Abstract

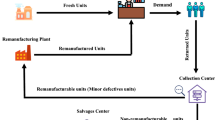

The major challenge faced by all the supply chains currently is to reduce supply chain (SC) costs while maintaining the flow of the items and reducing the pressure on the environment. Production of new items requires a significant amount of raw material and energy, which adds to the pressure on nature. In order to save natural resources, reusing, reworking, remanufacturing, and recycling are good alternatives. The present study is focused on developing a resource-efficient rework and remanufacturing model. For efficient control of inventory, the three layers of SC are considered to have a forward supply chain, closed-loop supply chain, and reverse supply chain. The three layers are linked with a collection centre. The collection centre holds the stock of returned items and bifurcates them into minor and major defectives. The minor defectives are sent to the rework plant, where they are reworked and made as-good-as new. The major defective items are sent to the scrap dealer. Thus, scrap dealer bifurcates them into remanufacturable and salvage items. The remanufacturable items are sent to the secondary manufacturer for the secondary product. Using analytical optimization technique, the minimal cost of the system is achieved with the optimal planning horizon. Lingo and Mathematica software are used to find out the optimal solution of the developed model. Also, sensitivity analysis is performed based on several parameters to see how parameters are robust to the objective function.

Similar content being viewed by others

Availability of data and materials

The authors confirm that the data supporting the findings of this study are available within the article. Derived data supporting the findings of this study are available from the corresponding author [ckjaggi@yahoo.com] on request.

Abbreviations

- SC:

-

Supply chain

- CLSC:

-

Closed-loop supply chain

- FSC:

-

Forward supply chain

- RSC:

-

Reverse supply chain

- GSC:

-

Green supply chain

- EOQ:

-

Economic order quantity

- EPQ:

-

Economic production quantity

- TC1 :

-

Total cost for case I

- TC2 :

-

Total cost for case II

- ETC1 :

-

Expected total cost for case I

- ETC2 :

-

Expected total cost for case II

- ETC1U:

-

Expected total cost for case I (per unit time)

- ETC2U:

-

Expected total cost for case II (per unit time)

- PDF:

-

Probability density function

References:

Abbey JD, Meloy MG, Guide VDR, Atalay S (2014) Remanufactured products in closed-loop supply chains for consumer goods. Prod Oper Manag 24(3):488–503. https://doi.org/10.1111/poms.12238

Abdallah T, Diabat A, Simchi-Levi D (2011) Sustainable supply chain design: a closed-loop formulation and sensitivity analysis. Prod Plan Control 23(2–3):120–133. https://doi.org/10.1080/09537287.2011.591622

Agrawal S, Singh RK, Murtaza Q (2015) A literature review and perspectives in reverse logistics. Resour Conserv Recycl 97:76–92. https://doi.org/10.1016/j.resconrec.2015.02.009

Bazan E, Jaber MY, El Saadany AMA (2015) Carbon emissions and energy effects on manufacturing–remanufacturing inventory models. Comput Ind Eng 88:307–316. https://doi.org/10.1016/j.cie.2015.07.002

Bazan E, Jaber MY, Zanoni S (2016) A review of mathematical inventory models for reverse logistics and the future of its modeling: an environmental perspective. Appl Math Model 40(5–6):4151–4178. https://doi.org/10.1016/j.apm.2015.11.027

Ben-Daya M, Asad R, Nabi KA (2019) A single-vendor multi-buyer production remanufacturing inventory system under a centralized consignment arrangement. Comput Ind Eng 135:10–27. https://doi.org/10.1016/j.cie.2019.05.032

Benkherouf L, Skouri K, Konstantaras I (2014) Optimal lot sizing for a production-recovery system with time-varying demand over a finite planning horizon. IMA J Manag Math 25(4):403–420. https://doi.org/10.1093/imaman/dpt015

Chung S-L, Wee H-M, Yang P-C (2008) Optimal policy for a closed-loop supply chain inventory system with remanufacturing. Math Comput Model 48(5–6):867–881. https://doi.org/10.1016/j.mcm.2007.11.014

Condeixa LD, Silva P, Moah D, Farias B, Leiras A (2022) Evaluating cost impacts on reverse logistics using an economic order quantity (EOQ) model with environmental and social considerations. CEJOR 30(3):921–940. https://doi.org/10.1007/s10100-020-00707-4

Daaboul J, Le Duigou J, Penciuc D, Eynard B (2016) An integrated closed-loop product lifecycle management approach for reverse logistics design. Prod Plan Control 27(13):1062–1077. https://doi.org/10.1080/09537287.2016.1177234

Dai R, Zhang J, Tang W (2017) Cartelization or cost-sharing? Comparison of cooperation modes in a green supply chain. J Clean Prod 156:159–173. https://doi.org/10.1016/j.jclepro.2017.04.011

Dobos I, Richter K (2004) An extended production/recycling model with stationary demand and return rates. Int J Prod Econ 90(3):311–323. https://doi.org/10.1016/j.ijpe.2003.09.007

Dobos I, Richter K (2006) A production/recycling model with quality consideration. Int J Prod Econ 104(2):571–579. https://doi.org/10.1016/j.ijpe.2005.09.006

Download free icons, music, stock photos, vectors. (2019). Icons8.com. https://icons8.com/

Dwicahyani AR, Jauhari WA, Rosyidi CN, Laksono PW (2017) Inventory decisions in a two-echelon system with remanufacturing, carbon emission, and energy effects. Cogent Eng. https://doi.org/10.1080/23311916.2017.1379628

El Saadany AMA, Jaber MY (2010) A production/remanufacturing inventory model with price and quality dependant return rate. Comput Ind Eng 58(3):352–362. https://doi.org/10.1016/j.cie.2009.01.017

Fleischmann M, Bloemhof-Ruwaard JM, Dekker R, van der Laan E, van Nunen JAEE, Van Wassenhove LN (1997) Quantitative models for reverse logistics: a review. Eur J Oper Res 103(1):1–17. https://doi.org/10.1016/s0377-2217(97)00230-0

Gao J, Han H, Hou L, Wang H (2016) Pricing and effort decisions in a closed-loop supply chain under different channel power structures. J Clean Prod 112:2043–2057. https://doi.org/10.1016/j.jclepro.2015.01.066

Gautam P, Maheshwari S, Kausar A, Jaggi CK (2021) Inventory models for imperfect quality items: a two-decade review. Adv Interdiscip Res Eng Bus Manag. https://doi.org/10.1007/978-981-16-0037-1_16

Ghosh D, Shah J (2015) Supply chain analysis under green sensitive consumer demand and cost sharing contract. Int J Prod Econ 164:319–329. https://doi.org/10.1016/j.ijpe.2014.11.005

Giri BC, Sharma S (2015) Optimizing a closed-loop supply chain with manufacturing defects and quality dependent return rate. J Manuf Syst 35:92–111. https://doi.org/10.1016/j.jmsy.2014.11.014

Giri BC, Mondal C, Maiti T (2018) Analysing a closed-loop supply chain with selling price, warranty period and green sensitive consumer demand under revenue sharing contract. J Clean Prod 190:822–837. https://doi.org/10.1016/j.jclepro.2018.04.092

Giutini R, Gaudette K (2003) Remanufacturing: the next great opportunity for boosting US productivity. Bus Horizons 46(6):41–48

Glock CH, Grosse EH (2021) The impact of controllable production rates on the performance of inventory systems: a systematic review of the literature. Eur J Oper Res 288(3):703–720. https://doi.org/10.1016/j.ejor.2020.05.033

Govindan K, Soleimani H, Kannan D (2015) Reverse logistics and closed-loop supply chain: a comprehensive review to explore the future. Eur J Oper Res 240(3):603–626. https://doi.org/10.1016/j.ejor.2014.07.012

Guide VDR, Van Wassenhove LN (2009) OR FORUM—the evolution of closed-loop supply chain research. Oper Res 57(1):10–18. https://doi.org/10.1287/opre.1080.0628

Guide VDR, Harrison TP, Van Wassenhove LN (2003) The challenge of closed-loop supply chains. Interfaces 33(6):3–6. https://doi.org/10.1287/inte.33.6.3.25182

Hasanov P, Jaber MY, Zolfaghari S (2012) Production, remanufacturing and waste disposal models for the cases of pure and partial backordering. Appl Math Model 36(11):5249–5261. https://doi.org/10.1016/j.apm.2011.11.066

Iqbal MW, Kang Y, Jeon HW (2020) Zero waste strategy for green supply chain management with minimization of energy consumption. J Clean Prod 245:118827. https://doi.org/10.1016/j.jclepro.2019.118827

Islam MT, Huda N (2018) Reverse logistics and closed-loop supply chain of waste electrical and electronic equipment (WEEE)/E-waste: a comprehensive literature review. Resour Conserv Recycl 137:48–75. https://doi.org/10.1016/j.resconrec.2018.05.026

Jaber MY, El Saadany AMA (2009) The production, remanufacture and waste disposal model with lost sales. Int J Prod Econ 120(1):115–124. https://doi.org/10.1016/j.ijpe.2008.07.016

Kazemi N, Modak NM, Govindan K (2018) A review of reverse logistics and closed loop supply chain management studies published in IJPR: a bibliometric and content analysis. Int J Prod Res 57(15–16):4937–4960. https://doi.org/10.1080/00207543.2018.1471244

Koh S-G, Hwang H, Sohn K-I, Ko C-S (2002) An optimal ordering and recovery policy for reusable items. Comput Ind Eng 43(1–2):59–73. https://doi.org/10.1016/s0360-8352(02)00062-1

Konstantaras I, Skouri K (2010) Lot sizing for a single product recovery system with variable setup numbers. Eur J Oper Res 203(2):326–335. https://doi.org/10.1016/j.ejor.2009.07.018

Laguir I, Stekelorum R, El Baz J (2020) Going green? Investigating the relationships between proactive environmental strategy, GSCM practices and performances of third-party logistics providers (TPLs). Prod Plan Control 32(13):1049–1062. https://doi.org/10.1080/09537287.2020.1784483

Mabini MC, Pintelon LM, Gelders LF (1992) EOQ type formulations for controlling repairable inventories. Int J Prod Econ 28(1):21–33. https://doi.org/10.1016/0925-5273(92)90110-s

Maiti T, Giri BC (2017) Two-way product recovery in a closed-loop supply chain with variable markup under price and quality dependent demand. Int J Prod Econ 183:259–272. https://doi.org/10.1016/j.ijpe.2016.09.025

Mawandiya BK, Jha JK, Thakkar J (2017) Production-inventory model for two-echelon closed-loop supply chain with finite manufacturing and remanufacturing rates. Int J Syst Sci Oper Logist 4(3):199–218. https://doi.org/10.1080/23302674.2015.1121303

Mishra JL, Hopkinson PG, Tidridge G (2018) Value creation from circular economy-led closed loop supply chains: a case study of fast-moving consumer goods. Prod Plan Control 29(6):509–521. https://doi.org/10.1080/09537287.2018.1449245

Munyaka J-CB, Yadavalli SV (2022) Inventory management concepts and implementations: a systematic review. S Afr J Ind Eng 32(2):15–36. https://doi.org/10.7166/33-2-2527

Nahmiasj S, Rivera H (1979) A deterministic model for a repairable item inventory system with a finite repair rate†. Int J Prod Res 17(3):215–221. https://doi.org/10.1080/00207547908919609

Özceylan E, Paksoy T, Bektaş T (2014) Modeling and optimizing the integrated problem of closed-loop supply chain network design and disassembly line balancing. Transport Res Part E Logist Transport Rev 61:142–164. https://doi.org/10.1016/j.tre.2013.11.001

Peng H, Shen N, Liao H, Xue H, Wang Q (2020) Uncertainty factors, methods, and solutions of closed-loop supply chain—a review for current situation and future prospects. J Clean Prod 254:120032. https://doi.org/10.1016/j.jclepro.2020.120032

Richter K (1996a) The extended EOQ repair and waste disposal model. Int J Prod Econ 45(1–3):443–447. https://doi.org/10.1016/0925-5273(95)00143-3

Richter K (1996b) The EOQ repair and waste disposal model with variable setup numbers. Eur J Oper Res 95(2):313–324. https://doi.org/10.1016/0377-2217(95)00276-6

Richter K (1997) Pure and mixed strategies for the EOQ repair and waste disposal problem. Or Spektrum 19(2):123–129. https://doi.org/10.1007/bf01545511

Richter K, Dobos I (1999) Analysis of the EOQ repair and waste disposal problem with integer setup numbers. Int J Prod Econ 59(1–3):463–467. https://doi.org/10.1016/s0925-5273(98)00110-8

Rogers DS, Tibben-Lembke RS (1998) Going backwards: reverse logistics trends and practices. Reverse Logistics Executive Council, Pittsburgh. https://www.icesi.edu.co/blogs/gestionresiduossolidos/files/2008/11/libro-lr.pdf

Ross SM, Kelly JJ, Sullivan RJ, Perry WJ, Mercer D, Davis RM (1996) Stochastic processes, vol 2. Wiley, New York

Sabbaghnia A, Taleizadeh AA (2021) Quality, buyback and technology licensing considerations in a two-period manufacturing–remanufacturing system: a closed-loop and sustainable supply chain. Int J Syst Sci Oper Logist 8(2):1–18. https://doi.org/10.1080/23302674.2020.1716095

Savaskan RC, Van Wassenhove LN (2006) Reverse channel design: the case of competing retailers. Manag Sci 52(1):1–14. https://doi.org/10.1287/mnsc.1050.0454

Savaskan RC, Bhattacharya S, Van Wassenhove LN (2004) Closed-loop supply chain models with product remanufacturing. Manag Sci 50(2):239–252. https://doi.org/10.1287/mnsc.1030.0186

Schrady DA (1967) A deterministic inventory model for reparable items. Naval Res Logist Quart 14(3):391–398. https://doi.org/10.1002/nav.3800140310

Singh M (2018) The costly journey of returned goods means big business for some. CNBC; CNBC. https://www.cnbc.com/2018/12/13/returned-goods-are-a-problem-for-retailers-resellers-are-cashing-in.html

Taleizadeh AA, Moshtagh MS, Moon I (2018) Pricing, product quality, and collection optimization in a decentralized closed-loop supply chain with different channel structures: game theoretical approach. J Clean Prod 189:406–431. https://doi.org/10.1016/j.jclepro.2018.02.209

Taleizadeh AA, Sane-Zerang E, Choi T-M (2016) The effect of marketing effort on dual-channel closed-loop supply chain systems. IEEE Trans Syst Man Cybern Syst 48(2):265–276. https://doi.org/10.1109/tsmc.2016.2594808

Teng H-M, Hsu P-H, Chiu Y, Wee HM (2011) Optimal ordering decisions with returns and excess inventory. Appl Math Comput 217(22):9009–9018. https://doi.org/10.1016/j.amc.2011.03.107

Teunter RH (2001) Economic ordering quantities for recoverable item inventory systems. Nav Res Logist 48(6):484–495. https://doi.org/10.1002/nav.1030

Teunter R (2004) Lot-sizing for inventory systems with product recovery. Comput Ind Eng 46(3):431–441. https://doi.org/10.1016/j.cie.2004.01.006

Trebilcock B (2002) Return to sender. Warehous Manag 9(4):24–27

Van Engeland J, Beliën J, De Boeck L, De Jaeger S (2020) Literature review: strategic network optimization models in waste reverse supply chains. Omega 91:102012. https://doi.org/10.1016/j.omega.2018.12.001

Acknowledgements

The authors show their sincere appreciation to the editor and anonymous reviewers for their insightful feedback in significantly shaping the manuscript.

Funding

This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the author(s).

Research involving human participants and/or animals

There is no involvement of human participation and/or animals.

Informed consent

All authors have approved the manuscript and agree with its submission to the Journal for publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Maheshwari, S., Kausar, A., Hasan, A. et al. Sustainable inventory model for a three-layer supply chain using optimal waste management. Int J Syst Assur Eng Manag 14 (Suppl 1), 216–235 (2023). https://doi.org/10.1007/s13198-022-01839-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13198-022-01839-3