Abstract

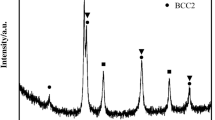

The microstructure, electrochemical corrosion behaviour and microhardness of Fe1.5CoNiCrCux (x = 0.5, 1.0, 1.5 and 2.0) high-entropy alloys (HEAs) were investigated by X-ray diffraction (XRD), scanning electron microscopy and an electrochemical workstation. The XRD spectra of Fe1.5CoNiCrCux HEAs confirmed the face-centred cubic solid solution structure and that all specimens consisted of an fcc matrix and a Cu-rich fcc phase. The results of electrochemical corrosion tests showed that Fe1.5CoNiCrCu0.5 HEAs exhibited low corrosion rates owing to their high corrosion potential and low corrosion current density. The major types of corrosion for Fe1.5CoNiCrCux HEAs belong to localised corrosion and pitting, which is attributed to Cu-rich and Cr-depleted phases in the interdendritic region. The microhardness of Fe1.5CoNiCrCux HEAs increases from 142 HV for alloys with x = 0.5 to 190 HV for alloys with x = 2.0.

Similar content being viewed by others

References

Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, Tsau C H, and Chang S Y, Adv Eng Mater6 (2004) 299.

Yeh J W, Chang S Y, Hong Y D, Chen S K, and Lin S J, Mater Chem Phys103 (2007) 41.

Zhou Y J, Zhang Y, Wang Y L, and Chen G L, Appl Phys Lett90 (2007) 181904.

Saikumaran A, Mythili R, Saroja S, and SrihariYe V, T Indian I Met72 (2019) 111.

Chen Y Y, Dural T, Hung U D, Yeh J W, and Shih H C, Corros Sci47 (2005) 2257.

Laws K J, Crosby C, Sridhar A, Conway P, Koloadin L S, Zhao M, Aron-Dine S, and Bassman L C, J Alloys Compd650 (2015) 949.

Zhang H, Pan Y, and He Y Z, Mater Des32 (2011) 1910.

Miracle D B, Senkov O N, Acta Mater122 (2017) 448.

Xu X D, Liu P, Guo S, Hirata A, Fujita T, Nieh T G, Liu C T, and Chen M W, Acta Mater84 (2015) 145.

Wang Z Q, Wang X R, Yue H, Shi G T, and Wang S H, Mater Sci Eng A627 (2015) 391.

Wu P H, Liu N, Yang W, Zhu Z X, Lu Y P, and Wang X J, Mater Sci Eng A642 (2015) 142.

He F, Wang Z J, Zhu M, Li J J, Dang Y Y, and Wang J C, Mater Des85 (2015) 1.

He J Y, Wang H, Wu Y, Liu X J, Mao H H, Nieh T G, and Lu Z P, Intermetallics79 (2016) 41.

Lu Y P, Dong Y, Guo S, Jiang L, Kang H J, Wang T M, Wen B, Wang Z J, Jie J C, Cao Z Q, Ruan H H, and Li T J, Sci Rep4 (2014) 6200.

Hsu Y J, Chiang W C, and Wu J K, Mater Chem Phys92 (2005) 112.

Lin C M, and Tsai H L, Mater Chem Phys128 (2011) 50.

Lin C M, and Tsai H L, J Alloys Compd489 (2010) 30.

YB/T 5337–2006, The Lattice Constant Determination of Metals–Method of X–ray Diffractometer (2006) p. 278.

Du W D, Liu N, Zhou P J, Wang X J, Wang B, and Peng Z, Int J Mater Res109 (2018) 844.

Verma A, Tarate P, Abhyankar A C, Mohape M R, Gowtam D S, Deshmukh V P, and Shanmugasundaram T, Scr Mater161 (2019) 28.

de Boer F R, Boom R, Mattens W C M, Miedema A R, and Niessen A K, Cohesion and Structures Vol.1: Cohesion in Metals–Transition Metal Alloys, North Holland, Amsterdam (1988), p. 179.

Ismail K M, Fathi A M, and Badawy W A, Corro Sci48 (2006) 1912.

Hurtado M R F, Simodjo P T A, and Benedetti A V, Electrochim Acta48 (2003) 2791.

Lin C M, Tsai H L, and Bor H Y, Intermetallics18 (2010) 1244.

Badawy W A, Al-Kharafi F M, and El-Azab A S, Corros Sci41 (1999) 709.

Rosalbino F, Angelini E, Zanicchi G, Carlini R, and Marazza R, Electrochim Acta54 (2009) 7231.

Yang X, and Zhang Y. Mater Chem Phys132 (2012) 233.

Guo S, Ng C, Lu J, and Liu C T, J Appl Phys109 (2011) 103505.

Guo S, and Liu C T, Prog Nat Sci21 (2011) 433.

Chen H H, Metallic Corrosion, Beijing Institute of Technology Press, Beijing (1995), p. 86.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant nos. 51301125, 51671151), China Scholarship Council (CSC) and Key Laboratory Scientific Research Program of Education Department of Shaanxi Province, China (Grant no. 17JS055).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, M., Li, K., Liu, Y. et al. Microstructure, Corrosion Behaviour and Microhardness of Non-equiatomic Fe1.5CoNiCrCux (0.5 ≤ x ≤ 2.0) High-Entropy Alloys. Trans Indian Inst Met 73, 389–397 (2020). https://doi.org/10.1007/s12666-019-01850-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01850-6