Abstract

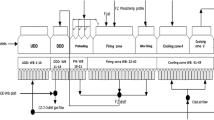

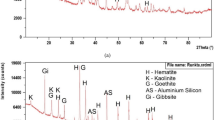

Indian iron ores are suffering from high amounts of alumina and loss on ignition (LOI), which are deleterious constituents in both the pelletizing as well as iron making processes. Iron ore fines utilized in pellet making consist of alumina in the range of 3.20–3.35% and LOI in the range of 3.50–3.70%. Detailed palletization studies have been carried out on high alumina as well as high LOI pellets to improve the properties of the pellet for direct reduced iron making plant (DRI) by optimizing the straight grate induration furnace firing cycle. Preheated and fired pellets were tested for physical and metallurgical properties. Mineralogical studies were carried out using an optical microscope. From the laboratory studies, it was found that under optimum conditions, such as preheating temperature of 1000 °C and preheating time of 2.7 min, roasting temperature of 1300–1310 °C and roasting time of 14.5 min, the roasted pellet properties like tumbler index (T.I) of 94.2%, cold crushing strength (CCS) of 275 kg/p and reduction degradation index (RDI) of 8.5% were achieved due to better coating of slag phase around the hematite grains by improving the fluidity of the melt phase, This led to an increase in the pore density of the pellet by decreasing the bigger size pores. For high alumina and high LOI pellets, the residence time of the existing firing cycle should be increased by 3.7 min (from 39.9 to 43.2 min) and machine speed should be decreased by 0.23 m/min (from 2.91 to 2.68 m/min) to achieve better pellet properties which are suitable for DRI making.

Similar content being viewed by others

References

L.D.M. Sandra, B.D.L Baptista, and R.R. Tiago, Iron ore pelletizing process: An Overview, Iron ores and Iron Oxide Materials, 2018, DOI:https://doi.org/10.5772/intechopen.73164.

Y.P Zhang, T.Y. Fu, T.Jiang, Y.B. Yang, The influence of the gangue contnets on properties of the pellet, Sintering pelletizing, Vol. 27, No.4 11(2002),

Jian-liang Zhang, Zhen-Yang Wnng, Xiang –dong Xing, and Zheng-jian Liu, Effect of aluminium oxide on the compressive strength of pellet, International Journal of Minerals, Metallurgy and Materials, Vol 21, No.4, 1-6 (2014).

J.L. Zhang, X D Xing and Z. Wang, Effect of alumina oxide on the compressive strength of pelelts, International journal of minerals, metallurgy and materials. Vol 21, 1-7(2014).

Q. Xiao, theory and practice of pelletizing, Central souty university of technology press, Changsha, 93(1991).

Y.M. Chen and J. Li, Crystal rule of Fe2O3 in oxidized pelelts. J Cent. South Univ. Sci. Technol., 38, No.1, 70(2007).

S.K. Biswal, Utilization of low grade iron ore fines, slimes and tailings by physical beneficiation to minimize the waste generation, J Sustain Planet, 46-58 (2010).

P. Pallishree, B. Kashinath, and D. Nilima, Effect of limestone and dolomite flux on the quality of pelelts using high LOI iron ore, Powder Technology, 379, 154-164(2020).

T Umadevi, K. Sridhara, Rameshwar sah, R. Srinidhi, Usgae of high LOI iron ore fines in pellet making, Transactions of the Indian Institute of Metals, Vol 72, 2599–2611(2019).

T Umadevi, P. Kumar, N.F.Lobo, M. Prabhu, P.C. Mahapatra, amd M.Ranjan, Influence of pelelt bacisity (CaO/SiO2) on iron ore pellet properties and microstructure, ISIJ Int., Vol 51, 14-20(2011).

M. Iljana, A Kemppainen, T. Paananenb, O. Mattila, E. Pisila, M. Kondrakov and T. Fabritius, Effect of adding limestone on the metallurgical properties of iron ore pelelts, Int. J. Miner. Process, Vol. 141 33-43(2015).

T Umadevi, A.Kumar. P. Karthik, R. Srinidhi, Characterization studies on swelling behaviour of iron ore pellets, Ironmaking and Steelmaking, Vol 45, No.2, 1-9(2018).

M. Meyer, L.E. Lagoeiro, l.M. Graca, C.J. Silva, Phase and microstructural characterization of iron ore pelelt and their relation with cold crushing strength, Mineral Processing and Extractive Metallurgy Review, Vol. 37, 295-304(2016).

F. Rafat, Effect of Different Heating rate on the Thermal Decomposition of urea. Arch. Appl. Sci. Res., Vol. 6, 75-78 (2014).

Goss C J, The kinetics and reaction mechanism of the goethite to hematite transformation, Mineral Mag 51, 437 (1987).

Coats A W, and Redfern J P, Kinetic Parameters from Thermogravimetric Data, Nature, 201, 68 (1964).

Y.M. Chen and J. Li, Crystal rule of Fe2O3 in oxidized pellets, J. Cent. South Univ. Sci. Technol., Vol. 38, 70 (2007).

Taichi MurakaMi, Shuya NakaMura, Daisuke Maruoka, Eiki Kasai Effects of Iron Ore Type and Gangue Mineral Components on Strength of Sintered Fine Powder Granule, Journal of the Iron and Steel Institute of Japan, Vol 107, 463-470 (2021).

H. P. Pimenta and V. Seshadri, Influence of Al2O3 and TiO2 degradation behaviour of sinter and hematite at low temperatures on reduction, Ironmaking and Steelmaking, Vol 29, 175-179 (2002).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Umadevi, T., Sridhara, K.S., Raju, M. et al. Optimization of Pellet Plant Straight Grate Induration Furnace Firing Cycle for High Alumina and High LOI Iron Ore Pellet. Trans Indian Inst Met 75, 3203–3212 (2022). https://doi.org/10.1007/s12666-022-02707-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02707-1