Abstract

Carbon dioxide (CO2) injection is implemented into the reservoir to further improve the oil production efficiency, by mixing with oil at reservoir condition, and becomes miscible. The miscibility affects the oil to become swelled and less viscous and thus easily flow through the reservoir. Most of the (CO2) EOR projects has higher recovery factor in miscible condition. Therefore, this article aims to determine the effects of the miscible (CO2) injection on production recovery in the Cornea Field. The Cornea Field is located in Browse Basin, Western Australia. It is a simple trap structure which is elongated and formed by unfaulted drape anticline over an eroded high basement. The importance of this research is that (CO2) injection has not been implemented in the Cornea Field since it is a complex reservoir. However, research showed that there was a high potential production recovery in this field. Therefore, research needs to be conducted to determine the effectiveness of the (CO2) injection on production recovery in this field. The model was validated, by comparing MMP obtained from the simulation model and correlation methods. The MMP of this reservoir is above 38 Bar. Sensitivity analysis on reservoir pressure, reservoir temperature and (CO2) injection rate was investigated. Oil production increases with the increase in reservoir pressure and reservoir temperature. As the (CO2) injection rate increases, oil production also increased. From the result, hence, this study should contribute to the knowledge gap in Cornea Field.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Carbon dioxide (CO2) injection is one of the promising enhanced oil recovery (EOR) methods that have been applied in the oil and gas industry for many years. The CO2 injection (Hoteit et al. 2019) into the reservoir to further improve the oil production efficiency is usually implemented after primary production of 10% to 20% of original oil in place and secondary production of addition 10% to 20%. Usually, CO2 acts as a solvent, injected into the reservoir to increase the residual oil production. Carbon di oxide is injected into the reservoir because it can mix with oil at reservoir condition and become miscible (Fig. 1 shows a typical miscible of CO2 flooding). The miscibility affects the oil to become swelled and less viscous and thus easily flow through the reservoir. Most of the CO2 EOR projects involve miscibility condition. Despite that, immiscibility condition may also be used to extract oil from reservoir (Cooney et al. 2018; Steinsbo et al. 2014; Tadesse 2018; Whittaker and Perkins 2013; Kalra et al. 2017).

However, not all reservoir is suitable for \(\hbox {CO}_{2}\) injection. The oil composition, depth, temperature and other reservoir characteristic must be considered during \(\hbox {CO}_{2}\) injection (Cooney et al. 2018; Steinsbo et al. 2014; Tadesse 2018; Whittaker and Perkins 2013; Kalra et al. 2017). At constant temperature, the lowest pressure at which liquid becomes miscible is known as “minimum miscibility pressure” (MMP). This is an important concept that explains the miscible gas injection because at this point, the injected gas and initial oil in place become a single phase, and the flow of the fluids becomes efficient. Accurate estimation of MMP for \(\hbox {CO}_{2}\) flooding can significantly improve the reservoir recovery (Al-netaifi 2008; Liu 2013; Rezaei et al. 2013). This mostly occurs at a depth greater than 2500 ft, and the oil should have greater than 22 degrees API gravity with less than 10cP viscosity. The saturation of the oil should be higher than 20% of the pore volume (Ansarizadeh et al. 2015; Aroher and Archer 2010; Meyer 2007). From the \(\hbox {CO}_{2}\) injection, the amount of oil recovered worldwide has been estimated to be around 450 billion BBL (Ansarizadeh et al. 2015; Bergmo and Anthonsen 2014; Cook 2012; US Chambers 2021; Tian and Zhao 2008).

Miscible \(\hbox {CO}_{2}\) flooding (Aroher and Archer 2010)

When \(\hbox {CO}_{2}\) mixed with oil is produced (Fig. 1), it can be separated and can be reinjected into the reservoir as a storage, which can contribute significantly to the reduction in the emission of greenhouse effect (Kamali and Cinar 2013; McLaughlin 2016; Melzer 2012; Parker et al. 2009; Qi et al. 2008; Safi et al. 2015).

As mentioned by Whittaker and Perkins (2013), miscible \(\hbox {CO}_{2}\) injection was commonly used in oil extraction due to its effectiveness in increasing oil recovery. Therefore, this study aims to evaluate the effect of miscible \(\hbox {CO}_{2}\) injection on the production of the Cornea Field (Fig. 2). The Cornea Field is located in Browse Basin, Western Australia. It is a simple trap structure that is elongated and formed by unfaulted drape anticline over eroded high basement (Ingram et al. 2000). This study is done because there was no investigation done previously in the Cornea Field on the effectiveness of \(\hbox {CO}_{2}\) injection to improve oil production. Figure 2 shows a structural perspective of Browse Basin.

Investigation on different cases of natural depletion of the reservoir in one of the Iranian oil fields had been done by Fath and Pouranfard (2013). They have also conducted the immiscible and miscible CO2 flooding to increase the oil production. To determine the minimum miscibility pressure, slim tube simulation was run at different pressures using model (Zene et al. 2019a, b; Mohyaldinn et al. 2019; Mohyaldin et al. 2019) with 600 grid (Zhalehrajabi et al. 2014; Naser et al. 2007) blocks. The MMP for injection of \(\hbox {CO}_{2}\) was about 4630 psia. From the simulation (Khan et al. 2003, 2001), the result showed that the optimum injection rates were 17,000 Mscf /day and 30,000 Mscf /day. These are for immiscible and miscible \(\hbox {CO}_{2}\) injection, respectively. At the end of 20 years of total oil production, the miscible \(\hbox {CO}_{2}\) injection showed 36.6% of recovery factor, while the recovery factor for immiscible \(\hbox {CO}_{2}\) injection was 34.5%. This showed that the miscible injection was more feasible. However, the miscible condition was tough to reach some point in the heavy oil reservoir. Therefore, immiscible condition was recommended for future study (Fath and Pouranfard 2013; Karaei et al. 2015; Vark et al. 2004).

Structural element of Browse Basin: Cornea Field on the upper right side of the map (black lines represent faults) [26,(Poidevin et al. 2015)]

On the other hand, Zarei and Azdarpour (2017) investigated the effectiveness of \(\hbox {CO}_{2}\) injection. Eclipse 300 was used to examine the \(\hbox {CO}_{2}\) injection. The oil in the tank was analyzed by software PVTi and experiment contact volume expansion and phase release on the oil. The PVTi output was used for Eclipse 300 input. Six wells were extracted for 10 years with \(\hbox {CO}_{2}\) injected for 50 years. The injection rate had a direct impact on the EOR. The miscibility condition was studied with an injection of 5000 Mscf/day, which was still under immiscibility condition and miscibility achieved at and injection of 9000 Mscf/day. There were different cases compared: miscible injection at different pressure, miscible and immiscible with different flow rate, water injection then \(\hbox {CO}_{2}\) injection and vice versa. The result showed that the alternate miscible \(\hbox {CO}_{2}\) injection and water was a good scenario for oil production (Zarei and Azdarpour 2017; Montazeri and Sadeghnejad 2017). This study was conducted with simulated PVT experiments to investigate the effects of the use of miscible and non-miscible \(\hbox {CO}_{2}\) in the Safah oil field. The results show that miscible \(\hbox {CO}_{2}\) injection—rich gases produce more oil than lean gases—leads to higher recovery (Hearn and Whitson 1995).

\(\hbox {CO}_{2}\) injection for different miscibility condition was also investigated by Han et al. (2014). The study was performed in the 2D vertical sandstone with unstable gravity drainage condition. \(\hbox {CO}_{2}\) was injected at the bottom with 100% oil saturation. The results show that these conditions are consistent with the results of the previous study on the effects of a single photon emission from a laser beam. The results showed that there is no significant difference in effect between the two types of laser beams. It was shown that the oil production increased when miscible condition reached (Han et al. 2014; Alsulaimani 2015; Bhatti et al. 2019; Binshan et al. 2012).

Verma (2015) researched the \(\hbox {CO}_{2}\) EOR processes to estimate the recoverable oil in the USA. It was studied because \(\hbox {CO}_{2}\) injection has been one of the methods that has been considered as a solution for the economic profitability. It was also studied that there were different tools that can be used to calculate the MMP (using slim tube tests), mathematical model (Saeid et al. 2018) and correlations. From the discussion, the mathematical model (Sern et al. 2012; Hamzah et al. 2012) provided best result in estimating the MMP, which used equilibrium data and equation of state, while slim tube was expensive and correlation was used only when there were no slim tube and mathematical correlation available even though it was easy to use. From the study, it was determined that the oil recovery increased when pressure increased until it reached MMP. To achieved optimum (Khan et al. 2012) recovery, miscible \(\hbox {CO}_{2}\) (Rashid et al. 2014a, b) EOR injection was chosen as a better condition than immiscible injection (Verma 2015; Abdalla et al. 2014; Olea 2017; Perera et al. 2016).

Rudyk et al. (2005) also aimed to examine the \(\hbox {CO}_{2}\) EOR and to determine the recoverable oil in the North Sea chalk samples. It was studied that there were few parameters that affect the MMP such as chemical composition, reservoir temperature and physical dispersion. Therefore, these factors need to be considered during the investigation. An experiment was performed on cylindrical and cubicle core at high pressure and temperature. It was shown that the oil recovery increased until it reached 180 MMP and the highest oil volume extracted was at 2611 psi. It also determined that the \(\hbox {CO}_{2}\) injection was applicable for the field with 29% of recovery (Rudyk et al. 2005; Akbari and Kasiri 2012; Jensen 2015; Tzimas et al. 2005).

The observation of the \(\hbox {CO}_{2}\) injection into a sand pack was studied by Yuechao et al. (2011) using 400 MHz NMR micro-imaging system. For immiscible \(\hbox {CO}_{2}\) displacement, it was shown that \(\hbox {CO}_{2}\) fingering was occurred due to difference in oil and \(\hbox {CO}_{2}\) viscosity and density. Therefore, there were 53% of residual oil left in the sand pack. For miscible \(\hbox {CO}_{2}\) flooding, it showed that the sweep efficiency was high. But the viscosity and density of gas were low and the velocity were the same. The residual oil left in the sand pack was 34%, which was lower than immiscible injection. Thus, this showed that the miscible injection can increase recoverable oil.

Contrarily, Al-Abri and Amin (2010) researched on the dependency between interracial tension and relative permeability and also the displacement efficiency of the \(\hbox {CO}_{2}\) injection into gas condensate reservoir. A laboratory condition was set at high pressure and temperature condition to simulate the reservoir conditions and to conduct relative permeability measurement on sandstone cores at constant reservoir temperature of 95C and displacement velocity of 10 cm/h. Displacement investigation at the immiscible condition at 1100 and 1200 psi, near miscible at 3000 psi and miscible at 4500 and 5900 psi was also included. The core flooding results showed that the pressure was the main factor that controlled the sweep efficiency. Miscible flooding showed optimum recovery of 32% with a better mobility ratio and delayed gas breakthrough, while near miscible was only recovered 23%. For the interfacial tension in the miscible displacement, the fluid properties and phase behavior relationships between \(\hbox {CO}_{2}\) and condensate were stated to be the driving force that increased the recovery by stabilizing the displacement front.

Farzad (2004) also examined the effects of the injection pressure, vertical/horizontal permeability ratio and relative permeability on the recovery in miscible and immiscible displacement. A 3D, three-phase, Peng–Robinson equation of state compositional simulator method was used to determine the effectiveness of the parameters on the miscible and immiscible displacement. With an estimation of MMP, miscible injection was proven to increase the oil recovery with injection pressure between 5000 psi and 5600 psi where MMP was at 5000 psi.

The research trend has been moved to assess the potential of the \(\hbox {CO}_{2}\) dissolved concept (Castillo et al. 2017), which combines two different approaches to research into carbon dioxide and its impact on climate change. The aim there was to identify and quantify the thermo-hydrochemical processes triggered by the release of dissolved \(\hbox {CO}_{2}\) from carbonated aquifers in the form of hydrochloric acid (HCA) and hydrofluoric acid into the atmosphere.

From the literature review, most of the studies showed that miscible \(\hbox {CO}_{2}\) injection was the most efficient way for oil recovery. Therefore, the aim of this paper is to determine production recovery by miscible \(\hbox {CO}_{2}\) injection into the reservoir. The objectives of this paper are:

Methodology

Data were primarily collected from Geoscience Australia and some from Occam Technology Company. The model was constructed using the PETREL software by importing data collected.

Pressure–volume–temperature analysis (PVTi) and ECLIPSE software were used in this research. PVTi as an equation of state-based code was used to characterize a set of reservoir fluid samples. This is important because the model needs to have a realistic physical model of the fluid sample before input it to the reservoir simulation. The output of the PVT data was then imported into ECLIPSE (Saoyleh 2016; Ying 2013). Table 1 shows the steps in generating PVT table. Equations 1 to 12 were implemented in the PVTi software to generate the result (Slumberger 2014).

-

Equation of state for real fluid

The real gas model is given by Eq. (1)

-

Cubic equation

The cubic form of model can be written as follows Eq. (2)

-

The intensive form of Peng Robinson EOS

The PR EOS is given by Eq. (8)

where

The PVT data were imported into ECLIPSE and used to simulate the \(\hbox {CO}_{2}\) injection. The \(\hbox {CO}_{2}\) injection keyword WINJGAS was used to implement the gas injection we ll. MISCIBLE keyword was used for miscible \(\hbox {CO}_{2}\) injection reservoir. The model was validated by comparing MMP obtained from the result with MMP correlation methods. Correlations were used because it was a more time saving and easier method despite its accuracy. The sensitivity analyses were done by varying different reservoir properties such as initial reservoir pressure, reservoir temperature and \(\hbox {CO}_{2}\) injection rate. Below are the correlations used to calculate the MMP (Adekunle 2014; Khazam et al. 2016) as stated by Eqs. (13), (14) and (15):

-

Alston (1985)

-

Glaso (1980)

Glaso proposed the model (Eq. 16)

Table 2 states the component and weight fraction data inputted to PVTi software.

Figure 3 shows the relative permeability of the oil and water.

Figure 4 shows the capillary pressure versus water saturation.

Results

Two wells were implemented in this reservoir model, which are injector and producer wells. This is to see the behavior of the injector and producer wells individually and to see how much it can be produced alone. Please refer to Fig. 5 for the reservoir model with injector and producer wells. Table 3 shows the model condition imported in PETREL. Table 1 shows component and weight fraction data inputted to PVTi software (Tables 4, 5).

After the model was validated, sensitivity analysis was performed to see how the variable changes effect the production recovery.

Effect of reservoir pressure

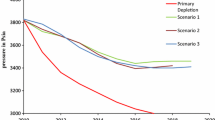

Reservoir pressure is very important, and this should be accounted in order to have an efficient oil recovery. Therefore, \(\hbox {CO}_{2}\) was injected to improve reservoir pressure after primary and secondary production. Therefore, the reservoir pressure was investigated to see its effect on oil production with constant \(\hbox {CO}_{2}\) injection rate. The reservoir pressure was tested from 30 to 50 Bar while maintaining other parameters constant. Figure 6 shows the oil production increased with an increase in reservoir pressure. This is because with \(\hbox {CO}_{2}\) injection, it helps to improved oil recovery by reducing oil surface tension, swelling the oil, then lowering the oil viscosity and by moving the lighter oil components, hence increasing sweep efficiency. Figure 7 states the field oil production total decreased as pressure increased with time.

Figure 6 shows that the MMP of this reservoir is at 40 Bar. The MMP was obtained from the point at which two straight lines intersected, as shown in Fig. 6. The correlation calculations show that the MMP of the reservoir is close with Glaso correlation with 45 Bar. This means that the miscibility of the reservoir is assumed to start at pressure above 4 bar. Therefore, it shows that the model is valid. Please refer to data of Figs. 7, 8, 9 and 10.

Effect of reservoir temperature

Reservoir temperature is also a crucial factor to be taken into account in the production recovery. Thus, the initial reservoir temperature was varied to see the effect of the temperature on oil production in the reservoir with constant \(\hbox {CO}_{2}\) injection rate. The initial reservoir temperature was tested from 110 to 160 °C while maintaining other parameter constants. Figure 11 describes the oil production increased with increasing reservoir temperature from 110 to 160 °C. This is because with \(\hbox {CO}_{2}\) injection and temperature increases, the kinetic energy of \(\hbox {CO}_{2}\) molecules increased, which result in more interaction with the residual oil in the reservoir, thus increased in oil production. In addition to that, the production increased with reservoir temperature because the reservoir is located at a deeper depth where it retains its supercritical \(\hbox {CO}_{2}\). With increased reservoir temperature, it also results in an increase formation pressure and hence leads to an increase in recovery. Reservoir temperature must be increased to avoid the complication of hydrocarbon production, which can lead to losses of valuable product in the hydrocarbon. Figure 12 shows the field oil production total increased as temperature increased with time. Figure 13 states the FWPT versus years for reservoir temperature for 110 °C, 120 °C, 130 °C, 140 °C, 150 °C, 160 °C, and Fig. 14 shows the reservoir simulation of reservoir temperature distribution at 110, 130, 150 and 160 °C

Effect of carbon dioxide injection rate

The permeability of the reservoir is the ability of fluid flow through the reservoir. Transmissibility is the degree of the fluid that can flow with respect to permeability. From Fig. 15, it shows that the permeability transmissibility percentage increased with increased in reservoir permeability. This is because with higher permeability, more fluid can flow through and more oil will be produced.

However, with implementation of \(\hbox {CO}_{2}\) injection (Fig. 16), additional oil can be produced when compared with natural drive production. From Fig. 17, it shows that with increasing injection rate, more production will be produced. This is because as oil mixed with \(\hbox {CO}_{2}\) gas, the oil swelled and results in lower interfacial tension and viscosity. This more oil will be recovery. The drop of the production at the end of the data might be due to early gas breakthrough.

Figure 18 shows FWPT versus year for \(\hbox {CO}_{2}\) injection rate at 500 sm3/day, 600 sm3/day, 700 sm3/day, 800 sm3/day and 900 sm3/day and FWPT nearly linearly increases with injection rate for all flow rate.

Figure 19 shows reservoir simulation of \(\hbox {CO}_{2}\) injection rate distribution of 500 sm3/day at 2019, 2025, 2029 and 2038. The change in contour color states the concentration change.

Therefore, from Table 6, it can be confirmed that oil production is higher with miscible \(\hbox {CO}_{2}\) injection when compared with naturally producing reservoir.

Comparison of EOR

Figure 20 illustrates the comparison between the cumulative oil productions for 20 years at 500 sm\(^{3}\)/day for \(\hbox {CO}_{2}\) and WAG injections. It shows that WAG injection initially produced higher than \(\hbox {CO}_{2}\) injection. However, at year 16 the cumulative oil production for WAG injection started to produce lesser compared to \(\hbox {CO}_{2}\) injection where production continues to increase. This might be due to early water breakthrough to the production well in WAG injection.

Conclusions

This concludes few important findings:

-

1.

MMP of this reservoir is at 38 Bar where oil production starts to produce.

-

2.

It shows that reservoir pressure, reservoir temperature and injection rate are very important factors to be considered in petroleum reservoir for recovery and determining its effects on the oil production in the reservoir. These factors are analyzed to determine the optimum pressure, temperature and injection rate to be able to achieve higher oil recovery.

-

3.

The production increased with an increase reservoir pressure and reservoir temperature. See Figs. 6 and 10.

-

4.

\(\hbox {CO}_2\) injection rate is also a crucial factor that boosts the recovery factor. The oil production increases with an increase \(\hbox {CO}_2\) injection rate. The ultimate \(\hbox {CO}_2\) injection rate is at 800 sm3/day.

-

5.

It shows that \(\hbox {CO}_2\) injection can boost the oil production in the reservoir when compared with naturally producing reservoir. Therefore, it proves that miscible \(\hbox {CO}_2\) injection is a feasible method to be used in boosting recovery factor.

-

6.

Table 7 shows that by injecting \(\hbox {CO}_2\), the production is a boost when compared with natural drive production.

Hence, this paper contributes to the knowledge gap present in the Cornea Field since no \(\hbox {CO}_2\)injection simulation was done before. Economic analysis was not included in the research. Also, for further improvement in oil recovery, it is recommended that more study needed to be done, such as implementing water alternating gas (WAG) to improve further the production. This article is produced with the donated software of Schlumberger Brunei/Malaysia (petrel and eclipse).

Abbreviations

- BBL:

-

Barrels

- MSCF/DAY:

-

Million Standard Cubic Feet Per Day

- MHz:

-

Million Hertz

- P :

-

Pressure (Bar)

- V :

-

Volume

- n :

-

No of moles

- R :

-

Universal gas constant

- T :

-

Temperature

- \(T_\mathrm{cm}\) :

-

Weight average pseudocritical temperature of mixture (°F)

- Z :

-

Compressibility factor

- \(X_\mathrm{vol}\) :

-

Mole fr of volatile (C1 and N2) oil components

- \(X_\mathrm{int}\) :

-

Mole fr of volatile (CO2 and C2–C6) oil components

- \(M_{C_{5\;\;}}{or\;\;M}_{C_{7+}}\) :

-

Mol wt of oil pentane and heavier fraction (lb/lbmol)

References

Abdalla AM, Yacoob Z, Nour AH (2014) Asian network for scientific information. Enhanced oil recovery techniques miscible and immiscible flooding. J Appl Sci 14:1016–1022

Abdullah N, Hasan N, Saeid N, Mohyaldinn ME, Zahran ESMM (2019) The study of the effect of fault transmissibility on the reservoir production using reservoir simulation–Cornea Field, Western Australia. J Pet Explor Prod Technol. https://doi.org/10.1007/s13202-019-00791-6

Adekunle O (2014) Experimental approach to investigate minimum miscibility pressures in the Bakken, Colorado School of Mines in partial fulfillment of the requirements for the degree of Master of Science (Petroleum Engineering)

Akbari MR, Kasiri N (2012) Determination of minimum miscibility pressure in gas injection process by using ANN with various mixing rules. J Pet Sci Technol 2(1):16–26

Al-Abri A, Amin R (2010) Phase behaviour, fluid properties and recovery efficiency of immiscible and miscible condensate displacements by SCCO2 injection: experimental investigation. Transp Porous Media 85(3):743–756

Al-netaifi AS (2008) Experimental Investigation of CO2—miscible oil recovery at different conditions, A Thesis Submitted in Partial Fulfillment of the Requirement of the Degree of Master of Science in the Department of Petroleum and Natural Gas Engineering, King Saud University, KSA

Alsulaimani TA (2015) Ethane miscibility correlations and their applications to oil shale reservoirs, PhD Thesis, The University of Texas, Austin

Ansarizadeh M, Dodds K, Gurpinar O, Pekot LJ, Kalfa O, Sahin S, Uysal S, Ramakrishnan TS, Sacuta N, Whittajer S (2015) Carbon dioxide—challenges and opportunities. Oilfield Rev 27(2):1–15

Aroher B, Archer R (2010) Enhanced natural gas recovery by carbon dioxide injection for storage. In: 17th Australia fluid mechanics, 5–9 December, Auckland, New Zealand

Bergmo P, Anthonsen KL (2014) Overview of available data on candidate oil fields for CO2 EOR. SINTEF Petroleum, pp 1–20

Bhatti AA, Raza A, Mahmood SM, Gholami R (2019) Assessing the application of miscible CO2 flooding in oil reservoirs: a case study from Pakistan. J Pet Explor Prod Technol 9(1):685–701

Binshan J, Shu WY, Jishun Q, Tailing F, Zhiping L (2012) Modeling CO2 miscible flooding for enhanced oil recovery. Pet Sci 9(2):192–198

Castillo C, Marty NCM, Hamm V, Kervévan C, Thiéry D, de Lary L, Manceau JC (2017) Reactive transport modelling of dissolved CO2 injection in a geothermal doublet. application to the CO2-DISSOLVED concept. Energy Procedia 114:4062–4074

Cook BR (2012) Wyoming’s miscible CO2 enhanced oil recovery potential from main pay zones: an economic scoping study, University of Wyoming, USA

Cooney G, Littlefield J, Marriott J, Skone TJ (2018) Evaluating the climate benefits of CO2-enhanced oil recovery using life cycle analysis. Environ Sci Technol 49(12):7491–7500

Farzad I (2004) Evaluating reservoir production strategies in miscible and immiscible gas injection projects, Latin American & Caribbean Petroleum

Fath AH, Pouranfard AR (2013) Evaluation of miscible and immiscible CO2 injection in one of the Iranian oil fields. Egypt J Pet 23(3):255–270

Hamzah AA, Hasan N, Takriff MS, Kamarudin SK, Abdullah J, Tan IM, Sern WK (2012) Effect of oscillation amplitude on velocity distributions in an oscillatory baffled column (OBC). Chem Eng Res Des 90:1038–1044. https://doi.org/10.1016/j.cherd.2011.11.003

Han J, Kim J, Seo J, Park H, Seomoon H, Sung W (2014) Effect of miscibility condition for CO2 flooding on gravity drainage in 2D vertical system. J Pet Environ Biotechnol 5(3):177

Hearn CL, Whitson CH (1995) Evaluating miscible and immiscible gas injection in the Safah Field. In: SPE reservoir simulation symposium, 12–15 February, San Antonio, Texas, Society of Petroleum Engineers

Hoteit H, Fahs M, Soltanian MR (2019) Assessment of CO2 injectivity during sequestration in depleted gas reservoirs. Geosciences 9(5):199

Ingram GM, Eaton S, Regtien JMM (2000) Cornea case study: lesson learned. APPEA J 40(1):56–65

Ishak MA, Islam MA, Shalaby MR, Hasan N (2018) The application of seismic attributes and wheeler transformations for the geomorphological interpretation of stratigraphic surfaces: a case study of the f3 block, Dutch offshore sector, north sea. Geosciences (Switzerland). https://doi.org/10.3390/geosciences8030079

Jensen GK (2015) Assessing the potential for CO2 enhanced oil recovery and storage in depleted oil pools in Southeastern Saskatchewan. Summary Investig 1

Kalra S, Tian W, Wu X (2017) A numerical simulation study of CO2 injection for enhancing hydrocarbon recovery and sequestration in liquid-rich shales. Pet Sci 15:103–115

Kamali F, Cinar Y (2013) Co-optimizing enhanced oil recovery and CO2 storage by simultaneous water and CO2 injection. Energy Explor Exploit 32:281–300

Karaei MA, Ahmadi A, Fallah H, Kashkoolli SB, Bahmanbeglo TJ (2015) Field scale simulation study of miscible water alternating CO2 injection process in fractured reservoirs. Geomaterials 5(1):25–33

Khan A, Abdullah AB, Hasan N (2012) Event based data gathering in wireless sensor networks. In: Wireless sensor networks and energy efficiency: protocols, routing and management, pp 445–462

Khan MNH, Fletcher C, Evans G, He Q (2001) CFD modeling of free surface and entrainment of buoyant particles from free surface for submerged jet systems. J ASME Heat Transf Div 369:115–120

Khan MNH, Fletcher C, Evans G, He Q (2003) CFD analysis of the mixing zone for a submerged jet system. In: Proceedings of the ASME fluids engineering division summer meeting, vol 1, pp 29–34

Khazam M, Arebi T, Mahmoudi T, Froja M (2016) A new simple CO2 minimum miscibility pressure correlation. Oil Gas Res 2(3):432–440

Liu R (2013) A miscible CO2 injection project and evaluation in Daqing, China. Pet Technol Altern Fuels 4(6):113–118

McLaughlin SR (2016) Simulation of CO2 Exsolution for Enhanced Oil Recovery and CO2 Storage, PhD Thesis, Stanford University, USA and Yuechao

Melzer LS (2012) Carbon dioxide enhanced oil recovery (CO2 EOR): factors involved in adding carbon capture, utilization and storage (CCUS) to enhanced oil recovery

Meyer JP (2007) Summary of carbon dioxide enhanced oil recovery (CO2 EOR) injection well technology, Prepared for the American Petroleum Institute

Mohyaldin ME, Ismail MC, Hasan N (2019) A correlation to predict erosion due to sand entrainment in viscous oils flow through elbows. In: Lecture notes in mechanical engineering—advances in material sciences and engineering (SPRINGER/Scopus), pp 287–297

Mohyaldinn ME, Husin H, Hasan N, Elmubarak MMB, Genefid AME (2019) Challenges during operation and shutdown of waxy crude pipelines. In: IntechOpen

Montazeri M, Sadeghnejad S (2017) An investigation of optimum miscible gas flooding scenario: a case study of an Iranian carbonates formation. Iran J Oil Gas Sci Technol 6(3):41–54

Naser J, Alam F, Khan M (2007) Evaluation of a proposed dust ventilation/collection system in an underground mine crushing plant. In: Proceedings of the 16th Australasian fluid mechanics conference, 16AFMC, pp 1411–1414

Olea RA (2017) Carbon dioxide enhanced oil recovery performance according to the literature, US Geological Survey

Parker ME, Meyer JP, Meadows SR (2009) Carbon dioxide enhanced oil recovery injection operation technologies. Energy Procedia 1(1):3141–3148

Perera MSA, Gamage RP, Rathnaweera TD, Ranathunga AS, Koay A, Choi X (2016) A review of CO2-enhanced oil recovery with a simulated sensitivity analysis. Energies 9(7):481

Poidevin SL, Kuske T, Edwards D, Temple R (2015) Report 7 browse basin: Western Australia and territory of ashmore and Cartier Islands adjacent area, Geoscience Australia

Qi R, Laforce TC, Blunt MJ (2008) Design of carbon dioxide storage in oilfields. In: SPE annual technical conference and exhibition, 21–24 September, Denver, Colorado, USA

Rashid H, Hasan N, Nor MIM (2014a) Accurate modeling of evaporation and enthalpy of vapor phase in CO2 absorption by amine based solution. Sep Sci Technol (Philadelphia) 49:1326–1334. https://doi.org/10.1080/01496395.2014.882358

Rashid H, Hasan N, Nor MIM (2014b) Temperature peak analysis and its effect on absorption column for CO2 capture process at different operating conditions. Chem Prod Process Model 9:105–115. https://doi.org/10.1515/cppm-2013-0044

Rezaei M, Eftekhari M, Schaffie M, Ranjbar M (2013) A CO2-oil minimum miscibility pressure model based on multi-gene genetic programming. Energy Explor Exploit 31(4):607–622

Rudyk S, Sogaard E, Khan G (2005) Experimental studies of carbon dioxide injection for enhanced oil recovery technique. University of Esbjerg, Esbjerg

Saeid NH, Hasan N, Ali MHBHM (2018) Effect of the metallic foam heat sink shape on the mixed convection jet impingement cooling of a horizontal surface. J Porous Media 21:295–309. https://doi.org/10.1615/JPorMedia.v21.i4.10

Safi R, Agarwal RK, Banerjee S (2015) Numerical simulation and optimization of carbon dioxide utilization for enhanced oil recovery from depleted reservoirs. Eng Appl Sci 144:30–38

Saoyleh HR (2016) A simulation study of the effect of injecting carbon dioxide with nitrogen or lean gas on the minimum miscibility pressure, Thesis, Submitted to the Graduate Faculty of Texas Tech University in Partial Fulfillment of the Requirements for the Degree.

Sern WK, Takriff MS, Kamarudin SK, Talib MZM, Hasan N (2012) Numerical simulation of fluid flow behaviour on scale up of oscillatory baffled column. J Eng Sci Technol 7:119–130

Slumberger E (2014) ECLIPSE pre- and post-processing suite PVTi

Steinsbo M, Brattekas B, Ferno MA, Graue A (2014) Supercritical CO2 injection for enhanced oil recovery in fractured chalk. In: International symposium of the society of core analysts, at Avignon, France

Tadesse NS (2018) Simulation of CO2 injection in a reservoir with an underlying paleo residual oil zone, Thesis, NTNU

Tian S, Zhao G (2008) Monitoring and predicting CO flooding using material balance equation. In: Petroleum Society of Canada, 8–10 June, Calgary, Alberta, Petroleum Society of Canada, p 47

Tzimas E, Georgakaki A, Cortes CG, Peteves SD (2005) Enhanced oil recovery using carbon dioxide in the European energy system. Rep EUR 21895(6):1–124

US Chambers C (2021) C02 enhanced oil recovery, Technological Breakthrough Allows for Greater Domestic Oil Production

Vark WV, Masalmeh SK, Dorp JV (2004) Simulation study of miscible gas injection for enhanced oil recovery in low permeable carbonate reservoirs in Abu Dhabi. In: Abu Dhabi international conference and exhibition, 10–13 October, Abu Dhabi, United Arab Emirates, Society of Petroleum Engineers

Verma MK (2015) Fundamentals of carbon dioxide-enhanced oil recovery (CO2-EOR): A supporting document of the assessment methodology for hydrocarbon recovery using CO2-EOR associated with carbon sequestration. US Department of the Interior, US Geological Survey, Washington, DC

Whittaker S, Perkins E (2013) Technical aspects of CO2 enhanced oil recovery and associated carbon storage. Global CCS Institute, Docklands

Ying ZH (2013) Evaluation of methods to lower MMP of crude oil in gas miscible displacement, thesis, Universiti Teknologi PETRONAS

Yuechao Z, Yongchen S, Yu L, Lanlan J, Ningjun, (2011) Visualization of CO2 and oil immiscible and miscible flow processes in porous media using NMR micro-imaging. 8(2):183–193

Zarei A, Azdarpour A (2017) Simulation study of miscible and immiscible injection of carbon dioxide into an oil reservoir in Iran. Int J Pharm Res Allied Sci 5(4):229–237

Zene MTAM, Hasan N, Ruizhong J, Zhenliang G (2019a) Volumetric estimation and OOIP calculation of the Ronier4 block of Ronier oilfield in the Bongor basin, Chad. Geomech Geophysci Geo-Energy Geo-Resour 5:371–381. https://doi.org/10.1007/s40948-019-00117-0

Zene MTAM, Hasan N, Ruizhong J, Zhenliang G, Trang C (2019b) Geological modeling and upscaling of the Ronier 4 block in Bongor basin, Chad. J Pet Explor Prod Technol 9:2461–2476. https://doi.org/10.1007/s13202-019-0712-z

Zhalehrajabi E, Rahmanian N, Hasan N (2014) Effects of mesh grid and turbulence models on heat transfer coefficient in a convergent-divergent nozzle. Asia-Pac J Chem Eng 9:265–271. https://doi.org/10.1002/apj.1767

Funding

These results are produced using Schlumber's donated (free for academics) software.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Abdullah, N., Hasan, N. Effects of miscible CO2 injection on production recovery. J Petrol Explor Prod Technol 11, 3543–3557 (2021). https://doi.org/10.1007/s13202-021-01223-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-021-01223-0