Abstract

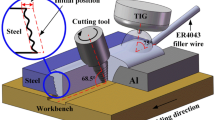

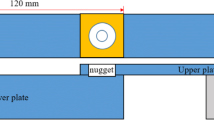

AA7075 aluminum and Q235 steel were successfully joined by self-riveting friction stir lap welding (SR-FSLW). The pre-drilled holes of Q235 were filled by AA7075, achieving the self-riveting process. In addition, the AA7075 rivets were locked by the aluminum/steel swirl-layered structure, and the swirl-layered structure consisted of fine grains and intermetallic compounds layers due to the mechanical and metallurgical impacts of SR-FSLW. A cyclic flow of AA7075 was observed inside the rivets, and a plunging-squeezing-filling-locking model was proposed to illustrate the formation mechanism of locked rivets. Compared with the traditional FSLW joint, the shear tensile properties of SR-FSLW joint were significantly enhanced. Moreover, enlarging the diameter of pre-drilled hole contributed to the increment in the effective sheet thickness, strengthening the SR-FSLW joint further. All FSLW/SR-FSLW joints were failed in the nugget zone of AA7075 side, and a mixture of ductile–brittle fracture was observed due to the existence of aluminum/steel hook.

Similar content being viewed by others

References

Schubert E, Klasen M, Zerner I, Walz C, and Sepold G, J Mater Process Technol 15 (2001) 2.

Leitao C, Arruti E, Aldanondo E, and Rodrigues D M, Mater Des 106 (2016) 153.

Zheng C X, Feng X M, Shen Y F, Huang G Q, and Zhao P C, J Alloy Compd 686 (2016) 693.

Liu G Q, Gao X D, Peng C, Liu X H, Huang Y J, Zhang Y X, and You D Y, T Nonferr Metal Soc 30 (2020) 2639.

Singh J, Arora K S, and Shukla D K, J Mater Process Tech 283 (2020) 116728.

Kar A, Vicharapu B, Morisada Y, and Fujii Hidetoshi, Mater Charact 168 (2020) 110572.

Liu X, Lan S H, and Ni J, Mater Des 59 (2014) 50.

Huang Y X, Huang T F, Wan L, Meng X C, and Zhou L, J Mater Process Tech 263 (2019) 129.

Pourali M, Abdollah-zadeh A, Saeid T, and Kargar F, J Alloy Compd 715 (2017) 1.

Wei Y N, Li J L, Xiong J T, and Zhang F S, J Mater Eng Perform 22 (2013) 3005.

Batistao B F, Bergmann L A, Gargarella P, Alcantara N G D, Santos J F D, and Klusemann B, J Mater Res Technol 9 (2020) 15132.

Huang Y X, Wang J C, Wan L, Meng X C, Liu H B, and Li H, Mater Lett 185 (2016) 181.

Wang H D, Wang K S, Wang W, Huang L Y, Peng P, and Yu H L, Mater Charact 155 (2019) 109803.

Chen Y, Ding H, Cai Z H, Zhao J W, and Li J Z, Mater Sci Eng A 650 (2016) 396.

Yue Y M, Li Z W, Ji S D, Huang Y X, and Zhou Z L, J Mater Sci Technol 32 (2016) 671.

Chen Y, Wang H, Wang X Y, Ding H, Zhao J W, Zhang F H, and Ren Z H, Mater Sci Eng A 739 (2019) 272.

Duan R H, Xie G M, Luo Z A, Xue P, Wang C, Misra R D K, and Wang G D, Mater Sci Eng A 791 (2020) 139620.

Yu M R, Zhao H Y, Jiang Z H, Guo F, Zhou L, and Song X G, J Mater Process Tech 270 (2019) 274.

Wang T H, Sidhar H, Mishra R S, Hovanski Y, Upadhyay P, and Carlson B, Mater Des 174 (2019) 107795.

Su J Q, Nelson T W and Sterling C J, Mater Sci Eng A 405 (2005) 277.

Chen Y, Wang H, Ding H, Zhao J W, Zhang F H, and Ren Z H, J Mater Eng Perform 28 (2019) 2845.

Zhao H Y, Yu M R, Jiang Z H, Zhou Li, and Song X G, J Alloy Compd 789 (2019) 139.

Wang L, and Huang Y X, Int J Adv Manuf Tech 99 (2018) 1781.

Malopheyev S, Kulitskiy V, Mironov S, Zhemchuzhnikova D, and Kaibyshev R, Mater Sci Eng A 600 (2014) 159.

Chen Y, Jiang Y F, Zhang F H, Ding H, Zhao J W, and Ren Z H, Trans Indian Inst Met 71 (2018) 3077.

Wang T, Sidhar H, Mishra R S, Hovanski Y, Upadhyay P, and Carlson B, Sci Technol Weld Join 24 (2019) 178.

Cox C D, Gibson B T, Strauss A M, and Cook G E, Mater Manuf Process 27 (2012) 472.

Ji S D, Sun X, Ma Z W, Gong P, and Wen Q, Mater Sci Eng A 800 (2021) 140369.

Acknowledgements

This project is supported by National Natural Science Foundation of China (Grant No.52005090), Natural Science Foundation of Liaoning Province (Grant No.2020-BS-051), Fundamental Research Funds for the Central Universities of China (Grant No.N2103012) and National Defense Key Disciplines Laboratory of Light Alloy Processing Science and Technology, Nanchang Hangkong University (Grant No.EG202080409).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, Y., Cai, Z., Ding, H. et al. Characteristics of Dissimilar Aluminum/Steel Joint Fabricated Via Self-Riveting Friction Stir Lap Welding. Trans Indian Inst Met 74, 2621–2629 (2021). https://doi.org/10.1007/s12666-021-02327-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02327-1