Abstract

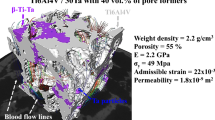

As a new biomedical bone tissue implant candidate, porous Ti–5Mo–5Cu alloy was developed by powder sintering from TiH2, Mo and Cu powders. Space holder material NH4HCO3 granules were added to regulate the pore characteristics like pore morphology and porosity and then mechanical properties including compressive strength and elastic modulus of the porous titanium alloy. The tailored elastic modulus (1.8–6.4 GPa) and compressive strength (93–152 MPa) of porous Ti–5Mo–5Cu alloys with porosity (49.6–61.8%) and average pore size (103–128 μm) fulfil the preliminary mechanical property and pore characteristics requirements of porous prosthesis. It is expected to be used for hard tissue prosthesis.

Similar content being viewed by others

References

Kaur M, and Singh K, Mater Sci Eng C 102 (2019) 844.

Niinomi M, Nakai M, and Hieda J, Acta Biomater 8 (2012) 3888.

Liu X, Chu PK, and Ding C. Mater Sci Eng R 47 (2004) 49.

Takeuchi Y, Tanaka M, Tanaka J, Kamimoto A, Furuchi M, and Imai H, J Prosthod Res 64 (2020) 1.

Djouina M, Esquerre N, Desreumaux P, Vignal C, and Body-Malapel M, Food Chem Toxicol 91 (2016) 108.

Costa BC, Tokuhara CK, Rocha L A, Oliveira RC, Lisboa-Filho PN, and Pessoa JC, Mater Sci Eng C 96 (2019) 730.

Li YH, Chen N, Cui HT, and Wang F, J Alloys Compd 723 (2017) 967.

Oliveira CSS, Griza S, Oliveira MV, Ribeiro AA, and Leite MB, Powder Technol 281 (2015) 91.

Wang X, Li Y, Xiong J, Hodgson PD, and Wen C, Acta Biomater 5 (2009) 3616.

Xu JL, Tao SC, Bao LZ, Luo JM, and Zheng YF, Mater Sci Eng C 97 (2019):156.

Yang D, Shao H, Guo Z, Liu X, and Ji Y, Biomed Mater 6 (2011) 045010.

Okulov IV, Okulov AV, Volegov AS, and Markmann J, Scripta Mater 154 (2018) 68.

Zhao L, Pei X, Jiang L, Hu C, Sun J, Xing F, Zhou C, Fan Y, and Zhang X, Compos Part B-Eng 162 (2019) 154.

Brailovski V, Prokoshkin S, Gauthier M, Inaekyan K, Dubinskiy S. Petrzhik M, and Filonov M, Materi Sci Eng C 31 (2011) 643.

Gao Z, Li Q, He F, Huang Y, and Wan Y, Mater Design 42 (2012) 13.

Xie F, He X, Cao S, Mei M, and Qu X, Electrochimica Acta 105 (2013) 121.

Bolat G, Izquierdo J, Gloriant T, Chelariu R, Mareci D, and Souto RM, Corro Sci 98 (2015) 170.

Liu J, Ruan J, Chang L, Yang H, and Ruan W, Mater Sci Eng C 78 (2017) 503.

Caparrós C, Guillem-Martí J, Molmeneu M, Punset M, Calero JA, and Gil FJ, J Mech Behav Biomed Mater 39 (2014) 79.

Hench LL, and Ethripge EC, Biomaterial: An interfacial Approach. Academic Press, New York (1982), p 90.

Rajagopalan KV, Annu Rev Nutr 8 (1988) 401.

Grass G, Rensing C, and Solioz M, Appl Environ Microbiol 77 (2011) 1541.

Zhang E, Li S, Ren J, Zhang L, and Han Y, Mater Sci Eng C 69 (2016)760.

Pypen CM, Dessein K, and Helsen JA, J Mater Sci Mater Med 9 (1998)761.

Liu J, Zhang X, Wang H, Li F, Li M, Yang K, and Zhang E, Biomed Mater 9 (2014) 025013.

Luo J, Guo S, Lu Y, Xu X, Zhao C, Wu S, and Lin J, Mater Charact 143 (2018) 127.

Suchanek W, and Yoshimura M, J Mater Res 13 (1998) 94.

Gibson LJ, and Ashby MF, Cellular Solids: Structure and Properties. Cambridge University Press, Cambridge (1997), p 183.

Acknowledgements

This work was supported by the Natural Science Foundation of Liaoning Province in China. (Grant No. 2019–ZD–0257).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, YH., Shang, XY. Porous Ti–5Mo–5Cu Alloy: Preparation, Microstructure and Mechanical Property. Trans Indian Inst Met 73, 2869–2873 (2020). https://doi.org/10.1007/s12666-020-02077-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-02077-6