Abstract

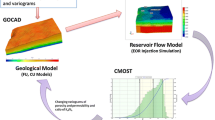

Risk or uncertainty assessment in the reservoir flow modeling, especially in real field-scale evaluation, is essential to make a trustful decision regarding the future development plans. This paper presents an efficient uncertainty assessment workflow of geological and production data through the cyclic \(\text{CO}_2\)-assisted gravity drainage (GAGD) process in South Rumaila oil field in Southern Iraq. First, the sequential Gaussian simulation created a large number of reservoir stochastic realizations that capture the entire geological uncertainty space. Second, ranking was applied to select the quartiles \((\text{P}10, \text{P}20,\ldots ,\text{P}90)\) of reservoir permeability and anisotropy ratio to quantify the geological uncertainty. Next, the equation of state-compositional flow model was constructed to evaluate these realizations by calculating the reservoir flow response. Then, 81 designed simulations were created by factorial design considering the combined realizations of permeability and anisotropy ratio. In a successive step, the most-likely model was considered for the uncertainty quantification of the operational decision parameters through the cyclic GAGD process to restrict the uncertainty space, which leads to obtain the true optimal scenario. The cyclic GAGD operational parameters include durations of injection, soaking, and production and the minimum bottom hole pressure in production wells. The compositional reservoir flow model was again used to evaluate the multiple simulations created by the proxy-based Box–Behnken design and Monte Carlo simulation. The combined geological and production uncertainty workflow gave an idea about the uncertainty or risk space of the predicted reservoir flow response in the future cyclic GAGD process performance.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Lacks in geological and reservoir data produces uncertain geomodels and then uncertain reservoir flow simulation. That leads to increase the risk with respect to making trustful decisions in the future reservoir development scenarios (Guyaguler and Horne 2001). Consequently, it is essential to assess the uncertainty in terms of the geological and production parameters to reduce that risk. Since there is limited geological information required to build efficient reservoir models, there is the inability to precisely evaluate the reservoir performance. That increases the uncertainty associated with forecasting in the future reservoir performance and negatively impacts the economic returns (Zhang 2003). Specifically, the limited knowledge comes from lack of observations, distinct scales of petrophysical data, measurement error, limited understanding of physical problems, and non-linear data behavior. Therefore, the uncertainty assessment is necessary to construct a solid basis in the reservoir management for development and optimization to improve the decision making (Cruz 2000).

The uncertainty is quantified through a large number of equiprobable reservoir stochastic images (realizations) with different sets of dynamic data to obtain a flow response distribution through the Cumulative Probability Function (CPF). In uncertainty assessment, nine quantiles, which represent a range of realizations from less-likely to most-likely, are collected based on a probability distribution to generate the same range of the calculated field cumulative oil production and/or net present value (Liu et al. 2001). As a result, uncertainty quantification includes three main steps in integrated reservoir simulation studies through experimental design approaches: sensitivity analysis for parameters screening, reservoir modeling, and Monte Carlo simulation (Carpenter 2013).

The most common methods for uncertainty assessment encompass: Monte Carlo simulation, experimental design-response surface methodology, multiple realization tree, relative variation method, and Bayesian methods. An empirical response surface model (RSM) has been developed with design of experiments (DoE) to diagnose and investigate several geologic factors (White et al. 2001). RSM usually considers the second-degree quadratic equation or kriging interpolation to model the response factor as a function of several variables in physical processes. The response surface model is not only used in identifying the most sensitive factors that affect a response, but also to obtain the most-likely scenario that achieves the optimal response through a process. RSM also identifies the possibility of estimating interactions between the factors (White and Royer 2003). IN RSM, a surface is fitted through the responses corresponding to a few sampled set of parameters. This surface could be a polynomial function or established using ordinary kriging and the surface is subsequently used for uncertainty quantification. Comparative applications of polynomial and kriged response surface models have been conducted considering orthogonal arrays sampling, Latin Hypercube Sampling, and Hammersley Sequence design as efficient approaches for uncertainty quantification (Kalla and White 2007).

Many other uncertainty quantification studies have been carried out through experimental design concepts with different methods of handling either variable sampling or sub-selections. Some of these methods represent coupling of streamline reservoir simulation and the neighborhood approximation algorithm along with the conventional reservoir model to assemble the model parameters separately from less-likely misfit regions of parameter space (Subbey et al. 2003). Another approach integrates the neighborhood approximation algorithm with Markov chain Monte Carlo as a stochastic sampling method to surmount the poor convergence (Okano et al. 2006). There are many lessons learned from real oil and gas fields using experimental design and response surface models in uncertainty quantification. They have shown how efficient using the DoE method to minimize the reservoir simulation runs during the formulation of proxy models. The experimental design has proved efficiency in conducting uncertainty framing, screening parameters, Bayesian updating of parameters, and risk analysis (Amudo et al. 2009). Many statistical validation tools such as analysis of variance (ANOVA) table and partial t test are required to validate the experimental design approach and assess the factors uncertainty. ANOVA is used in modeling the relationship between response and uncertainty factors. Moreover, it is used to investigate the accuracy of regression models and likewise to measure the effect of each factor on the response by computing the variance and mean square error (White and Royer 2003).

In geological uncertainty, the assessment of 3D Lithofacies, porosity, and permeability distributions should be accomplished considering the limited number of stochastic reservoir images (realizations) due to computer limitations. Many techniques have been adopted for ranking the geostatistical realizations to obtain the less-likely (pessimistic), median, and more-likely (optimistic) levels within a large number of realizations that capture the various reservoir heterogeneities. The main concept of ranking is to calculate a reservoir flow response, which represents the objective function for comparison between the realizations. Examples of the objective functions include: hydrocarbon production over a cross section (Ballin et al. 1993), the minimized error between calculated and observed field production through history matching (Kalogerakis 1994; Oliver 1996), cumulative field hydrocarbon production, net present value (NPV), and the production response through infill drilling (Deutsch and Journel 1998; Hegstad and Henning 2001; Landa and Horne 1997; Wen et al. 1997), and streamline reservoir simulation (Ates et al. 2003).

In this paper, the geological and production uncertainties were quantified to reduce the risk regarding the field development plans through the cyclic \(\text{CO}_2\)-assisted gravity drainage EOR process in the main pay reservoir of South Rumaila oil field, located in Southern Iraq. In particular, the geological and production uncertainties were quantified to restrict the risk towards obtaining the actual optimal solution through the optimization of the cycling \(\text{CO}_2\)-GAGD process. To the best of authors’ knowledge, this workflow of conducting sequential uncertainty quantification of geological and production parameters has not been adopted in the petroleum literature, especially regarding the gas-assisted gravity drainage (GAGD) process evaluation on a real field-scale heterogeneous sandstone reservoir. Unlike the conventional gas-EOR processes of continuous gas injection (CGI) and water-alternative gas (WAG), the GAGD process takes advantage of the natural segregation of reservoir fluids to provide gravity-stable oil displacement and then to improve oil recovery.

Field and reservoir description

The South Rumaila field consists of multiple oil producing formation. Zubair is the largest reservoir, which belongs to the Late Berriasian–Albian cycle in the Lower Cretaceous age (Al-Ansari 1993). The thickness range of Zubair reservoir is 280–400 m with levels decreasing towards south-west field side (Al-Obaidi 2010). Zubair formation is composed on five reservoirs based on sand-to-shale ratio: upper shale (top), upper sandstone, middle shale, lower sand, and lower shale (bottom). The upper sandstone reservoir in Zubair formation represents the main pay of South Rumaila Field (Mohammed et al. 2010). The main pay comprises of five dominated sandstone units (AB, DJ1, DJ2, LN1, and LN2), separated by four discontinuous shale layers (C1, C2, K1, and K2) located between the five units (Al-Mudhafar 2017). The shale layers represent as barriers to impede the vertical fluid migration in some areas. The entire stratigraphic column in Rumaila oil field is illustrated in Fig. 1.

The South Rumaila oil field has four production sectors: Qurainat (north), Shamiya, Rumaila, and Janubia (south). The area investigated includes Rumaila sector and souther and northern parts from Shamiya and Janubia sectors, respectively. This sector was selected based on the availability of data and the ability to represent the largest part, where the production and injection operations are carried out. In this sector, two kinds of boundary conditions encountered: a no-flow and an aquifer boundaries. The no-flow northern and southern boundaries are assumed, because the isobaric lines are perpendicular to these boundaries, where the production flow lines are in parallel. The infinite active aquifer at the eastern and western flanks represents a no-flow boundaries (Al-Mudhafer et al. 2010).

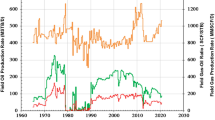

Primary oil production started in the South Rumaila field in early 1954, but water injection was not initiated until the 1980s to maintain infinite active edge-aquifer support from west flank, which accumulates up to 20 times the influx from east one (Al-Mudhafer et al. 2010; Kabir et al. 2007). During field production history, 40 producers were opened to flow in the sector under study. The production of some layers was ceased, because the high water cut values exceeded 98%. By the year 2004, the cumulative water injection was approximately 1.1 billion barrels. The injection rates have varied widely with a maximum of nearly 426,000 BPD for 2 months in 1988. Artificial lift has been recently installed in the main pay wells to handle the wells incapable of flowing to the surface after the water cuts reach approximately 80%. The estimated original oil in place (OOIP) for the main pay is 19.5 billion barrels and for the sector is around 6.123 billions barrel. Moreover, the approximate current recovery factor is 55%. The peak oil production was 1.35 MMBPD in May 1979. The current oil production in July 2013 was approximately 1,250,000 MMBPD.

Gas-assisted gravity drainage process

The GAGD process has been suggested to overcome the limitations of CGI and WAG by obtaining promising levels of oil recovery in secondary and tertiary operations through both immiscible and miscible gas flooding. The main concept of the GAGD process states that gas is injected through gravity-stable mode by vertical wells at the top of reservoir to formulate a gas cap. The difference in fluid densities leads to gravity segregation causing oil to drain down at the bottom of reservoir, where series of horizontal producers are placed (Rao et al. 2004). That process ensure significant improvements in vertical sweep efficiency and high oil recovery.

Carbon dioxide is the most preferred gas used for injection as it achieves high volumetric sweep and microscopic displacement efficiencies, especially in miscible injection processes. The high volumetric sweep efficiency eliminates gas breakthrough in the production wells, increases gas injectivity, and reduces the required injection pressure (Rao 2012). Figure 2 depicts the schematic of the GAGD process.

GAGD process simulation

To test the feasibility of the GAGD process to improve oil recovery in field-scale examples, a full Equation of state-compositional flow model was constructed to evaluate the main pay/South Rumaila oil field performance. A high-resolution geostatistical reservoir model, with 1,908,900 grids of 210, 202, and 45 grids in I, J, and K directions, was reconstructed and upscaled for the GAGD process flow simulation. The multiple-point geostatistics and sequential Gaussian simulation were adopted for the lithofacies and petrophysical property modeling, respectively. The upscaled reservoir model, with 55,000 grids of 69, 66, and 12 grid dimensions, was exported to build the compositional reservoir flow simulation. Figure 3 represents the lithofacies, porosity, and vertical and horizontal permeability models of the main pay in South Rumaila oil field.

For the GAGD process evaluation, 22 vertical injection wells and 11 horizontal producers were installed through the reservoir at high-permeable zones. \(\text{CO}_2\) is injected through the vertical wells at the top two layers of the reservoir. The third, fourth, and fifth layers were left to allow an interval for the gravity drainage. The horizontal wells were placed in the sixth, seventh, and eighth layers that have high oil saturation. The bottom four layers did not have any injection or production activities because of the high water saturation levels. The GAGD process was evaluated through a 10 years of future production period from 2016 to 2026. Figure 4 shows the locations of injection and production wells installed for \(\text{CO}_2\) flooding and oil production through the \(\text{CO}_2\)-assisted gravity drainage (GAGD) process in South Rumaila oil field.

Production and injection well locations in high-permeable regions (sand and shaly-sand). The reservoir body is represented by a red color, which denotes to shale zones. However, the perforations of producers and injectors were mainly placed in sand (indicator number 2) and shaly-sand (indicator number 1) regions of high permeability levels

The edge-water drive aquifer, which is located at the eastern and western boundaries, was activated in the reservoir model to support pressure maintenance and improve history matching procedure. The Carter–Tracy aquifer approach was adopted to simulate the infinite active aquifer. In addition, small grid blocks are needed in regions, where fluid saturations have large variations. Therefore, non-uniform grid refinements were set in the vicinity of the \(\text{CO}_2\) injection wells through the first two layers that have perforations. The grid refinement leads to eliminate sharp changes in the fluid property calculations. Moreover, it precludes the instability of the compositional transition between the injected \(\text{CO}_2\) and crude oil (viscous fingering). Contrary, selecting coarse grid blocks in the compositional modeling of the \(\text{CO}_2\) flooding gives rise to a significant effect of numerical dispersion, which leads to inaccurate recovery calculations.

On the other hand, an excellent history matching was obtained through trial and error process with respect to cumulative oil production and water injection as well as fluid flow rates in regard to the entire field. The production and injection matching is a good indicator of reservoir and fluid behavior as it reflects the matching of water cut and saturation distributions. The entire production history for the simulation period in this study is approximately 56 years. The production and injection flow rates were available until February 2010. Therefore, the history matching was achieved from 1954 until 2010. Figure 5 shows the matching between field production rates and cumulative oil production. In addition, Fig. 6 depicts the matching between field injection rates and cumulative water injection.

Design of experiments

The DoE is a systematic statistical tool that creates a proper set of experiments for simulation. DoE is used for the purpose of identifying the most sensitive factors that affect the response through the sensitivity analysis procedure. Furthermore, DoE helps an individual obtain the most-likely scenario that achieves the optimal response through a process. In addition, the DoE approach has the possibility to evaluate the interaction terms between some of all the factors to find out some combined influential roles in the process (Lazic 2006). Since the designed experiments are typically faster, cheaper, and more flexible than physical experiments, it is necessary to ensure achieving the most accurate model that mimics the physical model or process. To achieve that, the required numbers of factors and interactions should be analyzed to make the interpretation and application of results correct and reliable (White and Royer 2003; Al-Mudhafar 2016b).

The main terminologies in DoE are response variable that simply represents the outcome from an experiment or process. Factors are variable that affect the response variable. The values that a factor can assume are called levels. Primary and secondary factors are the variables that are most and less sensitive, respectively. The total number of designed experiments has an exponential formula. For instance, the number of experiments given k variables with 3 levels equal \(3^{k}\). The sampling techniques, such as factorial design, one factor at a time, and Box–Behnken design, etc., should be considered to combine multiple levels for each factor in a systematic procedure to create a population of observations (Montgomery and Runger 2003).

Box–Behnken design is an independent design, which include neither factorial nor fractional factorial designs, that mostly fits to the quadratic response surface design (Montgomery 1997). Box–Behnken design creates the experiments by selecting combinations at the midpoints and centers of the process space edges. The number of factors and levels should be more than two to be treated in the Box–Behnken design (Kalla and White 2007). Figure 7 depicts a Box–Behnken design for three factors example.

Box–Behnken design for three factors example (NIST 2012)

Box–Behnken design was adopted for the production uncertainty assessment given the most-likely model of the cyclic GAGD process, which resulted after quantifying the geological uncertainty assessment.

Geological uncertainty

The uncertainty assessments were successively quantified to count for geological and production uncertainties through the cyclic GAGD process optimization. The geological uncertainty assessment was conducted by embedding the nine quantiles of the geostatistical realizations \((\text{P}10, \text{P}20,\ldots , \text{P}90)\) for permeability and anisotropy ratio in the GAGD reservoir simulation. The permeability was distributed in 3D given the multiple-point geostatistics of the lithofacies simulation (Al-Mudhafar 2016a). The nine realizations of permeability are depicted in Fig. 8.

The optimal set of injection, soaking, and production periods along with the minimum bottom hole pressure in production wells were set as nominal values in the geological uncertainty assessment. Since there are nine quantiles from permeability and \(K_{\mathrm{v}}/K_{\mathrm{h}}\), the total number of simulations in the geological uncertainty was 81 \((9^2 = 81)\).

The workflow of the geological uncertainty quantification is outlined below (CMG 2015):

-

1.

Create discrete realizations of static reservoir properties that represent model uncertainty.

-

2.

Create a parameter that includes these realizations as candidate values in the assessment model.

-

3.

Generate multiple simulation jobs honoring the uncertain space realizations.

-

4.

Run the reservoir simulation jobs, including all the realizations.

-

5.

Evaluate and analyze the simulation outcome, then select the three quantiles of the model outcome.

Flowchart of geological uncertainty is illustrated in Fig. 9.

Production uncertainty

After conducting the geological uncertainty quantification and obtaining the most-likely reservoir model that has the actual cumulative oil production (objective function) given the optimal set of permeability and anisotropy realizations, production uncertainty was assessed given the uncertain operational decision parameters of the cyclic GAGD process. The uncertain parameters includes: injection, soaking, and production periods of the gas injection cyclic in addition to the minimum bottom hole pressure (BHP) in the horizontal producers. The optimal set of these parameters was obtained from the optimal cyclic GAGD process, which was addressed in a previous work (Al-Mudhafar et al. 2016). These optimal parameters might have some uncertain values that may lead to obtaining higher objective function. The uncertain values may be resulted from the significant difference between each two levels in the suggested values for each parameter in the optimization process.

Consequently, uncertainty assessment in the varied cyclic parameter levels was conducted through the DoE, proxy modeling, and Monte Carlo simulation. First, the Box–Behnken design was employed to generate the training and verification simulation jobs by combining the levels of each of the four influential cyclic parameters. To capture the overall uncertainty space with less number of observation, three levels of each parameter (min, median, and max) were sampled based on uniform, triangle, and truncated normal distributions. These distribution types were adopted to generate normal or semi-normal sampled data behavior as the all original data, used to build the geological model, was transformed to the normal distribution. The total number of simulation jobs sampled by Box–Behnken design that capture a wide variety of the uncertain parameters is 25. Next, the ordinary kriging algorithm, based on the reservoir outcome from the training simulation jobs, built a proxy model in this case. Then, the proxy model was validated by the verification simulation jobs. Finally, based on the verified proxy model, 65,000 simulation jobs were created by the Monte Carlo simulation to quantify and analyze the uncertainty in the reservoir cumulative oil production. The complete flow chart of cyclic uncertainty assessment procedure is illustrated in Fig. 10.

Results and discussion

Geological uncertainty quantification

In the geological uncertainty assessment, 81 simulation runs were conducted considering the combined realizations of permeability and anisotropy ratio. Figures 11 and 12 illustrate the outcome of integrating the geological uncertainties in the GAGD reservoir simulation with regard to cumulative oil production and field oil production rate, respectively. The figures show how the geological uncertainty assessment affected the reservoir flow response by producing distinct reservoir flow responses given the different geological realizations.

To obtain more detailed analysis of the geological uncertainty space, Fig. 13 shows the histogram of the quantified uncertainty effect on the reservoir flow response. The figure also illustrates the less-likely (P10), median (P50), and most-likely (P90) of field cumulative oil production. Furthermore, Fig. 14 depicts the cumulative probability distribution function in addition to the less-likely, median, and most-likely of cumulative oil production values. The wide variety range of the calculated reservoir flow response reflects the importance of quantifying the geological uncertainty in the cyclic GAGD process reservoir simulation.

From the mentioned four figures, the geological uncertainty has a significant impact on the reservoir flow response as there is a gap between the P90 and P10 of cumulative oil production (55.3 million bbls). The input quantiles for the geological parameters that led to generate the less-likely, median, and most-likely outcomes are outlined in Table 1.

The P80 level of reservoir permeability and the P70 level of the anisotropy ratio were both combined to obtain the most-likely reservoir flow response. All the resulted three quartiles have cumulative oil production less than the mean value of mean quartiles of permeability and anisotropy ratio. That indicates the risk in field development plans resulted from the geological uncertainties.

Production uncertainty quantification

The same optimal robust solution, included in the geological uncertainty assessment, was likewise integrated into the uncertainty assessment of the operational decision factors of the cyclic GAGD process simulation. The uncertain factors are minimum bottom hole pressure in production wells in addition to the injection, soaking, and production periods. Figures 15 and 16 illustrate the reservoir flow response with respect to cumulative oil production and field oil flow rate for all the simulation runs conducted using proxy-based Monte Carlo simulation, respectively.

There was a little variability in the reservoir flow response among the base case, the optimistic model of geological uncertainty, and other simulated models. The difference between the resulting less-likely and most-likely objective functions is only 7.5 million barrels of oil, as illustrated in Figs. 17 and 18. The limited uncertainty for some production control variables led to slight increment in oil recovery, which is equal to 6.53 million barrels of oil over the optimal robust solution. The maximum cumulative oil production obtained by the production uncertainty assessment is 4.632 billion bbls, whether the optimal robust solution was 4.62547 billion bbls.

The P10, P50, and P90 of the four uncertain cyclic parameters resulted in obtaining the less-likely, median, and most-likely objective functions in different impact levels, respectively. Figures 19, 20, 21, and 22 depict the probability distribution of the objective function (cumulative oil production) for the four uncertain parameters given the three model outcomes: less-likely, median, and most-likely. In these three figures, there is slight significant gap between the resulting reservoir flow responses given the different realizations of the injection, soaking, and production periods, as well as the minimum bottom hole pressure. More specifically, all the optimization processes of the cyclic GAGD simulation resulted in impeding the optimal range of reservoir flow response as a function of a small uncertain range for the decision parameters. From the cumulative probability distributions for the four parameters, it can be inferred that the injection periods and minimum BHP are more sensitive parameters than soaking and production periods.

Conclusions

To make a trustful decision about the future field development plans of the cyclic \(\text{CO}_2\)-assisted gravity drainage (GAGD) process, two different successive uncertainty quantification approaches were conducted to obtain the true optimal solution of oil recovery in the South Rumaila oil field. Given the base reservoir model of nominal production controls, the uncertainty was first quantified in terms of geological parameters. Therefore, nine realizations for each of permeability and anisotropy ratio were created and systematically simulated into the compositional reservoir model for geological uncertainty assessment. More specifically, DoE was adopted to create 81 distinct reservoir models honoring these nine realizations for each property to obtain the reservoir flow response of oil recovery. There was a significant impact of the geological uncertainties on the reservoir flow response as there was an important gap between the least-likely and most-likely field cumulative oil production.

Therefore, the most-likely solution was then adopted for extra uncertainty assessment with a production optimization glance with respect to the cyclic operation decision parameters of the GAGD process. These parameters are minimum bottom hole pressure in the injection wells in addition to the periods of injection, soaking, and production. Therefore, 65,000 simulation jobs were created by proxy-based Box–Behnken design and Monte Carlo simulation and then evaluated by the compositional reservoir model to obtain another set of flow responses. The production uncertainty results showed that there is limited uncertain space for the soaking and production periods. Nevertheless, there is wider uncertain space for the injection periods and minimum bottom hole pressure. As a result, the final optimal case of the cyclic GAGD simulation led to increase the cumulative oil production about only 6.53 million bbls larger than the base case. Finally, incorporating the production uncertainties effects in the GAGD optimization processes is an efficient way to obtain the true optimal solution that provides a significant increment in oil recovery. In addition, the combined geological and production uncertainty workflow gave an idea about the uncertainty of risk space with respect to the reservoir flow response in the future cyclic GAGD process performance.

References

Al-Ameri TK, Al-Khafaji AJ, Zumberge J (2009) Petroleum system analysis of the Mishrif reservoir in the Ratawi, Zubair, North and South Rumaila oil fields, southern Iraq. GeoArabia 14:91–108

Al-Ansari R (1993) The petroleum geology of the upper sandstone member of the Zubair Formation in the Rumaila South. Geological Study, Ministry of Oil, Baghdad

Al-Mudhafar W (2016a) Multiple-point geostatistical lithofacies simulation of fluvial sand-rich depositional environment: a case study from Zubair Formation/South Rumaila oil field. In: Offshore technology conference, Houston, TX, USA. https://doi.org/10.4043/27273-MS

Al-Mudhafar WJM (2016b) Statistical reservoir characterization, simulation, and optimization of field scale-gas assisted gravity drainage (GAGD) process with uncertainty assessments. LSU Doctoral Dissertations. 3097. http://digitalcommons.lsu.edu/gradschool_dissertations/3097

Al-Mudhafar WJ (2017) Geostatistical lithofacies modeling of the upper sandstone member/Zubair formation in south Rumaila oil field, Iraq. Arab J Geosci 10:153. https://doi.org/10.1007/s12517-017-2951-y

Al-Mudhafer WJ, Al Jawad MS, Al-Shamaa DA (2010) Using optimization techniques for determining optimal locations of additional oil wells in South Rumaila oil field. In: CPS/SPE international oil and gas conference and exhibition, Beijing, China. https://doi.org/10.2118/130054-MS

Al-Mudhafar WJ, Rao D, Hosseini Nasab SM (2016) Optimization of cyclic \(\text{CO}_2\) flooding through the gas assisted gravity drainage process under geological uncertainties. In: ECMOR XV-15th European conference on the mathematics of oil recovery, Amsterdam, Netherlands. https://doi.org/10.3997/2214-4609.201601830

Al-Obaidi RY (2010) Determination of palynofades to assess depositional environments and hydrocarbons potential, Lower Cretaceolls, Zubair Formation South Iraq. J Coll Educ 5:163–174

Amudo C, Graf T, Dandekar RR, Randle JM (2009) The pains and gains of experimental design and response surface applications in reservoir simulation studies. In: SPE reservoir simulation symposium, Houston, Texas. https://doi.org/10.2118/118709-MS

Ates H, Bahar A, El-Abd S, Charfeddine M, Kelkar M, Datta-Gupta A (2003) Ranking and upscaling of geostatistical reservoir models using streamline simulation: a field case study. In: SPE middle east oil show, Bahrain. https://doi.org/10.2118/81497-MS

Ballin PR, Aziz K, Journel AG, Zuccolo L (1993) Quantifying the impact of geologic uncertainty on reservoir performance forecasts. In: SPE symposium on reservoir simulation, New Orleans, Louisiana. https://doi.org/10.2118/25238-MS

Carpenter C (2013) Produced-water-reinjection design and uncertainties assessment. J Pet Technol 12(65):129–131. https://doi.org/10.2118/1213-0129-JPT

CMG (2015) Manual of computer modelling group’s software. Computer Modelling Group, Calgary

Cruz PS (2000) Reservoir management decision-making in the presence of geological uncertainty. PhD Dissertation, Department of Petroleum Engineering, Stanford University

Deutsch CV, Journel AG (1998) GSLIB. Geostatistical software library and user’s guide. Oxford University Press, New York

Guyaguler B, Horne RN (2001) Uncertainty assessment of well placement optimization. In: SPE-71625 presented at the SPE annual technical conference and exhibition, New Orleans, Louisiana, USA. https://doi.org/10.2118/71625-MS

Hegstad BK, Henning O (2001) Uncertainty in production forecasts based on well observations, seismic data, and production history. SPE J 6(04):409–424. https://doi.org/10.2118/74699-PA

Kabir CS, Mohammed NI, Choudhary MK (2007) Lessons learned from energy models: Iraq’s South Rumaila case study. In: SPE middle east oil and gas show and conference, Manama, Bahrain. https://doi.org/10.2118/105131-MS

Kalla S, White CD (2007) Efficient design of reservoir simulation studies for development and optimization. SPEREE 10(06):629–637. https://doi.org/10.2118/95456-PA

Kalogerakis N (1994) An efficient procedure for the quantification of risk in forecasting reservoir performance. In: SPE European petroleum computer conference, Aberdeen, UK. https://doi.org/10.2118/27569-MS

Landa JL, Horne RN (1997) A procedure to integrate well test data, reservoir performance history and 4-D seismic information into a reservoir description. In: SPE annual technical conference and exhibition, San Antonio, Texas. https://doi.org/10.2118/38653-MS

Lazic ZR (2006) Design of experiments in chemical engineering. Wiley-VCH, Weinhem

Liu N, Betancourt S, Oliver DS (2001) Assessment of uncertainty assessment methods. In: SPE annual technical conference and exhibition, New Orleans, Louisiana, USA. https://doi.org/10.2118/71624-MS

Mohammed WJ, Al Jawad MS, Al-Shamaa DA (2010) Reservoir flow simulation study for a sector in main pay-South Rumaila oil field. In: SPE oil and gas India conference and exhibition, Mumbai, India. https://doi.org/10.2118/126427-MS

Montgomery DC (1997) Design and analysis of experiments, 5th edn. Wiley, New York

Montgomery DC, Runger GC (2003) Applied statistics and probability for engineers, 3rd edn. Wiley, New York

NIST (2012) NIST/SEMATECH e-handbook of statistical methods. NIST, Gaithersburg

Okano H, Pickup GE, Christie MA, Subbey S, Sambridge M (2006) Quantification of uncertainty due to sub-grid heterogeneity in reservoir models. In: SPE Europec/EAGE annual conference and exhibition, Vienna, Austria. https://doi.org/10.2118/100223-MS

Oliver DS (1996) Multiple realizations of the permeability field from well test data. SPE J 1(02):145–154. https://doi.org/10.2118/27970-PA

Rao DN (2012) Gas-assisted gravity drainage process for improved oil recovery. United States Patent 8,215,392 B2

Rao DN, Ayirala SC, Kulkarni MM (2004) Development of gas-assisted gravity drainage (GAGD) process for improved light oil recovery. In: SPE/DOE symposium on improved oil recovery, Tulsa, Oklahoma, USA. https://doi.org/10.2118/89357-MS

Subbey S, Mike C, Sambridge M (2003) A strategy for rapid quantification of uncertainty in reservoir performance prediction. In: SPE reservoir simulation symposium, Houston, Texas. https://doi.org/10.2118/79678-MS

Wen X-H, Deutsch CV, Cullick AS (1997) High resolution reservoir models integrating multiple-well production data. In: SPE annual technical conference and exhibition, San Antonio, Texas. https://doi.org/10.2118/52231-PA

White CD, Royer SA (2003) Experimental design as a framework for reservoir studies. In: SPE reservoir simulation symposium, Houston, Texas, USA. https://doi.org/10.2118/79676-MS

White CD, Willis BJ, Narayanan K, Dutton SP (2001) Identifying and estimating significant geologic parameters with experimental design. SPE J 6(03):311–324. https://doi.org/10.2118/74140-PA

Zhang G (2003) Estimating uncertainties in integrated reservoir studies. PhD Dissertation, Texas A&M University

Acknowledgements

The authors thank Fulbright-Institute of International Education (IIE) for 3 years Ph.D. scholarship, Chevron Innovative Research Fund and LSU-LIFT along with software support from Computer Modeling Group, Ltd and Schlumberger.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Al-Mudhafar, W.J., Rao, D.N. & Srinivasan, S. Geological and production uncertainty assessments of the cyclic \(\text{CO}_2\)-assisted gravity drainage EOR process: a case study from South Rumaila oil field. J Petrol Explor Prod Technol 9, 1457–1474 (2019). https://doi.org/10.1007/s13202-018-0542-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-018-0542-4