Abstract

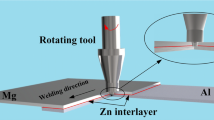

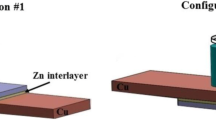

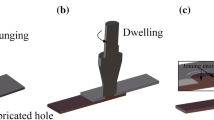

In order to improve the quality of friction stir spot welding joint of Al–Cu dissimilar metals, the pure Zn foils with different thicknesses were selected as the interlayer to perform the experiments. The thickness of Zn foil affected the morphology of the lap interface and the thickness of the intermetallic compound layer. The structure and composition of IMCs layer of Zn-added joint were similar when the thickness of Zn foil varied from 0.02 to 0.1 mm. The IMCs layer at the lap interface of the Zn-added joint was composed of AlxCuyZnz, Al2Cu, and αAl + Al2Cu three sub-layers structure. The thickness of the IMCs layer increased with the increase in Zn thickness, and the joint obtained the smallest IMCs layer of 79 μm with the addition of 0.02 mm Zn foil. The joint with 0.02 mm Zn foil obtained the maximum tensile shear load of 6.84 kN, which was 0.52 kN bigger than that of the joint without Zn foil. The fracture mode of the joints with 0.02 and 0.05 mm Zn foils was the quasi-cleavage characterized by cleavage surface, granular fracture surface and large tearing ridge, while the joint with 0.1 mm Zn and the joint without Zn foil belonged to the cleavage fracture.

Graphical abstract

Similar content being viewed by others

References

Meng X, Huang Y, Cao J, Shen J, dos Santos JF, Prog Mater Sci 115 (2021) 100706. https://doi.org/https://doi.org/10.1016/j.pmatsci.2020.100706

Li M, Zhang C, Wang D, Zhou L, Wellmann D, Tian Y, Materials 13 (2019) 156. https://doi.org/https://doi.org/10.3390/ma13010156

Heideman R, Johnson C, Kou S, Sci Technol Weld Joining 15 (2010) 597. https://doi.org/https://doi.org/10.1016/j.compositesa.2017.12.005.

Huang Y, Meng X, Xie Y, Wan L, Lv Z, Jian Cao, Jicai Feng, Compos Part A-Appl S 105 (2018) 235. https://doi.org/https://doi.org/10.1016/j.compositesa.2017.12.005.

D'Urso G, J Manuf Process 17 (2015) 108-119. https://doi.org/https://doi.org/10.1016/j.jmapro.2014.08.004

Lin YC, Liu JJ, Lin BY, Adv Mater Res 579 (2012) 109. https://doi.org/https://doi.org/10.4028/www.scientific.net/AMR.579.109

Li GH, Li Z, Zhou WL, Song XG, Huang YX, J Mater Res Technol 8 (2019) 2613. https://doi.org/https://doi.org/10.1016/j.jmrt.2019.02.015

Zhou L, Zhang R, Li G, Zhou W, Huang Y, Song X, J Manuf Process 36 (2018) 1. https://doi.org/https://doi.org/10.1016/j.jmapro.2018.09.017

Abbass M K, Hussein S K, Kudair A A, Int J Eng Sci Res Technol 4 (2015) 514. https://www.researchgate.net/publication/ 291346102

Manickam S, Rajendran C, Balasubramanian V, Heliyon 6 (2020) e04077. https://doi.org/https://doi.org/10.1016/j.heliyon.2020.e04077

Sun H, Zhou Q, Zhu J, and Peng Y, J Mater Eng Perform 26 (2017) 5715. https://doi.org/https://doi.org/10.1007/s11665-017-3029-4

Anna R, Franziska P, Tobias B, Pierre BJ, Weld World 63 (2019) 117. https://doi.org/https://doi.org/10.1007/s40194-018-0620-8

Zuo YY, Gong P, Ji SD, Li QH. Lv Z, J Manuf Process 62 (2021) 58. https://doi.org/https://doi.org/10.1016/j.jmapro.2020.11.019

Akbari M, Bahemmat P, Haghpanahi M, Sci Technol Weld Joining 18 (2013) 518. https://doi.org/https://doi.org/10.1179/1362171813Y.0000000130

Sahu PK, Pal S, Pal SK, Metall Mater Trans A 48 (2017) 3300. https://doi.org/https://doi.org/10.1007/s11661-017-4093-y

Huang G, Feng X, Shen Y, Zheng Q, Zhao P, Mater Des 99 (2016) 403. https://doi.org/https://doi.org/10.1016/j.matdes.2016.03.094

Kuang B, Shen Y, Chen W, Xin Y, Xu H, Gao J, Zhang J, Mater Des 68 (2015) 54. https://doi.org/https://doi.org/10.1016/j.matdes.2014.12.008

Boucherit A, Abdi S, Aissani M, Mehdi B, Badji R, Int J Adv Manuf Technol 111 (2020) 1553. https://doi.org/https://doi.org/10.1007/s00170-020-06202-z

Xue P, Xiao B, Wang D, Ma Z Y, Sci Technol Weld Joining 16 (2011) 657. https://doi.org/https://doi.org/10.1179/1362171811y.0000000018

Chen S, Wang D, Li R, Liu B. Wang J, J Mater Eng Perform 28 (2019) 5245. https://doi.org/https://doi.org/10.1007/s11665-019-04244-3

Acknowledgements

This project was funded by the National Natural Science Foundation of China (No. 51874201) and the Program for Liaoning Innovative Talents in University (LR2019049)

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, H., Ma, L., Gong, P. et al. Friction Stir Spot Welding of Al–Cu with Different Zn Foils. Trans Indian Inst Met 76, 979–988 (2023). https://doi.org/10.1007/s12666-022-02792-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02792-2