Abstract

This study revisits the impacts of the presence of OH− and Cl− anions and/or different forms of Pt precursors during polyol synthesis of carbon-supported electrocatalysts. Efficiency of the synthesis process in terms of the %conversion of a Pt complex to Pt metal has been quantified. It is observed that Pt precursors based on [PtCl6]2− are reduced easily compared to those based on [Pt(OH)6]2−. Furthermore, presence of excess Cl− during synthesis results in decreased %conversion and reduced ECSA, which is opposite from other reported work synthesized at higher temperature and pure solvents. For Pt/C synthesis under mild conditions, 100 °C and 30 vol% EG in water as solvent, presence of OH− during synthesis decreases the ECSA and hence increases the Pt nanoparticle size and change of catalyst surface structure. Finally, a method to get insights into the surface structure of Pt-nanoparticles through analysis of the H-adsorption/H-desorption peaks has been proposed.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Proton exchange membrane (PEM) fuel cells (PEMFCs) and PEM electrolyzers are important technologies towards reduction of the global carbon emissions [1,2,3,4]. Despite PEMFCs are currently being produced commercially, further technological development is needed for their widespread applications. Currently, only Pt-based electrocatalysts, e.g., Pt-nanoparticles (Pt-NPs) supported on carbon (Pt/C), have shown sufficient activity and stability for the cathode reaction, i.e., the oxygen reduction reaction (ORR). However, scarcity and high cost of Pt remain open challenges for the commercial viability of PEMFCs. Increasing the activity of Pt is therefore one of the most important aspects as it either increases the energy conversion efficiency or lowers the Pt loading ultimately lowering the total cost of the fuel cell [5,6,7]. The activity of Pt-based catalysts towards ORR generally depends on the surface area of Pt exposed to oxygen and the surface structure of Pt. Therefore, maximizing the specific surface area of Pt is an obvious strategy to enhance the mass specific catalytic activity [8]. Reducing the particle size increases the volume to surface ratio; however, variations in the relative number of step atoms or (111) and (100) facets at the surface is a function of the particle size resulting in an optimal particle size of 2–3 nm [8, 9].

The availability of catalyst surface is regarded to be one of the governing factors of the ORR activity [10]. Adsorption of nonreactive anionic species on the surface has been reported to decrease the ORR activity by hindering the availability of the metallic surface to reactants due to occupation of active sites [11]. Anionic species such as oxygenated species [10, 11], (bi)sulfate [12], phosphate [13], and Cl− [14,15,16] have been reported to efficiently block the active sites. Since Pt/C catalysts are often synthesized from Cl− containing precursors, small amounts of Cl− might remain adsorbed on the catalyst surface. Contamination of Cl− may also arise from the feed water stream to the PEMFCs or from the airborne salts. For these reasons, the effect of the presence of Cl− on the electrochemical activity of Pt/C has been investigated thoroughly [15, 17,18,19,20,21].

Several studies have now also reported the effect of Cl− on the particle size of Pt-NPs. Liu et al. have synthesized Pt-NPs through charge enhanced dry impregnation method by using different precursors with or without Cl− and carbon support. Compared to the Pt/C synthesized using a precursor free of Cl−, the authors noticed a larger average particle size and broader size distribution for the Pt/C sample synthesized using a precursor containing Cl− [22]. A similar observation of larger particle size in the presence of NaCl has been observed in our previous work [23].

On the other hand, several possibilities to control the size and agglomeration of Pt-NPs have been demonstrated. They include varying synthesis parameters such as the strength and/or concentration of reducing agent, Pt-precursor concentration, and presence of surfactants. The use of surfactants has been frequently used successfully to prevent agglomeration and to control the particle size [24,25,26]. However, the surfactant must be removed afterwards to avoid activity losses, which requires an additional step in the synthesis. Hence, other parameters such as pH, presence of water, and Pt-precursor concentration might be used during surfactant-free synthesis of metal nanoparticles using polyol method [27]. Among these, providing alkaline pH through presence of NaOH has been frequently reported as a mean of controlling the particle size [28,29,30]. In relation to this, Quinson et al. have found that the size control of Pt-NPs could be obtained by varying the NaOH/Pt molar ratio [30], where a larger NaOH/Pt molar ratio leads to lower particle size. Furthermore, it is observed that the OH− to Pt ratio not only controls the particle growth but also stabilizes the nanoparticles in the suspension [31].

Control on the particle size and surface crystallography of nanoparticles could be achieved through controlling their nucleation and growth. For example, presence of strong adsorbates could impede growth of certain crystalline facets leading to preferential growth of the others. Again, adsorption of species on the support carbon may affect the available sites for nucleation and hence may lead to altered particle size and surface structure. Surface crystallography and particle size controlled growth of Pt-NPs through electrodeposition of Pt in presence of adsorbates such as Cl− and SO42− have been demonstrated previously [32]. However, the effect and role of Cl− anions during wet chemical synthesis has not been investigated thoroughly as more focus has been drawn to their effect on the electrochemical performance of Pt/C.

Furthermore, reducibility of the Pt precursors, defined in terms of easiness of the conversion of the Pt-precursor species to the Pt metal during synthesis, may also be affected significantly by presence of such adsorbates on the support carbon or on the Pt-NPs. Hence, reducibility could be an important parameter governing the size and surface crystallography of the synthesized Pt-NPs. However, studies focused on size/structure-controlled synthesis of Pt-NPs, the important factor has not been investigated explicitly. Further, the effect of the presence of anionic species such as Cl− and OH− during synthesis of Pt/C on the reducibility of the Pt precursor has not been explored.

Here, an attempt has been made to investigate the effects of the Pt-precursor reducibility on the growth of Pt-NPs on commercially available high surface area support carbons. A microwave assisted polyol synthesis has been used to synthesize Pt/C electrocatalysts using three different Pt-precursors and different Cl− and/or OH− concentrations. The study investigates the reducibility of Pt-precursors and its effect on particle size and activity of the synthesized Pt/C electrocatalysts. Next, the individual effects of Cl− and OH− have been investigated systematically. Based on the reports regarding the use of NaOH and the effects of Cl− on particle size, this study investigates whether the presence of NaOH can be used to control the size of Pt-NPs synthesized in presence of Cl−.

Materials and Methods

Materials

High surface area carbon (Ketjenblack-EC300-J) was used as the catalyst support material, while four different Pt precursors, namely chloroplatinic acid (H2PtCl6;TCI EROPE, PT: 37.3 wt%), ammonium hexachloroplatinate ((NH4)2PtCl6; Alfa Aesar, Pt: 43.4 wt%), hydrogen hexahydroxyplatinate ((H2Pt(OH)6; Sigma-Aldrich, Pt: 65.2 wt%) and sodium hexahydroxyplatinate (Na2Pt(OH)6; Sigma-Aldrich, Pt: 56.9 wt%) were used to synthesize the Pt/C catalysts. A previously optimized ratio of a mixture of ethylene glycol (HOCH2CH2OH; EMSURE® grade, assay > 99.5%, Merck, Germany) and ultrapure water (Milli-Q; resistivity ≥ 18.2 MΩ·cm at 25 °C) was used as the reducing agent and solvent during the Pt/C synthesis. External sources of anions, specifically OH− and Cl−, were added from solutions of appropriate concentrations of sodium hydroxide (NaOH; Sigma-Aldrich, 5 M) and sodium Cl− (NaCl; VWR), respectively.

Pt/C Synthesis

The Pt/C electrocatalysts using (NH4)2PtCl6, H2Pt(OH)6 or Na2Pt(OH)6 as the Pt precursor and KB-EC300-J carbon as the support were synthesized through a microwave (MW)-assisted polyol route as described in our earlier work [27, 33]. The conditions used have been optimized previously. For a typical synthesis of 60 wt% Pt/C catalyst, the appropriate amount of Pt-precursor (Pt conc. 5.mM) was dissolved in ~31 mL of ethylene glycol/ultrapure water mixture (3:7 v/v; unless otherwise stated) and ultrasonicated for 60 s using a Hielscher UP200St ultrasonic homogenizer. When adding NaOH or NaCl, aqueous solutions of appropriate concentrations were prepared and added instead of the water. After ultrasonication, the mixture was analyzed by X-ray fluorescence (XRF) spectroscopy (Thermo Scientific Niton XL3t GOLDD+) for the initial Pt concentration (\({\mathrm{C}}_{\mathrm{i}}\)) determination. Hereafter, 20 mg of KB-EC300-J was added to the mixture and ultrasonicated again for 60 s followed by a MW-treatment using the CEM Discovery SP® microwave synthesizer either in open system or closed system. In the former case, a condenser was installed, and the microwave power was set at constant power mode of 100 W. A temperature ramp of 100 s was added to the total time allowing the mixture to reach the desired temperature and start refluxing. Unless otherwise stated, the holding time was set at 400 s under constant magnetic stirring after the desired temperature was obtained. In the latter case, the MW-synthesizer was operated in a closed system with a dynamic power of 200 W to achieve higher temperature of 140 °C, unless otherwise stated with a holding time of 150 s. After completion of the reaction, an air jet was used to cool the vessel and the samples were centrifuged, washed three times with 5 mL of ultrapure water each time and dried at 80 °C in air. The supernatant was analyzed with XRF to obtain the residual (unreduced) Pt concentration (\({\mathrm{C}}_{\mathrm{f}}\)). Degree of completion of the reduction was determined in terms of %conversion, defined as \(\mathrm{\%conversion}={(\mathrm{C}}_{\mathrm{i}}-{\mathrm{C}}_{\mathrm{f}}/{\mathrm{C}}_{\mathrm{i}})\times 100\)). Here, we define the %conversion as the fraction of Pt deposited on the carbon support and hence removed from the synthesis bath. The Pt that remains in the dissolution bath either in form of untreated Pt species (complex, ions) or in form of colloidal Pt-nanoparticles, is considered to be not converted as the desired product (Pt/C) and hence does not contribute in the %conversion. Figure 1 depicts the polyol synthesis process. Here, as the carbon support is present in the reaction bath while the nucleation and growth of Pt NPs takes place, a heterogeneous nucleation is more probable. Presence of additives (NaCl, NaOH) may affect both the Pt NPs formation and their deposition of the carbon support. However, here, we have not studied these effects separately.

Electrochemical Characterizations

The electrochemical performance of a typical Pt/C electrocatalyst was assessed based on their electrochemical surface area (ECSA), which was obtained through cyclic voltammetry (CV). The electrochemical measurements were performed, with a similar setup as reported earlier, using a Zahner®IM6e electrochemical workstation using a standard three-electrode setup consisting of a double junction Ag/AgCl (Aldrich; sat. KCl and sat. K2SO4 in the inner and outer junctions, respectively) reference electrode (RE), a graphite rod (Φ = 5 mm) counter electrode (CE) and a Pt/C catalyst coated glassy carbon (GC; Φ = 5 mm; Pine instruments) working electrode (WE). The potentials measured against the Ag/AgCl RE have been reported with respect to the reversible hydrogen electrode (RHE). A typical catalyst ink was prepared by mixing 10 mg of the dried catalyst in 5 mL of a stock solution consisting of isopropanol, 5 wt% Nafion solution (Dupont D521 form Ion Power) and ultrapure water in a volumetric ratio of 20:0.4:79.6 for 60 s. The typical WE was prepared by drop casting 10 µL of the catalyst ink on the glassy carbon (GC) rotating disc electrode (RDE) tip (polished with 0.05 µm alumina/water slurry) and spin-drying at 700 RPM. The catalyst loading on the WE was determined through X-ray fluorescence (XRF) analyzer as described elsewhere [34].

Before recording the CV for the ECSA calculation (observational CV), the WE was activated by potential cycling for 20 cycles between 0.02 and 1.2 V at a scan rate of 100 mV/s in nitrogen saturated 1 M H2SO4. The observational CV was recorded for 2 cycles between 0.02 and 1.2 V at a scan rate of 10 mV/s, where only the second scan was used to evaluate the ECSA. The area under the hydrogen adsorption peak between ~0.4 and ~0.02 V during the cathodic scan was used to estimate the ECSA, where the surface charge density of 210 µC/cm2 for H adsorption on polycrystalline Pt was used [35]. Accelerated stress test (AST) was performed by subjecting the Pt/C modified GC electrode with a total of 1600 stress cycles between 0.4 and 1.6 V at a scan rate of 1 V/s in 1 M sulfuric acid electrolyte. Observational CVs were recorded intermittently after specified numbers of stress cycles.

Structural Characterizations

The structural characterizations of the Pt/C electrocatalysts were performed to explore their physicochemical states. X-ray diffraction (XRD) patterns of the Pt/C catalysts were collected using a Rigaku Miniflex 600 X-ray diffractometer equipped with Cu K α (λ = 1.5418 Å) radiation. XRD data were collected for the diffraction angle \((2\uptheta )\) values between 10° and 90° at a scan rate of 3°/min and a step size of 0.02°. Scherrer’s formula (\(L=0.9\uplambda /\mathrm{\beta Cos\theta }\), with \(\upbeta\) being the width of the diffraction peak) was employed to determine the average crystallite size (L) of the Pt-NPs using the Pt (111) diffraction peak. FWHM of the peak was determined by fitting the corresponding XRD data with Lorentzian distributions.

Results and Discussion

Reducibility of the Pt-Precursors

Different Pt-precursors, depending on the ligands present, may have different stabilities against reduction during the polyol synthesis. The nature of the ligand environment have been shown to alter the stability and redox oxidation potential of the complex [36]. The effect of anions released from reducing the precursor have been indicated in the studies by Neumann et al. [37] and Schröder et al. [38]. Here, common Pt-precursors, namely H2PtCl6, (NH4)2PtCl6, H2Pt(OH)6, and Na2Pt(OH)6, were used to investigate the effect of ligand environment on their reducibility during polyol synthesis of Pt/C. The polyol synthesis conditions used here have been optimized in our earlier works [27, 33]. The reducibility has been measured in terms of %conversion of the Pt-precursor to Pt0 through Pt concentration measurements in the reaction bath before and after the polyol synthesis. The reducibility, combined with the measurements of ECSA, provides a fast-screening tool of feasible synthesis conditions/Pt-precursors. Table 1 gives an overview of the samples synthesized to investigate the reducibility of the Pt-precursor and its effect on the synthesized Pt/C samples, subdivided five groups based on common synthesis parameters.

Group G1 consists of the Pt/C samples synthesized at a reaction temperature of 100 °C using the three Pt-precursors with no additional OH− anions, while in case of group G2, synthesis has been performed in presence of 0.7 M NaOH. The molar concertation of NaOH was selected to provide a very high OH−/Pt molar ratio (~140) as higher OH−/Pt molar ratio has been reported to produce smaller Pt-NPs [39]. Further, group G3 belongs to the Pt/C samples synthesized at 140 °C in presence of 0.7 M NaOH. Groups G4 and G5 correspond to Pt/C samples synthesized using (NH4)2PtCl6 as the (NH4)2PtCl6 Pt-precursor to study the effect of different parameters such as (i) MW synthesis conditions in G4 and (ii) NaOH concentration in G5.

Effect of Ligands

The results for %conversion and ECSA values shown in Table 1 indicate that the reduction of the Cl-based precursor as compared to the OH-based is relatively easier. Within the OH-based precursors, H2Pt(OH)6 can be reduced more easily than Na2Pt(OH)6. In fact, for a reaction temperature of ~100 °C, the Na2Pt(OH)6 precursor could not be reduced at all. This suggests that not only the precursor complex ligand influences the reduction of the metal salt but also the cation, since H2Pt(OH)6 and Na2Pt(OH)6 have identical Pt-complex ([Pt(OH)6]2−) but different cations, i.e., H+ and Na+, respectively. Hence, the lower %conversion for Na2Pt(OH)6 as compared to that for H2Pt(OH)6 may be mainly attributed to the presence of Na+ and hence a different pH of the synthesis baths. The pH values for the synthesis baths containing the Pt-precursors Na2Pt(OH)6 and H2Pt(OH)6 are measured to be ~9 and ~6, respectively. The pH values in this case were found unaffected by the MW treatment. On the other hand, in our earlier studies [27, 33], it was observed that the Pt-precursors H2PtCl6 and (NH4)2PtCl6 show similar %conversion for reduction under similar conditions being studied here, suggesting no significantly different effect of [NH4]+ cation as compared to that of H+. This may also be attributed to the fact that the synthesis baths containing the H2PtCl6 and (NH4)2PtCl6 Pt precursors have respective pH values of ~1 and ~4 before the MW treatment. Again, after the MW treatment, both the samples (supernatant) have the pH values ~1. Hence, an acidic pH of the Pt precursors with the [NH4]+ or H+ cations provides superior %conversion values compared to those for the Pt precursors having Na+ cation and higher pH values (neutral or basic). The enhanced stability of the Pt complex in the latter case may be attributed to the interruption of the Pt-complex reduction reaction, which involves formation of Pt-complex/Alcoxy intermediates [40, 41], by the presence of Na+. Adsorption of Na+ on the Pt-NPs may reduce their affinity with the support carbon and hence may lead to apparently lower %conversion.

Apart from %conversion, size of the Pt-NPs, which plays major role determining their electrocatalytic activity in terms of ECSA [8, 9], is affected significantly by the Pt/C synthesis parameters. As depicted in Fig. 2a, the ECSA value of the Pt/C-OH01 is much lower compared to that of the Pt/C-Am01 sample, despite their similar %conversion. Inset of Fig. 2a shows the initial cyclic voltammograms (CVs) of the two Pt/C samples, showing the characteristic redox peaks corresponding to (i) the H-adsorption for potential lower than 0.4 V during negative-going CV, (ii) the H-desorption for potential lower than 0.4 V during positive-going CV, (iii) the Pt-oxide formation (potential > 0.9 V; positive-going scan), and (iv) the Pt-oxide reduction (0.5 V < potential < 1.0 V, negative-going scan) reactions [27, 33]. ECSA and CV of the Pt/C-Na01 sample are not available due to no conversion of Pt-precursor to Pt metal NPs. Both the CVs shown here exhibit similar characteristics apart from the lower intensities of the redox peaks in case of Pt/C-OH01, suggesting the Pt-NPs to be of similar crystallinity. Hence, the smaller ECSA value of the Pt/C-OH01 sample corresponds to the larger size of the Pt-NPs as compared to that for the Pt/C-Am01, and the size difference may be attributed to the different structure of the Pt-precursors, leading to lower number of the stable nuclei of Pt-NPs and hence larger particles in case of [Pt(OH)6]2−) complex.

Effect of Presence of NaOH

The addition of NaOH has frequently been reported and used to control the size of Pt-NPs [28, 30, 31, 39]. However, effect of presence of NaOH (or OH− in general) on the reducibility of the Pt-precursor has not been explored to the best of our knowledge. Here, it was hypothesized that in addition to providing smaller Pt-NPs, presence of NaOH also influence the reduction of the Pt-precursors. However, under similar synthesis conditions, the addition of NaOH (0.7 M) to the synthesis bath decreased the %conversion remarkably (G2) as compared to that without NaOH (G1). In the case of Pt/C-OH02 and Pt/C-Na02, the conversion of the Pt-complexes to metal is virtually zero, whereas that in case of Pt/C-Am02 is reduced to ~7% as compared to that of ~100% without NaOH. Hence, the NaOH stabilizes the Pt complexes in the suspension thereby impeding the reduction. Again, apart from lower %conversion, Pt/C sample synthesized from (NH4)2PtCl6 in presence of NaOH shows significantly lower ECSA compared to that synthesized without NaOH (Fig. 2b). As the corresponding CVs for Pt/C-Am01 and Pt/C-Am02 shown respectively as insets in Fig. 2a, b exhibit similar characteristics, the lower ECSA of the latter may be attributed to the larger Pt-NPs. However, although the calculated ECSA for the Pt/C-OH02 sample is comparable to that of the Pt/C-OH01 sample, it may not be considered reliable due to very low loading of Pt on GC (%conversion: ~7%) leading to measurement uncertainties. This is also reflected from the CV corresponding to Pt/C-OH02 (inset, Fig. 2b), which does not show characteristic redox peaks corresponding to Pt. Therefore, the calculated value of ECSA for the Pt/C-OH02 sample may be used only for a qualitative discussion and to show a contrast among the samples synthesized using different conditions. Overall, under the synthesis conditions studied here, presence of excess OH− decreases %conversion and also leads to decreased number of stable nuclei and hence the size of the Pt-NPs increases, leading to lower ECSA.

Moreover, the CV plots of Fig. 2b (inset) exhibit significantly different double layer capacitance (DLC), in terms of the difference between the anodic and cathodic currents in the non-faradaic region (~0.4 V). The variation of the currents associated to DLC may be attributed to (i) the different amounts of the support carbon on the GC RDE tip and (ii) the presence of different adsorbed species/functional groups on the carbon surface, depending on the composition of the synthesis bath [42]. The former contribution stems from the fact that different %conversion values during synthesis lead to difference in Pt loading of the synthesized samples and hence, when a fixed amount of the catalyst is loaded on the GC RDE, amount of support carbon is higher for the samples showing lower %conversion.

To increase the %conversion, the reduction in presence of NaOH was therefore investigated further at a higher temperature of 140 °C (G3). The higher temperature might also affect the size of the Pt-NPs through increased rate of the Pt-complex reduction as well as the lower probability of the stable nuclei formation. At this temperature, the %conversion generally increased for all of the samples (compared to G2) with the descending order of %conversion and hence ascending order of reducibility being Pt/C-OH03 > Pt/C-Na03 > Pt/C-Am03. Hence, the chemical environment affects the reducibility order. Similar to that observed with the catalysts Pt/C-OH01 and Pt/C-Na01, with an identical Pt-complex, lower reducibility for the Pt/C-Na03 compared to that for the Pt/C-OH03 is attributed to the presence of Na+ in the former case. Similarly, presence of OH− anions decreased the reducibility of (NH4)2PtCl6 significantly, leading to only ~81% conversion at 140 °C in presence of 0.7 M NaOH compared to ~ 100% conversion observed at a lower temperature (100 °C) in absence of NaOH. Again, despite higher %conversion, all the Pt/C samples of G3 show low ECSA values of < 20 m2/g, calculated from the CVs shown in Fig. S1 (Supporting Information). The low ECSA values are attributed to the large particle size values of corresponding Pt-NPs. Hence, increasing the reaction temperature decreased the number of stable nuclei further.

Further experiments have been conducted to attain high %conversion in presence of NaOH. As shown in Table 1 (G4), the sample Pt/C-Am03-300s is synthesized using a longer holding time of 300 s instead of the usual 150 s for the comparable samples. When compared to the comparable sample Pt/C-Am03, increasing the reaction time from 150 to 300 s improves the %conversion negligibly from ~81 to ~86%, i.e., only 5% increment by increasing the reaction time. This insignificant improvement in %conversion suggests high stability of the unreduced Pt-species. Further, increasing the temperature to 150 °C (sample: Pt/C-Am03-150) improves the %conversion from ~81% for 140 °C to ~92%. Holding at 150 °C for 300 s (sample: Pt/C-Am03-150-300s) leads to a marginally higher %conversion of ~94%. Overall, presence of NaOH decreases the reducibility of the Pt-precursor significantly.

In addition, the synthesis conditions leading to increased %conversion generally provide low ECSA values as shown in Table 1. For example, increasing the holding time at 140 °C to 300 s as compared to 150 s increased the %conversion slightly but did however not provide significantly better ECSA. Elevating the temperature to 150 °C also did not result in significant changes of the ECSA. Increasing both the temperature and holding time simultaneously increased the conversion but resulted in lower ECSA than the former. Owing to the fact that the CVs corresponding to the Pt/C samples from G4 show the characteristic redox peaks (Fig. S2, Supporting Information), which suggest formation of the electrochemically active Pt-NPs, the low ECSA may be assigned to larger size of Pt-NPs. Thus, at 0.7 M of NaOH, the reduction of Pt precursor and the synthesis of small Pt-NPs are not feasible using either of the three Pt precursors.

Here, a concentration of 0.7 M of NaOH in the synthesis bath may have been too excessive (OH−/Pt molar ratio:140) compared to what has been reported in the literature [39]. Therefore, further experiments were conducted with lower NaOH concentrations using only (NH4)2PtCl6 as the Pt precursor, as presented in Table 1 (G5) as the NaOH concentrations as small as 50 mM show reduced %conversion; however, with a lower effect as compared to that for 0.7 M NaOH. The ECSA values of Pt/C-Am05, Pt/C-Am06, and Pt/C-Am07, calculated using the CVs shown in Fig. S3 (Supporting Information) show a linearly declining tendency with the increasing NaOH concentration as shown in Fig. 3. At the same time, one can also observe that the %conversion decreases in the same sequence. The NaOH concentration of 50 mM and 100 mM corresponds to a OH−/Pt molar ratio of 10 and 20, respectively, similar to the ones reported by Quinson et al. [30]. However, the same results are not observed here possibly due to differences in the synthesis conditions such as: synthesis volume, reaction times, one-pot, or multiple step synthesis. Hence, the NaOH/Pt molar ratio does not seem to be a size-control measure that can be directly transferred to other synthesis systems and conditions.

Effect of Presence of NaCl on Pt/C Synthesis

The effect of Cl− on the performance of Pt/C electrocatalysts during electrochemical testing have been investigated throughout the years. The presence of Cl−, even in trace amounts, has been found to decrease the durability of the catalysts by enhancing the dissolution of Pt during electrochemical characterization [20, 43, 44]. The use of Cl−-based precursors is numerous and almost exclusively used to synthesize Pt-NPs. At the same time, the effect of Cl− as a parameter during synthesis is poorly understood, which have resulted in equivocal conclusions. On one side, halides are generally regarded as good stabilizing and size-controlling agents and are commonly used. Use of Cl− has also been reported to redisperse sintered Pt-NPs and to control the particle size [22, 45]. On the other hand, Cl− have also been found to exert a leaching ability resulting in larger particles at prolonged reaction times [37]. Therefore, the effect of presence of Cl− on the synthesis of Pt-NPs is outlined and clarified in this section. Several samples with varying concentrations of NaCl in the reaction bath (ethylene glycol/water mixture; 3:7 v/v) were synthesized through microwave-assisted polyol route using (NH4)2PtCl6 as the Pt-precursor and a reduction temperature of 140 °C. The concentration of NaCl was varied between 0 and 500 mM to synthesize the sequence of samples Pt/C-0 mM, Pt/C-5 mM, Pt/C-10 mM, Pt/C-50 mM, Pt/C-100 mM, and Pt/C-500 mM with the respective NaCl concentration in the reaction bath being 0, 5, 10, 50, 100, and 500 mM. Further, Fig. 4a shows the evolution of ECSA as a function of increasing NaCl concentration, calculated from the corresponding CV plots shown in Fig. 4b.

For all the synthesized samples, the %conversion was observed to be ~100%, regardless of the NaCl concentration. Hence, presence of NaCl did not impede the reduction of Pt-precursor to Pt metal. However, inspection of the CVs shown in Fig. 4b reveals a general decrease in the characteristic redox (H-adsorption and/or H-desorption) peak intensities associated to the Pt-NPs is observed with the increasing concentration of Cl− during synthesis. The observed decrease in the peak tensities of the H-adsorption and/or H-desorption peaks between 0.05 and 0.40 V with increasing NaCl concentration is caused by increased size of the Pt-NPs, and hence the decreased Pt surface area available for the related electrochemical reactions. The presence of residual Cl− anions from improper washing of the sample cannot be ruled out completely; however, there is only a small likelihood that any weak surface adsorbed Cl− anions would remain after washing. The presence of Cl− during cyclic voltammetry was investigated by Lam et al., which was shown to result in competitive adsorption between hydrogen and residual Cl− anions [18]. However, they observed distinct changes in the characteristic peaks of the CV, which is not observed in this study. While obvious changes in the CV plots shown in Fig. 4b occur with the increase of Cl−, these changes are general for all the characteristic peaks suggesting the loss of Pt surface area by enlargement of Pt-NPs and not because of Cl− adsorption. The reduction in ECSA is most prominent for Pt/C-50 mM followed by Pt/C-500 mM. Considering both the CVs and ECSA values, one can observe that the samples Pt/C-0 mM, Pt/C-5 mM and Pt/C-10 mM are relatively similar, apart from the larger double layer capacity of Pt/C-0 mM. This suggests that at this level of NaCl, the Cl− does not influence the synthesis hence similar ECSA is observed. However, by increasing the NaCl concentration to 50 mM, its effect of ECSA becomes visible. At this level, the ECSA drops from ~66 to ~42 m2 g−1, possibly due to growth of Pt-NPs. Increasing the NaCl concentration to 100 mM did, however, not result in a proportional decrease in ECSA, which might be a non-reproducible result. However, due to large number of samples synthesized with small changes in the experimental parameters, reproducibility studies have not been performed in this study. While increasing the NaCl concentration to 500 mM did significantly decrease the ECSA, thereby exhibiting a clear correlation between the NaCl concentration and the ECSA. Finally, the variation of current associated with DLC may be attributed to the factors such as the %conversion variation and the presence of adsorbed species on the support carbon, as discussed earlier.

Further, the presence of Cl− is a concern to Pt-NPs preparation for fuels cells due to a poisoning effect, where the activity is decreased, and the Pt dissolution is enhanced [20, 43, 46, 47]. Meanwhile, Pt catalysts are typically prepared using Cl−-based Pt salts, which therefore require complete reduction of the precursor and washing procedures to ensure no Cl− is adsorbed on the surface of the catalyst. In this relation, NaOH have been reported as an efficient removal agent for removing surfactants including Cl− [16, 48]. Moreover, the effect of NaOH could be further investigated for its reported size controlling properties, in this case by exploring the effect of NaOH in the presence of NaCl where it might suppress or offset the increased particle size in presence of NaCl as outlined in the previous section. However, synthesis of Pt/C in presence of both NaCl and NaOH does not show unambiguous effect on the particle size and especially, does not produce Pt-NPs of a size smaller or comparable to the Pt/C synthesized without NaCl and NaOH (supporting information). Here, unlike that reported in literature, we did not observe the particle size controlling effect of the presence of NaOH. Hence, under the studied synthesis conditions, it is not expected that particle size increase due to the presence of NaCl can be controlled by addition of NaOH.

Discussion

Insights into Surface Structure of Pt-NPs Through the CV Plots

The characteristic CV plot of Pt NPs for to potentials < 0.4 V corresponds to H-adsorption (negative-going scan) and H-desorption (positive-going scan). Each of the H-adsorption and H-desorption regions consists of two sharp peaks at the potential values of ~0.12 V (shown as H1 in Fig. 5) and ~0.26 V (shown as H2 in Fig. 5). The peak H1 at ~0.12 V corresponds to the {110} type sites of the Pt crystal, while the peak at H2 ~0.26 V corresponds to (i) the {100} step sites on {111} terraces and (ii) the sites close to the steps on the (100) terraces [49]. Therefore, the relative intensities of the peaks may provide useful insights into the surface structure of the Pt NPs. Here, relative intensities of the peaks H1 and H2 of selected Pt/C samples have been studied in terms of the peak area ratio-\({A}_{H1}/{A}_{H2}\), where \({A}_{H1}\) and \({A}_{H2}\) are the respective areas under the peaks H1 and H2, as demonstrated in Fig. 5. Table 2 summarizes the peak area ratios for different samples studied. As the ORR activity of different crystallographic surface of Pt decreases in the order (110) > (111) > (100) [50], a higher \({A}_{H1}/{A}_{H2}\) ratio is preferred for superior ORR activity. However, as the peaks H1 and H2 are not associated exclusively with the specific sites due to the fact that hydrogen adsorption on a specific Pt surface (e.g., (111) and (110)) extends to a wide range of potentials, the assignment of H1 and H2 peaks to the specific Pt surfaces may be considered as an indicator for qualitative understanding.

The studied samples exhibit significant variation in the area ratios \({A}_{H1}/{A}_{H2}\). For example, the Pt/C-Am01 sample synthesized using (NH4)2PtCl6, shows higher \({A}_{H1}/{A}_{H2}\) ratio compared to that of the Pt/C-OH01, which was synthesized under identical conditions except the Pt-precursor being H2Pt(OH)6. Hence, the presence of the Pt-complex [Pt(OH)6]2− forms the Pt-NPs having a surface structure with relatively higher fraction of {100} f step sites on {111} terraces, while the ligand [PtCl6]2− leads to a surface enriched with {110}-sites, a preferred structure for superior ORR activity. Similarly, a higher synthesis temperature of 140 °C leads to a surface rich in the {100} step sites on {111} terraces (samples: Pt/C-Am03, Pt/C-OH03, Pt/C-Na03), with a less effect of the Pt precursor type. Further, with increasing the NaOH concentration, the \({A}_{H1}/{A}_{H2}\) ratio decreases, suggesting formation of a surface rich in the {100} step sites on {111} terraces. Hence, presence of different ligands and/or anions (e.g. OH−) and synthesis conditions significantly affect the surface structure of the Pt NPs, which, in turn, affects their electrocatalytic activity. Formation of a specific surface structure in presence a particular ion may be attributed to its preferred adsorption on certain crystallographic phases, leading to inhibition of their growth.

Based on the analysis here, a moderate temperature (~100 °C), absence of NaOH and a Pt precursor consisting of [PtCl6]2− complex lead to higher \({A}_{H1}/{A}_{H2}\) ratio of the synthesized Pt/C catalysts. Frequently reported use of ethylene glycol/NaOH mixture and high reaction temperatures (150 °C –180 °C) during polyol synthesis may not necessarily generate Pt-NPs of superior ORR performance. Instead, an ethylene glycol/water mixture without NaOH may be used to synthesize high ORR active Pt/C catalysts at moderate temperatures.

Structure-Property Correlations

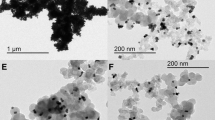

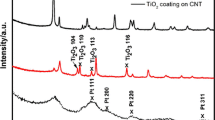

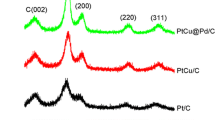

Strong correlation between particle size and ECSA of the Pt/C electrocatalyst has been demonstrated previously in the literature [30, 36]. Here, a typical example of the correlation between the structural characteristics of the Pt/C catalysts and their electrochemical characteristics has been provided. Figure 6 comprises the structural characterization of two typical Pt/C catalysts with varying particle sizes, synthesized using MW assisted polyol process at 140 °C in presence (Pt/C-01) and in absence (Pt/C-02) of water in the reaction bath [30, 36]. TEM images of the Pt/C-01 sample with small particle size and of the Pt/C-02 sample with large particles are shown in Fig. 6a, b, respectively, whereas XRD and initial CV of both samples are seen in Fig. 6c, d, respectively. A strong correlation between the ECSA and Pt particle size has been found, justifying the discussions made in the article using ECSA as an indicator of particle size, without performing the structural characterizations.

Correlation between structural characteristics and ECSA of two typical Pt/C: one with small particle sizes and one with larger particle sizes. a, b The TEM pictures of Pt/C-01 and Pt/C-02, respectively. c The XRD patterns of both sample with inlets of the respective particle sizes. d The initial CV recorded and the corresponding values of ECSA

Further, Fig. 7a exhibits the XRD patterns of three typical Pt/C catalysts, synthesized with MW assisted polyol process under identical conditions (listed in Table 1) but using H2PtCl6, (NH4)2PtCl6, and H2Pt(OH)6 as the Pt precursors, respectively. The Pt/C sample synthesized using the Pt precursor having [Pt(OH)6]2− complex shows significantly different XRD pattern compared to those synthesized using the Pt precursors having [PtCl6]2− complex. Particularly, as can be seen in Fig. 7b, the crystallite size values calculated using the Scherrer’s formula confirm ~2× larger Pt NPs for the Pt/C-OH00 sample. Again, the intensity ratios of different diffraction peaks, defined as the ratios of the areas under the concerned peaks (e.g., intensity ratio 111/200 = area of (111) peak/area of (200) peak), shown in Fig. 7b exhibit significant differences between the aforesaid sets of the Pt/C samples. For calculation of the intensity ratios, the areas under the peaks, obtained by integrating the peaks above the background (as shown in Fig. S6) were used. While Pt/C-Cl00 and Pt/C-Am00 show similar peak intensity ratios, Pt/C-OH00 shows relatively lower 111/200, 111/220 and 111/311 ratios.

Furthermore, cyclic voltammograms of the Pt/C-Cl00, Pt/C-Am00, and Pt/C-OH00 samples recorded after specific number of stress cycles during ASTs are shown in Fig. 8a–c, while the ECSA degradation trends for the concerned samples are shown in Fig. 8d. It is evident that the degradation pattern of the Pt/C-OH00 is extremely dissimilar to those of the Pt/C-Cl00 and Pt/C-Am00 samples. Significant activation of the Pt-NPs in Pt/C-OH00 samples is observed with the initial stress cycling. This may be attributed to (i) the fact that Pt/C-OH00 consists of large Pt-NPs, leading to less Ostwald ripening and (ii) the surface reconstruction leading to increased ECSA [51].

a–c Observational cyclic voltammograms of Pt/C electrocatalysts during stress cycling. Legends show the number of stress cycles (0.4 to 1.6 V; scan rate, 1 V/s; electrolyte, nitrogen saturated 1 M sulfuric acid) before recording of the specific cyclic voltammogram at a scan rate of 10 mV/s. d ECSA degradation trends obtained from the cyclic voltammograms shown in a–c

Comparing the ECSA values of the three samples from Table 1 and their crystallite sizes from Fig. 6b, it is clear that presence of OH− as a ligand in the Pt precursor leads to larger Pt NPs and hence poor electrochemical activity. Moreover, strong correlation between the ECSA values and crystallite size of Pt NPs is confirmed, as reported in the literature.

Furthermore, surface reconstruction of the Pt-NPs during AST can be monitored by monitoring the evolution of the observational cyclic voltammograms with number of stress cycles. Here, we use the \({A}_{H1}/{A}_{H2}\) ratio as an observable parameter exhibiting cyclic voltammogram evolution during AST. As shown in Fig. 9, While Pt/C-Cl00 and Pt/C-AM00 have the initial (cycle number 0) \({A}_{H1}/{A}_{H2}\) ratios higher than that of the Pt/C-OH00, after stress cycling, the \({A}_{H1}/{A}_{H2}\) ratios show an opposite trend. This may be attributed to different surface reconstructions for the Pt/C samples, leading to different type of active sites being evolved during AST.

Conclusions

In conclusion, effects of different precursors and externally introduced ionic species during the synthesis of Pt/C through the microwave assisted polyol route have been explored. The experimental parameters were varied to provide mild to strong reducing environments. Both the structural ligands in the Pt-precursors and the externally added ionic species affect the Pt-precursor reducibility and the electrochemical activity of the Pt-NPs. Specifically, under relatively mild conditions at a reaction temperature of 100 °C, [PtCl6]2− reduced readily as compared to [Pt(OH)6]2−, forming comparatively active Pt/C electrocatalyst. Although both the [PtCl6]2− and [Pt(OH)6]2− species reduce completely when exposed to harsh conditions (reaction temperature: 140 °C), the former leads to relatively more active catalyst. The presence of OH− as the externally added ionic species is found to impede the reduction and stabilize the Pt-species. Unlike previously reported, the presence of OH− during synthesis provided the Pt/C catalysts with lower activity most likely due to formation of larger Pt-NPs. The observation different from what reported previously is due to the mild conditions for reduction used here (30 vol% ethylene glycol and 100 °C–140 °C compared to 100% ethylene glycol and higher temperatures > 180 °C). In general, harsh reduction conditions lead to larger particles, where presence of OH− reduces the particle size. However, under mild conditions, that is not the case. Likewise, addition of Cl− to the synthesis bath results in larger Pt-NPs and hence lower electrocatalytic activity. Thus, the ability of OH− to control the particle size could not be obtained for the synthesis conditions used here. Finally, analysis of the H-adsorption and/or H-desorption peaks is used to get insights into the surface structure of the Pt-NPs. Presence of externally added ionic species and/or ligands associated to the Pt-precursor affect the surface structure of the Pt-NPs. Pt/C catalyst having the Pt surface structure favorable to high activity in terms of ECSA may be synthesized using a moderate temperature (~100 °C), absence of NaOH and a Pt precursor consisting of [PtCl6]2− complex.

Availability of Data and Materials

Data relevant to the manuscript from are available upon request can be provided by corresponding authors.

References

K. Huang, O. Morales-Collazo, Z. Chen, T. Song, L. Wang, H. Lin, J.F. Brennecke, H. Jia, The activity enhancement effect of ionic liquids on oxygen reduction reaction catalysts: from rotating disk electrode to membrane electrode assembly. Catalysts 11(8) (2021)

Y. Wang, D.F. Ruiz Diaz, K.S. Chen, Z. Wang, X. Cordobes Adroher, Materials, technological status, and fundamentals of PEM fuel cells – a review. Mater. Today 32, 178–203 (2020)

L. Fan, Z. Tu, S.H. Chan, Recent development of hydrogen and fuel cell technologies: a review. Energy Rep. 7, 8421–8446 (2021)

S.S. Kumar, V. Himabindu, Hydrogen production by PEM water electrolysis – a review. Mater. Sci. Energy Technol. 2(3), 442–454 (2019)

K. Kodama, T. Nagai, A. Kuwaki, R. Jinnouchi, Yu. Morimoto, Challenges in applying highly active Pt-based nanostructured catalysts for oxygen reduction reactions to fuel cell vehicles. Nat. Nanotechnol. 16(2), 140–147 (2021)

B. Garlyyev, K. Kratzl, M. Rück, J. Michalička, J. Fichtner, J.M. Macak, T. Kratky, S. Günther, M. Cokoja, A.S. Bandarenka, A. Gagliardi, R.A. Fischer, Optimizing the size of platinum nanoparticles for enhanced mass activity in the electrochemical oxygen reduction reaction. Angew. Chem. Int. Ed. 58(28), 9596–9600 (2019)

I.E.L. Stephens, A.S. Bondarenko, U. Grønbjerg, J. Rossmeisl, I. Chorkendorff, Understanding the electrocatalysis of oxygen reduction on platinum and its alloys. Energy Environ. Sci. 5(5), 6744–6762 (2012)

Z. Ma, Z.P. Cano, Yu. Aiping, Z. Chen, G. Jiang, Fu. Xiaogang, L. Yang, Wu. Tianpin, Z. Bai, Lu. Jun, Enhancing oxygen reduction activity of Pt-based electrocatalysts: from theoretical mechanisms to practical methods. Angew. Chem. Int. Ed. 59(42), 18334–18348 (2020)

G.A. Tritsaris, J. Greeley, J. Rossmeisl, J.K. Nørskov, Atomic-scale modeling of particle size effects for the oxygen reduction reaction on Pt. Catal. Lett. 141(7), 909–913 (2011)

J.X. Wang, N.M. Markovic, R.R. Adzic, Kinetic analysis of oxygen reduction on Pt(111) in acid solutions: intrinsic kinetic parameters and anion adsorption effects. J. Phys. Chem. B 108(13), 4127–4133 (2004)

K. Huang, T.M. Song, O. Morales-Collazo, H. Jia, J. Brennecke, Enhancing Pt/C catalysts for the oxygen reduction reaction with protic ionic liquids: the effect of anion structure. J. Electrochem. Soc. 164, F1448–F1459 (2017)

N.M. Markovic, H.A. Gasteiger, P.N. Ross, Oxygen reduction on platinum low-index single-crystal surfaces in sulfuric acid solution: rotating ring-Pt(hkl) disk studies. J. Phys. Chem. 99(11), 3411–3415 (1995)

F. El Kadiri, R. Faure, R. Durand, Electrochemical reduction of molecular oxygen on platinum single crystals. J. Electroanal. Chem. Interf. Electrochem. 301(1), 177–188 (1991)

N. Job, M. Chatenet, S. Berthon-Fabry, S. Hermans, F. Maillard, Efficient Pt/carbon electrocatalysts for proton exchange membrane fuel cells: Avoid chloride-based Pt salts! J. Power. Sources 240, 294–305 (2013)

A. Pavlišič, P. Jovanovič, V.S. Šelih, M. Šala, N. Hodnik, S. Hočevar, M. Gaberšček, The influence of chloride impurities on Pt/C fuel cell catalyst corrosion. Chem. Commun. (Camb.) 50(28), 3732–3734 (2014)

R. Devivaraprasad, T. Kar, P. Leuaa, M. Neergat, Recovery of active surface sites of shape-controlled platinum nanoparticles contaminated with halide ions and its effect on surface-structure. J. Electrochem. Soc. 164(9), H551–H560 (2017)

T.J. Schmidt, U.A. Paulus, H.A. Gasteiger, R.J. Behm, The oxygen reduction reaction on a Pt/carbon fuel cell catalyst in the presence of chloride anions. J. Electroanal. Chem. (Lausanne, Switzerland) 508(1), 41–47 (2001)

A. Lam, H. Li, S. Zhang, H. Wang, D.P. Wilkinson, S. Wessel, T.T.H. Cheng, Ex situ study of chloride contamination on carbon supported Pt catalyst. J. Power Sources 205, 235–238 (2012)

T.M. Arruda, B. Shyam, J.M. Ziegelbauer, S. Mukerjee, D.E. Ramaker, Source Brookhaven National Laboratory National Synchrotron Light, Investigation into the competitive and site-specific nature of anion adsorption on Pt using in situ x-ray absorption spectroscopy. J. Phys. Chem. C 112(46), 18087–18097 (2008)

S. Geiger, S. Cherevko, K.J.J. Mayrhofer, Dissolution of platinum in presence of chloride traces. Electrochim. Acta 179, 24–31 (2015)

A P. Yadav, A. Nishikata, T. Tsuru, Effect of halogen ions on platinum dissolution under potential cycling in 0.5 M H2SO4 solution. Electrochim. Acta 52(26), 7444–7452 (2007)

Q. Liu, J. Samad, J.E. Copple, S. Eskandari, C. Satterwhite, J.R. Regalbuto, A pinch of salt to control supported Pt nanoparticle size. Catal. Today 280, 246–252 (2017)

R. Sharma, S.M. Andersen, Circular use of Pt/C through Pt dissolution from spent PEMFC cathode and direct reproduction of new catalyst with microwave synthesis. Mater. Chem. Phys. 265 (2021)

T. Teranishi, M. Hosoe, T. Tanaka, M. Miyake, Size control of monodispersed Pt nanoparticles and their 2D organization by electrophoretic deposition. J. Phys. Chem. B 103(19), 3818–3827 (1999)

J.W. Kim, B. Lim, H.S. Jang, S.J. Hwang, S.J. Yoo, J.S. Ha, E.A. Cho, T.H. Lim, S.W. Nam, S.K. Kim, Size-controlled synthesis of Pt nanoparticles and their electrochemical activities toward oxygen reduction. Int. J. Hydrogen Energy 36(1), 706–712 (2011)

C. Coutanceau, P. Urchaga, S. Brimaud, S. Baranton, Colloidal syntheses of shape- and size-controlled pt nanoparticles for electrocatalysis. Electrocatalysis 3(2), 75–87 (2012)

R. Sharma, Y. Wang, F. Li, J. Chamier, S.M. Andersen, Particle size-controlled growth of carbon-supported platinum nanoparticles (Pt/C) through water-assisted polyol synthesis. ACS Omega 4(13), 15711–15720 (2019)

N. Rusnaeni, W.W. Purwanto, M. Nasikin, L. Hendrajaya, The effect of NaOH in the formation PtNi/C nanocatalyst for cathode of PEMFC. J. Appl. Sci. 10, 2899–2904 (2010)

I. Schrader, J. Warneke, S. Neumann, S. Grotheer, A.A. Swane, J.J.K. Kirkensgaard, M. Arenz, S. Kunz, Surface chemistry of “unprotected” nanoparticles: a spectroscopic investigation on colloidal particles. J. Phys. Chem. C 119(31), 17655–17661 (2015)

J. Quinson, M. Inaba, S. Neumann, A.A. Swane, J. Bucher, S.B. Simonsen, L.T. Kuhn, J.J.K. Kirkensgaard, K.M.Ø Jensen, M. Oezaslan, S. Kunz, M. Arenz, Investigating particle size effects in catalysis by applying a size-controlled and surfactant-free synthesis of colloidal nanoparticles in alkaline ethylene glycol: case study of the oxygen reduction reaction on Pt. ACS Catal. 8(7), 6627–6635 (2018)

J. Schröder, S. Neumann, J. Quinson, M. Arenz, S. Kunz, Anion dependent particle size control of platinum nanoparticles synthesized in ethylene glycol. Nanomaterials (Basel, Switzerland) 11(8), 2092 (2021)

R. Sharma, K.K. Kar, Particle size and crystallographic orientation controlled electrodeposition of platinum nanoparticles on carbon nanotubes. Electrochim. Acta 156, 199–206 (2015)

R. Sharma, Y. Wang, F. Li, J. Chamier, S.M. Andersen, Synthesis of a Pt/C electrocatalyst from a user-friendly Pt precursor (ammonium hexachloroplatinate) through microwave-assisted polyol synthesis. ACS Appl. Energy Mater. 2(9), 6875–6882 (2019)

M. Chourashiya, R. Sharma, S.M. Andersen, Accurate determination of catalyst loading on glassy carbon disk and its impact on thin film rotating disk electrode for oxygen reduction reaction. Anal. Chem. 90(24), 14181–14187 (2018)

R. Sharma, S. Gyergyek, S.M. Andersen, Critical thinking on baseline corrections for electrochemical surface area (ECSA) determination of Pt/C through H-adsorption/H-desorption regions of a cyclic voltammogram. Appl. Catal. B Environ. 311, 121351 (2022)

A.T. Hubbard, F.C. Anson, Study of electrochemistry of chloride and bromide complexes of platinum(II) and -(IV) by thin-layer electrochemistry. Anal. Chem. 38(13), 1887–1893 (1966)

S. Neumann, J. Schröder, F. Bizzotto, M. Arenz, A. Dworzak, M. Oezaslan, M. Bäumer, S. Kunz, Halide-induced leaching of pt nanoparticles – manipulation of particle size by controlled ostwald ripening. ChemNanoMat. 5(4), 462–471 (2019)

J. Schröder, S. Neumann, S. Kunz, Visible-light-induced synthesis of “surfactant-free” pt nanoparticles in ethylene glycol as a synthetic approach for mechanistic studies on nanoparticle formation. J. Phys. Chem. C 124(39), 21798–21809 (2020)

J. Quinson, A. Dworzak, S.B. Simonsen, L.T. Kuhn, K.M. Ø Jensen, A. Zana, M. Oezaslan, J.J.K. Kirkensgaard, M. Arenz, Surfactant-free synthesis of size controlled platinum nanoparticles: Insights from in situ studies. Appl. Surf. Sci. 549, 149263 (2021)

J. Quinson, K.M. Ø Jensen, From platinum atoms in molecules to colloidal nanoparticles: A review on reduction, nucleation and growth mechanisms, Adv. Colloid Interface Sci. 286, 102300 (2020)

S. Chen, Q. Yang, H. Wang, S. Zhang, Yu. Jiong Li, W.C. Wang, Q. Ye, L. Song, Initial reaction mechanism of platinum nanoparticle in methanol–water system and the anomalous catalytic effect of water. Nano Lett. 15(9), 5961–5968 (2015)

Z. Ding, V. Trouillet, S. Dsoke, Are functional groups beneficial or harmful on the electrochemical performance of activated carbon electrodes? J. Electrochem. Soc. 166(6), A1004 (2019)

A. Pavlišič, P. Jovanovič, V.S. Šelih, M. Šala, N. Hodnik, S. Hočevar, M. Gaberšček, The influence of chloride impurities on Pt/C fuel cell catalyst corrosion. Chem. Commun. 50(28), 3732–3734 (2014)

S. Zhu, Hu. Xiaomeng, M. Shao, Impacts of anions on the oxygen reduction reaction kinetics on platinum and palladium surfaces in alkaline solutions. Phys. Chem. Chem. Phys. 19(11), 7631–7641 (2017)

J. Junaidi, K. Triyana, H. Harsojo, E. Suharyadi, Chloride ion addition for controlling shapes and properties of silver nanorods capped by polyvinyl alcohol synthesized by polyol method. AIP Conf. Proc. 1725(1), 020092 (2016)

Z. Wang, E. Tada, A. Nishikata, In situ analysis of chloride effect on platinum dissolution by a channel-flow multi-electrode system. J. Electrochem. Soc. 161(9), F845–F849 (2014)

B.R. Shrestha, E. Tada, A. Nishikata, Effect of chloride on platinum dissolution. Electrochim. Acta 143, 161–167 (2014)

H. Yang, Y. Tang, S. Zou, Electrochemical removal of surfactants from pt nanocubes. Electrochem. Commun. 38 (2013)

F.J. Vidal-Iglesias, R.M. Arán-Ais, J. Solla-Gullón, E. Herrero, J.M Feliu, Electrochemical characterization of shape-controlled Pt nanoparticles in different supporting electrolytes. ACS Catal. 2(5), 901–910 (2012)

N.M. Marković, R.R. Adžić, B.D. Cahan, E.B. Yeager, Structural effects in electrocatalysis: oxygen reduction on platinum low index single-crystal surfaces in perchloric acid solutions. J. Electroanal. Chem. 377(1), 249–259 (1994)

Xu. Chen, J. Zhao, J. Lian, X. Wang, Achieving superior methanol oxidation electrocatalytic performance by surface reconstruction of PtNi nanoalloys during acid etching process. Green Chem. 25(8), 3198–3207 (2023)

Acknowledgements

The authors acknowledge Dr. Saso Gyergyek, Department for Materials Synthesis, Jozef Stefan Institute, Ljubljana 1000, Slovenia, and the CENN Nanocenter for the TEM analysis.

Funding

Open access funding provided by University Library of Southern Denmark The authors acknowledge the financial support from Innovation Fund Denmark, InnoExplorer program, Nr. 9122-00112; Danish Agency for Higher Education and Science, ESS lighthouse on hard materials in 3D, SOLID, Grant number 8144-00002B and EnergiFyn udviklingsfond.

Author information

Authors and Affiliations

Contributions

K.J.O.: Validation, Analysis, Visualization, Writing—original draft. R.S.: Conceptualization, Methodology, Writing—review & editing, Supervision. S.M.A.: Conceptualization, Methodology, Writing—review & editing, Supervision, Project administration, Funding acquisition.

Corresponding authors

Ethics declarations

Ethical Approval

Not relevant.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Omann, K.J., Sharma, R. & Andersen, S.M. Electrochemical Activity of Carbon-Supported Pt-Nanoparticles: Effect of Pt-Precursor Ligand and/or Presence of Anions During Polyol Synthesis. Electrocatalysis 15, 96–109 (2024). https://doi.org/10.1007/s12678-023-00856-5

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12678-023-00856-5