Abstract

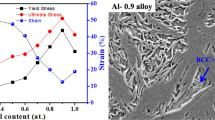

AlxCrFeNi (x = 1.25, 1.5, 1.75, 2.0) EHEAs were introduced by different coupling structures. Grain refinement triggered the continuous improvement of ductility with the increase of Al content. Double strengthening phases and grain refinement effect could be evolution of different coupling structures in strain-hardening-rate response of AlxCrFeNi. Specifically, alloy’s structure evolved from the coupling of mesh structure and labyrinth structure to completely labyrinth eutectic structure with the increase of Al content from 1.25 to 1.75, and the compressive mechanical properties appeared acute increased. Meanwhile, the ductility, yield strength and ultimate strength of Al1.75 reached 11.7%, 1325.4 MPa and 1621.0 MPa, respectively, which was significantly excellent compared to Al1.25 and Al1.5. It ascribed to the more stable combination of the two-phase cross labyrinth structure and stronger resistance to external impact.

Similar content being viewed by others

References

S. Yang, X. Yan, K. Yang, Z. Fu, Vacuum 131 (2016) 69-72.

E.P. George, D. Raabe, R.O. Ritchie, Nature Reviews Materials 4 (2019) 515-534.

M. Klimova, N. Stepanov, D. Shaysultanov, R. Chernichenko, N. Yurchenko, V. Sanin, S. Zherebtsov, Nat Rev Mater 11 (2018) 53.

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, S.Y. Chang, Adv Eng Mater 6 (2004) 299-303.

P. Bhattacharjee, G. Sathiaraj, M. Zaid, J. Gatti, C. Lee, C.-W. Tsai, J.-W. Yeh, J Alloys Compd 587 (2014) 544-552.

Takeuchi A, Yubuta K, Wada T, Mater Trans (2018) M2018216.

M. Wang, Z. wen, B. Ma, J. Liu, Z. Zou, Y. Zhao, J. Alloys Compd 893 (2021) 162242.

Y. Lu, X. Gao, L. Jiang, Z. Chen, T. Wang, J. Jie, H. Kang, Y. Zhang, S. Guo, H. Ruan, Acta Mater 124 (2017) 143-150.

X. Gao, Y. Lu, B. Zhang, N. Liang, G. Wu, G. Sha, J. Liu, Y. Zhao, Acta Mater 141 (2017) 59-66.

Y. Lu, Y. Dong, S. Guo, L. Jiang, H. Kang, T. Wang, B. Wen, Z. Wang, J. Jie, Z. Cao, Sci Rep 4(1) (2014) 1-5.

Q. Wu, Z. Wang, T. Zheng, D. Chen, Z. Yang, J. Li, J.-j. Kai, J. Wang, Mater Lett 253 (2019) 268-271.

Y. Lu, H. Jiang, S. Guo, T. Wang, Z. Cao, T. Li, Intermetallics 91 (2017) 124-128.

Y. Sui, S. Gao, X. Chen, J. Qi, F. Yang, F. Wei, Y. He, Q. Meng, Z. Sun, Vacuum 144 (2017) 80-85.

B. Chanda, J. Das, Adv Eng Mater 20 (2018) 1700908.

Murty B S, Yeh J W, Ranganathan S, Bhattacharjee P, High Entropy (2019) 177–193.

J. Miao, H. Liang, A. Zhang, J. He, J. Meng, Y. Lu, Tribol Int 153 (2021) 106599.

M. Asoushe, A.Z. Hanzaki, H. Abedi, B. Mirshekari, T. Wegener, S. Sajadifar, T. Niendorf, Mater Sci Eng A 799 (2021) 140012.

R. Gifkins, J Mater Sci 13 (1978) 1926-1936.

W. Jiao, H. Jiang, D. Qiao, J. He, H. Zhao, Y. Lu, T. Li, Mater. Chem Phys 260 (2021) 124175.

T. Xu, Y. Lu, Z. Cao, T. Wang, T. Li, J Mater Eng Perform 28 (2019) 7642-7648.

L. Jiang, Y. Lu, Y. Dong, T. Wang, Z. Cao, T. Li, Appl Phys A 119 (2015) 291-297.

J. Li, K. Yamanaka, A. Chiba, Mater Sci Eng A 817 (2021) 141359.

Z. Lei, X. Liu, Y. Wu, H. Wang, S. Jiang, S. Wang, X. Hui, Y. Wu, B. Gault, P. Kontis, Nature 563 (2018) 546-550.

D. Raabe, Z. Li, D. Ponge, MRS Bull 44 (2019) 266-272.

W.-h. Lee, Y. Oh, M.-G. Jo, H.N. Han, Y. Kim, J Alloys Compd 860 (2021) 158502.

A. Manzoni, H. Daoud, S. Mondal, S. Smaalen, R. Volkl, U. Glatzel, N. Wanderka, Ultramicroscopy 132 (2013) 212.

Y. Dong, Y. Lu, J. Kong, J. Zhang, T. Li, J Alloys Compd 573 (2013) 96-101.

S. Wolff-Goodrich, A. Marshal, K.G. Pradeep, G. Dehm, J.M. Schneider, C.H. Liebscher, J Alloys Compd 853 (2021) 156111.

X. Chen, Y. Sui, J. Qi, Y. He, F. Wei, Q. Meng, Z. Sun, J Mater Res 32 (2017) 2109-2116.

J. Wang, Q Wu, Y. Li, Z. Wang, J Li, J. Wang, J Alloys Compd 916 (2022) 165382

F. Yang, L. Wang, Z. Wang, Q. Wu, K. Zhou, X. Lin, W. Huang, J. Mater. Sci. Technol.106 (2022) 128-132

Q. Wu, Z. Wang, X. Hu, T. Zheng, Z. Yang, F. He, J. Li, J. Wang,Acta Mater.182 (2020) 278-286.

Y. Lu, Y. Dong, H. Jiang, Z. Wang, Z. Cao, S. Guo, T. Wang, T. Li, Peter K. Liaw, Scr. Mater. 187 (2020) 202-209.

X. Chen, J. Qi, Y. Sui, Y. He, F. Wei, Q. Meng, Z. Sun, Mater Sci Eng A 681 (2017) 25-31.

Y. Dong, L. Jiang, H. Jiang, Y. Lu, T. Wang, T. Li, Mater. Des 82 (2015) 91-97.

J. Morgiel, Z. Świątek, F. Czerwiński, Mater Sci Eng A 651 (2016) 590-597.

A.K. Singh, A. Subramaniam, J Alloys Compd 587 (2014) 113-119.

T. Xin, Y. Zhao, R. Mahjoub, J. Jiang, A. Yadav, K. Nomoto, R. Niu, S. Tang, F. Ji, Z. Quadir, Sci Adv 7 (2021) 3039.

C. Zhang, F. Zhang, H. Diao, M.C. Gao, Z. Tang, J.D. Poplawsky, P.K. Liaw, Mater Des 109 (2016) 425-433.

L.J. Zhang, K. Guo, H. Tang, M. Zhang, J.T. Fan, P. Cui, Y.M. Ma, P.F. Yu, G. Li, Mater Sci Eng A 757 (2019) 160-170.

L.J. Santodonato, Y. Zhang, M. Feygenson, C.M. Parish, M.C. Gao, R.J. Weber, J.C. Neuefeind, Z. Tang, P.K. Liaw, Nat Commun 6 (2015) 1-13.

Acknowledgements

This work is supported by Guangxi Natural Science Foundation, China (No. 2019 GXNSFBA245092, 2019GXNSFGA245006), the Science and Foundation of Guilin University of Technology (No. GUTQDJJ2019116) and the National Natural Science Foundation of China (No. 52062010).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, M., Lu, G., Li, J. et al. Effects of Al on Structure Evolution and Mechanical Performance of AlxCrFeNi (x > 1) Eutectic High-Entropy Alloys. Trans Indian Inst Met 76, 1045–1051 (2023). https://doi.org/10.1007/s12666-022-02765-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02765-5