Abstract

In the process of unconventional oil and gas exploitation, fracturing is generally needed to improve industrial productivity. Brittleness, an essential factor of reservoir fracturing evaluation, is the key to improving the production of unconventional reservoirs. Shanxi formation of Yanchang gas field in Ordos Basin has the features of low porosity, poor permeability, and strong heterogeneity, which result in low productivity in natural conditions. In order to study the mechanical properties and fracturing ability of the reservoir, triaxial compression tests were carried out on 35 sandstone cores in the study area, and the mechanical parameters, rupture mode, stress–strain, and brittleness characteristics of the sandstone were obtained. The results show that the compressive strength is positively correlated with the elastic modulus and negatively correlated with the Poisson’s ratio. The samples have obvious brittle rupture characteristics and the brittleness index in the range of 47.9–52.2%. The dynamic parameters obtained by logging can be converted into static parameters in petroleum engineering application, and then the reservoir brittleness can be evaluated dynamically and continuously. Taking well X-2 in the study area as an example, the brittleness index calculated by stress–strain method and mineral composition method is 47.9 to 53.5% and 48.8% respectively, which is well matched with the logging interpretation, indicating that the results obtained by logging interpretation are relatively accurate. Based on mechanical experiments and logging evaluation results, the study could provide a parameter basis for selecting the favourable fracturing position of Shanxi formation in Yanchang gas field.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

With the decline of conventional oil and gas production around the world and the continued growth of oil and gas demand, unconventional oil and gas with huge resource potential have gradually become a central point of exploration and development (Hu et al. 2013; Zou et al. 2013). Unconventional oil and gas refer to the oil and gas resources that cannot be effectively exploited by traditional technology, and new technology is needed in order to improve reservoir permeability or fluid viscosity. It mainly includes tight oil, shale oil, tight gas, shale gas, coal-bed methane, and natural gas hydrate (Qiu et al. 2013; Zou et al. 2014). Because unconventional oil and gas reservoirs generally demonstrate the characteristics of tight lithology, low matrix porosity and permeability, and complex micropore structure, large-scale fracturing is needed to improve the production and stable production period of a single well (Guo et al. 2015; Tang et al. 2012; Wang et al. 2012). And not every stratum could achieve ideal productivity. Only those with strong fracturing ability can form complex fractures to ensure oil and gas seepage. Therefore, the fracturing analysis based on rock brittleness evaluation plays an essential part in the favourable fracturing interval selection and economic benefits prediction (Amiri et al. 2021; Li et al. 2019a, b; Yuan et al. 2014).

Rock brittleness refers to the intrinsic characteristic of rock when it is damaged by an external force, which is a slight plastic strain before rock fracture, and releases in the form of elastic energy during rock fracturing (Rennie et al. 2016; Ya 2009). In the area of petroleum geology, a general definition for rock brittleness is the difficulty of transient changes when rock rupturing. It indicates the complexity of cracks after reservoir fracturing and could be quantitatively shown by the brittleness index (Songergeld et al. 2010; Sun et al. 2015; Zhao et al. 2020). In short, brittleness is a comprehensive characteristic related to lithology, rock mechanics, and pore structure. If the rock is brittle, complex crack networks form easily, which is more favourable for reservoir exploration. In contrast, reservoirs formed by less brittle rocks, only simple cracks occur during the fracturing process, which is unfavourable for oil and gas seepage (Zhang et al. 2014). Therefore, rock brittleness evaluation is an important factor to be considered in unconventional reservoir fracturing design (Diao 2013; Guo et al. 2013; Li et al. 2019a, b; Xu et al. 2014).

Because of different research purposes, investigators of different disciplines have proposed different definitions and calculation methods for brittleness. For instance, Honda and Sanada (1956) thought that the brittleness should be represented by the difference in hardness and firmness; Hucka and Das (1974) suggested that the brittleness refers to the difference in tensile strength and compressive strength; Bishop (1967) proposed that brittleness should be estimated by the rate of stress release. Most of these methods were put forward for specific problems and suitable for different disciplines. To date, there is no unified statement and standard test method for brittleness. In petroleum geology, brittleness calculation mainly includes the total stress–strain method, mineral composition and mechanics parameter method. The total stress–strain method records the stress–strain curves of rock samples from initial loading to final failure and obtains the rock brittle characteristics under different stress states. The mineral composition method mainly calculates the proportions of quartz, feldspar, carbonate, argillaceous and other minerals. However, in situations where brittle minerals contain cuttings, the brittleness evaluation method is no longer accurate (Zhang et al. 2018). In the rock mechanics parameter method, elastic modulus and Poisson’s ratio are used to calculate brittleness (Fan et al. 2015; Qin et al. 2016; Wang et al. 2020; Altawati et al. 2021; Lu et al. 2022). There are mainly two ways to obtain rock mechanics parameters. One is to obtain static mechanics parameters by mechanical testing of rock samples in the laboratory. Although accurate results are usually reachable in this way, dynamically and continuously mechanics parameters of strata cannot be reflected, and the cost is great. The other is to obtain dynamic mechanics parameters by calculating acoustic and density logging data. It helps to reflect the rock mechanics characteristics of strata dynamically and continuously. but shows helplessness in reflecting the stress condition of strata. To achieve this, the results must be transferred into static parameters (Gao et al. 2018; Zhang 2012).

Considering the geological characteristics and the problems in the exploration of Yanchang gas field, triaxial compression tests were carried out to analyze the rock mechanical characteristics and brittle characteristics of Shanxi formation. With the test data, the calculation of logging dynamic mechanics parameters and the evaluation of reservoir brittleness were discussed in this paper. The findings could provide a parameter basis for the favorable fracturing position selection of Shanxi formation in Yanchang gas field.

Geological setting

Ordos Basin is the second-largest sedimentary basin in China. With an area of about 370,000 square kilometers, its reserves of natural gas, coal bed methane and coal all rank first in China. According to its evolution history and present shape, the basin can be divided into six first-order tectonic units: Yimeng uplift, Jinxi flexural fold, Shanbei slope, Weibei uplift, Western margin thrust belt and Tianhuan depression (Fig. 1). The location of Yanchang gas field is on the east of Shanbei slope in Ordos Basin. It mainly experienced the formation stage of the early continental margin basin and late craton in Paleozoic. In Middle Permian, braided river delta deposits were dominant in Yanchang gas field, and shore shallow lacustrine and fluvial deposits were developed locally. Due to the alternation of sedimentary environment, the study area shows the features of strong heterogeneity, low porosity, low permeability, and diverse pore structure (Lei et al. 2015; Liang et al. 2021; Fan et al. 2022). Here, the large-scale fracturing is needed to overcome the difficulties of industrial oil and gas production under natural conditions.

Materials and methods

To obtain rock mechanics parameters and brittle characteristics, triaxial compression tests were carried out on 35 sandstone core samples in the study area. Sandstone core samples in the test were all picked from Shanxi formation sandstone of wells X-1, X-2, and X-3 with sampling depth of 2632.78–3132.58 m in Yanchang gas field, Ordos Basin (Fig. 1c). The samples are light gray and gray white in color and mainly consisted of quartz, feldspar, and clay, see Fig. 2. All samples were processed into a cylindrical shape. The sample specifications were fabricated into 38.1 mm in diameter and 76.2 mm in height for triaxial compression and compressive strength tests, and 38.1 mm in diameter, 19.0 mm in height for tensile strength tests. The diameter and height errors were controlled within 0.3 mm; the maximum non-parallelism errors of the two end surfaces were limited up to 0.05 mm; the maximum unevenness errors of the end surface were smaller than 0.02 mm; the end surface was always vertical to the axis, and the maximum deviation was no larger than 0.25°.

RMT-150C test machine, see Fig. 3, was adopted for the triaxial compression test. The main technical parameters are as follows: vertical maximum output: 1000.0 kN; horizontal maximum output: 500.0 kN; vertical piston stroke: 50.0 mm; horizontal piston stroke: 50.0 mm; maximum confining pressure: 50.0 MPa; deformation rate: 0.0001–1.0 mm/s (grade 13). When the required confining pressure and temperature were set, the confining pressure was continuously loaded to the required value within 5 min, and the temperature was increased by following a rate lower than 2 ℃/min. The axial load was applied when the confining pressure and temperature were stable; the strain and stress rates were selected so that the rock samples were broken in 2–10 min. The test results of triaxial compression tests are shown in Table 1.

Results and analysis

The results of the triaxial compression tests show that the elastic modulus in the study area ranges from 23.643 to 32.864 GPa, and the Poisson's ratio ranges from 0.205 to 0.297. Sandstone samples have prominent brittle rupture characteristics (elastic at low stress and transient plastic at high stress). The rock samples are mainly multiple horizontal splitting, and the fracture characteristics of rock samples are obvious.

Parameter characteristics

Rock mechanics parameters indicate the crack-forming ability of strata under force, and can be the quantitative characterization of strata’s brittleness. Elastic modulus suggests whether the rock can maintain crack opening or not, while Poisson’s ratio represents the rock deformation capability. If the elastic modulus is large, the Poisson’s ratio is small, the rock brittleness would be high, making it easier to form a complex crack network (Makowitz and Milliken 2003; Miskimins 2009).

According to the rock mechanics experiment results in the study area, see Table 1, one can note the elastic modulus and compressive strength of sandstone increased as the burial depth of sandstone samples increased. However, the Poisson’s ratio remained almost unchanged. Meanwhile, the plot of compressive strength versus elastic modulus (Fig. 4) indicates that compressive strength and elastic modulus are positively correlated. In contrast, Fig. 5 shows the compressive strength was negatively correlated to the Poisson’s ratio.

Stress–strain characteristics

The total strain of most sandstone samples in the study area is less than 0.6, the proportion of elastic deformation is large, the stage of plastic deformation was very short, and most samples had no obvious plastic deformation (see Fig. 6). Heard (1963) considered brittleness as the characteristic of sudden rupture without obvious plastic deformation before rupture. Evans et al. (2012) thought that if the total strain is less than 1%, it is brittle (Evans et al. (2012). According to their points of view, the sandstone samples in the study area have obvious brittle rupture characteristics. In the elastic deformation stage, the deformation characteristics are as follows: when the load stress was low, the samples were in the elastic equilibrium state, and almost no damage occurred. With the increase of load stress, when the yield stress was reached, damage and plastic deformation began to appear in the specimen. When the loading stress reached the peak value (compressive strength), the plastic deformation of the sample increased, and macroscopic ruptures appeared. With the further increase of the strain, the samples rupture completely.

Rupture characteristics

In the triaxial compression tests, the rupture patterns of rock samples were researched statistically, and the distribution characteristics of cracks under stress were obtained, as shown in Fig. 7. It is noticed the sandstone samples in the study area are mainly of multi-horizontal ruptures. The main ruptures were completely broken and surrounded by many micro-ruptures.

Brittleness characteristics

Because rock brittleness comprehensively reflects Poisson’s ratio and the elastic modulus, Rickman et al. (2008) proposed calculating equations for Brittleness index based on rock mechanics parameters—taking 50% of normalized elastic modulus and Poisson’s ratio respectively for weight calculation. The calculation equations are as follows:

where ΔE refers to the normalized elastic modulus (GPa), E refers to the average elastic modulus of rock (GPa), the normalized Poisson’s ratio is represented by Δμ, μ is the average Poisson’s ratio of rock, B is the brittleness index, (%), and the maximum and minimum parameters in a certain stratum are denoted by subscripts ‘max’ and ‘min’ respectively.

The brittleness index of sandstone in the study area was obtained by Eq. (3). The brittleness index of well X-1 is 48.5%, well X-2 is 52.2%, and well X-3 is 47.9%. We can know that the overall brittleness in the study area is between 47.9 and 52.2%, which is relatively high.

Mechanics parameters by logging interpretation

Dynamic mechanics parameters

Logging data and the results of the acoustic wave tests can determine the dynamic mechanics parameters. Based on linear elasticity theory and Newton’s law of motion, if the rock is assumed to be isotropic, the relations between the elastic parameters and wave velocity are expressed as follows:

From Eqs. (4) and (5), Eqs. (6) and (7) can be deduced:

where Ed refers to the dynamic elastics modulus (GPa), μd refers to the dynamic Poisson’s ratio of rock, ρ is the volume density (g/cm3), Vp and Vs are P-wave and S-wave velocity (m/s) respectively.

It is known that if the P-wave and S-wave velocity are given, through Eqs. (6) and (7), dynamic Poisson’s ratio and elastic modulus at any burial depth can be calculated. The results calculated through logging are very accurate and could reflect the reservoir mechanics characteristics in a dynamic and continuous manner. So far, it is the most widely used method to obtain rock mechanics parameters (Sui et al. 2019). However, because array acoustic logging is costly, there is not enough S-wave logging data for most wells. Therefore, it is very important to establish S-wave velocity calculation model with limited logging data in order to calculate dynamic mechanics parameters. The empirical relation of S-wave velocity is established by statistical analysis of laboratory observation data and geophysical measurements (Yang et al. 2008, 2014). For the sandstone strata, the relation proposed by Gristensen is given below.

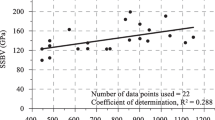

where Δts is S-wave time difference, (μs/m), Δtp is P-wave time difference (μs/m), ρ is rock density (g/cm3), e is the natural logarithm. The S-wave time difference calculated using Eq. (8) and that was measured in the study area is considerably different, which is unfavourable for practical application. Based on the measured S-wave time difference data, through the least square fitting of S-wave and P-wave time difference, and density logging data, the relation between S-wave and P-wave time difference of Shanxi formation in Yanchang gas field was correlated, see Eq. (9):

in which Δtp is P-wave time difference and ρ is rock density. Through Eq. (9), the S-wave time difference of typical wells in Yanchang gas field was calculated and compared with S-wave time difference of dipole logging, as shown in Fig. 8. The calculated S-wave time difference calculated is in good agreement with that of dipole logging measurements, which verifies the reliability of Eq. (9).

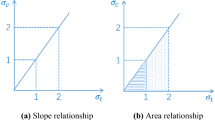

The conversion of mechanics parameters

Because the strata are heterogeneous, the dynamic and static mechanics parameters are different. In general, the dynamical elastic modulus is larger than the static elastic modulus (Wu et al. 2017). Because borehole deformation and stratum fracture are relatively static processes, in the research of rock mechanics and fracturing, the static mechanics parameters are firstly needed. Based on the properties of dynamic and static parameters, the relationship between dynamic and static parameters can be determined by linear regression, and the dynamic mechanics parameters of logging interpretation can be calibrated by the static mechanics parameters obtained in the laboratory so that the conversion from dynamic mechanics parameters to static mechanics parameters can be achieved.

Through the linear regression of the dynamic and static Poisson’s ratio and elastic modulus of samples from wells X-1, X-2 and X-3, the conversion relations between the dynamic and static parameters were obtained, as shown in Figs. 9 and 10. One can draw a conclusion that the static elastic modulus in the study area is smaller than the dynamic elastic. In contrast, the dynamic and the static Poisson’s ratio are almost similar. The conversion relation between the dynamic and static parameters are \(E_{\text{s}} = 0.5616E_{\text{d}} + 5.5477\) (R2 = 0.8538), \(\mu_{\text{s}} = 1.1646\mu_{\text{d}} - 0.072\) (R2 = 0.8301).

Analysis of application effect

To verify the accuracy of logging brittleness evaluation based on mechanics parameters, we used stress–strain method and mineral composition method to calculate the brittleness index of some typical well samples in the study area. The brittleness index calculated by the stress–strain method is 50.1%, and that calculated by the mineral composition method is 48.8%. They are very close to the brittleness index (47.9–52.2%) calculated by the previous mechanics parameter method. At the same time, according to the profile of strata mechanics parameters, the brittleness’s calculated by logging and mineral composition methods have a high fitting degree. The brittleness indexes given by the three methods jointly reflect that the Shanxi formation has high brittleness, which is conducive to reservoir fracturing.

Brittleness index calculated by stress–strain method

The stress–strain curve is one of the most direct and effective methods to evaluate rock brittleness qualitatively. Through the stress–strain curves recorded during the whole process of loading to rupture, the brittleness characteristics of different rocks under the same and different stress states were both obtained. The equation for calculating brittleness index by the stress–strain method is shown in Eq. (10):

where B is the rock brittleness index (%), σp is the rock rupture strength (MPa), i.e., rock compressive strength and σr is the rock residual strength after rupture (MPa).

Stress and strain tests were carried out on five sandstone samples from well X-2 of the burial depth of 2665–2673 m, and the test results are listed in Table 2. According to Eq. (10), the brittleness index of X-2 well ranges from 47.9 to 53.5%, and the average value is 50.1%, which is an indication that the brittleness of the sandstone sample is high.

Brittleness index calculated by mineral composition method

The content of brittle minerals determines the rock brittleness, and the rock brittleness can be quantitatively evaluated by analyzing the mineral composition. However, due to the lack of accurate definitions for brittle minerals, the judgment standards of brittle minerals are also different, and the calculation results may vary greatly. Therefore, how to define brittle minerals accurately is the key to evaluating rock brittleness by mineral composition method. Diao uses the specific gravity of quartz in minerals to calculate the brittleness index (Diao 2013); Glorioso considered that quartz and carbonate belong to brittle minerals (Glorioso and Rattia 2012); some investigators believe that all minerals except clay are brittle minerals. Qin put forward the weighted summation of mineral volume content and brittleness coefficient of each mineral to calculate the rock brittleness index. This method assigns minerals with different brittleness coefficients and avoids equal treatment of each mineral’s influence on the rock brittleness, making the physical meaning clearer and can well reflect the true rock brittleness. The specific equation is given as follows.

where B is the rock brittleness index (%), ai is the brittleness coefficient of ith mineral to quartz; i and m are the mineral species and volume perntage, respectively; Mi is mineral coefficient; Ei and μi are the elastic modulus and Poisson’s ratio of the ith mineral, respectively.

The statistical results of the whole rock diffraction analysis of sandstone samples from well X-2 are shown in Fig. 11. The main mineral components of the samples are quartz, feldspar, clay, carbonate, and pyrite, and the corresponding brittleness coefficients are 1, 0.44, 0.12, 0.39, and 3.2, respectively. The brittleness index of the samples was calculated as 48.8% using Eq. (11).

Effect analysis of logging brittleness evaluation

Logging can help to obtain continuous dynamic mechanics parameters. When the conversion relationship between dynamic and static parameters is known, one can convert them into corresponding continuous static parameters and then evaluate the reservoir brittleness. Taking well X-2 as an example, the dynamic mechanics parameters through logging data were first obtained. The brittleness index of strata (with a depth of 2660–2700 m) was then calculated by the dynamic and static parameter conversion relation using Eq. (3). Comparing the results with that from the mineral composition method, as shown in Fig. 12, one can notice a great agreement was achieved between these two methods, which indicates that the results obtained by logging interpretation are relatively accurate. Meanwhile, the brittleness index of Shanxi formation in well X-2 is generally high (> 40%), which suggests it is easy to form a complex crack network and makes it favorable for reservoir fracturing.

Conclusions

-

(1)

The triaxial compression test of sandstone samples in the study area shows that the elastic modulus and compressive strength increase with the increase of buried depth, while the Poisson’s ratio is basically unchanged, and the samples have prominent brittle rupture characteristics with brittleness index in the range of 47.9–52.2%.

-

(2)

The dynamic mechanical parameters obtained by logging can dynamically and continuously reflect the mechanical properties of the stratum, but can not truly reflect the deformation of the rock, so they must be converted into static parameters. The conversion relation of dynamic and static mechanics parameters in the study area are \(E_{\text{s}} = 0.5616E_{\text{d}} + 5.5477\) (R2 = 0.8538) and \(\mu_{\text{s}} = 1.1646\mu_{\text{d}} - 0.072\) (R2 = 0.8301).

-

(3)

The brittleness indexes of Shanxi formation of well X-2 in the study area calculated by stress–strain method and mineral composition method are 47.9–53.5% and 48.8% respectively, which are in good agreement with the log interpretation results, indicating that the reservoir is brittle and conducive to fracturing.

-

(4)

The application results show that the brittleness evaluation by logging interpretation is accurate and reliable, which provides a theoretical basis for fracturing evaluation of tight reservoir in Yanchang gas field.

Data availability

The data used to support the findings of this study are included in the article.

Abbreviations

- E :

-

Elastic modulus

- ΔE :

-

Normalized elastic modulus

- E max :

-

Maximum elastic modulus

- E min :

-

Minimum elastic modulus

- μ :

-

Poisson’s ratio

- Δμ :

-

Normalized Poisson’s ratio

- μ max :

-

Maximum Poisson’s ratio

- μ min :

-

Minimum Poisson’s ratio

- B :

-

Brittleness index

- V p :

-

P-wave velocity

- V s :

-

S-wave velocity

- E d :

-

Dynamic elastics modulus

- E s :

-

Static elastics modulus

- μ d :

-

Dynamic Poisson’s ratio

- μ s :

-

Static Poisson’s ratio

- ρ :

-

Density

- Δt s :

-

S-wave time difference

- Δt p :

-

P-wave time difference

- σ p :

-

Compressive strength

- σ r :

-

Residual strength

- a i :

-

Brittleness coefficient of ith mineral to quartz

- M i :

-

Mineral coefficient

- E i :

-

The ith mineral elastic modulus

- μ i :

-

The ith mineral Poisson’s ratio

References

Altawati F, Emadi H, Khalil R (2021) An experimental study to investigate the physical and dynamic elastic properties of Eagle Ford shale rock samples. J Petrol Explor Prod Technol 11:3389–3408

Amiri H, Ramezanzadeh A, Chamanzad M, Parhizgar M (2021) Recognizing the best intervals for hydraulic fracturing using a new fracability index. J Petrol Explor Prod Technol 11:3193–3201

Bishop A (1967) Progressive failure with special reference to the mechanism causing it. In: Oslo: Proceedings of the geotechnical conference, pp 142–150

Diao HY (2013) Rock mechanical properties and brittleness evaluation of shale reservoir. Acta Petrol Sin 9:3300–3306

Evans B, Fredrich T, Wong TF (2012) The brittle-ductile transition in rocks recent experimental and theoretical progress. Geophys Monogr Ser 56:1–20

Fan ZY, Lin CY, Wang TX (2015) Logging optimization on brittle index of tight formation rocks. Acta Peotrolei Sin 36:1411–1420

Fan JQ, Shi J, Wan XL, Xie QC, Wang C (2022) Classifcation evaluation method for Chang 7 oil group of Yanchang formation in Ordos Basin. J Petrol Explor Prod Technol 12:825–834

Gao H, Zhang X, He MQ, Xu CC, Du LB (2018) Study on evaluation of shale oil reservoir fracability based on well logging data volume. Prog Geophys (in Chinese) 33:0603–0612

Glorioso J, Rattia A (2012) Unconventional reservoirs: basic petro-physical concepts for shale gas. Soc Petrol Eng 153004:20–22

Guo Z, Li XY, Liu C, Feng X, Shen Y (2013) A shale rock physics model for analysis of brittleness index, mineralogy and porosity in the Barnett Shale. J Geophys Eng 10:25006–25015

Guo TK, Zhang SC, Ge HK (2015) A new method for evaluation of fracture network formation capacity of rock. Fuel 140:778–787

Honda H, Sanada Y (1956) Hardness of coal. Fuel 35–45

Hu WR, Bao JW, Hu B (2013) Trend and progress in global oil and gas exploration. Pet Explor Dev 40:409–413

Hucka V, Das B (1974) Brittleness determinatio of rocks by different methods. Int J Rock Mech Min Sci Geomech Abstracts 11:389–392

Kaunda RB, Asbury B (2016) Prediction of rock brittleness using nondestructive methods for hard rock tunneling. J Petrol Sci Eng 8:533–540

Lei YH, Luo XR, Wang XZ, Zhong LX, Jiang CF (2015) Characteristics of silty laminae in Zhangjiatan Shale of southeastern Ordos Basin, China: implications for shale gas formation. AAPG Bull 99:661–678

Li YW, Long M, Zuo LH, Li W, Zhao WC (2019a) Brittleness evaluation of coal based on statistical damage and energy evolution theory. J Petrol Sci Eng 172:753–763

Li ZH, Gai K, Chen ZJ, Zhang SY (2019b) Brittleness logging evaluation of Shihezi formation in Yanchang Gas field in Ordos Basin based on rock mechanical characteristics. E3S Web of Conferences, 2019b

Liang X, Xie Q, He M (2021) Reservoir characteristics and its comprehensive evaluation of gray relational analysis on the western Sulige gas field, Ordos Basin, China. Geofluids 2021:1–12

Lu C, Liu JX, Huang FL, Wang J, Zhou GQ, Wang JD, Liu YH, Wang XS, Guo JC (2022) Numerical simulation of proppant embedment in rough surfaces based on full reverse reconstruction. J Petrol Explor Prod Technol. https://doi.org/10.1007/s13202-022-01512-2

Makowitz A, Milliken K (2003) Quantification of brittle deformation in burial compaction, Frio and Mount Simon formation sandstones. J Sediment Res 73:1007–1021

Miskimins J (2009) The importance of geophysical and petrophysical data integration for the hydraulic fracturing of unconventional reservoirs. Lead Edge 28:844–849

Qin XY, Wang ZL, Yu HY, Cheng H, Lei YH (2016) Geophysical well logging in brittleness evaluation based on rock mechanics characteristic—a case study from the member 7 shale of Yanchang Formation in southeast Ordos Basin. Prog Geophys (in Chinese) 31:0762–0769

Qiu Z, Zou CN, Li JZ, Guo QL, Wu XZ, Hou LH (2013) Unconventional petroleum resources assessment: progress and future prospects. Nat Gas Geosci 24:238–246

Rickman R, Mullen MJ, Petre JE, Grieser WV, Kundert D (2008) A practical use of shale petrophysics for stimulation design optimization: all shale plays are not clones of the Barnett Shale. Society of Petroleum Engineers annual technical conference and exhibition. Denver 9:21–24

Songergeld C, Newsham K, Comisky J. (2010) Petrophysical considerations in evaluating and producing shale gas resources. In: SPE unconventional gas conference, pp 23–25

Sui HY, Gao W, Hu RL (2019) A new evaluation method for the fracability of a shale reservoir based on the structural properties. Geofluids 2019:2079458. https://doi.org/10.1155/2019/2079458

Sun JM, Han ZL, Qin RB, Zhang JY (2015) Log evaluation method of fracturing performance in tight gas reservoir. Acta Petrolei Sinica 36:74–80

Tang Y, Xing Y, Li LZ, Zhang BH, Jiang SX (2012) Influence factors and evaluation methods of the gas shale fracability. Earth Sci Front 19:356–363

Wang YH, Lu YJ, Li YP, Wang X, Zhang ZY (2012) Progress and application of hydraulic fracturing technology in unconventional reservoir. Acta Petrolei Sinica 33:149–158

Wang Q, Li H, Liu T, Li ZG, Dong YJ (2020) Characterization method and main controlling factors of shale brittleness. Fault-Block Oil Gas Field 27:458–463

Xu GC, Zhong GH, Xie B, Huang TJ (2014) Petrophysical experiment-based logging evaluation method of shale brittleness. Nat Gas Ind 34:38–45

Ya S (2009) Assessment of brittleness using rock strength and density with punch penetration test. Tunn Undergr Space Technol 24:66–74

Yang XJ, Zhang M, Yan XZ (2008) Study on acoustic logging-based rock elasticity parameters. Petrol Geol Eng 4:39–42

Yang BX, Li QF, Li WZ, He L (2014) The application of acoustic logging technologies in the unconventional dense reservoir. J Appl Acoust 33:16–22

Yuan JL, Deng JG, Zhang DY (2014) Fracability evaluation of shale-gas reservoirs. Acta Petrolei Sinica 34:523–527

Zhang JY, Sun JM (2012) Log evaluation on shale hydrocarbon reservoir. Well Log Technol 36:146–153

Zhang KS, Liu S, Jiang JF, Liu GP, Jiang R (2014) Calculation method about brittleness index in Chang 7 dense reservoir and its field application. Well Test 23:29–33

Zhang Y, Fan CH, Zhong C, Ye CY, Qin QR (2018) Study on the evaluation method of organic-rich shale brittleness in complex geological conditions. Geol Explor 54:1069–1083

Zhao YD, Gou XT (2020) A brittleness evaluation method based on breaking energy theory for tight reservoir in Dagang Oilfeld. J Petrol Explor Prod Technol 10:1689–1698

Zou CN, Zhang GS, Yang Z, Tao SZ, Hou LH, Zhu RK, Yuan XJ, Li DH, Wang ZP (2013) Geological concepts, characteristics, resource potential and key techniques of unconventional hydrocarbon: on unconventional petroleum geology. Pet Explor Dev 40:385–400

Zou CN, Yang Z, Zhang GS, Hou LH, Zhu RK et al (2014) Conventional and unconventional petroleum orderly accumulation: concept and practical significance. Pet Explor Dev 41:14–27

Acknowledgements

The author thanks the Continental Dynamics Laboratory of North-western University for providing the experiment, and also thanks China Aviation Coal Survey Bureau and Gansu Bureau of Coalfield Geology for providing some of data.

Funding

This research was funded by Youth Science and Technology Foundation of Gansu Province (Grant No. 20JR10RA139), the National Natural Science Foundation of China (Grant No. 42162015), and Science and Technology Foundation of Gansu Province (Grant No. 21CX6ZM107).

Author information

Authors and Affiliations

Contributions

ZL proposed research ideas and wrote the manuscript. ZC and LY assisted in interpretation of the data. SZ corrected the language of the manuscript. YF was involved in the validation analysis. KG and WH contributed to the sampling and experimental analysis.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Ethical approval

The manuscript doesn’t contain any experiments related to humans or animals.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Li, Z., Chen, Z., Yu, L. et al. Geophysical logging in brittleness evaluation on the basis of rock mechanics parameters: a case study of sandstone of Shanxi formation in Yanchang gas field, Ordos Basin. J Petrol Explor Prod Technol 13, 151–162 (2023). https://doi.org/10.1007/s13202-022-01542-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-022-01542-w