Abstract

Oil recovery from heavy oil resources has always been a challenging task. This work is aimed at investigating the recovery efficiency of polymer-augmented low salinity waterflooding in heavy oil reservoirs. The main recovery mechanism behind low salinity waterflooding is wettability alteration to more water-wet state. On the other hand, polymer flooding is performed to control fluids mobility and hence improve displacement efficiency. Combining both recovery methods is expected to add to recovery efficiency obtained by individual methods, and the aim of this work is to explore this experimentally. In this study, several laboratory experiments were conducted using Berea and Bentheimer sandstone cores starting with base runs of continuous secondary seawater and tertiary twice and 10 times diluted seawaterflooding (low salinity). Significant incremental oil recovery was obtained when flooded with low salinity water, and 10 times diluted seawater was determined to be used as low salinity water. Contact angle and Zeta potential measurements indicate wettability alteration due to clay detachment as the main recovery mechanism. Synergy of water secondary flooding and polymer tertiary flooding at different water salinity levels proved the efficiency of hybrid low salinity polymer flooding process in Berea sandstone. Low water salinity during secondary injection mode played a major role on ultimate recovery with less contribution to tertiary polymer slug injection. High salinity waterflooding provided lower secondary recovery leaving more residual oil for polymer slug to act on at that cycle. Smaller polymer slug of 0.1 pore volume was found to be sufficient in tertiary flooding with low salinity water but with slightly slower recovery rate. Bentheimer sandstones known for its low clay content were subjected to polymer-augmented waterflooding at high and low salinity levels. Close secondary and tertiary recoveries were obtained for the two salinity levels with slower recovery rate for low salinity run. Minute clay content and water-wet characteristic as determined by contact angle measurements may explain the lack of water salinity effect on recovery. The lack of salinity role and the two shock fronts with connate water bank in between known to exist during low salinity flooding may explain the slower recovery rate encountered. Comparison of both sandstones indicates that less ultimate recovery from Berea rocks, and this can be attributed to their initial intermediate wet state in contrast to the water-wet Bentheimer sandstone rocks.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Literature review

The role of low salinity water injection as EOR method in sandstone was observed as early as 1967 (Bernard 1967). Extensive work was conducted during the nineties to emphasize the potential and efficiency of LSW injection in sandstone reservoirs (Morrow 1990; Jadhunandan and Morrow 1991, Yildiz and Morrow 1996; Morrow et al. 1998). Many studies reported that the change of waterflooding brine composition could contribute to enhanced oil recovery (Tang and Morrow 1997; Yildiz et al. 1999; Webb et al. 2004; Robertson et al. 2007; Patil et al. 2008; Seccombe et al. 2008; Vledder et al. 2010; Rivet et al. 2010; Korrani et al. 2014; AlQuraishi et al. 2015). Experiments showed that LSW injection increased oil recovery in either tertiary or secondary recovery modes (Webb et al. 2005; Zhang et al. 2007; Lager et al. 2007; Agbalaka et al. 2009) while others showed no improvement in tertiary mode (Rivet et al. 2010; Nasralla et al. 2011). Extensive studies have been conducted to determine the LSW recovery mechanisms, and debatable conclusions were proposed. Among those suggested is fines migration (Tang and Morrow 1999a), multi-ion exchange (MIE) and double-layer expansion (Lager et al. 2008), pH effect (McGuire et al. 2005), and wettability alteration (Tang and Morrow 1999a, b; Austad et al. 2010; Alotaibi et al. 2010; Hilner et al. 2015).

Low salinity waterflooding can be unstable process due to the low mobility ratio (Tripathi and Mohanty 2007). Polymer flooding aims at improving sweep efficiency of the water displacement process by increasing the mobility ratio between the displacing agent and the in situ oil especially in heavy oil reservoirs. Polymers cannot tolerate high salinity (Levitt et al. 2008), and polymer adsorption tends to decrease as salinity decreases (Sorbie 1991). Adding polymer to low salinity water can improve sweep efficiency and mobilize part of detached oil by low salinity wettability alteration mechanism. Valderhaug (2013) reported an incremental 10% extra recovery when polymer was added to LSW in tertiary injection mode.

Hybrid injection of low salinity water and polymer can be implemented to enhance oil recovery in favorable conditions. Mohammadi (2012) simulated polymer-augmented LSW flooding and demonstrated its effectiveness in homogeneous and heterogenous heavy oil reservoirs with better outcome for tertiary injection mode. Borazjani et al. (2016) presented analytical solution for polymer slug injection with varying water salinity. They indicated that salinity reduction in the polymer slug slows the waterfront resulting in higher oil cuts observed after water breakthrough for low salinity polymer flooding than high salinity polymer. Skauge and Shaker Shiran (2013) investigated experimentally the combined effect of low salinity and polymer injection at low concentration. Their results proved the potential of the combined process with superior results obtained for secondary low salinity flooding in combination with polymer injection compared to tertiary injection. Mjøs (2014) reported that combining low salinity brine with surfactants and polymers yielded 11–32% ROIP recoveries with higher recovery for aged cores compared to unaged cores. The aim of this work is to investigate experimentally the merits, efficiency, and potential of polymer-augmented LSW flooding in sandstone reservoirs using different flooding scenarios.

Materials

Saudi heavy crude oil was used as oleic phase. Density and viscosity of measured crude at 60 °C and 2000 psi are 0.91 gm/cm3 and 33 cp, respectively. A solution of 57.23% sodium chloride (NaCl), 35.82% calcium chloride (CaCl2), and 7.26% magnesium chloride (MgCl2) all dissolved in distilled water at 20% (w/w) salinity was used as the aqueous phase resembling local formation brine. Both Arabian Gulf seawater and ten times diluted version of seawater were used as LSW displacing brine solutions. Total dissolved salt (TDS), PH, density, viscosity, turbidity, together with chemical composition of seawater and prepared formation brine are presented in Table 1. Polymer solution utilized was 5000 ppm hydrolyzed polyacrylamide (HPAM) dissolved in 10 times diluted seawater.

Core samples of Berea and Bentheimer sandstones were used as porous mediums for flooding process. Dimensions and physical properties of the samples are listed in Table 2. X-ray diffraction (XRD) analysis of both sandstone rocks (Figs. 1, 2) unveils rocks rich of quartz with slight amount of kaolinite clay. Kaolinite is more in Berea rock (6.5% compared to 0.7% for Bentheimer). Trace of Anhydrite was observed in Bentheimer sandstone.

Experimental procedure

Rheological measurements

Polymer rheology was determined using rotational AR-G2 rheometer. Concentric cylinder having a conical din rotor of 28 mm diameter and 42 mm height was used to perform steady-state simple shear for the polymer solution at concentration of 5000 ppm to obtain shear viscosity versus shear rate at different speed ranging from 5 to 60 RPM at constant temperature of 60 °C.

Interfacial tension

Interfacial tension (IFT) was carried out using pendent drop tensiometer. The measurements were performed in high-pressure cell packed with an aqueous phase where pressure and temperature were adjusted to reservoir conditions of 2000 Psi and 60 °C. Once temperature and pressure are stabilized, a predetermined stainless steel capillary needle was raised in the pressure cell and an adequate oil drop was formed at the needle tip using a hand pump. A digital camera was used to picture the drop and fluids densities, and drop dimensions were used to determine the aqueous oleic IFT. IFT can be considerably reduced with time by the presence of surfactant, scale, and corrosion inhibitors. As a result, multiple IFT measurements were made in 30 min time to observe any possible effect.

Wettability

Rock wettability was determined using contact angle measurement technique. That technique was applied on a cut and polished substrates of the sample rocks. These substrates were saturated and socked in different aqueous phases. Each substrate was hanged in pressure cell where it was surrounded by aqueous phase at 2000 Psi pressure and 60 °C temperature. When equilibrium is achieved, a drop of crude oil was injected to the bottom of the rock substrate with a capillary needle. The drop image was captured and processed for advanced contact angle measurement.

The impact of aqueous phase ionic composition on rock surface charge can be used to describe the rock wettability alteration. Zeta potential measurements on rock particles were conducted using ZETA-check. It consists of cylindrical Teflon beaker with oscillating displacement piston and two electrodes for streaming potential measurement. The test starts by preparing samples of dispersing pulverized particles of each core sample in different aqueous phases for several days. Samples were centrifuged, and representative quantity of each was heated to 60 °C and poured into the beaker. Up and down movement of the piston inside the beaker induces fluid stream along the charged beaker wall shearing the charge cloud of the electric double layer and creating an oscillating streaming potential which can be calibrated as Zeta potential.

Core flooding

Flooding runs were conducted using a flooding unit (Fig. 2). The unit consists of core holder, three fluids accumulators, syringe pump, back pressure regulator, set of pneumatic two- and three-way valves and line and differential transducers. All components are placed in air circulating oven. Effluents are collected in graduated tubes placed in timely set fraction collector. System components are linked to data acquisition for components control and continuous recording.

Runs were started with fresh and dry rock sample vacuumed and pressure saturated with formation brine. The dry and saturated samples weights were measured, and accordingly, the pore volume and porosity are calculated. Core sample was placed in core holder, and reservoir conditions of 4000 confining pressure, 2000 psi pore pressure, and 60 °C temperature were applied. Brine was injected at different rates, and corresponding pressure drops across the core were recorded. Darcy law was used to determine the core absolute permeability. Crude oil was then injected in the fully brine saturated core at 1 cm3/min until water production ceases and irreducible water saturation (S wirr) was determined through volumetric material balance. Steady-state pressure drop was measured to calculate oil effective permeability. The core sample was then flooded in secondary mode with seawater at 1 cm3/min until oil production ceases. Tertiary flooding commences with a slug of 0.3 pore volume polymer solution prepared with 10 times diluted sea followed by seawater until oil production ceases. In order to investigate the efficiency of low salinity flooding and the interaction of low salinity brine with polymer solution, the same experimental procedure was repeated with 10 times diluted seawater in secondary and tertiary cycles in place of seawater. Additionally, polymer slug was reduced to 0.1 pore volume and the run was repeated with 10 times diluted sea to premeditate the optimal polymer slug. In all runs, pressure drop was continuously recorded. The discontinuity in saturation at the end face of the core causes a net capillary force to persist in the porous medium, and this force tends to prevent the wetting phase from being produced. The accumulation of the wetting phase at the outlet end of the sample creates a saturation gradient along the core that influences the relative permeability measurements. In this work, the scaling rule of Leas and Rappaport (1952) was used and the criteria of stable flood were met at the injection flow rate implemented. The injection rate was increased at the end of the secondary and tertiary cycles of each run to ensure that end effect is not influencing the recovery obtained.

Results and discussions

Rheological tests

High viscoelasticity polymer has better sweep efficiency (Xia et al. 2008), and polymer viscoelasticity increases with decreasing solution salinity (Vermolen et al. 2014). HPAM polymer with molecular weight of 12,994 g/mol was used to prepare polymer solution (5000 ppm concentration) in 10 times diluted seawater. Such solution salinity (TDS of 3360 ppm) was chosen in order to successfully apply polymer flooding to Saudi reservoirs known for their high salinity and temperature. HPAM is known as a low-cost polymer with electrical charge resulting in viscosity sensitive to water salinity. Figure 3 shows the solution shear viscosity versus shear rate at 60 °C temperature. Clearly, polymer showed a shear thinning behavior with viscosity decreasing with increasing shear rate. Power law model was fit to the measured data, and flow behavior and flow consistency indices of 0.5 and 0.0075, respectively, were obtained. An average shear rate in a porous media is related to its permeability, porosity, and fluid actual velocity. This leads to an expression of an apparent shear rate (γapp) to describe the interstitial shear rate in porous media. Shear rate in porous media was calculated using Chauveteau and Zaitoun (1981), and a shear rate range of 70–90 s−1 was found in different rock samples used. This shear rate range corresponds to polymer apparent viscosity of 50–53 cp.

Interfacial tension

Figure 4 presents the IFT measurements of the oleic and different aqueous phases. Substituting high salinity formation brine with seawater promotes IFT drop by 10 U. Additional drop of 10 IFT units was obtained when 10 times diluted seawater was used as aqueous phase. Clearly, observed IFT reduction due to salinity variation is not enough to contribute to recovery and other recovery mechanisms have to be investigated.

Contact angle

The contact angle measurements for the two sandstone rocks in different aqueous solutions are summarized in Fig. 5. Berea sandstone showed intermediate wetting characteristic when socked in formation brine or seawater with contact angle measurements of 90° for both salinity levels. Dropping the salinity further by diluting seawater 10 times promotes wettability shift to water-wet condition with contact angle of 75°. Different mechanisms can be considered for sandstone wettability alteration. The first is the multi-component ion exchange (MIE) (Nasralla and Nasr-El-Din 2012). Lowering the brine salinity can result in a double-layer expansion that activates desorption of oil bearing divalent ions from the rock surface. Clay dispersion can also be considered. Desorption of divalent ions can only aid such mechanism since divalent ions promote clay flocculation (Tang and Morrow 1999b). On the other hand, Bentheimer sandstone substrate showed water-wet characteristic with contact angle of 70° in the presence of formation brine and seawater. Slight drop of 5° was noted when 10 times diluted seawater was used.

In order to determine the potential mechanisms for observed wettability alteration, the Zeta potential measurements of Berea and Bentheimer sandstone in different aqueous solutions were measured at 60 °C. Figure 6 indicates that changing the salinity and ionic strength of seawater increased the negative surface charge of both rock types with higher negative values for Berea sandstone. Substantial effect was seen with 10 times diluted seawater, and this correlates well with contact angle measurements discussed above.

Core flooding

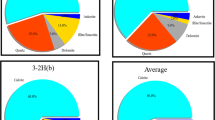

The findings of the flooding runs conducted are summarized in Table 3. Four Berea and two Bernheimer sandstone samples all fresh and unaged were used in flooding runs in secondary injection mode with diverse levels of brines salinity augmented with tertiary polymer injection. To decide the efficiency of low salinity flooding and the optimum salinity reduction level for recovery enhancement, a Berea sandstone sample (sample BER2) was subjected to secondary seawaterflooding and two cycles of twice and ten times diluted versions of seawaterflooding. Figure 7 presents the recovery curve obtained. The secondary flooding cycle provided cumulative oil recovery of 51% OOIP, mostly obtained by the first four pore volumes of seawater injection. Additional 10% OOIP was produced by several pore volumes injection of twice diluted seawater, and another 9% OOIP incremental recovery was produced by ten times diluted seawater injection. Hence, ten times diluted seawater salinity level was decided for low salinity flooding process. Release of mixed-wet clay particles induced by low salinity flooding is believed to be the main mechanism behind the additional oil recovery as fines were observed in produced effluents. Unfortunately, pressure data were not recorded in this run due to malfunctioning data acquisition system.

Two more Berea samples (samples BER1 and BER3) were subjected to high salinity water (seawater) and low salinity (10 times diluted seawater) flooding in secondary mode. Tertiary injection at the same salinity level augmented with 0.3 PV polymer slug was followed. Figure 8 presents the recovery and pressure drop for both runs. Low salinity flooding in secondary injection mode provided 15.1% OOIP higher than that administered by high salinity seawater injection with earlier breakthrough. The pressure drop was slightly higher during the high salinity seawater injection. Pressure drop was unstable throughout the low salinity injection run. Fines observed in the effluents stream may explain this noisy pressure profile. The higher oil recovery observed during secondary low salinity injection can be related to the detachment of mixed-wet clay particles and exposure of the underlying water-wet surface. The Berea samples were intermediate wet as indicated by contact angle measurements, and exposure to low salinity water tends to shift the rock wettability toward more water-wet characteristic.

The residual oil in both samples was targeted with tertiary flooding of 0.3 pore volume polymer slug chased with high salinity seawater for the first sample (BER1) and low salinity ten times diluted seawater for the second (BER3). Incremental recovery of 11.6% OOIP corresponding to 25.6% residual oil in place (ROIP) was obtained by tertiary polymer slug followed by low salinity chase water injection compared to 16.9% OOIP corresponding to 57.2% ROIP for tertiary polymer slug followed by high salinity chase waterflooding. Clearly, mixing of low salinity polymer solution with high salinity brine injected during secondary flooding did not affect polymer viscosity because of a low salinity buffer that will form between the two fluids due to polymer adsorption and the high salinity brine will be stably displaced by low salinity polymer (Vermolen et al. 2014). Ultimate overall recovery was boosted by 10% OOIP by low salinity hybrid process.

Clearly, water salinity level during secondary injection mode played a major role on ultimate recovery with less contribution to tertiary polymer slug injection. Lower secondary recovery by high salinity seawater injection left more residual oil for polymer slug to act on. Higher pressure drop was observed throughout the chase water injection stage of the tertiary cycle of high salinity seawater run assuring the increased polymer retention known to occur in high salinity environment. Skauge and Shaker Shiran (2013) studied the effect of low salinity polymer after establishing a low salinity environment in outcrop Berea cores. They reported a high ultimate oil recovery with recovery by polymer injection improved significantly when the low salinity environment had been established. The importance of the initial wettability was also noticed, as intermediate wet cores responded better than water-wet cores.

An additional low salinity waterflooding run was conducted in fresh Berea core (sample BER4) with 10% polymer slug in order to study the effect of polymer slug size in tertiary recovery. Figure 9 illustrates the recovery and pressure drop of this run in comparison with that conducted with 0.3 pore volume polymer slug at the same water salinity level. The figure shows quite matching secondary recovery trend. Similarly, equal tertiary recoveries were obtained but with slightly slower recovery rate for the smaller polymer slug size. The higher pressure shock due to the larger polymer slug resulted in better sweep leading to faster recovery rate. Both runs recorded equivalent pressure drop during the chase water period of the tertiary flooding cycle indicating equal polymer retention in both samples. Reduced polymer concentration will require larger slug volume to satisfy the adsorption potential of the rock (Vermolen et al. 2014). In this work, high polymer concentration was used and this may explain the absence of polymer slug size effect on recovery.

In order to study the effect of rock type, two Bentheimer sandstone samples were tested in two runs. Sample BEN1 was subjected to secondary high salinity seawaterflooding followed by tertiary flooding of 0.3 pore volume polymer slug chased with continuous seawater. Similarly, sample BEN2 was subjected to the same flooding sequence but with low salinity 10 times diluted seawater. Figure 10 presents the oil recovery and pressure drop profiles for both runs. The figure presents close secondary (65.6% OOIP) and tertiary recoveries (92.6% OOIP corresponding to 74.5% ROIP) with slower recovery rate for low salinity run (BEN2) in both secondary and tertiary cycles. Jerauld et al. (2006) indicated that ordinary Buckley–Leverett (BL) solution consists of a shock front and a spreading wave, whereas low salinity solution consists of two fronts, one corresponding to the transition between low and high salinity and a another corresponding to the transition between high water saturation and connate at high salinity. Between the spreading low salinity solution and the zone ahead of the front and connate water saturation is the connate water bank. This may explain the early breakthrough during high salinity waterflooding and the difference in recovery rate encountered in comparison with the low salinity flooding process during the secondary and tertiary flooding cycles. Close secondary recoveries in both runs indicate the absence of salinity reduction impact. This is related to the wetting characteristic of the Bentheimer sandstone, which illustrates water-wet characteristic with very limited wettability alteration with salinity reduction. Comparison of oil recoveries in both sandstones indicates less ultimate recovery from Berea rocks, and this can be attributed to their initial intermediate wet condition in contrast to the water-wet condition characterizing the Bentheimer sandstone rocks. This agrees with the findings of Shaker Shiran and Skauge (2012).

Conclusions

Polymer-augmented low salinity waterflooding was experimentally investigated on Berea and Bentheimer sandstone samples. Base experiment with Berea sandstone provided incremental oil recovery when flooded with low salinity water. Contact angle and Zeta potential measurements indicate wettability alteration as the main recovery mechanism. Wettability alteration was related to clay detachment and exposure of water-wet surfaces as fines were observed in produced effluents. Synergy of water secondary flooding and polymer tertiary flooding at different water salinity levels proved the efficiency of hybrid low salinity polymer flooding process in Berea sandstone. Low water salinity during secondary injection mode played a major role on ultimate recovery with less contribution to tertiary polymer slug injection. On the other hand, high salinity waterflooding provided lower secondary recovery leaving more residual oil for polymer slug to sweep boosting the oil recovery at that cycle. Polymer slug volume was investigated, and small slug was found to be sufficient in tertiary flooding with low salinity water but with slightly slower recovery rate.

Bentheimer sandstones were subjected to polymer-augmented waterflooding at high and low salinity. Close secondary and tertiary recoveries were obtained for the two salinity levels with slower recovery rate for low salinity run. Low clay content and water-wet characteristic of Bentheimer may explain the absence of low salinity water effect on recovery. The absence of salinity role and presence of two fronts during low salinity flooding with connate water bank in between may explain the difference in recovery rate encountered. Comparison of oil recoveries in both sandstones indicates less ultimate recovery from Berea rocks, and this can be attributed to their initial intermediate wet state in contrast to the water-wet Bentheimer sandstone rocks.

References

Agbalaka C, Dandekar A, Patil S, Khataniar S, Hemsath J (2009) Coreflooding studies to evaluate the impact of salinity and wettability on oil recovery efficiency. Transp Porous Media 76(1):77–94

Alotaibi MB, Nasralla RA, Nasr-El-Din HA (2010) Wettability studies using low-salinity water in sandstone reservoirs. Paper OTC 20718 presented at the offshore technology conference, Houston, 3–6 May

AlQuraishi AA, AlHussinan SN, AlYami HQ (2015) Efficiency and recovery mechanisms of low salinity water flooding in sandstone and carbonate reservoirs. In: Offshore mediterranean conference and exhibition, Ravenna, 25–27 Mar

Austad T, Rezaeidoust A, Puntervold T (2010) Chemical mechanism of low salinity waterflooding in sandstone reservoirs. Paper SPE 129767 presented at the SPE improved oil recovery symposium, Tulsa, 24–28 Apr

Bernard GG (1967) Effect of floodwater salinity on recovery of oil from cores containing clays. Paper SPE 1725 presented at the SPE California regional meeting, Los Angeles, 26–27 Oct. doi:10.2118/1725-MS

Borazjani S, Bedrikovetsky P, Farajzadeh R (2016) Analytical solutions of oil displacement by a polymer slug with varying salinity. J Pet Sci Eng 140:28–40

Chauveteau G, Zaitoun A (1981) Basic rheological behavior of xanthan polysaccharide solutions in porous media: effects of pore size and polymer concentration. In: Enhanced oil recovery: proceedings of the third European Symposium on Enhanced Oil Recovery, pp 197–212

Hilner EKM, Andersson MP, Hassenkam T, Matthiesen J, Salino PA, Stipp SLS (2015) The effect of ionic strength on oil adhesion in sandstone: the search for the low salinity mechanism. Sci Rep. doi:10.1038/srep09933

Jadhunandan PP, Morrow NR (1991) Spontaneous imbibition of water by crude oil/brine/rock systems. In Situ 15(4):319–345

Jerauld GR, Lin CY, Webb KJ, Seccombe JC (2006) Modeling low-salinity waterflooding. Paper SPE 102239 presented at the 2006 SPE annual technical conference an exhibition, San Antonio, 24–27 Sept

Korrani AKN, Jerauld GR, Sepehrnoori K (2014) Coupled geochemical-based modeling of low salinity waterflooding. Presented at the SPE improved oil recovery symposium, Tulsa. SPE-169115-MS, 12–16 Apr

Lager A, Webb KJ, Black CJJ (2007) Impact of brine chemistry on oil recovery. Paper A24 presented at the 14th European symposium on improved oil recovery, Cairo

Lager A, Webb KJ, Black CJJ, Singleton M, Sorbie KS (2008) Low-salinity oil recovery-an experimental investigation. Petrophysics 49(1):28–35

Levitt DB, Pope GA, Weatherl MH, Whitney JR, Slaughter WS (2008) Selection of polymers for enhanced oil recovery. Paper SPE 113845 presented at the SPE improved oil recovery symposium, Tulsa, 19–23 Apr

McGuire PL, Chatham JR, Paskvan FK, Sommer DM, Carini FH (2005) Low salinity oil recovery: an exciting new EOR opportunity for Alaska’s North Slope. Paper SPE 93903 presented at the SPE western regional meeting, Irvine

Mjøs JE (2014) Low salinity waterflood in combination with surfactant/polymer: effect of brine composition. M.S. Thesis, University of Bergen, Bergen

Mohammadi H, Jerauld GR (2012) Mechanistic modeling of benefit of combining polymer with low salinity water for enhanced oil recovery. Paper SPE 153161, presented at the eighteenth SPE improved oil recovery symposium, Tulsa, Apr 14–18

Morrow NR (1990) Wettability and its effect on oil recovery. SPE 21621 distinguished author series. J Pet Technol 42(12):1476–1484

Morrow NR, Tang GQ, Valat M, Xie X (1998) Prospects of improved oil recovery related to wettability and brine composition. J Pet Sci Eng 20(1998):267–276

Nasralla RA, Nasr-El-Din HA (2012) Double-layer expansion: is it a primary mechanism of improved oil recovery by low-salinity water flooding. Paper SPE 154334 presented at the improved oil recovery symposium, Tulsa

Nasralla RA, Bataweel MA, Nasr-El-Din HA (2011) Investigation of wettability alteration and oil-recovery improvement by low-salinity water in sandstone rock. J Can Pet Technol 52(2):144–154

Patil SB, Dandekar AY, Patil S, Khataniar S (2008) Low salinity brine injection for EOR on Alaska North Slope (ANS). Int Pet Technol Conf. doi:10.2523/IPTC-12004-MS

Rapoport LA, Leas WJ (1952) Properties of linear waterfloods. Paper No. SPE 213-G, fall meeting of the petroleum branch, Houston, Oct 1–3

Rivet SM, Lake LW, Pope GA (2010) A core flooding investigation of low salinity enhanced oil recovery. Paper SPE 134297 presented at the SPE annual technical conference and exhibition, Florence, 19–22 Sept

Robertson E et al (2007) Low-salinity waterflooding to improve oil recovery: historical field evidence. Paper SPE 109965 presented at the SPE annual technical conference and exhibition, Anaheim, 11–14 Nov

Seccombe JC, Lager A, Webb K, Jerauld G, Fueg E (2008) Improving waterflood recovery: LoSal™ EOR field evaluation. Paper SPE 113480 presented at the SPE/DOE symposium on improved oil recovery, Tulsa, 20–23 Apr

Shaker Shiran B, Skauge A (2012): Wettability and oil recovery by low salinity injection. Paper SPE 155651 presented at the SPE EOR conference at oil and gas West Asia, Muscat, 16–18 Apr

Skauge A, Shaker Shiran B (2013) Low salinity polymer flooding. Paper A14 presented at 17th European symposium on improved oil recovery, St. Petersburg, 16–18 Apr

Sorbie KS (1991) Polymer-improved oil recovery. Springer, Boca Raton, pp 82–125

Tang GQ, Morrow NR (1997) Salinity, temperature, oil composition, and oil recovery by waterflooding. SPE Reserv Eng 12(4):269–276

Tang GQ, Morrow NR (1999a) Influence of brine composition and fines migration on crude oil/brine/rock interactions and oil recovery. J Pet Sci Eng 24:99–111

Tang GQ, Morrow NR (1999b) Oil recovery by waterflooding and imbibition: invading brine cation valency and salinity. Paper SCA-9911 presented at the 1999 international symposium of the society of core analysts, Golden, 1–4 Aug

Tripathi I, Mohanty KK (2007) Flow instability associated with wettability alteration. Paper SPE 110202 presented at the SPE annual technical conference and exhibition, Anaheim, 11–14 Nov 2007

Valderhaug OM (2013) Investigating EOR for SS by low salinity water. Master’s Thesis, University of Stavanger

Vermolen ECM, Pingo-Almada M, Wassing BM, Ligthelm DJ, Masalmeh SK (2014) Low-salinity polymer flooding: improving polymer flooding technical feasibility and economics by using low-salinity make-up brine. Paper SPE 17342, SPE international petroleum technology conference, Doha

Vledder P, Fonseca JC, Wells T, Gonzalez I, Ligthelm D (2010) Low salinity water flooding: proof of wettability alteration on a field wide scale. Paper SPE 129564 presented at the SPE improved oil recovery symposium, Tulsa, 24–28 Apr

Webb KJ, Black CJJ, Al-Ajeel H (2004) Low salinity oil recovery-log-inject-log. Paper SPE 89379 presented at the SPE/DOE symposium on improved oil recovery, pp 17–21

Webb KJ, Black CJJ, Tjetland G (2005) A laboratory study investigating methods for improving oil recovery in carbonates. Paper IPTC 10506 presented at the international petroleum technology conference, Doha, 21–23 Nov

Xia H, Wang D, Wang G, Wu J (2008) Effect of polymer solution viscoelasticity on residual Oil. Pet Sci Technol 26(4):398–412. doi:10.1080/10916460600809600

Yildiz HO, Morrow NR (1996) Effect of brine composition on recovery of moutray crude oil by waterflooding. Pet Sci Eng 14:159–168

Yildiz HO, Valat M, Morrow NR (1999) Effect of brine composition on wettability and oil recovery of a prudhoe bay crude oil. J Can Pet Technol 38(1):26–31

Zhang Y, Xie X, Morrow N (2007) Waterflood performance by injection of brine with different salinity for reservoir cores. Paper SPE 109849 presented at the SPE annual technical conference and exhibition, Anaheim, 11–14 Nov

Acknowledgement

The authors acknowledge King Abdulaziz City for Science and Technology (KACST) for their financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Almansour, A.O., AlQuraishi, A.A., AlHussinan, S.N. et al. Efficiency of enhanced oil recovery using polymer-augmented low salinity flooding. J Petrol Explor Prod Technol 7, 1149–1158 (2017). https://doi.org/10.1007/s13202-017-0331-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-017-0331-5