Abstract

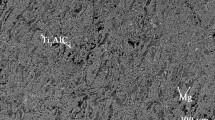

The predominant objective of this exploration is analyses of the wear conduct of pure Mg and Mg–B4C (5–15%) composites developed by powder metallurgy technique. The elemental map and microscopic examination of the composites were executed by energy dispersive spectroscopy (EDS) and scanning electron microscope (SEM) analysis. Wear conduct of the Mg–B4C composites was investigated at 2000 m sliding faraway with about 30, 60 and 90 N varying loads with and distinct sliding paces of 1, 1.5 and 2 m/s. The wear samples surfaces were explored by SEM, EDS and profilometer analysis. The outcomes establish that the Mg–15% B4C specimen has excellent wear behavior. The Mg–15% B4C composite has significantly minimum specific wear rate than that of Mg and Mg–(5–10%) B4C composites under all load conditions. The surface roughness of Mg decreases from 3.718 to 0.647 µm with increasing of B4C inclusion.

Similar content being viewed by others

Abbreviations

- ρ th :

-

Theoretical density (g/cc)

- ρ a :

-

Experimental or actual density (g/cc)

- ρ w :

-

Density of distilled water (g/cc)

- W a :

-

Mass of the specimen in air (g)

- W w :

-

Mass in distilled water (g)

- H v :

-

Microhardness

- D :

-

Crystalline size (nm)

- λ :

-

Wavelength (Å)

- β :

-

Line width

- θ :

-

Angle of diffraction

References

Khandelwal A, Mani K, Srivastava N, Gupta R, and Chaudhari G P, Compos Part B123 (2017) 64.

Kavimani V, Prakash K S, and Thankachan T, Compos Part B162 (2019) 508.

Wang X, Li L, Xie Z, and Yu G, Electrochim Acta283 (2018) 1845.

Gupta M, and Wong W L E, Mater Charact105 (2015) 30.

Dinaharan I, Vettivel S C, Balakrishnan M, and Akinlabi E T, J Magnes Alloys7 (2019) 155.

Falcon-franco L, Bedolla-becerril E, Lemus-ruiz J, Gonzalez-rodríguez J G, Guardian R, and Rosales I, Compos Part B42 (2011) 275.

Zhang Y, Gore P, Rong W, Wu Y, Yan Y, Zhang R, Peng L, Feng Nie J and Birbilis N, Corros Sci136 (2018) 106.

Adsul S H, Soma Raju K R C, Sarada B V, Sonawane S H, and Subasri R, J Magnes Alloys6 (2018) 299.

Ghasali E, Alizadeh M, Niazmand M, and Ebadzadeh T, J Alloys Compd697 (2017) 200.

Viswanath A, Dieringa H, Kumar K K A, Pillai U T S, and Pai B C, J Magnes Alloy3 (2015) 16.

Poddar P, Srivastava V C, De P K, and Sahoo K L, Mater Sci Eng A460 (2007) 357.

Thévenot F, J Eur Ceram Soc6 (1990) 205.

Ghasali E, Alizadeh M, Ebadzadeh T, Pakseresht A, and Rahbari A, Integr Med Res4 (2015) 411.

Dieringa H, J Mater Sci46 (2011) 289.

Domnich V, Reynaud S, Haber R A, and Chhowalla M, J Am Ceram Soc94 (2011) 3605.

Jung J, and Kang S, J Am Ceram Soc87 (2004) 47.

Asgari A, Sedighi M, and Krajnik P, J Clean Prod232 (2019) 1187.

Kubasek J, Dvorsky D, Cavojsky M, Vojtech D, Beronska N, and Fousova M, J Mater Sci Technol33 (2016) 652.

Yan Y, Cao H, Kang Y, Yu K, Xiao T, Luo J, Deng Y, Fang H, Xiong H and Dai Y, J Alloys Compd693 (2016) 1277.

Guleryuz L F, Ozan S, Uzunsoy D, and Ipek R, Powder Metall Met Ceram51 (2012) 456.

Ren Z, Zhang X G, Sui L, Zhang T, Pang L, and Jin J Z, Mater Res Innov14 (2010) 206.

Zhenzhen W, Xiaoshan L, Guoqiu H, Jingquan L, Bin G, and Peiwen L, Mater Res Express6 (2019) 096563.

Aatthisugan I, Razal Rose A, and Selwyn Jebadurai D, J Magnes Alloy5 (2017) 20.

Li X, Shi T, Zhang C, Li S, Zhang J, and Zhang L C, Mater Res Express5 (2018) 086502.

Majzoobi G H, Rahmani K, and Atrian A, Mater Res Express5 (2018) 015046.

Yang Z R, Wang S Q, Zhao Y T, and Wei M X, Mater Charact61 (2010) 554.

Wang Y Q, Afsar A M, Jang J H, Han K S, and Song J I, Wear268 (2010) 863.

Selvam B, Marimuthu P, Narayanasamy R, Anandakrishnan V, Tun K S, Gupta M, and Kamaraj M, Mater Des58 (2014) 475.

Narayanasamy P, Selvakumar N, and Balasundar P, Trans Indian Inst Met68 (2015) 911.

Labib F, Ghasemi H M, and Mahmudi R, Wear348 (2016) 69.

Habibnejad Korayem M, Mahmudi R, Ghasemi H M, and Poole W J, Wear268 (2010) 405.

Yuan C Q, Peng Z, Yan X P, and Zhou X C, Wear265 (2008) 341.

Kubiak K J, Liskiewicz T W, and Mathia T G, Tribol Int44 (2011) 1427.

Ramanan G, Suresh S, Rajesh Prabha N, and Edwin Raja Dhas J, Mater Res Express6 (2019) 066544.

Manivannan I, Ranganathan S, Gopalakannan S, and Suresh S, Trans Indian Inst Met71 (2018) 1897.

MPIF Standard 42, Determination of Density of Compacted or Sintered Metal Powder products, Metal Powder Industries Federation (1977).

Navaneetha Krishnan M, Suresh S, and Vettivel S C, J Alloys Compd747 (2018) 324.

Vettivel S C, Selvakumar N, Leema N, and Haiter Lenin A, Mater Des56 (2014) 791.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Navaneetha Krishnan, M., Suresh, S. & Vettivel, S.C. Effects on Micro-Surface Texturing of Mg/B4C Matrix Composites Under Dry Sliding Wear Condition. Trans Indian Inst Met 73, 897–912 (2020). https://doi.org/10.1007/s12666-020-01913-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-01913-z