Abstract

The swelling and softening of mudstones caused by water often lead to serious geological disasters. In petroleum exploration and development, the hydration expansion of mudstone can also lead to serious wellbore instability hazards. The swelling of smectite clays is the main reason for this hydration expansion in mudstones. It is generally recognized that illite and illite–smectite mixed layer clays are both poor swellable and has a low effect on rock strength of smectite-poor mudstone. Furthermore, weakening law and degree of smectite-poor mudstone in water is not clear. This study conducted swelling tests and rock mechanics experiments on a smectite-poor mudstone from the Sichuan basin. The results show that both water content and swelling capacity tend to remain steady after soaking the samples for 24 h. The mudstone water content reached 5.36%, and the swelling rate was 2% after soaking in water for 72 h, and the rock had a lower unconfined compressive strength (UCS) value of 1.41 MPa. Adding KCl inhibited these processes, and elevated KCl concentrations drastically reduced the mudstone water content and swelling rate. Compared to water, the water content and swelling rate of mudstone soaked in a 6% KCl solution both decreased by 50%. The UCS and the elastic modulus also increased for a half-dry mudstone, although the inhibitor was important. At elevated KCl inhibitor concentrations, the UCS and elastic modulus of the hydrated mudstone were lower than those of the dry mudstone. The findings of this study can help for better understanding of the application of KCl inhibitor in water-based fluid for drilling engineering.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The swelling and softening characteristics of mudstones are closely related to many engineering accidents (Al-Homoud et al. 1996; Jiang et al. 2014; Zhang et al. 2013). For example, in petroleum engineering, serious wellbore instability is often caused by the hydration, swelling, and softening of mudstones in the borehole. This slows the construction rate of many drilling projects (Gholami et al. 2018). Oil-based drilling fluid may be the solution, but water-based drilling is increasingly being used for shale exploration and is considered to be more environmentally acceptable (Anderson et al. 2010). As a result, it is an urgent and challenging work to study the reaction mechanism between water-based drilling fluid and rocks and avoid engineering accidents.

Many researchers have previously studied swelling in mudstones. It is generally believed that when rocks are soaked in water they tend to expand and deform (Zheng et al. 2018), have a weaker strength (Shi et al. 2016), and produce expansion cracks (Li et al. 2019) that often cause geological disasters. Many studies of hydrated mudstones have also been carried out. The strength of clay-rich mudstone decreases significantly after soaking in water, to strengths below 60% of the dry rock value (Erguler and Ulusay 2009; Goodman 1989). Previous studies have established that this swelling and the associated weakness are mainly caused by the hydration and expansion of smectite clays. The ion exchange responded to hydration of shale which includes smectite clay (Wang et al. 2020). The reduction in interlayer spacing by means of K+ exchange could be a major reason for the attenuation of swelling behavior (He et al. 2019). The water activity is positively correlated with the total clay mineral content, especially the amount of smectite in illite–smectite mixed layer clay (Wen et al. 2015). In petroleum engineering, KCl has been used to restrain wellbore instability caused by mudstone hydration swelling (Horsrud et al. 1998; Olayiwola and Dejam 2020; Simpson et al. 1995). The swelling capacity of shale decreases with increasing KCl concentration (Shi et al. 2019). Furthermore, smectites are called swelling clay minerals (Li et al. 2017; Liu and Chen 2013; Zhang et al. 2014). However, existing results fail to resolve effects on swelling between smectite-rich (> 50%), low-smectite (< 10%), and smectite-poor (< 5%) mudstones and few studies have investigated hydration swelling in low-smectite or smectite-poor mudstones and previous studies have not dealt with the effect of KCl on swelling and weakening of smectite-poor mudstone.

This study focuses on hydration swelling and rock mechanics in smectite-poor mudstone. A smectite-poor mudstone was selected. Swelling and unconfined compressive strength (UCS) tests were conducted on a mudstone from the Sichuan basin, and X-ray diffraction (XRD) analyses were carried out. The results highlight the importance of clay minerals, especially illite–smectite mixed layer clays, and KCl concentration on mudstone hydration and swelling (Fig. 1). This study turns to the poor content of smectite of mudstone, but still need to investigate the more continuous change content of smectite of mudstone and more inhibitor KCl experiments.

Materials and methods

Materials

The mudstone used in this study was collected from the Sichuan basin. Cylindrical samples were cut from the mudstone, each with a diameter of 25 mm and a height of 50 mm (Fig. 2). XRD analyses were first carried out on the mudstone to analyze its mineral composition, including the total mineral content and the relative clay mineral content (Fig. 3). The mudstone contained clay minerals, quartz, calcite, and plagioclase as its main mineral components. The clay minerals were illite, chlorite, and illite–smectite mixed layer clays. Porosity, permeability, and density tests were also conducted on the mudstone. The porosity of the mudstone was 7.47%, and the permeability was 0.0149 mD (Table 1).

Methods

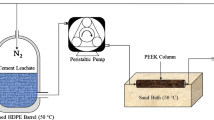

The rock samples were placed in an electro-thermostatic drying oven and dried at 105 °C for 24 h. The samples were allowed to cool, after which their masses were determined. A ZNP-01 swelling meter was used for the swelling tests (shown in Fig. 4) that had an accuracy of 0.01 mm and a range of 10 mm. The dried mudstone samples were placed into the swelling meter and soaked in water (0%) and 2%, 4%, 6%, and 8% KCl solutions, respectively. The swelling capacities of samples soaked for 72 h were recorded, and we calculated the swelling rate as follows:

where δt is the unloaded swelling rate at time t (%); Rt is the meter reading at time t (mm); R0 is the meter reading at the beginning of the test (mm); and h0 is the initial height of sample (mm).

The mass of each rock sample was then measured after soaking, and the water content was calculated as follows:

where w is the water content, mw is the mass after soaking, and m is the mass before soaking.

In order to study the effect of KCl concentration on the mechanical properties of the mudstone samples, UCS experiments were conducted on the rock samples that were soaked for 72 h. An RTR-1000 (GCTS, American) triaxial rock mechanics apparatus was used for these analyses. A displacement-controlled load (0.1 mm/min) was applied to each sample, and the axial stress, axial strain, and lateral strain were measured (Fig. 5).

Results

Water content

The absorption of the mudstone samples soaked in various KCl solutions is shown in Table 2. The results show that with increased KCl concentrations, the water content of the samples gradually decreased. When the KCl concentration was 6%, the water content of the sample was reduced by 50%. At higher KCl concentrations, the water content remained steady. Figure 6 shows the changes in water content with KCl concentration. The KCl concentration and water content have a negative exponential relationship as follows:

where w is the water content and a, b, c are the fitting parameters, and λ is the KCl concentration.

Equation 3 largely describes the relationship between KCl concentration and water content. Using the fitting results, a, b, and c can be obtained as 2.2627, 3.1430, and 0.3772, respectively, and the correlation coefficient R2 is 0.98 (Fig. 6).

Swelling rate

The swelling capacities of the mudstone samples soaked in various KCl solutions are shown in Fig. 7. Compared to the conditions in the other experiments, the swelling capacity was the largest for water (0% KCl) and reached its maximum at 20 h. However, the swelling capacities of the other samples increased within 24 h but did not reach their maxima until 48 h, after which the swelling capacity continued to increase, but only minimally. KCl had a good inhibitory effect on the swelling capacity. With increased KCl concentrations, the swelling capacity decreased. The final swelling capacity decreased from 1.02 mm (0% KCl) to 0.19 mm (6% KCl) and 0.23 mm (8% KCl), thus reducing the swelling capacity of the mudstone by approximately 80%.

The final swelling rate at 72 h is calculated using Eq. 1. The KCl concentration and swelling rate have a negative exponential relationship (Eq. 4). With an increased KCl concentration, the swelling rate decreased. When the KCl concentration was 6%, the swelling rate tended to remain stable. The final swelling rate decreased from approximately 2% to 0.5%.

where δt is the swelling rate, a, b, c are the fitting parameters, and λ is the KCl concentration.

From the fitting results, a, b, and c can be obtained as 0.1589, 1.9272, and 0.2966, respectively, and the correlation coefficient R2 is 0.96 (Fig. 8).

Rock mechanical properties

Figure 9 shows the stress–strain curve obtained from the UCS analyses, and Table 3 lists the mechanical parameters of the mudstone. The UCS of the dry rock was 33.86 MPa. It is worth mentioning that the mudstone soaked in water broke completely and we could not obtain its UCS, elastic modulus, or Poisson’s ratio. The UCS and elastic modulus of the mudstone increased with increased KCl concentrations, while Poisson’s ratio decreased (Fig. 10). When the KCl concentration reached 8%, the UCS of the mudstone increased to 13.33 MPa, the elastic modulus increased to 1.48 GPa, and Poisson’s ratio decreased to 0.27. Although the KCl had a strong inhibitory effect on swelling, the UCS and elastic modulus of the 8% KCl-soaked sample were both more than 50% lower than those of the dry rock.

Failure state

Figure 11 shows the failure states of the mudstone samples soaked in various KCl concentrations after UCS testing. The mudstone soaked in the water broke completely, and UCS testing could not be carried out, and the failure state could not be obtained. By comparing Fig. 11 and the stress–strain curves in Fig. 9, it is clear that the dry rock underwent significant brittle failure. After the stress peaked, it dropped abruptly and splitting cracks appeared in the middle of the sample. Brittle failure can therefore be considered the failure mode for mudstone that did not undergo hydration. The failure mode for the mudstone soaked in the 8% KCl solution was similar to that of the dry rock; both samples exhibited brittle failure. However, the failure mode of the mudstones soaked in 2%, 4%, and 6% KCl solutions was clearly plastic failure. The Poisson’s ratio of these samples (2%, 4%, and 6% KCl) was larger than that of the dry rock. The 8% KCl-soaked sample had a Poisson’s ratio above 0.3. After the stress peaked in these samples, the stress decreased gradually rather than declining sharply. These factors are all signs of plastic failure. The cracks in these samples were complex, and the sample soaked in 2% KCl appeared to contain more horizontal cracks.

Discussion

The swelling capacity of smectite in our samples was very obvious after soaking in water, as it is the main clay mineral that causes swelling and weakening in mudstone. However, the swelling effects of other minerals on the overall rock strength should not be neglected. The illite and illite–smectite mixed layer clays both have the capacity to swell and weaken the mechanical characteristics of the rock. The volume of the illite when soaked in water could increase by 50–60% (Du et al. 2018; Horsrud et al. 1998). The mudstone used in this study contained 27.4% clay minerals, of which 52% was illite and 38% was illite–smectite mixed layer clays. The mudstone that was soaked in water swelled extensively and softened to the point where the rock strength could not be tested. However, the KCl solutions had a good inhibiting effect on the mudstone. With increased KCl concentration, the rock strength and elastic modulus gradually increased, while the Poisson’s ratio declined. The KCl concentration and rock mechanical properties have a relatively linear relationship. When the KCl concentration was 8%, the UCS of the mudstone increased to 13.33 MPa, which is approximately half of the dry rock value, and the elastic modulus increased to 1.48 GPa, which is only 39.75% of the dry rock value. As mentioned previously, KCl had a good inhibiting effect on swelling; however, the decrease in rock strength caused by soaking the mudstone in water should not be overlooked. But these findings of this paper need to be verified in more rocks.

Summary and conclusions

We conducted a set of experiments to investigate the effect of inhibitor KCl on smectite-poor mudstone. The results show that smectite-poor mudstone still has the capacity to exhibit strong swelling and softening characteristics when soaked in water. The KCl is able to inhibit the hydration of smectite-poor mudstone and led to the following conclusions.

-

For water contents above 6%, KCl had an inhibiting effect on swelling and water absorption of the mudstone. However, the water content and swelling rate tended to remain steady when the KCl concentration was above 6%. Water content and KCl concentration show a negative exponential relationship, as do KCl concentration and swelling rate.

-

The mudstone lost most of its strength after soaking in water for 72 h; however, with increased KCl concentrations the strength and elastic modulus gradually increased. When the KCl concentration increased to 8%, the rock strength increased to 13.33 MPa and the elastic modulus increased to 1.48 GPa. However, both of these values are still far below the strength and elastic modulus of the dry rock by more than 50%.

-

Brittle failure mode occurred in dry mudstone samples; plastic failure occurred in wet rock samples when soaked in KCl solutions.

References

Al-Homoud AS, Khoury H, Al-Omari YA (1996) Mineralogical and engineering properties of problematic expansive clayey beds causing landslides. Bull Eng Geol Environ 54:13–31. https://doi.org/10.1007/bf02600694

Anderson RL, Ratcliffe I, Greenwell HC, Williams PA, Cliffe S, Coveney PV (2010) Clay swelling—a challenge in the oilfield. Earth-Sci Rev 98:201–216

Du J, Hu L, Meegoda JN, Zhang G (2018) Shale softening: observations, phenomenological behavior, and mechanisms. Appl Clay Sci 161:290–300. https://doi.org/10.1016/j.clay.2018.04.033

Erguler ZA, Ulusay R (2009) Water-induced variations in mechanical properties of clay-bearing rocks. Int J Rock Mech Min Sci 46:355–370. https://doi.org/10.1016/j.ijrmms.2008.07.002

Gholami R, Elochukwu H, Fakhari N, Sarmadivaleh M (2018) A review on borehole instability in active shale formations: interactions, mechanisms and inhibitors. Earth Sci Rev 177:2–13. https://doi.org/10.1016/j.earscirev.2017.11.002

Goodman RE (1989) Introduction to rock mechanics, vol 2. Wiley, New York

He Y, Ye W-M, Chen Y-G, Cui Y-J (2019) Effects of K+ solutions on swelling behavior of compacted GMZ bentonite. Eng Geol 249:241–248. https://doi.org/10.1016/j.enggeo.2018.12.020

Horsrud P, Bostrom B, Sonstebo EF, Holt RM (1998) Interaction between shale and water-based drilling fluids: laboratory exposure tests give new insight into mechanisms and field consequences of KCl contents. Paper presented at the SPE annual technical conference and exhibition, New Orleans, Louisiana, 1998/1/1/

Jiang Q, Cui J, Feng X, Jiang Y (2014) Application of computerized tomographic scanning to the study of water-induced weakening of mudstone. Bull Eng Geol Environ 73:1293–1301. https://doi.org/10.1007/s10064-014-0597-5

Li S, Xu Q, Zhang L, Peng D, Liu H, Song S (2017) Time effect and mechanism of strength weakening of loess soaked in water in Heifangtai area. Rock Soil Mech 38(2043–2048):2058. https://doi.org/10.16285/j.rsm.2017.07.026

Li B, Liu J, Bian K, Ai F, Hu X, Chen M, Liu Z (2019) Experimental study on the mechanical properties weakening mechanism of siltstone with different water content. Arab J Geosci. https://doi.org/10.1007/s12517-019-4852-8

Liu T, Chen Y (2013) A molecular dynamics study of the swelling patterns of Na/Cs-montmorillonites and the hydration of interlayer cations. Chin Phys B 22:027103

Olayiwola SO, Dejam M (2020) Experimental study on the viscosity behavior of silica nanofluids with different ions of electrolytes. Ind Eng Chem Res 59:3575–3583. https://doi.org/10.1021/acs.iecr.9b06275

Shi X, Cai W, Meng Y, Li G, Wen K, Zhang Y (2016) Weakening laws of rock uniaxial compressive strength with consideration of water content and rock porosity. Arab J Geosci. https://doi.org/10.1007/s12517-016-2426-6

Shi X, Wang L, Guo J, Su Q, Zhuo X (2019) Effects of inhibitor KCl on shale expansibility and mechanical properties. Petroleum 5:407–412. https://doi.org/10.1016/j.petlm.2018.12.005

Simpson JP, Walker TO, Jiang GZ (1995) Environmentally acceptable water-base mud can prevent shale hydration and maintain borehole stability. SPE Drill Completion 10:242–249. https://doi.org/10.2118/27496-pa

Wang Y, Liu X, Liang L, Xiong J (2020) Experimental study on the damage of organic-rich shale during water-shale interaction. J Nat Gas Sci Eng 74:103103. https://doi.org/10.1016/j.jngse.2019.103103

Wen H, Chen M, Jin Y, Zhang Y, Ge W, Du J, Zeng C (2015) Water activity characteristics of deep brittle shale from Southwest China. Appl Clay Sci 108:165–172. https://doi.org/10.1016/j.clay.2015.02.015

Zhang Y, Guo C, Yao X, Qu Y, Zhou N (2013) Engineering geological characterization of clayey diatomaceous earth deposits encountered in highway projects in the Tengchong region, Yunnan, China. Eng Geol 167:95–104. https://doi.org/10.1016/j.enggeo.2013.10.009

Zhang L, Lu X, Liu X, Zhou J, Zhou H (2014) Hydration and mobility of interlayer ions of (Nax, Cay)-Montmorillonite: a molecular dynamics study. J Phys Chem C 118:29811–29821. https://doi.org/10.1021/jp508427c

Zheng Y, Chen C, Liu T, Zhang W, Song Y (2018) Slope failure mechanisms in dipping interbedded sandstone and mudstone revealed by model testing and distinct-element analysis. Bull Eng Geol Environ 77:49–68. https://doi.org/10.1007/s10064-017-1007-6

Funding

This research was funded by the National Natural Science Foundation of China (No. 51774248), International Science and Technology Innovation Cooperation Foundation of Sichuan in China (No. 2019YFH0166), Major Science and Technology Project Group of Sinopec of China (No. P18021-1), and National Major Science and Technology Projects of China (No. 2016ZX05053-004-001).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chen, X., Yi, H., Gao, L. et al. Effects of inhibitor KCl on hydration swelling and softening of a smectite-poor mudstone. J Petrol Explor Prod Technol 10, 2685–2692 (2020). https://doi.org/10.1007/s13202-020-00948-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-020-00948-8