Abstract

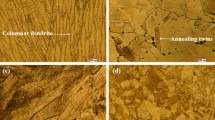

In the current study, 3, 5 and 8 at% aluminum were added to Cantor alloy, and the subsequent effects on microstructure, recrystallization temperature, hardness and work-hardening rate were investigated. For this purpose, the alloy was prepared employing vacuum arc remelting method. After casting, homogeneous annealing and cold rolling, the samples were annealed at different temperatures of 400–1100 °C for 1 h. Results showed that the melting point decreased with increasing aluminum content, while recrystallization was delayed with an increase in the temperature. The recrystallization temperature of the Cantor alloy by adding of 3, 5 and 8 at% aluminum increased from 800 to 900, 1000, and 1100 °C, respectively. In the annealing process of the samples, it was found that the B2 precipitates formed and the hardness of the alloy increased significantly by 8 at% Al at 600 °C. Furthermore, addition of Al to a Cantor alloy also increased the lattice strain and consequently reduced the stacking fault energy. A new kind of nanotwinned materials called hierarchical nanotwinned have been developed and could be more important in strain-hardening capability. Therefore, the behavior of work-hardening rate of the alloy indicated the effect of twins on the deformation mechanism of the alloy. Finally, the presence of nanotwin and B2 precipitates was investigated by TEM.

Similar content being viewed by others

References

J.-W. Yeh, S.-K. Chen, S.-J. Lin, J.-Y. Gan, T.-S. Chin, T.-T. Shun, C.-H. Tsau, S.-Y. Chang, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater. 6 (2004) 299–303. https://doi.org/https://doi.org/10.1002/adem.200300567.

J.-W. Yeh, Recent progress in high-entropy alloys, Eur. J. Control - EUR J Control. 31 (2006) 633–648. https://doi.org/10.3166/acsm.31.633-648.

W. Lu, X. Luo, Y. Yang, J. Zhang, B. Huang, Effects of Al addition on structural evolution and mechanical properties of the CrCoNi medium-entropy alloy, Mater. Chem. Phys. 238 (2019) 121841. https://doi.org/10.1016/j.matchemphys.2019.121841.

C.-C. Tung, J.-W. Yeh, T. Shun, S.-K. Chen, Y.-S. Huang, H.-C. Chen, On the elemental effect of AlCoCrCuFeNi high-entropy alloy system, Mater. Lett. 61 (2007) 1–5. https://doi.org/https://doi.org/10.1016/j.matlet.2006.03.140.

Y.-L. Chen, Y.-H. Hu, C.-W. Tsai, C.-A. Hsieh, S.-W. Kao, J.-W. Yeh, T.-S. Chin, P.-H. Lee, Alloying behavior of binary to octonary alloys based on Cu–Ni–Al–Co–Cr–Fe–Ti–Mo during mechanical alloying, J. Alloys Compd. 477 (2009) 696–705. https://doi.org/10.1016/j.jallcom.2008.10.111.

B. Cantor, I.T.H. Chang, P. Knight, A.J.B. Vincent, Microstructural development in equiatomic multicomponent alloys, Mater. Sci. Eng. A. 375–377 (2004) 213–218. https://doi.org/https://doi.org/10.1016/j.msea.2003.10.257.

Y. Zhang, X. Yang, P.K. Liaw, Alloy Design and Properties Optimization of High-Entropy Alloys, JOM. 64 (2012) 830–838. https://doi.org/10.1007/s11837-012-0366-5.

M.S. Lucas, G.B. Wilks, L. Mauger, J.A. Muñoz, O.N. Senkov, E. Michel, J. Horwath, S.L. Semiatin, M.B. Stone, D.L. Abernathy, E. Karapetrova, Absence of long-range chemical ordering in equimolar FeCoCrNi, Appl. Phys. Lett. 100 (2012) 251907. https://doi.org/10.1063/1.4730327.

X. Yang, Y. Zhang, P.K. Liaw, Microstructure and Compressive Properties of NbTiVTaAlx High Entropy Alloys, Procedia Eng. 36 (2012) 292–298. https://doi.org/https://doi.org/10.1016/j.proeng.2012.03.043.

S. Guo, C. Ng, J. Lu, C.T. Liu, Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys, J. Appl. Phys. 109 (2011) 103505. https://doi.org/10.1063/1.3587228.

X. Li, X. Yang, D. Yi, B. Liu, J. Zhu, J. Li, C. Gao, L. Wang, Effects of NbC content on microstructural evolution and mechanical properties of laser cladded Fe50Mn30Co10Cr10-xNbC composite coatings, Intermetallics. 138 (2021) 107309. https://doi.org/https://doi.org/10.1016/j.intermet.2021.107309.

C.-H. Tsau, M.-C. Tsai, The Effects of Mo and Nb on the Microstructures and Properties of CrFeCoNi(Nb,Mo) Alloys, Entropy . 20 (2018). https://doi.org/10.3390/e20090648.

C. Dai, T. Zhao, C. Du, Z. Liu, D. Zhang, Effect of molybdenum content on the microstructure and corrosion behavior of FeCoCrNiMox high-entropy alloys, J. Mater. Sci. Technol. 46 (2020) 64–73. https://doi.org/https://doi.org/10.1016/j.jmst.2019.10.020.

H.S. Oh, D. Ma, G.P. Leyson, B. Grabowski, E.S. Park, F. Körmann, D. Raabe, Lattice Distortions in the FeCoNiCrMn High Entropy Alloy Studied by Theory and Experiment, Entropy . 18 (2016). https://doi.org/10.3390/e18090321.

X. Yang, Y. Zhang, Prediction of high-entropy stabilized solid-solution in multi-component alloys, Mater. Chem. Phys. 132 (2012) 233–238. https://doi.org/https://doi.org/10.1016/j.matchemphys.2011.11.021.

Z. Wu, H. Bei, G.M. Pharr, E.P. George, Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures, Acta Mater. 81 (2014) 428–441. https://doi.org/https://doi.org/10.1016/j.actamat.2014.08.026.

F.J. Wang, Y. Zhang, G.L. Chen, Atomic packing efficiency and phase transition in a high entropy alloy, J. Alloys Compd. 478 (2009) 321–324. https://doi.org/https://doi.org/10.1016/j.jallcom.2008.11.059.

D.B. Miracle, O.N. Senkov, A critical review of high entropy alloys and related concepts, Acta Mater. 122 (2017) 448–511. https://doi.org/https://doi.org/10.1016/j.actamat.2016.08.081.

T.-T. Shun, C.-H. Hung, C.-F. Lee, Formation of ordered/disordered nanoparticles in FCC high entropy alloys, J. Alloys Compd. 493 (2010) 105–109. https://doi.org/https://doi.org/10.1016/j.jallcom.2009.12.071.

J. Kumar, N. Kumar, S. Das, N.P. Gurao, K. Biswas, Effect of Al Addition on the Microstructural Evolution of Equiatomic CoCrFeMnNi Alloy, Trans. Indian Inst. Met. 71 (2018) 2749–2758. https://doi.org/10.1007/s12666-018-1443-4.

N. Singh, Y. Shadangi, G.S. Goud, V.K. Pandey, V. Shivam, N.K. Mukhopadhyay, Fabrication of MgAlSiCrFe Low-Density High-Entropy Alloy by Mechanical Alloying and Spark Plasma Sintering, Trans. Indian Inst. Met. 74 (2021) 2203–2219. https://doi.org/10.1007/s12666-021-02262-1.

V. Shivam, J. Basu, Y. Shadangi, M.K. Singh, N.K. Mukhopadhyay, Mechano-chemical synthesis, thermal stability and phase evolution in AlCoCrFeNiMn high entropy alloy, J. Alloys Compd. 757 (2018) 87–97. https://doi.org/https://doi.org/10.1016/j.jallcom.2018.05.057.

Z. Tang, M.C. Gao, H. Diao, T. Yang, J. Liu, T. Zuo, Y. Zhang, Z. Lu, Y. Cheng, Y. Zhang, K.A. Dahmen, P.K. Liaw, T. Egami, Aluminum Alloying Effects on Lattice Types, Microstructures, and Mechanical Behavior of High-Entropy Alloys Systems, JOM. 65 (2013) 1848–1858. https://doi.org/10.1007/s11837-013-0776-z.

J.Y. He, W.H. Liu, H. Wang, Y. Wu, X.J. Liu, T.G. Nieh, Z.P. Lu, Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system, Acta Mater. 62 (2014) 105–113. https://doi.org/https://doi.org/10.1016/j.actamat.2013.09.037.

X. Li, D. Yi, X. Wu, J. Zhang, X. Yang, Z. Zhao, Y. Feng, J. Wang, P. Bai, B. Liu, Y. Liu, Effect of construction angles on microstructure and mechanical properties of AlSi10Mg alloy fabricated by selective laser melting, J. Alloys Compd. 881 (2021) 160459. https://doi.org/https://doi.org/10.1016/j.jallcom.2021.160459.

Y. Zhao, K. Liu, H. Hou, L.-Q. Chen, Role of interfacial energy anisotropy in dendrite orientation in Al-Zn alloys: A phase field study, Mater. Des. 216 (2022) 110555. https://doi.org/https://doi.org/10.1016/j.matdes.2022.110555.

V. Shivam, J. Basu, V.K. Pandey, Y. Shadangi, N.K. Mukhopadhyay, Alloying behaviour, thermal stability and phase evolution in quinary AlCoCrFeNi high entropy alloy, Adv. Powder Technol. 29 (2018) 2221–2230. https://doi.org/https://doi.org/10.1016/j.apt.2018.06.006.

Y. Zhong, J. Xie, Y. Chen, L. Yin, P. He, W. Lu, Microstructure and mechanical properties of micro laser welding NiTiNb/Ti6Al4V dissimilar alloys lap joints with nickel interlayer, Mater. Lett. 306 (2022) 130896. https://doi.org/https://doi.org/10.1016/j.matlet.2021.130896.

Y. Zhao, Stability of phase boundary between L12-Ni3Al phases: A phase field study, Intermetallics. 144 (2022) 107528. https://doi.org/https://doi.org/10.1016/j.intermet.2022.107528.

M. Tayebi, H. Najafi, S. Nategh, A. Khodabandeh, Creep Behavior of ZK60 Alloy and ZK60/SiCw Composite After Extrusion and Precipitation Hardening, Met. Mater. Int. 27 (2021) 3905–3917. https://doi.org/10.1007/s12540-020-00877-5.

M. Tayebi, S. Nategh, H. Najafi, A. Khodabandeh, Tensile properties and microstructure of ZK60/SiCw composite after extrusion and aging, J. Alloys Compd. 830 (2020) 154709. https://doi.org/https://doi.org/10.1016/j.jallcom.2020.154709.

F. Otto, N.L. Hanold, E.P. George, Microstructural evolution after thermomechanical processing in an equiatomic, single-phase CoCrFeMnNi high-entropy alloy with special focus on twin boundaries, Intermetallics. 54 (2014) 39–48. https://doi.org/https://doi.org/10.1016/j.intermet.2014.05.014.

G. Laplanche, O. Horst, F. Otto, G. Eggeler, E.P. George, Microstructural evolution of a CoCrFeMnNi high-entropy alloy after swaging and annealing, J. Alloys Compd. 647 (2015) 548–557. https://doi.org/https://doi.org/10.1016/j.jallcom.2015.05.129.

Q.H. Tang, Y. Huang, Y.Y. Huang, X.Z. Liao, T.G. Langdon, P.Q. Dai, Hardening of an Al0.3CoCrFeNi high entropy alloy via high-pressure torsion and thermal annealing, Mater. Lett. 151 (2015) 126–129. https://doi.org/https://doi.org/10.1016/j.matlet.2015.03.066.

O. Renk, A. Hohenwarter, K. Eder, K.S. Kormout, J.M. Cairney, R. Pippan, Increasing the strength of nanocrystalline steels by annealing: Is segregation necessary?, Scr. Mater. 95 (2015) 27–30. https://doi.org/https://doi.org/10.1016/j.scriptamat.2014.09.023.

L. Liang, M. Xu, Y. Chen, T. Zhang, W. Tong, H. Liu, H. Wang, H. Li, Effect of welding thermal treatment on the microstructure and mechanical properties of nickel-based superalloy fabricated by selective laser melting, Mater. Sci. Eng. A. 819 (2021) 141507. https://doi.org/https://doi.org/10.1016/j.msea.2021.141507.

Z.M. Liang, G.Y. Wang, Z. Bin Sun, D.L. Wang, L.W. Wang, Y.M. Liang, Rapidly improved tensile strength of 6N01 Al alloy FSW joints by electropulsing and artificial aging treatment, Mater. Sci. Eng. A. 841 (2022) 143056. https://doi.org/https://doi.org/10.1016/j.msea.2022.143056.

X. Xian, Z.-H. Zhong, L.-J. Lin, Z.-X. Zhu, C. Chen, Y.-C. Wu, Tailoring strength and ductility of high-entropy CrMnFeCoNi alloy by adding Al, Rare Met. 41 (2022) 1015–1021. https://doi.org/10.1007/s12598-018-1161-4.

N. Kumar, Q. Ying, X. Nie, R.S. Mishra, Z. Tang, P.K. Liaw, R.E. Brennan, K.J. Doherty, K.C. Cho, High strain-rate compressive deformation behavior of the Al0.1CrFeCoNi high entropy alloy, Mater. Des. 86 (2015) 598–602. https://doi.org/https://doi.org/10.1016/j.matdes.2015.07.161.

Z. Li, S. Zhao, H. Diao, P.K. Liaw, M.A. Meyers, High-velocity deformation of Al0.3CoCrFeNi high-entropy alloy: Remarkable resistance to shear failure, Sci. Rep. 7 (2017) 42742. https://doi.org/10.1038/srep42742.

L. Jiang, D. Qiao, Z. Cao, C. Lu, M. Song, L. Wang, Tunable mechanical property and strain hardening behavior of a single-phase CoFeNi2V0.5Mo0.2 high entropy alloy, Mater. Sci. Eng. A. 776 (2020) 139027. https://doi.org/https://doi.org/10.1016/j.msea.2020.139027.

M.N. Hasan, Y.F. Liu, X.H. An, J. Gu, M. Song, Y. Cao, Y.S. Li, Y.T. Zhu, X.Z. Liao, Simultaneously enhancing strength and ductility of a high-entropy alloy via gradient hierarchical microstructures, Int. J. Plast. 123 (2019) 178–195. https://doi.org/https://doi.org/10.1016/j.ijplas.2019.07.017.

L. Sun, X. He, J. Lu, Nanotwinned and hierarchical nanotwinned metals: a review of experimental, computational and theoretical efforts, Npj Comput. Mater. 4 (2018) 6. https://doi.org/10.1038/s41524-018-0062-2.

V. Shivam, J. Basu, R. Manna, N.K. Mukhopadhyay, Local Composition Migration Induced Microstructural Evolution and Mechanical Properties of Non-equiatomic Fe40Cr25Ni15 Al15Co5 Medium-Entropy Alloy, Metall. Mater. Trans. A. 52 (2021) 1777–1789. https://doi.org/10.1007/s11661-021-06188-7.

H. Kaypour, S. Nategh, R. Gholamipour, A. Khodabandeh, High-temperature compressive behavior and kinetics analysis of Al0.4MnCrCoFeNi high entropy alloy, Mater. Res. Express. 8 (2021) 66505. https://doi.org/10.1088/2053-1591/ac045c.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kaypour, H., Nategh, S., Gholamipour, R. et al. Effect of Aluminum Addition on Microstructure, Recrystallization and Work Hardening of MnCrCoFeNi High-Entropy Alloy. Trans Indian Inst Met 76, 119–133 (2023). https://doi.org/10.1007/s12666-022-02718-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02718-y