Abstract

Because inorganic scales reduce permeability near wellbores, they cause an additional pressure drop in this region (skin damage) and reduce production. NaCl precipitation, particularly in gas-producing wells, is one of the formation damage problems which impair the permeability. The use of backwashing water not only requires a large quantity of water, but is also inefficient. This study examined the effect of the ultrasonic waves in NaCl scale removal. Twenty core samples with different permeabilities were saturated with NaCl. After precipitation of NaCl within the cores, the samples were first subjected to water injection and then to water injection with ultrasonic wave radiation. At each stage, the permeability of cores was measured and recorded. Experimental results reveal that applying ultrasonic waves restores the permeability of cores more than water injection alone. In samples with permeability lower than 20, 30–100, 100–700 md and cores with permeabilities higher than 1000 md, ultrasonic waves recover permeability to 80, 42, 87 and 81%, respectively. In contrast, water injection alone improves permeability to 29, 18.5, 62 and 77%, respectively. The effect of these waves is much more obvious than water injection alone in low-permeability cores. SEM images from cores show that ultrasonic waves destroy the structure of deposits of sodium chloride. This phenomenon is due to propagation of these waves and the resulting temperature increase in the surroundings, which leads to the increased solubility of these scales. After exposure to ultrasonic waves, sodium chloride deposits inside the induced fractures of cores could be removed from the fracture, whereas water injection alone could not wash and remove the deposits from the fracture. According to the results of this paper, ultrasonic waves can be used as a novel and efficient technology in gas wells to remove inorganic scales in the near-wellbore region.

Similar content being viewed by others

Introduction

Inorganic salts deposited in the porous media of oil and gas reservoirs, or scale, have been recognized to be an important problem in production treatment. Scale deposits as formation damage, or “skin,” around the wellbore contribute to a reduction in the permeability to any fluids and plug the pore throat, resulting in decreased potential for fluid flow (Moghadasi et al. 2003).

Many oil and gas wells are affected by scale deposition within their porous media during primary, secondary and tertiary recovery (Ismail 2009). Damaged formation by scales has high costs, including:

-

Drastic declines in production rate.

-

Permeability reduction in the reservoir.

-

The need for re-perforation treatment of the pay-zone intervals.

-

Stimulation of the formation damaged.

-

The need for remedial workovers.

-

The need for re-drilling or directional drilling of the plugged wells.

-

Dehydration of connate water and increased salt concentration in gas wells.

-

Reactions occurring during acid treatment.

Inorganic scale formation is not due to the incompatibility of various fluids that naturally occur in the reservoir (Abbasi and Farahani 2010; Bayona 1993). Mineral solutes and halides existing in the water of crude oil are usually supersaturated and in thermodynamic equilibrium with reservoir conditions. This equilibrium is disturbed by drops in pressure and water temperature during extraction, at which point minerals precipitate and deposit in the formation pores. In reservoir conditions, the water is supersaturated with NaCl due to various factors such as temperature, pressure, pH, mixing of incompatible waters (water injection to improve oil recovery), turbulence, evaporation and condensation (Civan 2000; Collins et al. 2004). In the production process, where decreases in pressure and temperature mostly take place in the near-wellbore region, NaCl in porous media and perforations largely precipitates and causes skin in the reservoir (Kleinitz et al. 2001; Paulo et al. 2001). To induce crystallization in the reservoir, various factors such as supersaturation, nucleation and precipitation are required (Crabtree et al. 1999; Mackay 2003). The induced skin greatly reduces permeability, causing a slope rise in the inflow performance relationships used for evaluating reservoir deliverability (Economides et al. 2012). Productivity and injectivity of oil and gas wells decrease with formation damage in the near-wellbore region; in some cases, the well becomes completely plugged (Ghalambor and Economides 2000). In the presence of organic deposits such as wax and asphaltene, wettability alteration, rock polarity and plugged-in pore throats are a matter of great importance. Therefore, evaluation of the tenacity and adherence of the bonds between deposit and rock are important to select proper chemical solvents to remove them (Amin et al. 2010; Subramanian et al. 2017). On the other hand, in inorganic scales such as halides the only parameter to be considered is permeability reduction due to their precipitation in porous media, which is a function of their amount and size. Unlike organic scales, inorganic scales’ absolute and effective permeability, not relative permeability, determines the intensity of formation damage (Civan 2000; Boyun et al. 2007). NaCl precipitation in gas and gas-condensate reservoirs and reservoirs with high pressure and temperature can be significant (Moghadasi et al. 2003). Precipitation of NaCl in the near-wellbore zone can plug the matrix of formation if saline groundwater is present during natural gas storage treatment (Wylde and Slayer 2013; Hebert et al. 2016). The most common driving force for NaCl oversaturation is evaporation of the produced water into the gas phase, typically caused by pressure drops near the wellbore (Frigo et al. 2000; Yeager et al. 1997; Sorbie and Collins 2010). Other mechanisms include cooling the brine; introduction of less-polar solvents (e.g., methanol) (Djamali et al. 2012; Goodwin et al. 2016), used as a thermodynamic hydrate inhibitor, or ethanol (Zhu et al. 1994); or, rarely, mixing incompatible brines, all of which result in a lower solubility for sodium chloride (Sorbie and Collins 2010). In investigating the effect of NaCl in gas wells in North Sea, Maxwell and Young 2014 found that the most common mechanism by which scale was formed in the southern North Sea was the dehydration of formation water by the expansion of gas as it entered the wellbore (Maxwell and Young 2014). In cases with NaCl scale problems, the typical procedure has been reactive, with the NaCl being allowed to build up in the well before being removed by freshwater treatment. However, this approach has a number of disadvantages, particularly the loss of production due to poor performance and shut-in time during washing and the production of other scales. In addition, the washing process rarely completely removes the deposits and may cause progressive formation damage (Maxwell and Young 2014).

Ultrasonic wave technology is used for cleaning filters (Nguyen et al. 2016), size distribution (Kudo et al. 2017), extraction (Zhu et al. 1994), separation (Bounos et al. 2017) and other applications. Some studies have been performed in the field of enhanced oil recovery using ultrasonic waves (Wang and Xu 2015; Wang and Zhou 2004). Experimental models for ultrasonic-based enhanced oil recovery have been presented and indicated that ultrasonic waves can greatly increase production (Mohsin and Meribout 2015; Wegener et al. 2001; Amro et al. 2007). Changes in crude oil characteristics due to ultrasonic wave irradiation are also evaluated (Shi et al. 2017). Research has also been conducted into the impact of ultrasonic waves on oil–water emulsions (Ding et al. 2016) and their separation (Antes et al. 2017). The effects of ultrasonic waves on organic and polymeric deposits are compared in this study; the findings are that ultrasonic waves remove organic deposits much more effectively than they do polymeric deposits (Venkitaraman et al. 1995; Roberts et al. 2000). Tutuncu et al. investigated the effect of ultrasonic waves on the removal of asphaltene deposits in the near-wellbore area and mentioned that the energy of ultrasonic waves can have a great impact on permeability, restoring between 50 and 75% (Tutuncu and Joha 2008). Furthermore, some studies have been carried out on the effect of ultrasonic waves on fine foreign particles (suspended particles in drilling fluid). Experimental results show that waves with a very short pulse are more effective than long, continuous waves (on the condition that the total amount of acoustic energy is constant) (Poesio and Ooms 2009). Few studies have been carried out on the effect of ultrasonic waves in removing inorganic deposits. Using ultrasonic waves has many advantages over other borehole-cleaning methods, such as lower cost and environmental impact (Hartwig and Wölfel 2014). Ultrasonic waves can reduce deposits due to drilling and paraffinic fluids as well as plugging deposits (Wang et al. 2017). Pečnik et al. evaluated impact of ultrasonic waves on the structure of calcium carbonate scale on steel and enameled surfaces of different roughness. They believed that removing these deposits depends on scale surface hardness and microstructure. In another study, ultrasonic-assisted acid was shown to remove inorganic scales better than most solvents currently in use (Wang et al. 2016). Experiments conducted to remove fine foreign particles (which plug reservoir rock pores) using ultrasonic waves have shown that this technology is highly efficient in removing and cleaning these particles (Poesio and Ooms 2004).

As mentioned before, NaCl precipitates near wellbores cause skin due to decreasing permeability. Water backwashing cannot remove these scales; removal requires the injection of large amounts of water. However, water injection in large volumes can itself cause another damage to the formation. In this study, using ultrasonic waves in the removal of NaCl scales is addressed at the laboratory scale. Experimental results show that this method effectively removes these scales and can be considered as a novel technology in oil and gas wells.

Experimental setup and procedures

Twenty core samples from reservoirs in Iran’s southwest with a different range of permeabilities were used for carrying out the experiments (Table 1). The experiments were conducted according to the following steps:

-

Cores were completely saturated with brine (NaCl + deionized water) with a concentration of 220,000 ppm within a cell under 4000 psi pressure for 4 days.

-

Saturated samples were placed into a humidity oven for a week at 60 °C, during which time the water in the sample evaporated and NaCl was deposited in the cores (Fig. 1).

-

After the saturated samples were dried, their porosity and permeability were measured and recorded with helium porosity and air permeability, respectively.

-

The cores were subjected to simultaneous water injection and ultrasonic waves in a developed flooding apparatus.

-

Finally, the samples were again placed in a humidity oven, and after drying, their porosity and permeability were measured.

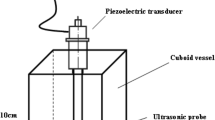

Figure 2 gives a schematic of the flooding apparatus equipped with the ultrasonic wave generator. The samples were saturated and then flooded under water injection. In this process, the overburden pressure and injection rate were 1000 Psi and 8.2 cc/min, respectively. The amount of injection for each core was two pore volumes. After the samples were dried, porosity and permeability were measured. The samples were then washed thoroughly in soxhlets with methanol and ethanol until all NaCl deposits were removed from the sample. The samples were again saturated and water-injected while exposed to ultrasonic radiation at a frequency of 22 kHz and a power of 1000 W. The pressure and injection rate were similar in both conditions.

Results and discussion

Figure 3 shows the changes in the permeability of samples after each step: saturation of the cores with NaCl, water injection and water injection with ultrasonic wave radiation. As shown in Fig. 3, water in core samples with low permeability (less than 20 md) cannot remove sodium chloride deposits. In core samples with lower permeability, water cannot fully penetrate the pore throats and remove the formed deposits. However, in core samples with greater permeability, water more effectively washes and removes the NaCl deposits and restores more permeability. Combining water injection with ultrasonic wave radiation restores permeability to a greater extent than water alone in all cores, but particularly in samples with low permeability levels. Therefore, ultrasonic waves in these cores reduce the deposits and restore permeability more effectively.

Ultrasonic radiation creates a mechanical turbulence in the medium irradiated. When waves cross within the matter, its particles vibrate so that the emitted energy travels through the matter parallel to the particle vibration. The matter’s inner particles are limited to moving back and forth following the wave energy. These particles find free movement within the matter. The wave energy causing particle movement disrupts the balance in the substance as it passes through. The particle of matter due to exerted force leaves its equilibrium state and displaces. This displacement is in direct proportion to the force applied to the particle and takes the form of simple harmonic motion (Fakhru’l-Razi et al. 2009). This action distorts the crystals of sodium chloride adhering to the rock and crushes the bonding energy that allows them to stick to the matrix surface. As a result, injected water can readily evacuate separated salts from the core. Another mechanical effect of ultrasonic waves is the creation of distortion in the boundaries, which raises the temperature, increasing the instability between the sodium chloride crystals and rock. Absorbed sound waves are a determinant factor for converting energy into heat in the medium. Furthermore, the friction and abrasion in the boundaries also produce heat, and cavitation is a major factor in releasing excessive heat. All these factors contribute to the heating effect of ultrasonic waves, which is a factor in breaking the crystals of deposited material and increasing its solubility in water. When ultrasonic waves pass through the core sample, they accelerate solubility (Xu et al. 2009). Finally, these waves increase the solubility of sodium chloride with raising temperature, destroying bonding energy and breaking crystal of deposit. In samples with permeability lower than 20 md, ultrasonic waves recover permeability to 80%. In contrast, water injection alone improves permeability to 29%. In the core samples with 30–100 md of permeability, ultrasonic waves restored permeability to near 42%, compared to water injection alone, which restored it to around 18.5%. In the core samples with a permeability range of 100–700 md, injection with ultrasonic waves restored permeability to around 87% and water injection alone to 62%. In cores with permeabilities higher than 1000 md, the ultrasonic wave could restore permeability to around 81% while the water injection alone could restore permeability to near 77%.

To process the results of water injection with and without ultrasonic radiation in the saturated core samples, a thin layer of saturated core sample under both ultrasonic radiation and water injection was selected and analyzed with scanning electron microscopy (SEM). Figure 4 shows one of the images of a saturated core sample with sodium chloride. Highlighted sections are related to sodium chloride deposits. To analyze more precisely, EDS was obtained from the surface of the rock (Fig. 5). The green and red sections of the figure indicate sodium chloride deposition, with green indicating a higher ratio of Cl to Na. To confirm this phenomenon, samples were mapped (Fig. 6), and areas in which Cl was found also contained Na. In other sectors, calcium was plentiful, which is characteristic of carbonate rock.

Figure 7 shows SEM images of a thin layer of core sample exposed solely to water injection. The water injection has altered the sodium chloride crystal’s structure; however, changes in the crystal of sodium chloride are more evident. In fact, the cluster structure is almost unchanged; the small changes observed in the NaCl particles. Ultrasonic waves, due to their mechanical effects, severely alter these scales. As shown in Fig. 8, the crystal structure of sodium chloride has been thoroughly destroyed, thus raising its solubility in water and detaching it from the rock matrix. This ultimately improves permeability. Figure 8 shows that NaCl particles subject to ultrasonic waves exhibit significant structural changes including microcracks and cracks. Another change observed in NaCl particles was edge cracking. SEM images related to the core sample 193 treated after ultrasonic (from the near to the distant of ultrasonic transducer) are shown in Fig. 9. In Sects. 1 and 2, almost no NaCl particle is observed in the core. In Sect. 3, there are very few NaCl deposits which is shown in the figure. NaCl clusters find a lath-like structure which is due to mechanical effect of ultrasonic wave. In Sects. 4 and 5, scattered NaCl structures are observed as a result of ultrasonic waves. NaCl particle size in Sect. 4 is larger than Sect. 5. Getting away from the radiation of ultrasonic waves in the core, the amount and size of NaCl deposits increase. Fragmentation and disintegration of NaCl particles and clusters increase the core permeability. The majority of NaCl cluster particles have been destroyed using ultrasonic wave irradiation and appear as fine powders on the rock surface. This increases the solubility of NaCl in injected water, which means more NaCl will be removed and permeability will be more fully restored. Results of core analysis and salt particles show that the NaCl particles can show dramatic changes in particle shape due to exposure to ultrasonic wave radiation during the flooding experiment.

Ultrasonic waves are high-frequency wave that are converted to compression and expansion waves. They constitute a novel technique to remove inorganic salt and increase core permeability during core flooding. Ultrasonic waves have two forms of energy: the energy that was initially radiated to the matter, and secondary energy, which is related to cavitation. Energy induction is associated with temperature changes. When a core is subjected to a coreflooding experiment, the amount of dissolved salt and salt particles in the outlet water are different when ultrasonic waves are applied. NaCl particles precipitate on the core and aggregate on each other, becoming compacted. The force of injected water exerted on the pore surface causes these surfaces to erode, promoting the adsorption of salt. Several factors affect the solubility of NaCl salt in water, including temperature, pressure and salt particle distribution in the aqueous phase. When ions are in balance, the salt ceases to dissolve and the solution will be saturated. In the waterflooding process when a core’s pore space is covered with precipitated salt, the salt particles dissolve in the water. Therefore, whatever perturbation in the flooded water regime increases the amount of distribution and transmission of salt particles from the common level between the water and the pore space increases the salt coverage. Thus, the aqueous solution approaches ionic balance relatively late. At the irradiation stage of ultrasonic waves, the waves exert stress on the salt particle. As shear stress increases on the particle, it breaks down and forms a more active surface.

Changes in water temperature of core sample 193 which is under ultrasonic irradiation are given in Fig. 10. Increasing the exposure time of ultrasonic waves also rises the temperature of injected water. The water temperature varies from 22 to 37 °C in which this temperature rise increases NaCl solubility and permeability improvement in ultrasonic wave irradiation. Disintegration of salt particles increases their solubility in the aqueous phase. The energy and stress due to the explosion of bubbles create perturbation and increase the frequency at which salt particles collide and the extent of the active surface, ultimately increasing solubility. In addition, the explosion of existing bubbles in the water phase increases the temperature of system. This temperature rise further increases NaCl solubility in water (Xu et al. 2009).

One of the most crucial issues in managing inorganic scales is the natural fracture of the reservoir and perforations. For this purpose, a cement core with a 3.85 diameter, 30 cm length and a hole with a 1.2 cm diameter through the entire core was obtained, and NaCl was deposited within the core (Fig. 11). Then, we injected water to this core sample once with and once without the ultrasonic wave. As it is shown in Fig. 12, in case of water injection a canal is formed. While in case of water injection with ultrasonic wave, not only hole diameter increases but also further pores are formed in the scales due to ultrasonic wave action. This figure clearly shows that in destructing the structure of deposited scale, ultrasonic waves could remove large amounts of scale from the hole. Figure 12 shows that NaCl particles subject to ultrasonic waves exhibit significant structural changes including wormholes. Another change observed in NaCl particles was edge cracking. In some NaCl crystals, cracking occurs in boundary sections between the NaCl and the rock surface.

Conclusion

The results of this study can be summarized as follows:

-

Ultrasonic wave with water in core samples with different permeabilities can have efficient removal of NaCl scales and permeability improvement compared with water injection alone.

-

Ultrasonic waves applied along with water injection to core samples with low permeability (with NaCl deposited) can restore permeability up to 51% more than water injection alone.

-

Ultrasonic waves, due to their mechanical effects, cause the destruction of NaCl crystals, reducing the binding energy between matrix and scale and raising the temperature, which in turn increases the solubility of scale in water. This action leads to decreased deposition within the core sample.

-

Ultrasonic waves combined with water injection remove NaCl deposits more efficiently than water washing alone. These waves induce microfractures within the scales, distorting them and facilitating their removal from fractures and perforations.

References

Abbasi S, Farahani H (2010) Scale deposition and formation damage during water injection process in oil reservoirs. Research Instituted of Petroleum Industry Publishing, Tehran

Amin JS, Nikooee E, Ayatollahi S, Alamdari A (2010) Investigating wettability alteration due to asphaltene precipitation: imprints in surface multifractal characteristics. Appl Surf Sci 256(21):6466–6472

Amro M, Al-Mobarky M, Al-Homadhi E (2007) Improved oil recovery by application of ultrasound waves to waterflooding. In: SPE middle east oil and gas show and conference

Antes FG, Diehl LO, Pereira JSF, Guimarães RCL, Guarnieri RA, Ferreira BMS, Flores EMM (2017) Effect of ultrasonic frequency on separation of water from heavy crude oil emulsion using ultrasonic baths. Ultrason Sonochem 35:541–546

Bayona HJ (1993) A review of well injectivity performance in Saudi Arabia’s ghawar field seawater injection program. Society of Petroleum Engineers, SPE-25531-MS

Bounos G, Andrikopoulos KS, Moschopoulou H, Lainioti GC, Roilo D, Checchetto R, Voyiatzis GA (2017) Enhancing water vapor permeability in mixed matrix polypropylene membranes through carbon nanotubes dispersion. J Membr Sci 524:576–584

Boyun G, Lyons WC, Ghalambor A (2007) Introduction to: petroleum production engineering fundamentals. Petroleum production engineering: a computer-assisted approach. Elsevier. doi:10.1016/B978-075068270-1/50004-9

Civan F (2000) Reservoir formation damage, fundamental, modeling, assessment and mitigation. Gulf Publishing Company, Houston

Collins IR, Graham GM, Stalker R (2004) Laboratory and economic evaluation of the impact of chemical incompatibilities in comingled fluids on the efficiency of a produced water reinjection system: a North Sea example. Society of Petroleum Engineers, SPE-86525-MS

Crabtree M, Eslinger D, Fletcher F, Miller M, Johnson A, King G (1999) Fighting scale—removal and prevention. Autumn

Ding B, He LP, Luo JH, Peng BL, Geng XF, Wang PM (2016) Determination of particle size of heavy oil in water dispersion system by ultrasonic attenuation method. J Petrol Sci Eng 146:764–769

Djamali E, Lu H, Kan AT, Tomson MB (2012) Effects of hydrate inhibitors on the solubility of barite and halite in produced water. In: SPE international conference on oilfield scale. Society of Petroleum Engineers, SPE-155042-MS

Economides MJ, Hill AD, Ehlig-Economides C, Zhu D (2012) Petroleum production systems. Pearson Education, Upper Saddle River

Fakhru’l-Razi A, Pendashteh A, Abdullah LC, Biak DR, Madaeni SS, Abidin ZZ (2009) Review of technologies for oil and gas produced water treatment. J Hazard Mater 170:530–551

Frigo DM, Jackson LA, Doran SM, Trompert RA (2000) Chemical inhibition of halite scaling in topsides equipment. In: International symposium on oilfield scale. Society of Petroleum Engineers, SPE-60191-MS

Ghalambor A, Economides MJ (2000) Formation damage abatement: a quarter-century perspective. In: SPE international symposium on formation damage control. Society of Petroleum Engineers

Goodwin N, Graham GM, Frigo DM, Kremer E (2016) Halite deposition–prediction and laboratory evaluation. In: SPE international oilfield scale conference and exhibition. Society of Petroleum Engineers, SPE-179861-MS

Hartwig K, Wölfel S (2014) Scale removal with ultrasonic waves. In: SPE international oilfield scale conference and exhibition. Society of Petroleum Engineers, SPE-169770-MS

Hebert J, Leasure J, Saldungaray P, Ceramics C (2016) Prevention of halite formation and deposition in horizontal wellbores: a multi basin developmental study. Society of Petroleum Engineers, SPE-181735-MS

Ismail MMR (2009) Oil fields scale deposition prediction methodology. Society of Petroleum Engineers, SPE-21710-PA

Kleinitz W, Koehler M, Dietzsch G (2001) The precipitation of salt in gas producing wells. In: SPE European formation damage conference, Society of Petroleum Engineers

Kudo T, Sekiguchi K, Sankoda K, Namiki N, Nii S (2017) Effect of ultrasonic frequency on size distributions of nanosized mist generated by ultrasonic atomization. Ultrason Sonochem 37:16–22

Mackay EJ (2003) Modelling in-situ scale deposition: the impact of reservoir and well geometries and kinetic reaction rates. Society of Petroleum Engineers, SPE-81830-PA

Maxwell D, Young K (2014) Concept, design and implementation of a halite scale mitigation completion in a gas well. In: SPE international oilfield scale conference and exhibition. Society of Petroleum Engineers, SPE-169764-MS

Moghadasi J, Jamialahmadi M, Müller-Steinhagen H, Sharif A, Ghalambor A, Izadpanah MR, Motaie E (2003) Scale formation in iranian oil reservoir and production equipment during water injection. Society of Petroleum Engineers, SPE-80406-MS

Mohsin M, Meribout M (2015) An extended model for ultrasonic-based enhanced oil recovery with experimental validation. Ultrason Sonochem 23:413–423

Nguyen DD, Ngo HH, Yoon YS, Chang SW, Bui HH (2016) A new approach involving a multi transducer ultrasonic system for cleaning turbine engines’ oil filters under practical conditions. Ultrasonics 71:256–263

Paulo J, Mackay EJ, Menzies N, Poynton N (2001) Implications of brine mixing in the reservoir for scale management in the alba field. Society of Petroleum Engineers, SPE-68310-MS

Poesio P, Ooms G (2004) Formation and ultrasonic removal of fouling particle structures in a natural porous material. J Petrol Sci Eng 45:159–178

Poesio P, Ooms G (2009) Fouling by external particles and ultrasonic cleaning of a porous material. SPE J 14(1):14–29

Roberts PM, Venkitaraman A, Sharma MM (2000) Ultrasonic removal of organic deposits and polymer-induced formation damage. SPE Drill Completion 15(1):19–24

Shi C, Yang W, Chen J, Sun X, Chen W, An H, Pei M (2017) Application and mechanism of ultrasonic static mixer in heavy oil viscosity reduction. Ultrason Sonochem 37:648–653

Sorbie KS, Collins I (2010) A proposed pore-scale mechanism for how low salinity waterflooding works. In: SPE improved oil recovery symposium. Society of Petroleum Engineers, SPE-129833-MS

Subramanian S, Sørland GH, Simon S, Xu Z, Sjöblom J (2017) Asphaltene fractionation based on adsorption onto calcium carbonate: part 2. Self-association and aggregation properties. Colloids Surf A 514:79–90

Tutuncu AN, Joha R (2008) An experimental study for removal of near-wellbore asphaltene deposits using ultrasonics. Prepared for SEG Las Vegas annual meeting

Venkitaraman A, Sharma MM, Roberts PM (1995) Ultrasonic removal of near-wellbore damage caused by fines and mud solids. SPE Drill Completion 10(3)

Wang Z, Xu Y (2015) Review on application of the recent new high-power ultrasonic transducers in enhanced oil recovery field in China. Energy 89:259–267

Wang Y, Zhou K (2004) Influence of ultrasonic frequency on the radiation impedance of ultrasonic transducers used in oil production. China Acad J Electron Publ House 12

Wang J, Gao X, Xu Y, Wang Q, Zhang Y, Wang X, Gao C (2016) Ultrasonic-assisted acid cleaning of nanofiltration membranes fouled by inorganic scales in arsenic-rich brackish water. Desalination 377:172–177

Wang Z, Zeng J, Song H, Li F (2017) Research on ultrasonic excitation for the removal of drilling fluid plug, paraffin deposition plug, polymer plug and inorganic scale plug for near-well ultrasonic processing technology. Ultrason Sonochem 36:162–167

Wegener DC, Zornes DR, Maloney DR, Vienot ME, Fraim ML (2001) Heavy oil viscosity reduction and production. US Patent 6279653, Aug 28

Wylde JJ, Slayer JL (2013) Halite scale formation mechanisms, removal and control: a global overview of mechanical, process, and chemical strategies. Society of Petroleum Engineers, SPE-164081-MS

Xu N, Wang WX, Han PF, Lu XP (2009) Effects of ultrasound on oily sludge deoiling. J Hazard Mater 171:914–917

Yeager V, Behenna F, Blauch M, Foh S (1997) Investigation of storage-well damage mechanisms. In: Proceedings of the natural gas conference: emerging technologies for the natural gas industry. United States Department of Energy

Zhang L, Zhou C, Wang B, Yagoub AEGA, Ma H, Zhang X, Wu M (2017) Study of ultrasonic cavitation during extraction of the peanut oil at varying frequencies. Ultrason Sonochem 37:106–113

Zhu Z, Cheng CH, Toksöz MN (1994) Electrokinetic conversion in a fluid-saturated porous rock sample (no. CONF-941015-). Society of exploration geophysicists, Tulsa

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Taheri-Shakib, J., Naderi, H., Salimidelshad, Y. et al. Using ultrasonic as a new approach for elimination of inorganic scales (NaCl): an experimental study. J Petrol Explor Prod Technol 8, 553–564 (2018). https://doi.org/10.1007/s13202-017-0369-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-017-0369-4