Abstract

Electromagnetic (EM) radiation has long been recognized as an effective method for enhancing the quality and recovery of heavy and extra-heavy crude oil. The incorporation of EM absorbers, particularly nanoparticles, has demonstrated significant potential to boost efficiency and expand the stimulated reservoir volume. However, the application of simultaneous EM radiation and nanofluid injection in a natural porous medium, which is critical for the successful implementation of this approach in field-scale operations, remains an underexplored frontier. In this context, this research represents a pioneering endeavor, aiming to bridge this knowledge gap through a comprehensive statistical and optimization study. The primary objective was to unravel the intricate interplay between five distinct types of magnetic nanoparticles and their concentrations within the base fluid to improve oil production. Notably, it focused on iron oxide (Fe3O4) magnetic nanoparticles and their innovative hybridization with multi-walled carbon nanotubes (MWCNT) and nickel oxide (NiO) nanomaterial. A newly designed glass sandpack was employed as the porous medium, thus mirroring real reservoir conditions more accurately. Then, a rigorous full factorial design scrutinized the multifaceted effects of nanoparticle type and concentration when introduced into deionized water during this process. The results showed that microwave radiation, applied at 400 W, dramatically improved oil recovery, catapulting it from a baseline of 19% to an impressive 39.5% during water injection. The addition of magnetic nanoparticles to the base fluid enhances efficiency. However, the specific type of nanoparticle exerts varying effects on oil recovery rates. Notably, the synthesis of Fe3O4–MWCNT nanoparticles had a substantial impact on the ultimate oil recovery factor, achieving approximately 69%. Furthermore, the hybridization of Fe3O4 nanoparticles with MWCNT and NiO nanoparticles leads to reduced consumption (using low weight percentages) while achieving the highest oil recovery rates during the injection process. Finally, the optimization analysis demonstrated that employing 0.34 wt.% of Fe3O4–MWCNT nanoparticles under 400 W of microwave radiation represents the optimal condition for achieving the highest oil production in a sandpack porous medium. Under these conditions, the oil recovery factor can increase to 78%.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

EM radiation is a novel method to improve crude oil production from heavy and extra-heavy oil reservoirs (Taheri-Shakib and Kantzas 2021; Farshadfar et al. 2023). This method increases production from these reservoirs by directly radiating EM waves to the reservoir and converting EM energy into thermal energy as heat. This process is called the EM heating process (Bera and Babadagli 2015; Shafiai and Gohari 2020). The EM heating process generally relies on the preferential absorption of EM energy and increasing the temperature of dielectric materials (Hasanvand and Golparvar 2014). The ability of a substance to absorb EM waves depends on its molecular composition. The EM wave is applied to polar molecules. Dipole tails align themselves with the oscillating electric fields of EM waves. As a result, the oscillating polar molecule interacts with its neighbors and creates frictional heat that increases the medium temperature. The generated heat is then gradually distributed through other dielectric materials (Hassan et al. 2021; Li et al. 2021).

Dielectric heat loss and magnetic heat loss are the two dominant mechanisms of EM heating. The material’s inherent properties and ability to absorb one of the electric (E-field) or magnetic (H-field) terms of the EM wave determine the dominant heating mechanism. Interacting polar molecules (like water) or mobile charge carriers (like electrons or ions) with each other caused a dielectric heat loss. Magnetic heat loss further occurs by rotating magnetic moments inside the ferromagnetic substances (such as iron oxide). Therefore, the level of temperature rise in an EM heating process depends on the potential of the irradiated material to absorb EM energy (Li et al. 2014; Adil et al. 2017). Microwaves are a type of EM wave with high-frequency and short-wavelength waves ranging from 300 to 300,000 MHz (Rehman and Meribout 2012). The limited penetration depth of microwaves is the main challenge of using this technique, which reduces the stimulated volume in the reservoir. Using additional materials like nanoparticles as excellent microwave absorbers can help distribute heat better and more useful inside the reservoir (Carpenter 2021; Yadali Jamaloei 2022).

The magnetic material can absorb radiated EM energy and generate local heat inside the reservoir (Bera and Kumar 2022). Reducing the size of magnetic particles is one of the ways to increase their efficiency in absorbing EM waves. Nanoparticles have a high surface area, dispersing ability, mechanical and thermal resistance, and appropriate catalytic activity (Tohidi et al. 2022). So, nanoparticles can absorb radiated EM energy and transfer it to their surroundings through several mechanisms, such as conduction and convection in an oil reservoir (Hussain et al. 2007). Furthermore, adding other EM heating mechanisms to magnetic particles can improve their efficiency in the EM heating process. This work occurs when particles with suitable dielectric properties, such as carbon nanotubes, graphene, or metal oxide particles, are added to their structure (Duan and Guan 2016; Gharibshahi et al. 2020).

Previous studies have shown that nanoparticles can reduce the viscosity of crude oil (Adil et al. 2016; Mozafari and Nasri 2017). These materials can act as catalysts and cause the catalytic cracking of large crude oil molecules such as resins and asphaltenes (Ali et al. 2020a; Vakhin et al. 2021). Nanoparticles reduce the produced coke and sulfur content in crude oil and upgrade the crude oil, consequently (Nasri and Mozafari 2018; Taheri-Shakib et al. 2018; Gharibshahi et al. 2022b). They change the reservoir rock wettability (Lee et al. 2019; Armandi et al. 2021; Gharibshahi et al. 2022a), reduce the interfacial tension (IFT) between crude oil and injection fluid (Adil et al. 2020; Hasani and Jafari 2022), and, as a result, increase the oil recovery factor from the reservoir (Greff and Babadagli 2013; Zaid et al. 2014; Adil et al. 2018; Belhaj et al. 2019; Ali et al. 2020b). Despite all the efforts made, various challenges such as identifying and synthesizing the best nanoparticles for EM wave absorption, economical production of nanoparticles, the effect of size and concentration of nanoparticles on the heating mechanism and production of crude oil are facing the researchers to utilize this method at field-scale operations.

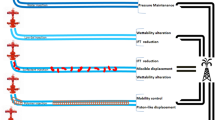

This research aims to find the mechanism of magnetic nanofluid injection under EM waves radiation in producing heavy crude oil reservoirs. The previous studies of the authors showed that various parameters, such as the time and power of EM radiation and the type and concentration of nanoparticles in the base fluid, can be effective on the crude oil production mechanisms (Gharibshahi et al. 2020, 2022a, b). In this study, the authors used the previous results to study sandpack flooding of microwave absorbent nanofluids under EM radiation and their effect on the oil recovery factor. For this purpose, a glass sandpack as the porous medium that can be exposed to microwaves was used to make the results closer to the injection condition in an actual field operation. Magnetic Fe3O4 nanoparticles and their hybridization with MWCNT and NiO nanomaterial synthesized via a co-precipitation approach were used as microwave absorbers. Finally, a full factorial design determined the best type of nanoparticles and their optimal concentration in the base fluid to reach the maximum oil recovery factor. Figure 1 illustrates the schematic of the experimental procedure in this study.

Materials and methods

Materials

The Fe3O4 nanoparticles and their hybridization with MWCNT and NiO nanoparticles were used. All of these nanostructure materials were synthesized via a co-precipitation method. Commercial MWCNT (lengths of 30 µm and outer diameter of < 8 nm) and NiO nanoparticles (diameter of 20 nm) were also purchased from US Research Nanomaterials to compare better and study the effect of hybridizing these nanoparticles with Fe3O4 nanoparticles. The average size of synthesized Fe3O4 nanoparticles and Fe3O4–MWCNT and Fe3O4–NiO nanohybrid was estimated at approximately 24, 30, and 40 nm, respectively. All nanoparticles were characterized through several analyses. Previous studies present the synthesis procedure details and the characterization analysis results (Gharibshahi et al. 2020, 2022a).

The aggregation of nanoparticles can diminish the absorption efficiency of EM energy. While only a small quantity of nanoparticles is employed in the EM heating process, enhancing the heating speed is possible by reducing nanoparticle size and ensuring their uniform dispersion within a porous medium, thanks to the significant surface-to-volume ratio. Therefore, to enhance the stability of these nanoparticles in the base fluid (DI water), their surface was modified by citric acid. The results demonstrated that all of these nanoparticles exhibited high colloidal stability. Sedimentation was first observed in these nanofluids after one week, although certain types, such as Fe3O4–MWCNT nanoparticles, remained stable for several months (Gharibshahi et al. 2020, 2022a). A crude oil sample from one of the Iranian heavy oil reservoirs saturated the porous medium. The properties of the heavy oil sample are given in Table 1.

The glass sandpack

In general, a metal core holder is needed to provide high operating overburden pressure to perform a core flood process. This system allows injection fluid to be injected into the core plug with high pressure. Placing any metal object inside the microwave oven as the EM radiation device causes sparks and fire. Also, any metal part inside the microwave oven will disrupt its operation. Therefore, a glass sandpack was used in this study due to safety issues. The schematic and dimensions of the glass sandpack for use as the porous medium are shown in Fig. 2. This porous medium was made of strong glass to allow waves to pass through. This container can withstand temperatures up to 500 °C.

Increasing the pressure of the reservoir reduces the attenuation and increases the penetration depth of the EM wave in the porous medium (Morte et al. 2018). It can increase the stimulated volume and reduce the cost of conducting an EM heating process in an oil reservoir. The diameter of the porous medium used in this research is small (4 cm). Therefore, the EM waves will penetrate to the full depth of the porous medium at atmospheric pressure. For this reason, the effect of reservoir pressure on the results of this study was ignored, and the injection tests were performed at ambient pressure.

Sandstone particles with an average diameter of 300 µm (range of 240–380 µm and standard deviation of 27 µm) were used to fill the sandpack and create a porous medium. For this purpose, after each addition of particles to the container, the sandpack containing the sandstone particles was shaken for 5 min using a vibrating device to ensure the packing of the sand inside it. This work continued until the sandpack was filled with sandstone particles. Using a sandpack is essential to measure the porosity and permeability. So, the sandpack was placed vertically, and distilled water was injected into it at the rate of 1 cm3/min. The porosity of the sandpack was obtained using the following equation:

Darcy’s relation (Eq. 2) and pressure drop along the sandpack were also used to measure the permeability as follows (Tooseh et al. 2017):

where μ is the viscosity of distilled water, L is the length of the sandpack (cm), Q is the injection rate (cm3/min), A is the cross-sectional area of the sandpack (cm2), and ∆P is the pressure difference between the two ends of the sandpack (atm.). Finally, for the injection processes inside the glass sandpack, the porosity was measured from 36 to 39% (average porosity of 37% and standard deviation of 1.05%), and the permeability was measured between 320 and 365 mD. Then, the porous medium was completely saturated with oil in the core aging system at 90 °C. The glass sandpack was left at this temperature for one week to restore oil-wet reservoir wettability before each injection process.

Experimental setup

In this project, a home microwave (Feller MW-305) at the frequency of 2.45 GHz was used as the EM radiation device. Some modifications were made to vary the radiation power of this device. Two sides (left and right) of the device were drilled so that the flow tubes of nanofluid injection and produced oil could be inserted into the microwave. A syringe injection pump (SP1000 Nanoscale Technologies Company) is also used to inject nanofluid into the porous medium. Finally, an EM wave leak detector controls the device’s safety and prevents the leakage of EM waves to the outside. The schematic of the experimental setup is shown in Fig. 3.

Statistical analysis and full factorial design of experiments (DOE)

A full factorial design was applied to investigate the effect of different parameters on the oil recovery factor in the EM heating process. The full factorial method is a multi-level with detailed information to study the effect of limited variables and their interactions on the system response. It designs the least required tests when there is a combination of categorical and numerical parameters compared to other DOE methods. It considers the range between the upper and lower values of numerical parameters continuous in the DOE plan. Also, in this method, it is possible to provide a statistical model, optimize the process, and find the best combination of parameters for the optimum system outcome. Two parameters included the type of nanoparticles as a categorical factor (in five levels), and the concentration of nanoparticles in the base fluid as a numerical (in three levels) was considered in the DOE plan. Design-Expert software chose the ultimate oil recovery factor as the system’s response. The evaluated parameters and their levels are listed in Table 2.

As shown, five different nanoparticles were considered. This work studied the effect of using nanoparticles alone and when they are hybridized on the amount of crude oil recovery. Also, the concentration of nanoparticles in the base fluid (DI water) was selected from 0.01 to 0.5 wt.%. This range was determined by considering economic issues, reducing the amount of nanoparticle usage, and preventing the possibility of nanoparticle sedimentation into the porous medium. The porous medium was fully saturated with crude oil before each flooding test. Nanoparticles were dispersed in DI water using ultrasonic waves to prepare stable nanofluids. Then, the nanofluid was injected into the porous medium at 10 cm3/hr. The results from a prior study indicated that the lowest viscosity and the highest API of crude oil were achieved when utilizing 400 W of power (Gharibshahi et al. 2022b). The flooding experiments persisted until one pore volume of the porous medium had been injected under the influence of 400 W of microwave radiation. All the injection operations started at ambient temperature. However, by radiating the microwave energy, the oil heated up, raising its temperature (even more than 200 °C). In this method, the oil recovery factor was obtained by weighing the amount of oil saturating the porous medium (before the injection process) and the oil produced from the porous medium (after the injection process) and calculating the difference between these two numbers.

Results and discussion

Water injection under EM radiation

Water injection was carried out with and without microwave radiation to obtain a basis for comparing the performance of nanoparticles on the EM heating process. The oil recovery factor during water injection was calculated at specific time intervals, which is shown in Fig. 4.

As shown, the oil recovery factor inside the glass sandpack in the case of no microwave radiation is much lower than when microwaves with a power of 400 W are irradiated to the porous medium. The breakthrough of the injected fluid occurs in a shorter time in no microwave radiation mode. The injection fluid in this state will have less potential to produce oil from the porous medium. The ultimate oil recovery factor in this state for water injection is equal to 19%. The addition of nanoparticles to water resulted in a slight increase in the oil recovery factor, primarily due to the improvement in the mobility ratio of the injection fluid. Preliminary experimental results of the oil recovery factor for nanofluid injection alone, with varying types and concentrations, ranged from 21 to 27%.

However, when microwave radiation was applied, the oil recovery factor for water injection reached 39.5%, marking a substantial increment of approximately 207%. In the case of microwave radiation, heating the oil inside the porous medium and reducing its viscosity is a very influential factor in extracting oil from heavy oil reservoirs, which causes better and easier movement of the injection fluid inside the porous medium. It causes the breakthrough point to occur in a higher pore volume of fluid injection, which increases its ability to produce oil from the porous medium. Figure 5 shows the schematic of the glass sandpack before and after the water injection process.

The injected fluid movement inside the porous medium has been improved under microwave radiation. In this case, the oil comes out from the porous medium more easily and with less force. This issue can be seen on a microscopic scale in that more oil is removed around the sand grains and moved toward the production point. As a result, the injected fluid produced more oil from the sandpack than the no microwave radiation mode.

Statistical evaluation and optimization

A series of experiments were designed to investigate the effective parameters of nanofluid injection under microwave radiation on the oil recovery process by applying the full factorial method. All 15 runs proposed by the full factorial method were carried out in the laboratory, and the ultimate oil recovery factor was evaluated in each test. The maximized ultimate oil recovery factor was the basis of the response analysis in the Design-Expert software. Table 3 shows each test of the designed DOE plan and the ultimate oil recovery factor. The run order in this table was randomized to mitigate the influence of uncontrolled variables on the experiments. The injection tests were consistently conducted in the laboratory following this specific run order.

Analysis of variance (ANOVA) is based on the law of total variance to analyze the differences among two or more means. This method uses this method to measure the relative effect of each parameter on the system response and determine the critical influencing factors (Gharibshahi et al. 2022b). The ANOVA results for the response system are shown in Table 4.

The F value is the ratio of each parameter’s mean square to the residual error’s mean square. It is usually used to determine the importance of a parameter. The most influential parameter has a higher F value (Antony 2014). Referring to Table 4, it becomes evident that both the type of nanoparticle and its concentration are important factors, yet the influence of the nanoparticle type (parameter A) on the oil recovery factor outweighs that of its concentration in the base fluid. Notably, the squared main effect of nanoparticle concentration (B2) had the most significant impact on the system’s response. This disparity arises from variations in nanoparticles’ optimal ability to absorb and transmit radiated microwave energy (Gharibshahi et al. 2022b). Nevertheless, as the nanoparticle concentration in the base fluid increases, so does the number of active sites available to absorb radiated energy. In such circumstances, the effect of this parameter becomes more pronounced than that of the nanoparticle type when used in smaller quantities.

The p-value serves as a statistical measure to gauge the significance of differences observed in a study (Mehrooz et al. 2022). A small p-value indicates that the disparity in the data is both statistically significant and meaningful. As depicted in Table 4, the p-values for the model and all parameters were less than 0.05, signifying that the observed differences in results hold statistical significance with a 95% confidence level. A quadratic model was used to model the results. This model considers binary interactions of parameters such as B2 and AB. The quadratic model surpasses the linear model in flexibility and accuracy, adept at capturing nonlinear relationships and accommodating curvature in experimental responses through terms like X2. Its versatility makes it invaluable for modeling various experimental scenarios, offering a better fit for nonlinear data and ensuring more precise predictions, thereby providing a reliable representation of complex experimental patterns (Antony 2014). Moreover, the power function with a coefficient of 0.08 has been used to transform the results (based on Box–Cox analysis). The models provided by the software based on the actual values for each level of parameters are presented in Table 5.

In Table 5, the symbol B represents the actual amount of the nanoparticles dispersed in the base fluid (wt.%). The R-square value for this model, which means the percentage of dispersion of the predicted values around the actual values, is equal to 0.9984 (Fig. 6 (a)). Figure 6b shows the results of the normality test. The closer the R-square value is to one, the higher the presented model’s accuracy in predicting the new results and fitting the obtained results from the designed experiments. The statistical results of the proposed model are shown in Table 6.

The effect of each parameter on the system response

One of the advantages of the DOE method is to find the effect of changing each parameter within the specified range on the system response. In the full factorial method, the levels of each parameter are considered continuously (Gharibshahi and Jafari 2021). It means that the entire range of a numerical parameter is considered in the presented model. Figure 7 shows the effect of the nanoparticle type on the ultimate oil recovery factor.

The synthesized Fe3O4–MWCNT nanoparticles greatly affected the ultimate oil recovery factor. This issue is due to the high potential of these nanoparticles to absorb the radiated microwave energy. Crude oil is not an appropriate absorber of microwaves. Additionally, microwaves have limited penetration depth in oil reservoirs. Consequently, to enhance efficiency and reduce the cost of implementing this technique in field operations, the use of additional materials like nanoparticles is necessary. These nanoparticles efficiently absorb microwave energy, leading to uniform heating. Subsequently, they transfer this heat to the surrounding fluid through conduction, convection, and radiation mechanisms. As a result, the temperature within a larger area of the oil reservoir rises, expanding the stimulated region and improving overall reservoir performance. As a result, the viscosity of the crude oil will decrease more. At this condition, the injected fluid has less resisting force and can produce more oil from the porous medium (Gharibshahi et al. 2020).

Furthermore, Fe3O4–NiO hybrid nanoparticles are in second place, with the highest ultimate oil recovery factor in this process. That shows that the hybridization of Fe3O4 nanoparticles with MWCNT and NiO nanoparticles increases their efficiency in the EM heating process. It is because of the very suitable electrical properties of MWCNT nanoparticles and the high magnetic potential of NiO nanoparticles. The effects of the nanoparticles concentration in the base fluid on the ultimate oil recovery factor are shown in Fig. 8.

As shown, the oil recovery factor increases continuously by increasing the nanoparticles concentration in the base fluid from 0.01 to 0.1 wt.%. It is because by increasing the amount of nanoparticles in this range, the injection fluid’s ability to absorb and transfer the radiated microwave energy to its surroundings increases. In this period, nanoparticles have a positive effect on changing the hydrodynamic properties of the injected fluid, such as density and viscosity, and consequently improving its mobility ratio. They can also change the wettability of the porous medium to become more hydrophilic (Gharibshahi et al. 2020, 2022a). These effects will enhance the movement of injected fluid inside the porous medium. As a result, the injection fluid can be in contact with a larger surface of the oil reservoir and, as a result, produce more oil from the production point.

The oil recovery factor did not follow a specific trend by increasing the nanoparticles concentration in the base fluid from 0.1 to 0.5 wt.%. Increasing this value improves the oil recovery factor for Fe3O4 and MWCNT. Moreover, NiO nanoparticles had almost the same ultimate oil recovery factor at concentrations of 0.1 and 0.5% wt.%. However, the ultimate oil recovery factor increases to a certain amount and then decreases from 0.01 to 0.5 wt.% for Fe3O4–MWCNT and Fe3O4–NiO hybrid nanoparticles. That means that this parameter has an optimal value from 0.01 to 0.5 wt.%. This insight was derived by modeling the results obtained from all 15 implementations in the DOE plan using a quadratic model, which accounts for binary interactions of parameters, such as B2 and AB. Adding more nanoparticles to the base fluid increases the injected fluid ability to absorb more microwave energy. Nevertheless, the negative effect of these nanoparticles on reducing the permeability of the porous medium through sedimentation at pore throats and changing the mobility ratio of the injected fluid will be greater than their positive effect on reducing the viscosity of crude oil. Thus, the ultimate oil recovery factor decreases after a certain amount of nanoparticle concentration in the base fluid.

Another point is that hybridizing Fe3O4 nanoparticles with MWCNT and NiO nanoparticles reduces their consumption (use low concentration) to achieve the highest oil recovery factor in an injection process. Because by hybridizing nanoparticles with each other, their absorption mechanism of EM waves is improved so that one nanoparticle can absorb the magnetic term, and the other will have the potential to absorb the electric term of an EM field. This work also improves the effect of the final hybrid nanoparticle on parameters, including change of wettability, reduction of surface tension between injection fluid and oil, or oil viscosity. Therefore, the efficiency of the synthesized nanoparticle will increase in an EM heating process inside an oil reservoir.

Additionally, it is important to note that in Fig. 8, the blue curves represent the 95% confidence interval bands. These bands visually depict the range within which it can be 95% confident that the true population mean of the response variable falls for each level of the factor. They assist in evaluating the variability and precision of measurements and serve as a basis for comparing the statistical significance of different factor levels. As observed, the narrower confidence interval bands around the solid circle points (representing performed tests) indicate lower variability and higher precision in the measurements and experiments conducted in this study.

The effect of interaction between parameters on the system response

One of the capabilities of the full factorial design compared to the classical experimental methods is to study the effect of parameter interaction on the system response (Antony 2014). In other words, the impact of simultaneous changes of two or more parameters on the system’s response can be investigated using this method. So, this research investigated the effect of simultaneous change of two considered parameters on the system response. Figure 9 shows the interaction effect of nanoparticle type and their concentration on the ultimate oil recovery factor.

As shown in Fig. 9, the same trend of the oil recovery factor has been repeated for different nanoparticles by increasing the concentration of nanoparticles in the base fluid from 0.01 to 0.5 wt.%.

Determination of optimum conditions and confirmatory test

Each influencing parameter in a nanofluid injection under the EM heating process must be optimal to have the highest system response. So, the best level for each parameter was determined due to the maximum oil recovery factor. According to the selected range for each parameter and considering the maximum oil recovery factor, the optimum combination of parameters is suggested in Table 7.

The optimal conditions for achieving the highest oil recovery factor are using 0.34 wt.% of Fe3O4–MWCNT hybrid nanoparticles under 400 W of microwave radiation. It is because of these nanoparticles’ high efficiency and ability to absorb and effectively transfer the radiated energy to their surroundings (crude oil). In experimental design with a full factorial method, a confirmatory test validates predicted optimum conditions by implementing them physically and comparing results with the statistical model predictions. This entails collecting relevant data, measuring the response variable, and assessing the model’s accuracy. Discrepancies prompt further analysis to identify sources of error. A successful confirmatory test, aligning observed and predicted results, confirms the model’s reliability for decision making within the studied parameter space. Overall, the confirmatory test ensures the validity of predicted optimum conditions in the experimental system (Antony 2014). Therefore, the suggested optimal conditions by the model were applied in the laboratory to check the study’s accuracy and precision. Then, the oil recovery factor result was compared with the presented value in the Design-Expert software (Table 8).

The full factorial method with a 95% confidence interval predicts an interval [74–80] for the optimum implementation. The obtained result should be placed in this range. As shown in Table 8, the result obtained from the optimal test shows a 74% oil recovery factor, which is in the predicted range. Thus, it confirms the correctness of the DOE method used in this study (5.4% error). This validates the assumption of the quadratic model, demonstrating the existence of an optimal nanoparticle concentration between 0.1 and 0.5 wt.%, along with the nonlinear and parabolic behavior of the oil recovery factor based on nanoparticle concentration in Fig. 8.

Conclusions

A comprehensive parametric and optimization analysis was conducted to investigate the impact of microwave-absorbing nanomaterial injection under EM radiation. This investigation utilized an innovative glass sandpack injection system. This study applied a full factorial approach to thoroughly analyze how five distinct types of magnetic nanoparticles and their concentrations influence the oil production process, yielding the following results:

-

Microwave radiation significantly enhances the efficiency of the water injection process, increasing oil recovery from 19 to 39.5% when exposed to 400 W of microwave radiation.

-

Increasing the concentration of nanoparticles does not consistently lead to higher oil production. Instead, an optimal concentration (around 0.3 wt.%) was identified, yielding the highest oil recovery factor.

-

Hybridizing Fe3O4 nanoparticles with NiO and MWCNT nanostructures improves their performance in the EM heating process, achieving maximum oil production at lower concentrations.

-

The Fe3O4–MWCNT nanohybrids, with a remarkable 69% oil recovery factor, outperformed Fe3O4–NiO nanohybrids (65%) in improving oil production. This superiority can be attributed to the high capacity of MWCNT nanoparticles to absorb the electric component of radiated EM energy.

-

The optimal conditions for maximum crude oil production in a sandpack porous medium involve using 0.34 wt.% of Fe3O4–MWCNT nanoparticles under 400 W of microwave radiation, resulting in an impressive 78% oil recovery factor.

Abbreviations

- ANOVA:

-

Analysis of variance

- DI water:

-

Deionized water

- DOE:

-

Design of the experiment

- E-field:

-

Electric field

- EM:

-

Electromagnetic

- H-field:

-

Magnetic field

- IFT:

-

Interfacial tension

- MWCNT:

-

Multi-walled carbon nanotube

- MW:

-

Microwave

- NiO:

-

Nickel oxide

- wt.%:

-

Weight percent

References

Adil M, Zaid HM, Chuan LK, Latiff NRA (2016) Influence of electromagnetic waves on viscosity and electrorheology of dielectric nanofluids-scale-based approach. J Teknol 78:49–54. https://doi.org/10.11113/jt.v78.8974

Adil M, Mohd Zaid H, Chuan LK, Ahmad Latiff NR (2017) Effect of EM propagation medium on electrorheological characteristics of dielectric nanofluids. J Dispers Sci Technol 38:570–576. https://doi.org/10.1080/01932691.2016.1182922

Adil M, Lee K, Mohd Zaid H et al (2018) Experimental study on electromagnetic-assisted ZnO nanofluid flooding for enhanced oil recovery (EOR). PLoS One 13:e0193518. https://doi.org/10.1371/journal.pone.0193518

Adil M, Zaid HM, Chuan LK (2020) Electromagnetically-induced change in interfacial tension and contact angle of oil droplet using dielectric nanofluids. Fuel 259:116274. https://doi.org/10.1016/j.fuel.2019.116274

Ali H, Soleimani H, Yahya N et al (2020) Enhanced oil recovery by using electromagnetic-assisted nanofluids: a review. J Mol Liq 309:113095. https://doi.org/10.1016/j.molliq.2020.113095

Ali H, Soleimani H, Yahya N et al (2020b) Absorption of electromagnetic waves in sandstone saturated with brine and nanofluids for application in enhanced oil recovery. J Taibah Univ Sci 14:217–226. https://doi.org/10.1080/16583655.2020.1718467

Antony J (2014) Design of experiments for engineers and scientists. Elsevier, London

Armandi HS, Jafari A, Gharibshahi R (2021) Nanoparticles assisted microwave radiation: fluid-rock interactions in oil reservoirs. Pet Sci 18:1797–1812. https://doi.org/10.1016/j.petsci.2021.09.002

Belhaj AF, Elraies KA, Janjuhah HT et al (2019) Electromagnetic waves-induced hydrophobic multiwalled carbon nanotubes for enhanced oil recovery. J Pet Explor Prod Technol 9:2667–2670. https://doi.org/10.1007/s13202-019-0653-6

Bera A, Babadagli T (2015) Status of electromagnetic heating for enhanced heavy oil/bitumen recovery and future prospects: a review. Appl Energy 151:206–226. https://doi.org/10.1016/j.apenergy.2015.04.031

Bera A, Kumar S (2022) Applications of magnetic nanoparticles in thermal enhanced oil recovery. Fundamentals and industrial applications of magnetic nanoparticles. Elsevier, pp 527–553

Carpenter C (2021) Study interprets electromagnetic-wave penetration, absorption for bitumen reservoir. J Pet Technol 73:48–49. https://doi.org/10.2118/0121-0048-JPT

Duan Y, Guan H (2016) Microwave absorbing materials. CRC Press, New York

Farshadfar H, Armandi HS, Gharibshahi R, Jafari A (2023) Simultaneous electromagnetic radiation and nanofluid injection and their interactions in EOR operations: a comprehensive review. J Magn Magn Mater 580:170863. https://doi.org/10.1016/j.jmmm.2023.170863

Gharibshahi R, Jafari A (2021) Numerical investigation of controllable parameters effect on nanofluid flooding in a random pore generated porous medium. Iran J Chem Chem Eng 40:780–795. https://doi.org/10.30492/IJCCE.2020.66919.2560

Gharibshahi R, Omidkhah M, Jafari A, Fakhroueian Z (2020) Hybridization of superparamagnetic Fe3O4 nanoparticles with MWCNTs and effect of surface modification on electromagnetic heating process efficiency: a microfluidics enhanced oil recovery study. Fuel 282:118603. https://doi.org/10.1016/j.fuel.2020.118603

Gharibshahi R, Omidkhah M, Jafari A, Fakhroueian Z (2022a) Experimental investigation of nanofluid injection assisted microwave radiation for enhanced heavy oil recovery in a micromodel system. Korean J Chem Eng 39:562–575. https://doi.org/10.1007/s11814-021-0961-7

Gharibshahi R, Omidkhah M, Jafari A, Mehrooz N (2022b) Parametric optimization of in-situ heavy oil upgrading using simultaneous microwave radiation and magnetic nanohybrids via Taguchi approach. Fuel 325:124717. https://doi.org/10.1016/j.fuel.2022.124717

Greff J, Babadagli T (2013) Use of nano-metal particles as catalyst under electromagnetic heating for in-situ heavy oil recovery. J Pet Sci Eng 112:258–265. https://doi.org/10.1016/j.petrol.2013.11.012

Hasani M, Jafari A (2022) Electromagnetic field’s effect on enhanced oil recovery using magnetic nanoparticles: microfluidic experimental approach. Fuel 307:121718. https://doi.org/10.1016/j.fuel.2021.121718

Hasanvand MZ, Golparvar A (2014) A critical review of improved oil recovery by electromagnetic heating. Pet Sci Technol 32:631–637. https://doi.org/10.1080/10916466.2011.592896

Hassan YM, Guan BH, Zaid HM et al (2021) Application of magnetic and dielectric nanofluids for electromagnetic-assistance enhanced oil recovery: a review. Crystals 11:106. https://doi.org/10.3390/cryst11020106

Hussain S, Youngs IJ, Ford IJ (2007) The electromagnetic properties of nanoparticle colloids at radio and microwave frequencies. J Phys D Appl Phys 40:5331. https://doi.org/10.1088/0022-3727/40/17/048

Lee K, Adil M, Zaid HM et al (2019) Wettability, interfacial tension (IFT) and viscosity alteration of nanofluids under electromagnetic (EM) waves for enhanced oil recovery (IFT) applications. Engineering design applications. Springer, pp 305–311

Li K, Hou B, Wang L, Cui Y (2014) Application of carbon nanocatalysts in upgrading heavy crude oil assisted with microwave heating. Nano Lett 14:3002–3008. https://doi.org/10.1021/nl500484d

Li Y, Wang Z, Hu Z et al (2021) A review of in situ upgrading technology for heavy crude oil. Petroleum 7:117–122. https://doi.org/10.1016/j.petlm.2020.09.004

Mehrooz N, Gharibshahi R, Jafari A et al (2022) Low-temperature in-situ synthesis of cerium oxide nanoparticles applicable in EOR processes: parametric study by Taguchi approach. J Pet Sci Eng 219:111078. https://doi.org/10.1016/j.petrol.2022.111078

Morte M, Bloom E, Huff G, et al (2018) Factors affecting electromagnetic wave penetration in heavy oil reservoirs. Soc Pet Eng-SPE Canada heavy oil technical conference CHOC, 13–14 January 2018. https://doi.org/10.2118/189746-ms

Mozafari M, Nasri Z (2017) Operational conditions effects on Iranian heavy oil upgrading using microwave irradiation. J Pet Sci Eng 151:40–48. https://doi.org/10.1016/j.petrol.2017.01.028

Nasri Z, Mozafari M (2018) Multivariable statistical analysis and optimization of Iranian heavy crude oil upgrading using microwave technology by response surface methodology (RSM). J Pet Sci Eng 161:427–444. https://doi.org/10.1016/j.petrol.2017.12.004

Rehman MM, Meribout M (2012) Conventional versus electrical enhanced oil recovery: a review. J Pet Explor Prod Technol 2:169–179. https://doi.org/10.1007/s13202-012-0034-x

Shafiai SH, Gohari A (2020) Conventional and electrical EOR review: the development trend of ultrasonic application in EOR. J Pet Explor Prod Technol 10:2923–2945. https://doi.org/10.1007/s13202-020-00929-x

Taheri-Shakib J, Kantzas A (2021) A comprehensive review of microwave application on the oil shale: prospects for shale oil production. Fuel 305:121519. https://doi.org/10.1016/j.fuel.2021.121519

Taheri-Shakib J, Shekarifard A, Naderi H (2018) Heavy crude oil upgrading using nanoparticles by applying electromagnetic technique. Fuel 232:704–711. https://doi.org/10.1016/j.fuel.2018.06.023

Tohidi Z, Teimouri A, Jafari A et al (2022) Application of Janus nanoparticles in enhanced oil recovery processes: current status and future opportunities. J Pet Sci Eng 208:109602. https://doi.org/10.1016/j.petrol.2021.109602

Tooseh EK, Jafari A, Teymouri A (2017) Experimental investigation of injection pressure effect on the natural gas storage in aquifers. Int J Chem Eng Appl 8:351–354. https://doi.org/10.18178/ijcea.2017.8.6.682

Vakhin AV, Khelkhal MA, Tajik A et al (2021) The role of nanodispersed catalysts in microwave application during the development of unconventional hydrocarbon reserves: a review of potential applications. Processes 9:420. https://doi.org/10.3390/pr9030420

Yadali Jamaloei B (2022) Electromagnetic heating for heavy-oil and bitumen recovery: experimental, numerical, and pilot studies. SPE Reserv Eval Eng 25:433–454. https://doi.org/10.2118/209194-PA

Zaid HM, Latiff NRA, Yahya N et al (2014) Application of electromagnetic waves and dielectric nanoparticles in enhanced oil recovery. J Nano Res 26:135–142. https://doi.org/10.4028/www.scientific.net/JNanoR.26.135

Acknowledgements

The authors would like to thank Tarbiat Modares University and the National Iranian Oil Company (NIOC) for supporting this research.

Funding

No funding was secured for this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gharibshahi, R., Omidkhah, M. & Jafari, A. Sandpack flooding of microwave absorbent nanofluids under electromagnetic radiation: an experimental study. J Petrol Explor Prod Technol 14, 853–865 (2024). https://doi.org/10.1007/s13202-023-01736-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-023-01736-w