Abstract

The response surface methodology has been extended to study the adsorption of malachite green dye (MG) on Indian Neem leaf powder (NLP), Azadirachta indica. The study was experimented by varying the solution concentration from 10 to 100 mg/l. The removal percentage of MG was determined by spectrophotometer at wavelength of 618 nm. Design Expert 11.0 was used as a tool to study the optimal conditions of MG adsorption (applying 2-factorial interaction model of central composite design) and evaluation of interaction effects of different operating parameters including pH, time, solute concentration, temperature and adsorbent dosage. Numerical optimization helped to identify the optimal conditions for achieving the targeted dye removal of 95.493% when the pH, time, solute concentration, temperature and adsorbent amount were set at the range of 6.868, 36.4 min, 27.899 mg/l, 308.477 K, and 4.3475 g/l respectively. The experimental results indicate that the maximum adsorption capacity of NLP depends on various operating parameter like, pH, dye concentration, particle size of adsorbents and it’s activation. It was noted that adsorption capacity of the NLP increases from 33.33 to 66.72 mg/g when it was activated with dilute HCl. The higher correlation coefficient value (R2) of Langmuir isotherm 0.996 and lower p value (0.01203) indicate the fitness of the response surface 2FI model developed. Kinetic studies displayed the suitability of pseudo second order reaction for this adsorption process. The thermodynamic study show that the sorption process is exothermic and spontaneous in nature. It was observed that the adsorbent NLP in the form of fine powder are very effective for the removal of MG from its aqueous solution. The satisfactory values of regression coefficients at different temperature, and fittings of adsorption isotherms indicate that Indian NLP is a promising adsorbent for treatment of textile dyes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The Neem tree (Azadirachta indica) of family Meliacae is native to the Indian sub-continent and it has been in use (especially its leaves and barks) since ancient periods to treat various human disorders and other hygienic activities (Bhattacharyya and Sharma 2003). From the ancient time, the medicinal and germicidal activities of this tree (A. indica) have been well described. A huge range of useful products like anti-malarial, spermicidal, anti-tuberculosis agents, anti-pyrehetics, anti-viral drugs anti-fungal agents, anti-allergic medicines, etc. has been extracted from Neem (Chopra et al. 1956; Sharma and Bhattacharyya 2005). It has been reported that fresh Neem leaves contain maximum 59.4% of moisture, 22.9% of carbohydrates, 7.1% of proteins, 6.2% of fiber, 3.4% of minerals and 1% of fats with other chemicals (Neem Foundation 1997).

Various chemical process industries like textile, pulp and paper, paints and pigments, printing, food, cosmetics, petroleum, rubber, etc. use synthetic dyes extensively (Ergene et al. 2009; Kiran et al. 2009). Annually, over million tonnes of production of commercial dyes and pigments are taken place among the different existing dyes and pigments (Gupta 2009). Textile industries consume the dyes extensively higher compared to other industries, almost 50% of the dyes are lost during textile processing among which 10–15% are discharged to effluents (Yang et al. 2009). The effluents of dyeing industries use highly colored compounds having high chemical and biological oxygen demand (Garg et al. 2004). These dye containing effluents can harm the living systems of the natural water bodies as well as the human beings due to their carcinogenic, allergenic and toxic effect (Akar et al. 2009; Chakraborty et al. 2020). Since water is an indispensable part of our life (Halder et al. 2016; Roy et al. 2020), several physicochemical processes have been developed to reduce the impact of carcinogenic dyes on the environment. It was reported that among various selective and expensive treatment processes, adsorption is highly cost effective. Though commercial activated carbon is widely acceptable adsorbent due to its high porosity and large surface area, but it is expensive in comparison to naturally obtained bio-adsorbent like NLP. Thus, effective utilization of NLP as an alternative adsorbent for the treatment of textile dying wastes and the investigation of its adsorption characteristics is a big challenge to the researchers till now.

Malachite green (MG), an N-methyl-di-amino-tri-phenyl-methane dye, is water-soluble, organic cationic dye (Fig. 1) is widely used for dyeing purposes (Chowdhury et al. 2011; Ahmad et al. 2017). This cationic dye is generally used for the coloring of cotton, wool, silk, paper, and leather and also in distilleries. It is also used as a therapeutic agent (fungicide, ectoparasiticide) and as antiseptic, but only for external applications on the wounds and ulcers (Crini et al. 2007). Some noticeable detrimental nature of MG dye are to effect on nervous system, brain and liver while consumed, to reduce the efficiency of food intake, growth and fertility rates (Raval et al. 2017). It is environmentally persistent and responsible to damage liver, spleen, kidney and heart etc. (Hameed and El-Khaiary 2008; Bulut et al. 2008). Hence, treatment of the effluent containing carcinogenic dye has become an area of interest to the researchers.

In classical methods of optimization, it is difficult to solve the complex interactions between the variables and responses since it can handle the variation of only one parameter at a time, keeping other factors constant (Mukherjee et al. 2020; Dey et al. 2019). Response surface methodology is one of the most user friendly, potable method to design experiments statistically. Development of mathematical model and its optimization to reduce the complicacy of the process is another importance of RSM (Khajeh et al. 2013, 2016; Khajeh and Gharan 2014; Khuri and Cornell 1996). It can provide the effects of several factors at various level with their influence on each other with the aim of optimizing the response based on the investigating factors (Mothgomery 1997; Myers and Mothgomery 2002; Jana et al. 2018). Major benefits of this statistical analytical method are reported by Jana et al. (2018) and Cochran and Cox (1992) as:

- 1.

Minimum number of experimental runs are required instead of full experimental design at the same level.

- 2.

It allows to visualize the interaction effects of a factor at several levels with other factors and their estimation.

- 3.

It helps to obtain the surface variations of response that provides a good way of envisioning the parameter interaction.

Though dye removal from textile effluent have already been investigated using hard wood, saw dust and charcoal by Asfour et al. (1985), Hameed and El-Khaiary (2008) and Ferrero (2007). Moreover, performance efficiency of saw dust as low cost adsorbent has also been studied for the removal of toxic heavy metal, hexavalent chromium (Cr) and dyes by Siboni et al. (2011), Das et al. (2015) and Karunanithi et al. (2000). Similarly low-cost rice-husk has been used to study adsorption efficiency of hexavalent chromium by Mullick et al. (2017). Garg et al. (2004) and Ho and McKay (1998) explained the overview performance characteristics of timber wastes for dyes removal from textile wastes. In spite of the above-mentioned development, we have considered the following aspects as objectives of the present work:

- 1.

To design the experimental and statistical analysis for the batch adsorption of malachite green dye using Neem leaf powder as low-cost adsorbent and observe the effects of five primary operational parameters (i.e. pH, time, solute concentration, temperature and adsorbent amount) on one output parameter i.e. percentage dye removal during the batch adsorption of synthetic wastewater solution.

- 2.

To investigate the suitability of proposed design and its statistical analysis (ANOVA) in adsorption phenomena for its optimization.

- 3.

To enlighten the adsorption characteristics of NLP for the treatment of MG dye based on the kinetic and thermodynamic study.

- 4.

To investigate the optimal conditions of five operational parameters which maximize the dye removal quantity using RSM.

Materials and methods

Adsorbate collection

Malachite green the chemical formula of MG is \( \left[ {{\text{C}}_{6} {\text{H}}_{5} {\text{C}}\left( {{\text{C}}_{6} {\text{H}}_{4} {\text{N}}\left( {{\text{CH}}_{3} } \right)_{2} } \right)_{2} } \right]{\text{Cl}} \) and mol. wt. of 364.11 (g/mol) used in this experiment was of analytical reagent grade and purchased from Merck Specialities Pvt. Ltd (Mumbai, 40018). Different concentrations of MG solutions were prepared by dissolving the required amounts of MG dye in distilled water. Laboratory grade HCl and NaOH (Fisher Scientific, Kolkata) was used in this experiment.

Adsorbent preparation

Neem leaves were collected from local area which were washed several times, dried at room temperature till it became crispy and grounded to fine powder, sieved to 125–250 µm, washed several times with distilled water. Then about 30 g NLP were boiled in a 250 ml beaker adding 5 ml, (5 N) HCl to activate the adsorbents and to remove dark green color and soluble impurities. The Neem leaf powder were filtered and boiled 2–3 times with distilled water again to remove the color fully and dried at room temperature for 48 h. It was kept in the oven at about 60–70°C for 6–8 h, to remove the moisture completely and dry activated NLP were kept in an air tight vessel.

Adsorption study in batch process

Batch adsorption study was carried out using magnetic stirrer at constant rpm of 300 in a 250 ml Erlenmeyer flasks by adding different concentrations of MG solution (10–100 mg/l) and NLP of 3–10 g/l. Kinetic studies were performed at 308 K, 318 K and 333 K. The concentrations of MG left in supernatant solutions after different time intervals (10–120 min) were determined using a UV–Vis spectrophotometer (Simazu-1800) at wave length of 618 nm. The amount of MG adsorbed per unit mass of NLP (Q) and the dye removal efficiency (R) were calculated according to the following Eq. (1):

where Co and Ct (mg/l) are the initial (before adsorption) and final (after adsorption) concentration of dye solution. The effect of pH was performed by adjusting the solution using 0.1 mol/l of NaOH or 0.1 mol/l of HCl solutions.

Characterization processes for Neem leaf powder (NLP) adsorbent

Scanning electron microscopy (SEM)

Scanning electron microscopy (SEM) is used to study the surface topography of any solid material (Chatterjee et al. 2012). It shows better results than optical microscopy because of its high and better resolution and enhanced depth of field. SEM photographs were taken with scanning electron microscope (Zeiss EVO 10, U.K.) at the required magnification at room temperature. The working distance of 7 mm was maintained and acceleration voltage used was 5–20 kV at different magnification, with the secondary electron image (SEI) as a detector.

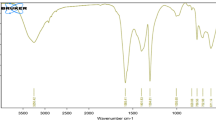

Fourier transform infra-red (FTIR) study

IR spectroscopy is used for obtaining information of functional groups present on solid NLP surface (Mullick and Neogi 2016). The principle of IR spectroscopy is based on molecular vibration in crystal lattice with specific frequencies associated with internal vibrations of groups of atoms. These frequencies occur in the IR region of the electromagnetic spectrum, i.e. in the range of 500–4000 cm−1. The Fourier transform infrared spectrometer (FT1R) employs an interferometer instead of a monochromator. It was conducted with the help of Fourier Transform Infra-Red machine (ATR, Thermo Fischer Scientific, USA). The infrared spectra were recorded in the mid IR region (i.e. 2–25 µm, 500–4000 cm−1) using FTIR spectrometer.

Energy dispersive X-ray (EDX)

Energy (electron) dispersive X-ray analysis (EDX) technique is used for performing elemental analysis or chemical characterization of a sample in conjunction with scanning electron microscopy (SEM). For determining elemental content, the electron-beam strikes the surface of conducting sample (SEM) (Kibami et al. 2017). Here, it was used for the elemental/chemical characterization of the pure adsorbent A. indica (NLP). Its characterization capabilities were due to the principle that each element has a unique atomic structure, thus allowing a unique set of peaks on its X-ray spectra which was shown in Fig. 3.

Response surface methodology for optimization process

Model selection

Since the pattern of combinations between the independent and response variables is unknown in most of the cases, suitable approximation is required to determine. Among various approximation functions, polynomials are such functions which are used in a large extent (Nair et al. 2014). Since a simple linear equation cannot describe the interaction effect between different parameters and also unable to determine the critical point, the full quadratic second-order function is has been used expressing their various interaction terms given in the Eq. (2).

where y is the predicted response in the system, xi is the independent variable, β0 is the constant term, βi are the linear coefficients, βii is the squared coefficients, the βij is the interaction coefficient, and ϵ is the error.

Experimental design

This statistical method was used to design a model using the experimental data obtained from the findings and its optimization (Arivoli et al. 2010; Sahu et al. 2009). Basically, the analysis was done by following three steps viz., (1) conducting the experiments statistically, (2) evaluating the correlation coefficients from mathematical model and predicting responses and (3) analysing the adequacy of the proposed model (Myers and Montgomery 1995). RSM helps to enumerate the relationships Eq. (3) between output variables called responses (O) and input variables called factors (Ins) (Sahu et al. 2009).

As a response surface methodology and central composite design (CCD) has been applied in the present work. This method is suitable for fitting a quadratic surface with analyzing the interaction between the parameters (Arivoli et al. 2010).

In this present study, response surface design was developed based on three levels two factorial central composite design (CCD) having five factors for developing the CCD model using Design-Expert 11.0. In this purpose, i1, i2, i3, i4, and i5 were taken as input parameters and O1 was taken as response in this model. In this perspective, as explained before, the applied variables and their levels were represented in Table 1, whereas the design matrix was depicted in Table 2.

For statistical analysis, the levels of five variables in [i1, i2, i3, i4, and i5] were coded according to the following relationship in Eq. (4):

where In is coded value of factors in, and i0 at the center point and δi represents the step change.

Results and discussions

With respect to every inputs and output, we have formulated a central composite design model for toxic dye removal using adsorption process. In order to maintain the percentage dye removal of the predictive model, we have defined some statistical parameters. The predicted capability of proposed CCD model was evaluated and compared the outputs with the experimental values. In addition, the statistical parameter such as the co-relation coefficient (R2) was used to compare the predicted value with experimented values of flexible modulus.

Characterization results of Neem leaf powder

SEM analysis

SEM micrographs of the Neem leaf powder (Fig. 2) showed that the powder was an assemblage of fine particles, which did not have regular, fixed shape and size. Some of the particles may be quite small while some others may be as big as 10 µm in diameter. All the particles have broken edges with steps and kinks contributing to the uneven topography. The surface appeared as a fibrous material with irregular macro-pores and some expanded cavities which may allow for the diffusion of the molecules through the macro-pores of the adsorbent.

EDX analysis

Due to the low X-ray intensity, EDX images usually take a number of hours to be acquired. Elements of low atomic number are difficult to detect by EDX. EDX image analysis from Fig. 3 show that the Neem leaf sample highly consists of carbon, oxygen, and calcium at varied proportions. EDX analysis of the sample (i.e. weight percentage and atomic percentage) (table inside the Fig. 3) indicate the presence of phosphorus which carried rather good adsorbent properties particularly for this Neem leaf powder. This analysis also displayed the presence of Ca, Mg, Br, Fe, and Si in a trace amount compare to the activated carbon quantity.

FTIR analysis

The principal IR bands obtained for the sample were presented in Table 3. The results obtained from FTIR spectra of the Neem leaf powder were in conformity with the large number of constituents present in the Neem leaves. The presence of polar groups on the surface has been shown to be responsible for considerable cation exchange capacity of a solid, which was therefore also likely in case of the Neem leaf powder. IR-bands from Fig. 4 showed a broad peak at 3599–2500 cm−1 which was due to the O–H stretching vibration mode in carboxylic acid groups. Bands at 2377 cm−1 shown by the result were connected with O–H in carboxylic acid molecules in stretching mode. The C=O stretching near 1765–1725 cm−1 was the specific peak for the acid anhydrides due to C=O stretching. The general presence of C=O group’s vibration mode at about 1650–1800 cm−1 were probably due to stretching vibration of C=O moieties of conjugated systems or aromatic ring stretching coupled to highly conjugated carbonyl groups (Kibami et al. 2017). While bands at 1615–1590 cm−1 were clearly observed and correspond to benzene ring stretching in aromatic compounds. Bands at 1575–1545 cm−1 were connected with NO2 in aliphatic nitro-compounds due to anti-symmetric stretching. Bands at 1440–1400 cm−1 were connected with to O–H in carboxylic acid groups due to in plane O–H bonding and 1400–1310 cm−1 were connected to COO– due to symmetric stretching.

Effect of operating parameters on adsorption process for the removal of malachite green

Effect of adsorbent dosage and contact time

The effect of adsorbent amount and contact time on removal of MG has been shown in Fig. 5. It also explains, that the adsorption increases with contact time, and it attends the equilibrium concentration at about 120 min. Results also indicate that percentage removal of MG increases from 90 to 98% for the increase amount of adsorbent from 3 to 10 g/l NLP. The results agree with the findings of other investigator also (Bulut et al. 2008; Chen et al. 2014a), it implies that with increase of surface area of the adsorbent, percentage of solute removal also increases consequently.

Effect of solute concentrations and time of contact

The effect of concentration of MG dye on its removal has been described in Fig. 6. It was noted that removal quantity of dye decreases with increase in solute concentration. This was because at lower concentration, the ratio of available surface area to the moles of dye was higher. But with the increase in solute concentration, this ratio became small due to unavailability of vacant spaces on the adsorbent surfaces after formation of monolayer. Similar adsorption characteristics have been reported by other researchers also (Chen et al. 2014a; Chopra et al. 1956; Ferrero 2007).

Effect of pH

Effect of pH on adsorption of MG has been shown in the Fig. 7. It show that adsorption increases from 80 to 95% with increase of pH from 2.46–9.76 indicating that adsorption of MG on NLP favors in alkaline media.

Effect of temperature

Effect of temperature on removal of MG on NLP has been studied and shown in the Fig. 8. It shows that percentage removal of MG decreases from 97 to 90% with increase of temperature from 308 to 333 K. Variation of adsorption capacity with temperature has been shown in Figs. 8 and 9. It also shows that adsorption capacity reduces from 33 to 31.0 mg/g of adsorbent (for raw NLP) indicating that this sorption process is exothermic in nature.

Studies on regeneration of adsorbent

Though neem leaves are available abundantly, yet in this work the used up adsorbent NLP was regenerated twice to investigate the efficiency of the regenerated NLP to regain its original adsorption capacity. For regeneration used up NLP were boiled with distilled water along with 5 N HCl in a 250 ml beaker 2–3 times until the color of MG dye was removed completely. Then the filtered residue was boiled with distilled water and was dried at room temperature followed by drying in the oven at 70–80 °C for 2–3 h. It was observed that initial adsorption was lower and it increases gradually and about 95% adsorption capacity may be achieved after 1 h adsorption with regenerated adsorbent. The Fig. 10 shows the adsorption property of the regenerated NLP for various solute concentration.

Adsorption isotherms

Langmuir adsorption isotherm

The experimental results obtained from Neem leaf powder-Malachite green adsorption process at 308 K have been correlated with the following rearranged Langmuir model of adsorption in Eq. (5):

where Qo and KL are Langmuir constants related to the capacity and energy of the activated NLP. The plot of Ce/Qe versus Ce is shown in Fig. 11. The linear plot with satisfactory regression coefficient of 0.996 suggests the applicability of the Langmuir isotherm for the systems. It also indicates the formation of monolayer coverage at the outer surface of the adsorbent. The Langmuir constants values of Qo and KL are obtained as 66.72 mg/g and 2.77 l/mg respectively. KL is Langmuir constant related to the sorption energy, it is the affinity of adsorbent toward the adsorbate. High values of KL implies strong binding between adsorbent NLP and solute MG.

Freundlich isotherm

Applicability of the Freundlich isotherm for the present system has also been estimated by correlating the results empirically using the well-known Freundlich Eqs. (6) and (7) as:

where X/M or Qe is surface load in (mg/g). The linear plot of log(X/M) versus log Ce in Fig. 12 also suggests that the system follows Freundlich isotherm. The values of n is 0.015, KF is 30.90 l/mg, R2 is 0.990. The values of regression co-efficient for Langmuir and Freundlich isotherm are 0.996 and 0.990 for MG. Results indicate that Langmuir’s model and Freundlich’s model both are applicable for this adsorption process.

The separation factor (Rl) related to Langmuir isotherm was used to evaluate the feasibility of adsorption on adsorbent. It can be calculated by Eq. (8) (Mullick and Neogi 2016).

where Co (mg/l) was initial dye concentration and Kl (l/mg) is Langmuir constant. The value of Rl indicates the type of the isotherm: irreversible (Rl = 0), favorable (0 < Rl < 1), linear (Rl = 1), unfavorable (Rl > 1). The Rl of MG adsorption onto NLP is 0.042 for solution having concentration of 100 mg/l. It can demonstrate the MG adsorption onto NLP is favorable.

Adsorption kinetics

Adsorption kinetics model are very important in this process of removal of complex dyes from industrial textile wastes or from aqueous solutions. Different reversible models are tested as below.

Lagergren pseudo first order model

The adsorption kinetics may be described by Pseudo First order reaction model (Siboni et al. 2011; Das et al. 2015) as expressed below in Eq. (9):

where ‘Qe’ is the amount of solute adsorbed at equilibrium per unit mass of adsorbent and ‘Q’ is the amount of solute adsorbed at any time ‘t’, and ‘k1’ is the rate constant. Applying boundary conditions and simplifying Eq. (9) we may obtain the following Eq. (10):

The plot of log(Qe–Q) versus ‘t’ was plotted at different temperature in Fig. 13. Result shows that correlation coefficients are in good agreement with pseudo first order reaction kinetics which are given in the Table 4.

Pseudo second order reaction kinetics

Pseudo second order reaction model is also applicable for the sorption process and equation for this reaction may be written as Eq. (11):

Integrating the Eq. (11) and applying boundary conditions as t = 0 to t >0 and Q = 0 or >0 the following Eqs. (12 and 13) may be achieved as:

where h = (k2·Q2e) and is known as initial sorption rate. The kinetics plot of t/Q versus t as per Eq. (13) were made at different concentration (Fig. 14) and the values of correlation coefficients, ‘h’ (mg/g min) and ‘k2’ (g/g min) may be calculated from the graph. Results show (Table 5) that this process follows pseudo second order reaction kinetics better than the first order kinetics which also agree with the results of other researchers.

Adsorption thermodynamics

Thermodynamic parameter, Gibb’s free energy \( \Delta G \) of a process determines the spontaneous and non-spontaneous nature of a process. Hence, this thermodynamic parameters study gives the idea of the feasibility of any adsorptive reaction. Also it provides the information regarding the mechanisms involved in the adsorption process. Considering the adsorption equilibrium constant Kl (l/mg) the free energy change of the process is given by the following Eq. (14):

where \( \Delta G \) and \( \Delta S \) are standard enthalpy and entropy change, respectively, during the adsorption process and T is the absolute temperature (K). Combining Eqs. (14) and (15), it can be written as follows:

where \( Ro \) is the universal gas constant = 8.314 (J/mol K). From the slopes and intercepts of the linear plots of ln KL versus 1/T (Fig. 15) the values of \( \Delta H \) and \( \Delta S \) were calculated as 1.143 kJ/mol and 24.775 J/mol K. The values of \( \Delta G \) calculated as − 8.8, − 9.03 and − 9.337 kJ/mol at 308 indicating a spontaneous and favorable adsorption process. The negative value of enthalpy change \( \Delta H \) (−1.695 kJ/mol) for the adsorption process suggested that the process was exothermic in nature and the positive values of (\( \Delta S \)) indicate the disorder created in the system due to adsorption.

Meanwhile, the positive \( \Delta S \) value implies some structural changes in the adsorbent and adsorbate and the increasing randomness at the solid-solution interface during fixation of MG onto the active sites NLP. All the thermodynamic parameters mentioned above (Table 6) indicated that NLP may be used as a high-efficiency adsorbent to remove MG from industrial wastes.

Diffusion model

The intra-particle diffusion model was (a kinetic model) proposed by Weber and Morris and is used to understand the controlling mechanism of the adsorption process and can be expressed in Eq. (17) (Weber and Morris 1963)

where Qt is the amount of solute adsorbed at time t (mg g−1), Kdiff was the intra-particle-diffusion rate constant (mg g−1 min0.5) obtained from the slopes of Qt versus t0.5 plot, t was the time (min), and C was the intercept (mg g−1). Kdiff was calculated from the Fig. 16 and it was found to be 0.047 mg g−1 min0.5.

Response surface of 2-factor interaction (2FI) model

The interaction among the different independent variables and their corresponding effect on the response on the Malachite green dye removal was investigated by analyzing the response surface analysis. Five process parameters—time, pH, temperature, adsorbent amount and solute concentration were considered as the variable parameters for the experimental studies using Neem leaf powder as adsorbent based on response surface methodology (RSM). The interaction effects of process were estimated by conducting the experiment using 2-factorial central composite design (CCD). The two factorial model equation in terms of coded variables as developed by the simulation is expressed in Eq. (18).

Estimation of response surface for maximum percentage of textile dye removal

Here the goodness of fit of the model was verified by the correlation coefficient (R2) between the experimental and model predicted values of the response variables in Fig. 17. It was observed that the model p value (0.01203) was highly significant model terms for malachite green dye removal. A high R2 value of 0.9678 and model F value of 2.93 implied that the results were in agreement with the model. The value of coefficient of variance 1.46% indicated good precision and reliability of the experimentally obtained value. Here, our Adeq precision measured the signal noise ration. This analysis was given in Table 7. The quadratic ANOVA model for percentage malachite green dye removal from its dilute solution was given by Table 8 based on 2-factorial interaction model. The response variable which was expressed as a function of independent variables was expressed in the form of different numerical factors in Eq. (18) and its corresponding coefficient table was given in Table 9.

Interaction effect of pH, time, temperature, solute concentration, and adsorbent amount

In order to study the interaction among the different independent variables and their corresponding effect on the response surface plots were represented in the Figs. 18, 19 and 23. The combined effect of time and pH on percentage dye removal was shown in the surface plot of Fig. 18. Figures show that Percentage dye removal increased with increase in time as well as pH value, which was confirmed by the experimental results within the experimental limit. This type of behavior indicates that the amount of dye removal depends on the alkalinity of the medium highly.

Figure 19 illustrated the interaction effect of time and solute concentration on the removal percentage of malachite green dye. Within the experimental limit, dye removal percentage increases with the time and decreases with solute concentration of the dye (MG). Similar nature was found in the experimental results. Therefore, it can be predicted that the treatment efficiency will be higher at longer time and lower solute concentration.

The surface plot in Fig. 20 illustrated the combined effect of temperature and pH on the dye removal of textile waste water using batch adsorption process. At high pH, low temperature the dye removal percentage was also high. Figure 21 illustrated the interaction effect of adsorbent amount and temperature on the removal of MG. Within the experimental limit, removal efficiency was higher at low temperature for increase amount of Neem leaf adsorbent, during adsorption process of malachite green from its solution.

The combined effect of solute concentration and adsorbent dose on percentage dye removal was represented in Fig. 22. In this case, the dye removal percentage was maximum at higher amount of adsorbent dose and lower value of solute concentration. The interaction effect of solute conc. and pH on dye removal was shown in Fig. 23. Here, the dye removal efficiency was higher at low pH when solute concentration was at high region.

Optimization analysis using the desirability function

In this study, the desired outcomes i.e. the response functions were selected from design. The overall desirability function was achieved from the combination of all the response functions. Experimentally, it was observed that the malachite green dye removal from wastewater in batch adsorption process became 95.493%. If the pH, time, solute concentration, temperature and adsorbent amount were set within the range of 6.868, 36.4 min, 27.899 mg/l, 308.477 K, and 4.3475 g/l respectively, then the maximum desirability i.e. optimum condition was achieved which was illustrated in the desirability ramp (Fig. 24). A desirability value of 0.869 indicated the good agreement with the experimental model and design.

Validation of the model

The numerical optimization of the present study indicate that the optimum values of the different independent variables such as pH: 6.868, time: 36.40 min, temperature: 308.477 K, solute concentration:, 27.899 mg/l, and adsorbent amount: 4.3475 g/l in order to achieve the targeted malachite green removal of 95.493% which is very close to the experimental value of dye removal: 94.3004%. Therefore, the response surface optimization model can be taken as valid.

Conclusion and future prospects

Present study confirmed the potential capability of Indian Neem leaf powder (A. indica) as natural bio-adsorbent to remove MG dye from aqueous synthetic solution or industrial wastes. Results show that the maximum adsorption of MG on activated NLP was 66.72 mg/g and maximum removal of 98% dye may be achieved from 100 mg/l using 3 g/l of activated NLP. The comparison of the maximum adsorption capacity of MG dye by different low cost bio-adsorbents with the NLP used in this study has been shown in Table 10. The adsorbent was characterized by Fourier Transform Infrared Spectroscopy (FTIR), scanning electron microscope (SEM) and energy dispersive X-ray (EDX) techniques. The kinetics of adsorption followed second-order rate expression. The linear plot and the satisfactory values of correlation coefficients (R2) suggested the applicability of both Freundlich’s as well as Langmuir’s model for this adsorption. The negative values of ΔG and enthalpy changes ΔH at 308 K indicate that this adsorption process is spontaneous and favorable. The positive values of ΔS implies that the disorder created in the system due to adsorption. It was found that the process was exothermic in nature and favored at lower temperature. The maximum adsorption of malachite green dye was found at pH: 6.868, time: 36.40 min, temperature: 308.477 K, solute concentration: 27.899 mg/l and adsorbent dose: 4.3475 g/l, the overall desirability function was achieved by estimating the interaction effects of independent variables with response variables. Thus it can be concluded that activated NLP, a low-cost adsorbent has an excellent potential to remove various carcinogenic dyes from industrial wastes also to protect the environment.

Abbreviations

- NLP:

-

Neem leaf powder (adsorbent)

- MG:

-

Malachite green (treatable dye)

- BOD:

-

Biological oxygen demand

- COD:

-

Chemical oxygen demand

- SEM:

-

Scanning electron microscope

- EDX:

-

Energy dispersive X-ray

- FTIR:

-

Fourier transform infrared spectrum

- ANOVA:

-

Analysis of variance

- R 2 :

-

Correlation coefficient

- R :

-

Dye removal efficiency (%)

- C o :

-

Initial concentration of malachite green solution (mg/l)

- C t :

-

Final concentration of malachite green solution (after adsorption) (mg/l)

- Q o :

-

Langmuir constant (mg/g)

- K l :

-

Langmuir constant (l/mg)

- X = Qe :

-

Surface load (mg/g)

- R l :

-

Separation factor

- Q :

-

Amount of adsorbent (g)

- h :

-

Initial sorption rate = k2·Q2 (mg/g min) and k2 (g/g min)

- ΔS :

-

Entropy (J/mol K)

- ΔH :

-

Enthalpy (kJ/mol)

- ΔG :

-

Gibb’s Energy (kJ/mol)

References

Ahmad MA, Afandi NS, Bello OS (2017) Optimization of process variables by response surface methodology for malachite green dye removal using lime peel activated carbon. Appl Water Sci 7:717–727

Akar ST, Ozcan AS, Akar T, Ozcan A, Kaynak Z (2009) Biosorption of a reactive textile dye from aqueous solutions utilizing an agro-waste. Desalination 249:257–261

Arivoli S, Hema M, Martin P, Prasath D (2009) Adsorption of malachite green onto carbon prepared from borassus bark. Arab J Sci Eng Sect A 34(2):31–42

Arivoli S, Hema M, Parthasarathy S, Manju N (2010) Adsorption dynamics of methylene blue by acid activated carbon. J Chem Pharm Res 2:626–641

Asfour HM, Nasser MM, Fadi OA, El-Geundi MS (1985) Colour removal from textile effluent using hard wood and saw dust as adsorbents. J Chem Technol Biotechnol 35A:28–35

Bhattacharyya KG, Sharma A (2003) Adsorption characteristics of the dye, Brilliant Green, on Neem leaf powder. Dyes Pigm 57:211–222

Bulut E, Ozacar M, Sengil IA (2008) Adsorption of malachite green onto bentonite: equilibrium and kinetic studies and process design. Microporous Mesoporous Mater 115:234–246

Chakraborty S, Mukherjee A, Das S, Maddela NR, Iram S, Das P (2020) Study on isotherm, kinetics, and thermodynamics of adsorption of crystal violet dye by calcium oxide modified fly ash. Environ Eng Res. https://doi.org/10.4491/eer.2019.372

Chatterjee S, Kumar A, Basu S, Dutta S (2012) Application of response surface methodology for methylene blue dye removal from aqueous solution using low cost adsorbent. Chem Eng J 181182:289–299

Chen ZH, Fu JW, Wang MH, Wang XZ, Zhang JN, Xu Q (2014a) Adsorption of cationic dye (methylene blue) from aqueous solution using poly(cyclotriphosphazene-co-4,4′-sulfonyldiphenol) nanospheres. Appl Surf Sci 289:495–501

Chen ZH, Zhang JN, Fu JW, Wang MH, Wang XZ, Han RP, Xu Q (2014b) Adsorption of methylene blue onto poly(cyclotriphosphazene-co-4,4′-sulfonyldiphenol) nanotubes: kinetics, isotherm and thermodynamics analysis. J Hazard Mater 273:263–271

Chopra RN, Nayer SL, Chopra IC (1956) Glossary of Indian medicinal plants. C.S.I.R, New Delhi, p 31

Chowdhury S, Mishra R, Saha P, Kushwaha P (2011) Adsorption thermodynamics, kinetics and isosteric heat of adsorption of malachite green onto chemically modified rice husk. Desalination 265:159–168

Cochran WG, Cox GM (1992) Experimental designs, 2nd edn. Wiley, New York

Crini G, Peindy HN, Gimbert F, Robert C (2007) Removal of C.I. Basic Green 4 (Malachite Green) from aqueous solutions by adsorption using cyclodextrin-based adsorbent: kinetic and equilibrium studies. Sep Purif Technol 53:97–110

Das R, Mukherjee A, Das B, Mitra P, Sinha I (2015) Adsorption characteristics of Malachite green and Methylene blue dye on fly ash generated from Kolaghat Thermal Power Plant: a case study. GE Int J Emerg Eng Res 3(11):30–40

Dey S, Jana DK, Khatua PK, Mukherjee A (2019) Application of fuzzy inference techniques in the production of eco-friendly aminoplast based modified resins for plywood panel industries. Int J Fuzzy Comput Model 2(4):303

Ergene A, Ada K, Tan S, Katircioglu H (2009) Removal of Remazol Brilliant Blue R dye from aqueous solutions by adsorption onto immobilized Scenedesmus quadricauda: equilibrium and kinetic modelling studies. Desalination 249:1308–1314

Ferrero F (2007) Dye removal by low cost adsorbents: hazelnut shells in comparison with wood sawdust. J Hazard Mater 142(1–2):144–152

Garg VK, Kumar R, Gupta R (2004) Removal of malachite green dye from aqueous solution by adsorption using agro-industry waste: a case study of Prosopis cineraria. Dyes Pigm 62:1–10

Guo HX, Chen JH, Weng W, Wang QX, Li SX (2014) Facile template-free one-pot fabrication of ZnCo2O4 microspheres with enhanced photocatalytic activities under visible-light illumination. Chem Eng J 239:192–199

Gupta VK (2009) Application of low-cost adsorbents for dye removal: a review. J Environ Manag 90:2313–2342

Halder D, Mondal S, Mukherjee A, Ghosh A (2016) An overview on the treatment of wastewater using renewable energy. Int J Res Eng Technol 5(1):78–83

Hameed BH, El-Khaiary MI (2008) Batch removal of malachite green from aqueous solutions by adsorption on oil palm trunk fibre: equilibrium isotherms and kinetic studies. J Hazard Mater 154:237–244

Ho YS, McKay G (1998) Kinetics models for the sorption of dye from aqueous solution by wood. Trans IChemE 76B:183–191

Jana DK, Roy K, Dey S (2018) Comparative assessment on lead removal using micellar-enhanced ultrafiltration (MEUF) based on type-2 fuzzy logic and response surface methodology. Sep Purif Technol 207:28–41

Karunanithi T, Bhoopathy S, Palaniappan M, Karuppaiya S, Arun PTK (2000) Treatment of textile dyeing industry effluent using different adsorbents. In: Proceedings of Indian chemical engineering congress

Khajeh M, Gharan M (2014) Separation of organic acid compounds from biologica samples by zinc oxide nanoparticles–chitosan using genetic algorithm based on response surface methodology and artificial neural network. J Chemom 28:539–547

Khajeh M, Kaykhaii M, Sharafi A (2013) Application of PSO-artificial neural network and response surface methodology for removal of methylene blue using silver nanoparticles form water samples. J Ind Eng Chem 5:1624–1630

Khajeh M, Sarafraz-Yazdi A, Natavan ZB (2016) Combination of artificial neural network and genetic algorithm method for modeling of methylene blue adsorption onto wood sawdust from water samples. Toxicol Ind Health 32:437–446

Khattri SD, Singh MK (2009) Removal of malachite green from dye wastewater using neem sawdust by adsorption. J Hazard Mater 167:1089–1094

Khuri AI, Cornell JA (1996) Response surfaces design and analysis. Marcel Dekker Inc, New York

Kibami D, Pongener C, Rao KS, Sinha D (2017) Surface characterization and adsorption studies of Bambusa vulgaris: a low cost adsorbent. J Mater Environ Sci 8(7):2494–2505

Kiran I, Ilhan S, Caner N, Iscen CF, Yildiz Z (2009) Biosorption properties of dried Neurospora crassa for the removal of Burazol Blue ED dye. Desalination 249:273–278

Mothgomery DC (1997) Design and analysis of experiment. Wiley, New York

Mukherjee A, Roy K, Jana DK, Hossain SA (2020) Qualitative model optimization of almond (Terminalia catappa) oil using soxhlet extraction in type-2 fuzzy environment. Soft Comput 24(1):41–51

Mullick A, Neogi S (2016) Synthesis of potential biosorbent from used stevia leaves and its application for malachite green removal from aqueous solution: kinetics, isotherm and regeneration studies. R Soc Chem (RSC Adv) 6:65960–65975

Mullick A, Moulik S, Bhattacharjee S (2017) Removal of hexavalent chromium from aqueous solutions by low-cost rice husk-based activated carbon: kinetic and thermodynamic studies. Indian Chem Eng 60(1):58–71

Myers RH, Montgomery DC (1995) Response surface methodology: process and product optimization using designed experiments, 1st edn. Wiley, New York

Myers RH, Mothgomery DC (2002) Response surface methodology: process and product optimization using designed experiments, 2nd edn. Wiley, New York

Nair AT, Makwana AR, Ahammed MM (2014) The use of response surface methodology for modelling and analysis of water and wastewater treatment processes: a review. Water Sci Technol 69:464–478

Neem Foundation (1997). http://www.neemfoundation.org

Nethajia S, Sivasamya A, Thennarasua G, Saravananb S (2010) Adsorption of Malachite Green dye onto activated carbon derived from Borassus aethiopum flower biomass. J Hazard Mater 181:271–280

Parthasarathy S, Manju N, Hema M, Arivoli S (2011) Removal of malachite green from industrial waste-water by activated carbon prepared from cashew nut bark. Int J Chem 2(2):41

Qu S, Huang F, Yu S, Chen G, Kong J (2008) Magnetic removal of dyes from aqueous solution using multi-walled carbon nanotubes filled with Fe2O3 particles. J Hazard Mater 160(2–3):643–647

Raval NP, Shah PU, Shah NK (2017) Malachite green “a cationic dye” and its removal from aqueous solution by adsorption. Appl Water Sci 7:3407–3445

Roy K, Mukherjee A, Maddela NR, Chakraborty S, Shen B, Li M, Du D, Peng Y, Lu F, Cruzatty LCG (2020) Outlook on the bottleneck of carbon nanotube in desalination and membrane-based water treatment—a review. J Environ Chem Eng 8(1):103572

Sahu JN, Acharya J, Meikap BC (2009) Response surface modeling and optimization of chromium(VI) removal from aqueous solution using tamarind wood activated carbon in batch process. J Hazard Mater 172:818–825

Sharma A, Bhattacharyya KG (2005) Azadirachta indica (Neem) leaf powder as a biosorbent for removal of Cd(II) from aqueous medium. J Hazard Mater B125:102–112

Siboni MS, Samarghandi MR, Azizian S, Kim WG, Lee SM (2011) The removal of hexavalent chromium from aqueous solutions using modified holly sawdust: equilibrium and kinetics studies. Environ Eng Res 16(2):55–60

Tamai H, Kakii T, Hirota Y, Kumamoto T, Yasuda H (1996) Synthesis of extremely large mesoporous activated carbon and its unique adsorption for giant molecules. Chem Mater 8:454–462

Weber WJ Jr, Morris JC (1963) Kinetics of adsorption on carbon from solution. J Sanit Eng Div Am Soc Civ Eng 89:31–59

Yang XQ, Zhao XX, Liu CY, Zheng Y, Qian SJ (2009) Decolorization of azo, triphenylmethane and anthraquinone dyes by a newly isolated Trametes sp. SQ01 and its laccase. Process Biochem 44:1185–1189

Yao YJ, Xu FF, Chen M, Xu ZX, Zhu ZW (2010) Adsorption behavior of methylene blue on carbon nanotubes. Biores Technol 101:3040–3046

Zhao MF, Liu P (2008) Adsorption behavior of methylene blue on halloysite nanotubes. Microporous Mesoporous Mater 112:419–424

Acknowledgements

The study on the characterization of Indian Neem leaf powder (Azadirachta indica) was supported by Shraddha Analytical Laboratory, Ghatkopar, Mumbai, India. Authors are also grateful to Dr. Achintya Sinha of Bose Institute, Kolkata, for their kind support and assistance to analyze the adsorbents.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have declared no conflict of interest for the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Das, R., Mukherjee, A., Sinha, I. et al. Synthesis of potential bio-adsorbent from Indian Neem leaves (Azadirachta indica) and its optimization for malachite green dye removal from industrial wastes using response surface methodology: kinetics, isotherms and thermodynamic studies. Appl Water Sci 10, 117 (2020). https://doi.org/10.1007/s13201-020-01184-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-020-01184-5