Abstract

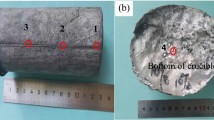

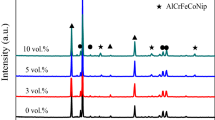

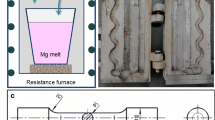

High-entropy alloy particles have excellent mechanical properties and have potential uses as reinforcing materials. In this study, AZ91D-based composites reinforced with AlCrFeCoNi particles were fabricated using a squeeze casting technology. The average grain size of the AZ91D–AlCrFeCoNi composites was reduced from 95.4 μm (0 vol.%) to 81.5 μm (10 vol.%). Several particle clusters occurred in the 5 vol.% and 10 vol.% composites. Transmission electron microscopy analysis showed that strong interfacial bonding between AlCrFeCoNi and α-Mg was present due to the formation of semi-coherent interfaces. The AlCrFeCoNi particles were found to have a substantial influence on the mechanical properties of the composite; it was found that composites with 3 vol.% AlCrFeCoNi had the highest yield strength (95.1 MPa) and tensile strength (180.0 MPa) as well as the largest elongation 1.1%; the composites with 10 vol.% AlCrFeCoNi particles resulted in the samples with the highest micro-hardness (105.2 HV). The excellent mechanical properties that were obtained could be attributed to the refined grain size and the stress transfer between the AlCrFeCoNi particles and the Mg matrix.

Similar content being viewed by others

References

Ye J, Li J, Luo H, Tan J, Chen X, Feng B, Zheng K and Pan F. Mater Sci Eng A, 833 (2022) 142526.

Yang L, Shi XH, Feng GH, Tian XF, Wang JC and Qi LH. Ceram Int, 46 (2020) 22564

Xue Y, Li H, Qi L, Yang L, Wang J and Ma Y. Ceram Int, 47 (2021) 31149

Chang Z, Lan Q, Wu Y, Su N, Deng Q, Ding C, Iizuka T, Peng L and Ding W. Mater Charact, 183 (2022) 111649

Chandradass J, Thirugnanasambandham T and Sethupathi P B. Mater Today: Proc, 45 (2021) 6507

Surendran K T S, Gnanavelbabu A and Rajkumar K. Mater. Today: Proc, 45 (2021) 7822.

Zhou J, Yuan M, Li Z, Meng H, Zhang T and Qi L. Mater Sci Eng, A, 762 (2019) 138061.

Lingaraju S V, Mallikarjuna C, Annappa A R and Venkatesha BK. Mater Today: Proc, (2021).

Ebrahimi M, Zhang L and Wang Q, Mater Sci Eng, A, 821 (2021) 141605.

Li S, Su Y, Zhu X, Jin H, Ouyang Q and Zhang D. Mater Des, 107 (2016) 130.

Zhang T, Qi L, Fu J, Chao X, Li W and Li H. Ceram Int, 45 (2019) 12563.

Meng G, Lin X, Xie H, Wang C, Wang S and Ding X. J Alloy Comp, 672 (2016) 660.

Yuan Z, Tian W, Li F, Fu Q, Wang X and Qian W. J Alloy Compd, 822 (2020) 153658.

Sathiyamoorthi P and Kim H S. Prog Mater Sci, 123 (2022) 100709.

Meng G, Yue TM, Lin X, Yang H, Xie H and Ding X. Opt Laser Technol, 70 (2015) 119.

Liu Y, Chen J, Li Z, Wang X, Fan X and Liu J. J Alloy Compd, 780 (2019) 558.

Chen J, Niu P, Wei T, Hao L, Liu Y, Wang X and Peng Y. J Alloy Compd, 649 (2015) 630.

Chen Y, Ji Z, Hu M, Xu H and Feng G. Int J Mater Res, 112 (2021) 538.

Arunkumar T, Selvakumaran T, Subbiah R, Ramachandran K and Manickam S. Ultrason. Sonochem, 76 (2021) 105631

Wang C, Dong Z, Li K, Sun M, Wu J, Wang K, Wu G and Ding W. J Mater Process Technol. (2022) 117537

Zhao D, Lü S, Li J, Guo W and Wu S. Mater Sci Eng A, 808 (2021) 140942.

Srivastava N and Anas M. Mater Today: Proc, 26 (2020) 1914.

Park Y, Cho K, Park I and Park Y. Procedia Engineering. 10 (2011) 1446.

Yuan Q, Zhou G, Liao L, Liu Y and Luo L. Carbon, 127 (2018) 177

Alizadeh A, Khayami A, Karamouz M and Hajizamani M. Ceram Int, 48 (2022) 179

He Y, Xu H and Jiang B, J Alloys Compd, 888 (2021) 161578.

Zhang T, Fu J, Lu Z, Chao X, Zhou J and Qi L. Ceram Int, 47 (2021) 30310.

He Y, Xu H, Hu M, Jiang B and Ji Z. J Mater Sci Technol, 53 (2020) 82.

Akçamlı N and Şenyurt B. Ceram Int, 47 (2021) 6813.

Yuvaraj N and Aravindan S. J Mater Res Technol, 4 (2015) 398

He Y, Xu H and Jiang B, J Alloy Compd, 888 (2021) 161578.

Funding

This work was supported by the University Nursing Program for Young Scholars with Creative Talents in Heilongjiang Province (UNPYSCT-2020033) and National Natural Science Foundation of China (No. 51574100).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, Y., Wei, R., Shao, Q. et al. AZ91D Matrix Composites Reinforced with AlCrFeCoNi High-Entropy Alloy Particles Fabricated via Squeeze Casting. Trans Indian Inst Met 75, 2829–2836 (2022). https://doi.org/10.1007/s12666-022-02652-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02652-z