Abstract

Water companies and their consumers affected with leakages in water distribution system worldwide. This has attracted many practitioner’s attention as well as researchers over the past years. Selected study area suffers from water losses of about 10 to 15% which accounts to loss of about 9 to 9.75 million liters per month. The present study was under taken to understand, analyze and evaluate the losses and suggest preventive measures of wrapping and repair clamping for control of these losses. The assessment of water losses is done through comparative analysis of data using Microsoft Excel software. Population forecasting is done in context of assessing the amount of water lost that can be prevented in future decades, adjusting to increased water demand and losses. For better efficiency of the suggested methods, experimental analysis was carried out on a reduced scale model of a single stretched pipeline. Cost estimation of the preventive measures was done by obtaining information about the materials used by trading professionals.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Adequate and clean water supply to the population is an important aspect in water management system. Water conservation in most of the water supply system in India has paid less attention. The reason for this is due to lack of knowledge and fund for routine maintenance. This results in loss of water sources from a distribution system. The losses may also occur from a reservoir, service pipes, fitting, bends, etc. As the pressure increases in the supply line result in the increase in leakage of water. The water losses in the Netherlands are about 3 to 7% of total water supplied. The losses in United States of America are about 7.5 to 15%, The losses of water in Australia is about 20%. Denmark has UFW as low as 3 to 4% (Farly and Liemberger 2005). When compared to the above-mentioned developed countries the water losses occurring in India are massive, which should be conserved by studying and adopting the methods utilized by the developed countries in prevention of these losses considering into account the feasibility and economy of implementation of the project. In order to balance the water demand of the rapidly increasing population, provision must be made to supply sufficient and uniform quantity of water through an efficient water distribution system avoiding losses. But in the present-day scenario, reduction in water loss in the supply systems has become one of the main challenges faced in distribution due to various reasons such as defective pipes, leakages, unattended damaged supply pipes, water theft; among the many causes of the water loss, which directly impacts on the system’s revenue. In addition to this, consumer may waste the water due to failure of closing water taps and excessive usage for various activities. These can be minimized through proper awareness and education system. Also, by introducing metering system in the primacies of consumer. But prompt attempt is needed to reduce the losses in the system through corrective action. Hence the main goal of this research work undertaken is to reduce the water loss by implementing the new techniques and modifications for the existing water supply lines which are geographically and economically feasible.

Many studies were found related to this study and few were discussed in this section. Raman (1983) studied effective water management system consist of clear water supply to the population. Fontana and Morais (2016) presented an decision model integrating the features of multi-attribute value, SMARTER method, with an technique with linear programming method. Charalambous et al. (2014) conducted the water audit from source to system. Also derived the methodology for water accountability and integrated approach for water losses through revenue and non-revenue component. Dighade et al. (2014) has addressed the key issues faced by developing countries in water loss problems are noted such as the distribution system is usually designed as a continuous system based on the assumption of continuous supply. Selek et al. (2018) estimated both apparent and physical losses. Such that approximately 60% of total water losses are comprised of physical losses and the remaining 40% are accounted for apparent losses in Turkey. Araceli et al. (2020) represents a straight forward methodology using the flow rate as constant. Here total cost is equivalent to variable demand flow. Blinco et al. (2017) developed a framework, which enable the user to develop optimization of their water supply system using multiple sources, policies and design options. Suribabu (2017) explained the procedure for to normalize the objective function having distinct metrics considering resilience indices and power efficiency as the factors. Daniel and Eelco (2017) explained the issue which need planning and management. Also highlighted how computer-based model help to solve the issue related to this. Jang (2018) Independent factors were created considering three criteria which includes: parameter properties, data availability and its characteristics and quantifiable data. Jung and Kim (2018) this study highlights the differences in design based on topological and hydraulic reliability. Farley and Liemberger (2005) strategy and its developments steps were discussed through network upgrading by improved infrastructure management and zoning, with proper equipment for monitoring and detecting the losses. Mario et al. (2015) explains the process includes model building, calibration process and other issue to be developed near future. Rabab et al. (2019) highlights the techniques, sustainable methods and other suitable techniques which are adopted in the internal and external design of school building. Yilikal et al. (2019) checked the household ability to pay for the service improvement through their choices and mode of supply among several options.

In this study, we investigated the modifications in various efficient distribution systems adapted widely having lower water losses percentage. This study also analyzed the conventional methods followed by water regulatory board in the Study area and comparison of the methods was done in terms of various parameters like efficiency, cost of adaption, estimation of water conserved. Amount of water conserved using this method was also compared with the conventional method. To execute the above work, cost analysis and adaption were done.

Study area

Devasandra is one of the nine wards belonging to the K.R. Puram assembly Constituency located at the Northern part of Bangalore City. It is situated about 15 Kms from the center of the City, and is one the fastest growing regions of Bangalore in terms of Population. It has been numbered as Ward no. -55 under BBMP and BWSSB organizations and it is grouped under East Subdivision-3 of these organizations along with other areas like Horamavu, Ramamurthy Nagar, Vijnanapura, Basavanapura, A. Narayanapura and K. R. Puram. It has a population of 33,946 (according to 2011 census) and population density of around 9754 persons/sq.km within an area of 3.5 sq.km, making it one of the most densely populated regions of Bangalore. It has a water demand of about 90 ML to 92ML per month for the present population and this demand has been increasing every year due to new immigrant population settling in the region. The area is located close to National Highway (NH-4) Old Madras Road and Outer Ring road of Bangalore, traffic flow of heavy vehicle is high in this region. It has been housing many IT firms since the venture of software companies and start-ups during the early and mid-2000, due to the suitability of the region and easy access to the City CentreCentre. With the bloom in Real estate and Infrastructure of the region, it has been a desirable location for many investors and developers in past few decades. This region has a tropical savanna climate with distinct wet and dry seasons and is free from any natural disaster risks (Table 1). Methodology used in the study is shown in Fig. 1.

Geometric mean method

The formula for population forecasting using this method is:

where Pn = Increased Population after nth decade. P = present population. I = population growth rate. n = number of decades.

-

i.

Population forecast for 2021:

$$\begin{aligned} P_{n} & = P*\left( {1 + I/100} \right)^{n} \\ P_{1} & = 33,946*\left( {1 + 53.90/100} \right)^{1} \\ P_{1} & = 52,242 \\ \end{aligned}$$ -

ii.

Population forecast for 2031:

$$\begin{aligned} P_{n} & = P*\left( {1 + I/100} \right)^{n} \\ P_{2} & = 33,946*\left( {1 + 53.90/100} \right)^{2} \\ P_{2} & = 80,402 \\ \end{aligned}$$ -

iii.

Population forecast for 2041:

$$\begin{gathered} P_{n} = P*\left( {1 + I/100} \right)^{n} \hfill \\ P_{3} = 33,946*\left( {1 + 53.90/100} \right)^{3} \hfill \\ P_{3} = 123,738 \hfill \\ \end{gathered}$$

Figure 2, represents the Population forecast of Devasandra region. The population at the end of three decades will be about 365% of the current population. At present the water demand in the Devasandra region is about 90 ML to 92 ML per month, considering the daily per capita usage as 120 L/head/day.

By using this data, if when we calculate the water requirement in the year 2041, it will be:

From the forecasting data and current water demand data, the calculated amount of water required for the Devasandra region in 2041 is about 445.45 ML per month.

Water loss details

There are many factors attributing the water losses in the Devasandra region, some of the reasons understood through site visit and discussion with professionals are:

Scouring

This is due to corrosion of cast iron pipes used in the distribution mains due to high pressure of the flow during the peak time of the day, due to intermittent supply system. From the data obtained, the cast iron pipes that were present in the distribution system were found to be decades old and some pipes having both inner and outer surfaces corroded due to high pressure and corrosion like rust. Scouring accounts to 4 ML to 4.5 ML per month in the study area. These losses often go undetected due to lack of investigative methods for losses identification.

Leakages

Leakages form a major part of water losses in distribution system of case study area and are caused due to cracks or breakages in the concrete and asbestos pipes due to their brittle nature and due to the roadworks, which includes excavation of surface of roads, which can possibly damage the pipes laying underneath. As the location of study area is near to Highway, roadworks and repairs are common due to distortion of road surfaces by heavy load vehicles, this further accompanied by the excavation of roads for laying of Optic Fiber Cables (OFC) in the region for tele-communication services cause the breakages during excavation and filling of earthwork. Leakages cause around 5 ML water losses per month in the study area, it is the biggest contributor to the water losses in the region. With delayed repairs of these damages due to lack of knowledge about the location of leakages, significant amount of water is lost each month.

Traffic density

With increase in wheel load due to heavy movement of traffic, there will be pressure exerted on the water supply pipes laid beneath the surface which often tends to get damaged. Movement of heavy vehicles in the sub roads, cross roads and arterial roads causes deflection in pipes and ultimately its breakage. Pipes laid in these roads are usually brittle in nature and do not possess strength to withstand these types of heavy loads exerted on them. Instead of laying the pipes directly beneath the surface of the pavement, it will be desirable to lay the pipes below the shoulder of the pavement.

Tank overflows

Most of the overhead tanks (OHT) present in the study area are manually operated, with no automatic sensors adopted to cut the flow of water automatically after completion of filling to the required level. Because of manual methods of operation, it is very inefficient due to human errors like negligence, inaccurate perception, etc.

Delayed notice and repairs

When leakages occur, they start with only small amount of loss and often does not get noticed till a significantly large amount of water is lost. The losses must be attended immediately and repaired to avoid further damages, but in the study area the action of repair of leakage occurs only after receiving complaint and repair works starts with the availability of staff.

Apparent minor losses

Meters in the study area are not completely digitalized yet and can be tampered easily leading to unaccounted flow of water. These types of losses contribute to about 0.75 ML to 1 ML per month. These losses occur generally in economically backward places of the study area, where meter tampering, illegal un-authorized connections can be seen.

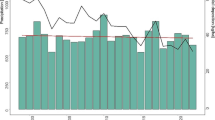

Experimental procedure

The main goal of the experiment is to observe the efficiency of the methods of wrapping and clamping in water losses prevention. These methods and its suitability were checked in the study area for control of the Unaccounted Flow of Water. For this purpose, an experiment was conducted to determine the efficiency of the material polymer rubber and metal clamps and the methods wholly in prevention of water losses and simultaneous calculation of the amount of water losses prevented was done. The experiment was carried out by creating a small model of a distribution mains with a reduced scale and adopting various conditions such as breakages in pipes, scoured and eroded surface of the pipe and determination of losses before and after implementing the above-mentioned methods. The clamping of pipes is carried out by using mild steel as the material, likewise for wrapping polymer rubber material is used. (Figs. 3, 4, 5, 6). For this work, Water drum (250 lts), container with marked gradation(30 lts) electric water pump(0.5HP), pipes and pipe connections (elbow, T-connection, collar, etc.) of diameter 1 inch, adhesive, polymer rubber, mild steel clamps, stopwatch were used. The experimental model is built as shown in network diagram and checked for any visible defects. Here the drum is filled with water up to the brim level and the end of the inlet pipe is submerged into it. The pump was run for 20 s and the quantity of water received at the end was measured. Three trials were conducted and average of these trials were taken. The surface of the pipe is damaged at selected locations manually to demonstrate the leakage in the pipes and the above procedure is followed and average of three trials is taken. The previously damaged portion of the pipe is clamped and wrapped by the polymer rubber and metal clamps and fastened by bolts and stuck together using adhesive. The pump is again run for 20 s in each trial and average quantity of three trials were considered (Table 2). Graphical representation of water output at different locations was shown in Fig. 7.

Results and discussion

-

1.

Avg. loss during leakages = Avg. output in normal condition—Avg. output during leakage

$$\begin{aligned} & = {\text{ }}15.03{-}11.37 \\ & = {\text{ }}3.67\;{\text{lts}} \\ \end{aligned}$$ -

2.

Avg. loss after Wrapping and Clamping = Avg. output in normal condition – Avg. output after wrapping and clamping

$$\begin{aligned} & = {\text{ }}15.03{\text{ }} - {\text{ }}13.97 \\ & = {\text{ }}1.07{\text{ lts}} \\ \end{aligned}$$ -

3.

Percentage of loss due to leakage = (leakage loss/Avg. output in normal condition) *100

$$\begin{aligned} & = {\text{ }}\left( {3.67/15.03} \right){\text{ }}*100 \\ & = {\text{ }}24.39\% \\ \end{aligned}$$ -

4.

Efficiency of Clamping and wrapping methods = (loss during leakages-loss after wrapping & clamping)/loss during leakages *100

$$\begin{gathered} = {\text{ }}\left( {\left( {3.67 - 1.07} \right)/3.67} \right){\text{ }}*100 \hfill \\ = {\text{ }}70.98\% \hfill \\ \end{gathered}$$

This method of conservation is done to reduce the percentage of reduction in water losses in study area, by implementing wrapping and clamping methods. Around 70 ML to 72 ML per month is supplied to the study area to compensate the water demand, out of which around 9 ML to 9.75 ML were lost in leakages, scouring and apparent losses. About 90% of these losses are caused by leakages and scouring. After conduction of population forecasting, it was found that population at the end of three decades will be 365% of current population and the water demand at that period will be about 445 ML per month, if this current rate of loss prevails there will be a loss of 66.75 ML per month which is almost nearer to the total amount of water supplied at present for the area under considered. Through the experimental analysis performed, the efficiency of the method was found to be around 70.98%. If these methods were used for leakage repairs and maintenance about two-third to three-fourth of the total water losses can be controlled. Also, Fig. 8, shows the graphical presentation of water losses before and after the implementation of technique. A huge difference in reduction in percentage of water loss was observed, if the method of wrapping and clamping adopted. On an average, the water losses can be reduced to about 3.2 to 4% from around 10 to 15% occurring currently in study area. The cost estimation of the suggested method and their comparison with the conventional method estimation obtained from the water regulatory board at a particular location of leakage in the study area. It is observed that the expenses of adoption of these methods are in par with the methods followed currently. If these methods are applied widely in the water regulatory board with mass production of materials, cost of repairs can be further reduced about 20% of existing cost. Since these methods have higher efficiency than traditional method, the amount of water conserved is more. Hence the benefit of these methods was obtained in the form of amount of water conserved from losses (Table 3).

Calculation

-

i.

Total amount of water losses occurring per year through leakages and scouring

$$\begin{aligned} ~ & = {\text{ }}\left( {{\text{Total water losses in the distribution per year}}} \right){\text{ }}*{\text{ }}0.{\text{9}} \\ & = {\text{ }}\left( {\left( {{\text{9}}.{\text{75 }}*{\text{1}}0^{{\text{6}}} } \right)*{\text{12}}} \right){\text{ }}*{\text{ }}0.{\text{9}} \\ & = {\text{1}}0{\text{5}}.{\text{3}}\;{\text{ML per year}} \\ \end{aligned}$$ -

ii.

Total amount of water losses that can be prevented by wrapping and clamping

$$\begin{aligned} & = {\text{ }}\left( {{\text{Amount of water losses due to leakages and scouring}}} \right){\text{ }}*{\text{ Efficiency of methods}} \\ & = {\text{ }}\left( {\left( {{\text{8}}.{\text{775 }}*{\text{ 1}}0^{{\text{6}}} } \right)*{\text{12}}} \right){\text{ }}*{\text{ }}\left( {{\text{7}}0.{\text{98}}/{\text{1}}00} \right) \\ & = {\text{74}}.{\text{74ML per year}} \\ \end{aligned}$$ -

iii.

Percentage of water losses after implementation of the suggested methods

$$\begin{aligned} & = {\text{ }}\left( {{\text{amount of water losses through leakages and scouring }}{-}{\text{ amount of losses prevented by implementation of these methods}}} \right)/\left( {{\text{average total water supplied per year}}} \right){\text{ }}*{\text{1}}00 \\ & = {\text{ }}\left( {\left( {{\text{1}}0{\text{5}}.{\text{3 }} - {\text{ 74}}.{\text{74}}} \right){\text{ }}*{\text{1}}0^{{\text{6}}} /{\text{84}}0*{\text{1}}0^{{\text{6}}} } \right){\text{ }}*{\text{1}}00 \\ & = {\text{ 3}}.{\text{63}}\% \\ \end{aligned}$$

Conclusion

In this work, an attempt was made to reduce the water losses from the system by understanding various types of actual and apparent losses, their causes and number of losses. Through analysis from the study area, data accompanied with the series of site visits to location of leakages, the factors leading to losses and the measures taken by the water regulatory board (BWSSB) to curb these losses were learnt. After conducting the population analysis and forecasting of the study area, it was learnt that the population will be tripled in the next two decades and the water demand increases by about five times, if the present trend of water losses prevails at that time, the amount of water lost through distribution network will be as huge as the total amount of water supplied at present. By conducting the experimental analysis, the efficiency of the used method to prevent the losses was obtained as 70% more than the current traditional method of prevention followed by the water supply board. An estimated amount of 74.74 ML per year can be conserved in the study area by implementing the proposed method. The proposed method having same expense for installation compared to existing method and hence additional cost is not necessary.

Future scope

-

Applicability to larger area of pipe network.

-

Usage of recycled materials for studies on these methods is desirable as the recyclable raw materials are easily available and prove to be efficient over the time

-

The system of water supply can be switched to continuous instead of intermittent system to enable steady flow and reduce losses due to scouring, pipe bursts, etc.

References

Araceli MC, David S, Ana I, Luis G (2020) Optimization of the design of water distribution systems for variable pumping flow rates. Water 12:359. https://doi.org/10.3390/w12020359

Blinco LJ, Lambert MF, Simpson AR et al (2017) Framework for the optimization of operation and design of system with different alternative water sources. Earth Perspect. https://doi.org/10.1186/s40322-017-0038-2

Charalambous B, Foufeas D, Petroulias N (2014) Leak detection and water loss management. Water Util J 8:25–30

Daniel PL, van Eelco B (2017) Water Resources planning and management: an overview. Water Res Syst Plann Manag 2017:1–49

Dighade RR, Kadu MS, Pande AM (2014) Challenges in water loss management of water distribution systems in developing countries. Int J Innov Res Sci Eng Technol 3(6), ISSN: 2319-8753

Farley M, Liemberger R (2005) Developing a nonrevenue water reduction strategy: planning and implementing the strategy. Water Sci Technol Water Supply 5(1):41–50

Fontana ME, Morais DC (2016) Decision model to control water losses in distribution networks. Production 26(4):688–697. https://doi.org/10.1590/0103-6513.201815

Jang D (2018) A parameter classification system for Nonrevenue water Management in water distribution networks. Adv Civil Eng Article ID 3841979. https://doi.org/10.1155/2018/3841979

Jung D, Kim JH (2018) water distribution system design to minimize costs and maximize topological and Hydraulic reliability. J Water Res Plann Manag. https://doi.org/10.1061/(ASCE)WR.1943-5452.0000975

Mario CG, Emilio AL, Quan P, Andreja J (2015) Water distribution network model building, case study : Milano, Italy. In: 13th international conference on computing and control for the water industry, CCWI2015, procedia engineering 119 (2015), pp 573–582

Rabab IE-N, Ibrahim M, Waled A-A (2019) Water management as a vital factor for a sustainable school. Alex Eng J 58(1):303–313

Raman V (1983) Significance of losses in water distribution systems in India. Bull World Health Organ 61(5):867–870

Selek B, Adiguzel A, Iritas O, Karaaslan Y, Kinaci C, Muhammetoglu A, Muhammetoglu H (2018) Management of water losses in water supply and distribution networks in Turkey. Turk J Water Sci Manag 2(1):58–75

Suribabu CR (2017) Resilience based optimal design of water distribution network. Appl Water Sci 7:4055–4066. https://doi.org/10.1007/s13201-017-0560-2

Yilikal A, Zeleke G, Gebremariam E (2019) valuing the water supply: ecosystem based potable water supply management for the legedadie- dire catchments, central Ethiopia. Ecol Process 8:9. https://doi.org/10.1186/s13717-019-0160-1

Funding

The author(s) received no specific funding for this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Surendra, H.J., Suresh, B.T., Ullas, T.D. et al. Economic design of alternative system to reduce the water distribution losses for sustainability. Appl Water Sci 11, 131 (2021). https://doi.org/10.1007/s13201-021-01460-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-021-01460-y