23 October. https://doi.org/10.2118/78234-MS

Xianjie Y (2003) Numerical and analytical modeling of sanding onset prediction. Dissertation, Texas A&M University, Available electronically from http://hdl.handle.net/1969.1/369

Xiong Y, Xu H, Wang Y et al (2018) Fluid flow with compaction and sand production in unconsolidated sandstone reservoir. Petroleum 4:358–363. https://doi.org/10.1016/j.petlm.2018.05.003

Xue S, Yuan Y (2004) Sanding process and permeability change. In: Canadian international petroleum conference. Petroleum Society of Canada, Calgary, Alberta, Accessed 8–10 June. https://doi.org/10.2118/2004-118

Xue S, Yuan Y (2007) Sanding process and permeability change. J Can Pet Technol 46:33–39. https://doi.org/10.2118/07-04-03

Yasar E, Erdogan Y (2003) Yapı-kaplamakayalarının P dalgahızı ile fiziko-mekanik özellikleri arasındaki ilişkilerin ist atikselanalizi (in Turkish). In: Türkiye IV. Marble Semposioum (mersem). pp 353–362

Yilmaz PO, Isaksen GH (2007) Oil and gas of the greater Caspian area. Am Assoc Pet Geol Tulsa, Oklahoma. https://doi.org/10.1306/St551205

Younessi A, Rasouli V, Wu B (2013) Sand production simulation under true-triaxial stress conditions. Int J Rock Mech Min Sci 61:130–140. https://doi.org/10.1016/j.ijrmms.2013.03.001

Zang A, Stephansson O (2010) Stress field of the earth’s crust, 1st edn. Springer, Dordrecht. https://doi.org/10.1007/978-1-4020-8444-7

Zhang J (2011) Pore pressure prediction from well logs: Methods, modifications, and new approaches. Earth Sci Rev 108:50–63. https://doi.org/10.1016/j.earscirev.2011.06.001

Zhang J, Roegiers J-C (2010) Discussion on “Integrating borehole-breakout dimensions, strength criteria, and leak-off test results, to constrain the state of stress across the Chelungpu Fault, Taiwan.” Tectonophysics 492:295–298. https://doi.org/10.1016/j.tecto.2010.04.038

Zoback MD (2007) Reservoir geomechanics, 1st edn. Cambridge University Press, Cambridge. https://doi.org/10.1017/CBO9780511586477

Acknowledgements

Khazar Exploration and Production Company (KEPCO) is acknowledged for the data preparation of this research. Ali Kadkhodaie is acknowledged for his help and cooperation during the preparation of this article.

Funding

The current research and the authors received no specific grant and financial support from any funding agency in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

AGV contributed to writing and edition, original draft preparation, software, methodology, and computation. MHS was involved in writing and edition, software, conceptualisation, methodology, and review. DAW performed the conceptualisation, review, and editing.

Corresponding author

Ethics declarations

Conflict of interest

All authors confirm that there are no competing financial interests or personal relationships that have influenced the work reported in this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Vijouyeh, A.G., Sedghi, M.H. & Wood, D.A. Prediction of wellbore sand production potential from analysis of petrophysical data coupled with field stress: a case study from the Shah-Deniz gas field (Caspian Sea Basin). J Petrol Explor Prod Technol 14, 761–784 (2024). https://doi.org/10.1007/s13202-023-01738-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-023-01738-8