Abstract

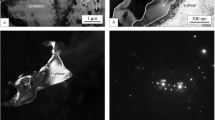

Ni–Mo–Cr–Ti alloys are one of the proposed structural materials for molten salt breeder reactors. In the current work, the evolution of precipitates in the alloy at various stages of thermo-mechanical processing followed by thermal ageing at 750 °C is studied. The microstructure after thermal ageing for various durations shows the presence of ‘MC’-type carbides with different morphologies and compositions. Formation of carbide networks with bulky titanium-rich ‘MC’ carbides of irregular morphology and spherical ‘MC’ around it is observed in the early stages, while fine uniform dispersion of ‘MC’-type needle-like carbides that possess a cube-on-cube orientation relationship with the FCC matrix is observed in the latter stages. High-resolution transmission electron micrograph reveals the presence of misfit dislocations on the semi-coherent interface between the fine needle-like MC carbides and the matrix which is attributed to the lattice parameter mismatch between them.

Similar content being viewed by others

References

Vijayan P K, Basak A, Dulera I V, Vaze K K, Basu S, and Sinha R K, Pramana -J phy, 85 (2015) 539.

Vijayan P K, Shivakumar V, Basu S, and Sinha R K, Progress in Nuclear Energy, 101 (2017) 43.

Sinha R K, Chellapandi P, Srinivasan G, Dulera I, Vijayan P K, Chande S K, Handbook of Generation IV Nuclear Reactors, Woodhead Publishing Series in Energy (2016), P413.

Umashankari K, and Krishnani P D, Sadhana, 38 (2018) 817.

Jeremy T B, Lauren M G, Lianshan L, Stephen S R, Ting L S, Chinthaka S, and Hong W, Technical Gap Assessment for Materials and Component Integrity Issues for Molten Salt Reactors, ORNL/SPR-2019/1089 (2019).

Ding X, Sun H, Yu G, and Zhou X, Journal of Chinese society of corrosion and protection, 35 (2015) 543.

McCoy H E, Status of Materials Development for Molten Salt Reactors, ORNL/TM-5920, 1978.

Braski, D N, and Leitnaker, J.M “Production of homogeneous Titanium-Hastelloy N alloys”, ORNL/TM-5697 (1977), Oak Ridge National Lab, 1977.

Lin S, Li J, Renduo L, Xiang X, Wenzhu Z, Changjiang S, Zhijun L, Xingtai Z, Materials Characterization, 133 (2017) 54.

Yamamoto N, Nagakawa J, Shiraishi H, Journal of Nuclear Materials, 226 (1995) 185.

Braski D N, Leitnaker J M, Metallurgical Transactions A, 10 (1979) 427.

Sundararaman M, Mukhopadhyay P, Banerjee S, Superalloys, 718 (1997) 625.

Wang Z, Zhang H, Guo C, Liu W, Yang Z, Sun X, Zhang Z, and Jiang F. Journal of materials science, 51 (2016) 4996.

Acknowledgements

The authors acknowledge the contributions of Dr. K.V. Mani Krishna for academic discussions and Shri. Ravi Hankare for his help in thermo-mechanical processing. The project is funded by the Department of Atomic Energy (DAE), Government of India.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Donthula, H., Ananth, K., Vishwanadh, B. et al. A Study on the Precipitation of Carbides in Ti-Modified Ni–Mo–Cr-based Alloy During Thermal Ageing at Elevated Temperature. Trans Indian Inst Met 75, 967–974 (2022). https://doi.org/10.1007/s12666-021-02520-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02520-2