Abstract

Power transformers are classified among the most crucial power system components. Currently, the power transformer international competitive market drives manufacturers to adopt design strategies that lead to cost minimization while maintaining performance quality. Obviously, most of the aforementioned strategies rely on precise computation techniques involving electromagnetic field aspects for calculated refinements. In all cases, rough design detail estimation is indispensable to initiate the design refinement process and, in some cases, to address price quotation requests. This paper presents a fast specifications-oriented initial design methodology. Although the proposed methodology is analytical in nature it implicitly incorporates design parameter restrictions inferred from more sophisticated studies. Details of the proposed methodology in addition to a couple of design case studies are given in the paper.

Similar content being viewed by others

Abbreviations

- a :

-

Spacing between low and high voltage windings

- \(a_{c1}\) :

-

Primary winding conductor cross sectional area

- \(a_{c2}\) :

-

Secondary winding conductor cross sectional area

- B :

-

Maximum core flux density

- b :

-

Primary or secondary winding thickness

- \(C_{Fe}\) :

-

Specific core losses constant

- D :

-

Core bounding diameter

- f :

-

Supply frequency

- \(H_W\) :

-

Window Height

- \(I_{ph1}\) :

-

Primary phase current

- \(I_{ph2}\) :

-

Secondary phase current

- J :

-

Windings current density

- \(K_c\) :

-

Gross area to maximum circular area ratio

- \(K_f\) :

-

Laminations stack factor

- \(K_H\) :

-

Winding height to window height ratio

- \(K_W\) :

-

Window height to width ratio

- \(l_{mt}\) :

-

Average windings turn length

- \(l_{mt1}\) :

-

Average primary winding turn length

- \(l_{mt2}\) :

-

Average secondary winding turn length

- \(l_{WH}\) :

-

Windings height

- \(N_{1}\) :

-

Primary winding number of turns

- \(N_{2}\) :

-

Secondary winding number of turns

- \(P_{cu}\) :

-

Copper losses

- \(P_{cu-con}\) :

-

Termination connections losses

- \(P_{cu-eddy}\) :

-

Windings eddy current losses

- \(P_{cu-ohmic}\) :

-

Ohmic copper losses

- \(P_{{F}_{e}}\) :

-

Core losses

- \(P_{NL}\) :

-

No-load losses

- \(P_{stray}\) :

-

Stray losses

- S :

-

Rated Volt-Ampere

- \(S_{W}\) :

-

Window space factor

- \(V_{l1}\) :

-

Primary line voltage

- \(V_{l2}\) :

-

Secondary line voltage

- \(Vol_{cu}\) :

-

Overall copper volume

- \(V_{ph1}\) :

-

Primary phase voltage

- \(W_{Fe}(B,f)\) :

-

Specific core losses as a function of flux density and frequency

- \(W_{W}\) :

-

Window width

- X :

-

Equivalent leakage reactance per phase

- \(\delta _{Fe}\) :

-

Steel laminations density

- \(\rho _{cu}\) :

-

Specific resistivity of copper

- \(\mu _{o}\) :

-

Permeability of free space

References

Enders, J., Powell, W.B., Egan, D.M.: Robust policies for the transformer acquisition and allocation problem. Energy Syst. 245–272 (2010)

Doukas, H., Xidonas, P., Angelopoulos, D., Askounis, D., Psarras, J.: Robust policies for the transformer acquisition and allocation problem. Energy Syst. 1–13 (2016)

Adly, A.A., Abd-El-Hafiz, S.K.: Automated transformer design and core rewinding using neural networks. J. Eng. Appl. Sci. 46, 351–364 (1999)

Tsili, M.A., Kladas, A.G., Georgilakis, P.S., Souflaris, A.T., Paparigas, D.G.: Advanced design methodology for single and dual voltage wound core power transformers based on a particular finite element model. Electric Power Syst. Res. 76, 729–741 (2006)

Georgilakis, P.S., Tsili, M.A., Souflaris, A.T.: A heuristic solution to the transformer manufacturing cost optimization problem. J. Mater. Process. Technol. 181, 260–266 (2007)

Hernández, C., Arjona, M.A.: Design of distribution transformers based on a knowledge-based system and 2D finite elements. Finite Elem. Anal. Des. 43, 659–665 (2007)

Hernández, C., Arjona, M.A.: An intelligent assistant for designing distribution transformers. Expert Syst. Appl. 34, 1931–1937 (2008)

Georgilakis, P.S.: Recursive genetic algorithm-finite element method technique for the solution of transformer manufacturing cost minimization problem. IET Electric Power Appl. 3, 514–519 (2009)

Adly, A.A., Abd-El-Hafiz, S.K.: A performance-oriented power transformer design methodology using multi-objective evolutionary optimization. J. Adv. Res. 6, 417–423 (2015)

Georgilakis, P.S.: Spotlight on Modern Transformer Design. Springer Science & Business Media, Berlin (2009)

Sawhney, A.K.: A Course in Electrical Machine Design. Dhanpat Rai & Sons, Delhi (1984)

Flanagan, W.M.: Handbook of Transformer Design and Applications. McGraw Hill, New York (1992)

Kulkarni, S.V., Khaparde, S.A.: Transformer Engineering, Design and Practice. Marcel Dekker Inc, New York (2004)

Saleh, A., Adly, A., Fawzi, T., Omar, A., El-Debeiky, S.: Estimation and minimization techniques of eddy current losses in transformer windings. In: Proceedings of the CIGRE conference, Paris, France, Paper No. 12-105, pp. 1-6 (2002)

Saleh, A., Omar, A., Amin, A., Adly, A., Fawzi, T., El-Debeiky, S.: Estimation and minimization techniques of transformer tank losses. In: Proceedings of the CIGRE Conference, Paris, France, Paper No. A2-104, pp. 1–6 (2004)

Adly, A.A., Abd-El-Hafiz, S.K.: Utilizing particle swarm optimization in the field computation of nonlinear media subject to mechanical stress. J. Appl. Phys. 105, 07D507\(\_\)1-07D507\(\_\)3 (2009)

Adly, A.A., Mayergoyz, I.D.: Simulation of field-temperature effects in magnetic media using anisotropic Preisach models. IEEE Trans. Magnet. 34, 1264–1266 (1998)

Olivares-Galván, J.C., Georgilakis, S.P., Ocon-Valdez, R.: A review of transformer losses. Electric Power Compon. Syst. 37, 1046–1062 (2009)

http://www.aksteel.com/markets_products/electrical.aspx#tran-cor

Author information

Authors and Affiliations

Corresponding author

Appendix 1: detailed worked example

Appendix 1: detailed worked example

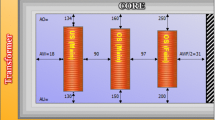

A detailed worked example for the implementation of the proposed design methodology is provided in this Appendix. More specifically, a detailed worked example is given for a core-type, oil immersed, three-phase stack core power transformers whose material type is Armco Steel TRAN-COR-H0 CARLITE-3 [19].

1.1 Target specifications

1.2 Estimated design parameters

From [10, 11], it is reasonable to assume the following parameters:

Knowing that the number of stack core steps = 11, it can be deduced from [10, 11] that:

Referring to the core material data specifications [19], thus:

From [14], it is reasonable to assume: \(K_W =2.28.\)

It is also well known that \(\mu _o =4\pi \times 10^{-7}\,\mathrm{H/m}\) and \(\rho _{cu} =2.1\times 10^{-8}\,\Omega \mathrm{m}.\)

1.3 Step-by-step design calculations and results

From (13):

From (14):

From (15):

From (16):

From (17):

From (18):

911

Hence,

Substituting (19) and (22) into (20) and (21) we get:

and,

1.4 Comparison between actual and computed results

A comparison between actual and computed leading design parameters are given in the following table. These results demonstrate the capability of the proposed approach to offer a relatively accurate initial design details (Table 3).

Rights and permissions

About this article

Cite this article

Adly, A.A. A specifications-oriented initial design methodology for power transformers. Energy Syst 8, 285–296 (2017). https://doi.org/10.1007/s12667-016-0197-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12667-016-0197-5