Abstract

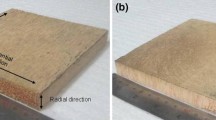

Sandwich panel consisting of oil palm wood core and rubberwood veneer faces were produced. Effects of three different oil palm core density ranges (200–250, 300–350 and 400–450 kg/m3) and two different oil palm core grain orientations (oriented in vertical and horizontal direction of the flat plane) on flatwise properties of the panels under uniform compressive (load displacement curve, maximum stress and Young’s modulus) and localized point loads (load displacement curve and load at limit) were explored. The result revealed that the feature of load displacement curve under compression and indentation test was strongly influenced by oil palm core grain orientation. The maximum stress, Young’s modulus and load at limit values were very dependent on grain orientation and density of oil palm wood core. The panels with core grain oriented in vertical direction of the flat plane and higher core density showed greater maximum stress, Young’s modulus and load at limit than those of core grain oriented in horizontal direction of the flat plane and lower core density. From this result, it was suggested that the panel with oil palm core grain oriented in vertical direction of the flat plane would have a greater performance to be used to carry uniform compressive and localized point loads.

Similar content being viewed by others

References

Abdi B, Azwan S, Abdullah MR, Ayob A, Yahya Y, Xin L (2014) Flatwise compression and flexural behavior of foam core and polymer pin-reinforced foam core composite sandwich panels. Int J Mech Sci 88:138–144

Allen HG (1969) Analysis and design of structural sandwich panels. Pergamon Press, London

ASTM C365-12 (2012) Standard test method for flatwise compressive properties of sandwich cores. ASTM annual book of standards. ASTM International, West Conshohocken

ASTM D143-12 (2012) Standard test methods for small clear specimens of timber. ASTM annual book of standards. ASTM International, West Conshohocken

Bodig J, Jayne BA (1982) Mechanics of wood and wood composites. Van Nostrand Reinhold, New York

Cahyono TD, Novriyanti E, Bahtiar ET, Massijaya MY (2014) Development of composite beams made from tali (Gigantochloa apus) and hitam bamboo (Gigantochloa atroviolacea). J Indian Acad Wood Sci 11(2):156–161

Erwinsyah E (2008) Improvement of oil palm trunk properties using bioresin. Doctoral dissertation, Technische Universität Dresden, Germany

Gibson LJ (2012) The hierarchical structure and mechanics of plant materials. J R Soc Interface 9:2749–2766

Gibson LJ, Ashby MF (1988) Cellular solids: structure and properties. Pergamon press, Oxford

Hou Y, Neville R, Scarpa F, Remillat C, Gu B, Ruzzene M (2014) Graded conventional-auxetic Kirigami sandwich structures: flatwise compression and edgewise loading. Compos B 59:33–42

Kawasaki T, Zhang M, Kawai S (1999) Sandwich panel of veneer-overlaid low-density fiberboard. J Wood Sci 45(4):291–298

Lim SC, Gan KS (2005) Timber technology bulletin (No. 35): characteristics and utilization of oil palm stem. Forest research institute Malaysia, Kepong

Panjehpour M, Abang Ali AA, Voo YL (2013) Structural insulated panels: past, present, and future. J Eng Proj Prod Manag 3(1):2–8

Pokharel N (2003) Behavior and design of sandwich panels subject to local buckling and flexural wrinkling effects. Doctoral dissertation, Queensland University of Technology, Australia

Ruan D, Lu G, Wong YC (2010) Quasi-static indentation tests on aluminium foam sandwich panels. Compos Struct 92:2039–2046

Srivaro S (2014) Lightweight sandwich panel from oil palm wood core and rubberwood veneer faces. Doctoral thesis, Walailak University, Thailand

Wang X, Zhou G (2013) The static compressive behavior of aluminium foam. Rev Adv Mater Sci 33:316–321

Wongprot T, Matan N, Matan N, Preechatiwong W, Kyokong B (2012) Response surface modeling of hydrothermal treatment conditions on color change, strength and durability properties of rubberwood. BioResources 8(1):302–312

Acknowledgments

The authors gratefully acknowledge Walailak University, Thailand for the financial support and AICA Co., Ltd., Songkhla, Thailand for providing MUF adhesives and Phang-Nga Timber Industries Co., Ltd., Phang-Nga province, Thailand for providing the rubberwood veneer used within this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Srivaro, S. Flatwise compressive properties of oil palm core sandwich panel subjected to static compressive load. J Indian Acad Wood Sci 12, 110–115 (2015). https://doi.org/10.1007/s13196-015-0152-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13196-015-0152-4