Abstract

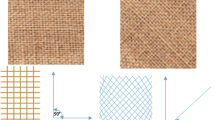

The environmental consciousness and consumer pressure have forced manufacturing industries to use natural fibres as a substitute for conventional non-renewable reinforcing materials. In the present investigation, the effect of rate of loading on jute fibre-reinforced polymer composite was studied. The mechanical properties (in three-point bend test) like interlaminar shear strength, yield strength and energy at break were examined as a function of strain rate. It was observed that the untreated fibre-reinforced composites were not very sensitive to the rate of loading; however, loading rate sensitivity was observed in alkali-treated fibre-reinforced composites. It has been proposed that fibre pull-out dominates over mechanism of composite failure in alkali-treated condition, and the interlaminar shear strength/yield strength was increased due to the increase in stiffness of the composite with rate of loading (in initial stage); however, at higher strain rate, matrix became susceptible to brittleness as there was lesser time available for crack-blunting to take place. All the microstructures were generated using a scanning electron microscope, and mechanical testing was done using tensile testing machine Instron 1195.

Similar content being viewed by others

References

Dhakal H N, Zhang Z Y, and Richardson M O W, Compos Sci Technol67 (2007) 1674.

Thielemans W, Can E, Morye S S, and Wool R P, J Appl Polym Sci83 (2002) 323.

Mishra S, Misra M, Tripathy S S, Nayak S K, and Mohanty A K, Macromol Mater Eng286 (2001) 107.

Wang H, Memon H, AM Hassan E, Miah M, and Ali M, Materials12 (2019) 1226.

Liu X, Featherston C A, and Kennedy D, Compos Struct211 (2019) 337.

Sanjay M R, and Yogesha B, J Miner Mater Charact Eng4 (2016) 15.

Chandramohan D, Murali B, Vasantha-Srinivasan P, and Kumar S D, J Bio Tribo-Corros5 (2019) 66.

Ramnath B V, Manickavasagam V M, Elanchezhian C, Krishna C V, Karthik S, and Saravanan K, Mater Des60 (2014) 643.

Ashik K P, and Sharma R S, J Miner Mater Charact Eng3 (2015) 420.

Pinto M A, Chalivendra V B, Kim Y K, and Lewis A F, Polym Compos35 (2014) 310.

Dobah Y, Bourchak M, Bezazi A, Belaadi A, and Scarpa F, Compos Part B Eng90 (2016) 450.

De Albuquerque A C, Joseph K, de Carvalho L H, and d’Almeida J R, Compos Sci Technol60 (2000) 833.

Bachtiar D, Sapuan S M, and Hamdan M M, Mater Des29 (2008) 1285.

Stocchi A, Lauke B, Vazquez A, and Bernal C, Compos Part A Appl Sci Manuf38 (2007) 1337.

Vilaseca F, Mendez J A, Pelach A, Llop M, Canigueral N, Girones J, Turon X, and Mutje P, Process Biochem42 (2007) 329.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, P., Tiwari, M., Makhatha, M.E. et al. Effect of Rate of Loading on Jute Fibre-Reinforced Polymer Composite. Trans Indian Inst Met 73, 1573–1577 (2020). https://doi.org/10.1007/s12666-020-01934-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-01934-8