Abstract

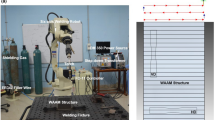

In this study, a multi-layered wall was fabricated using Wire Arc Additive Manufacturing (WAAM) process using ER321 filler wire to evaluate the static and dynamic mechanical properties. The micrographs of WAAM processed SS 321 revealed the existence of columnar and equiaxed dendrites along the building direction, and recrystallization of grains was observed due to the re-melting of former layers. The microstructure was dominantly austenitic with a small fraction of ferrite (FN) within the austenitic matrix. Comparable tensile properties were noticed for as-deposited SS 321 WAAM samples in comparison to wrought grade. This is attributed to the presence of equiaxed and columnar dendritic microstructure with a formation of residual delta ferrites along the build direction. The hardness gradually reduced from the bottom (250 HV) to the top (199 HV) region in WAAM SS 321 wall due to the difference in microstructure with varying ferrite fractions (5.9 to 3.6 FN). The fracture toughness of wrought SS 321 and WAAM processed SS 321 was 162 kJ/m2 and 153 kJ/m2. The manufacturing techniques influenced the fracture behaviour and were confirmed from the J-R curves obtained from the strain energy rate required to initiate the crack growth. This study demonstrates the potential of WAAM technology for the fabrication of free-form structural components with comparable mechanical properties and fracture toughness in comparison to wrought alloy.

Similar content being viewed by others

References

Cheepu M, Lee C I, and Cho S M, Trans Indian Inst Met 73 (2020), 1475. https://doi.org/10.1007/s12666-020-01915-x

Liu Z, He B E I, Lyu T, and Zou Y U, JOM 73 (2021) 1804. https://doi.org/10.1007/s11837-021-04670-6

Milner B B, Gradl P, Snedden G, Brooks M, Pitot J, Lopez E, Leary M, Berto F and Plessis A, Mater Des 209 (2021) 110008. https://doi.org/10.1016/j.matdes.2021.110008

Nkhoma R K C, Siyasiya C W, and Stumpf W E, J Alloys Compd 595 (2014), 103. https://doi.org/10.1016/j.jallcom.2014.01.157

Kasana S S and Pandey O P, Mater Today Commun 26 (2021) 101959. https://doi.org/10.1016/j.mtcomm.2020.101959

Wang J, Su H, Chen K, Du D, Zhang L, and Shen Z, Corros Sci 158 (2018), 108079. https://doi.org/10.1016/j.corsci.2019.07.005

Huang Y, Bull Mater Sci 25 (2002), 47. https://doi.org/10.1007/BF02704594

Beaman J J, Bourell D L, Seepersad C C, and Kovar D, J Manuf Sci En 142 (2020) 110812. https://doi.org/10.1115/1.4048193

Cunningham C R, Flynn J M, Shokrani A, Dhokia V, and Newman S T, Addit Manuf, 22 (2018), 672. https://doi.org/10.1016/j.addma.2018.06.020

Kannan A R, Shanmugam N S, Ramkumar K D, and Rajkumar V, Trans Indian Inst Met 74 (2021) 1673. https://doi.org/10.1007/s12666-021-02257-y

Patel M, Mulgaonkar S, Desai H, and Borse T, Trans Indian Inst Met, 74 (2021) 1129. https://doi.org/10.1007/s12666-020-02154-w

Kumar S M, Kannan A R, Pramod R, Shanmugam N S, Muthu S M, and Dhinakaran V, Mater. Lett., 314 (2022) 131913. https://doi.org/10.1016/j.matlet.2022.131913

Osipovich K S, Kalashnikov K N, and Beloborodov V A, Mechanical properties of 321 stainless steel samples obtained by electron-beam additive manufacturing AIP Conf. Proc., 2167 (1) (2019) 20255.https://doi.org/10.1063/1.5132122

Moskvina V, Astafurova E, Astafurov S, Reunova K, Panchenko M, Melnikov E, Kolubaev E, Metals, 12 (2022), 176. https://doi.org/10.3390/met12020176

Gordon J V, Haden C V, Nied H F, Vinci R P, Harlow D G, Mater Sci Eng A 724 (2018) 431. https://doi.org/10.1016/j.msea.2018.03.075

Ganesh P, Moitra A, Sathyanarayanan S, Kaul R, Sasikala G, Prasad R C, and Kukreja L M, Mater Des 59 (2014), 509. https://doi.org/10.1016/j.matdes.2014.03.013

Dirisu P, Ganguly S, Mehmanparast A, Martina F, and Williams S, Mater Sci Eng A 765 (2019), 138285. https://doi.org/10.1016/j.msea.2019.138285

Kumar D, Jhava S, Arya A, Prashanth K G, and Suwas S, Int J Fract 235 (2021) 1. https://doi.org/10.1007/s10704-021-00574-3

Lucon E, Scibetta M, Chaouadi R, and van Walle E, J ASTM Int, 3 (2006). 1 https://doi.org/10.1520/JAI13235

Zhu X K and McGaughy T, Evaluation of Fracture Toughness CTOD Testing and its Standard Test Methods for SENB Specimens, Proceedings of the ASME 2018 Pressure Vessels and Piping Conference, 51678 (2018), V06AT06A023. https://doi.org/10.1115/PVP2018-84975

ASTM E1820–21 Standard Test Method for Measurement of Fracture Toughness, 2022. https://www.astm.org/e1820-21.html

Palani P K and Murugan N, Mater Manuf Processes, 21 (2006) 431.

Ge J, Lin J, Chen Y, Lei Y, and Fu H, J Alloys Compd 748 (2018) 911. https://doi.org/10.1016/j.jallcom.2018.03.222

Rodrigues T A, Escobar J D, Shen J, Duarte V R, Ribamar G G, Avila J A, Schell E, Maawad N, Santos T G, and Oliveira J P, Addit Manuf 48 (2021) 102428. https://doi.org/10.1016/j.addma.2021.102428

Vieille B, Keller C, Mokhtari M, Briatta H, Breteau T, Nguejio J, Barbe F, Ben Azzouna M, and Baustert E, Mater Sci Eng A, 790 (2020) 139666. https://doi.org/10.1016/j.msea.2020.139666

Ghorbanpour S, Sahu S, Deshmukh K, Borisov E, Riemslag T, Reinton E, Bertolo V, Jiang Q, Popovich A, Shamshurin A, Knezevic M, and Popovich V, Mater Charact 179 (2021) 111350. https://doi.org/10.1016/j.jmatprotec.2022.117573

Al-Haidary J T, Wahab A A, and Salam E H A, Metall Mater Trans A 37 (2006) 3205. https://doi.org/10.1007/BF02586155

Idris R, and Prawoto Y, Mater Sci Eng A 552 (2012) 547. https://doi.org/10.1016/j.msea.2012.05.085

Nakajima Y, Uno Y, and Suzuki M, Eng Fract Mech 33 (1989) 295. https://doi.org/10.1016/0013-7944(89)90031-3

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Prakash, K.S., Kannan, A.R., Pramod, R. et al. Microstructure, Mechanical Properties and Fracture Toughness of SS 321 Stainless Steel Manufactured Using Wire Arc Additive Manufacturing. Trans Indian Inst Met 76, 537–544 (2023). https://doi.org/10.1007/s12666-022-02713-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02713-3