Abstract

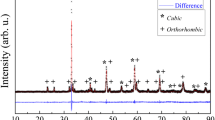

The electrocrystallisation of the alloys of Cox–Cu100−x onto stainless steel cathode was investigated by performing cyclic voltammetry (CV) to understand the mechanism of deposition. The deposit morphology and crystal structure of deposit were analysed using scanning electron microscopy (SEM) and X-ray diffraction (XRD), respectively. The kinetic parameters were obtained from the cathodic polarisation of the CV to predict the electron transfer mechanism in the process. The transfer coefficient value (α) of the kinetic parameter revealed that both cathodic and anodic processes were unsymmetrical. It was demonstrated that the current efficiency of the deposit increased from 96.8% at pH 4.0 to 99.2% at pH 7, and then it dropped to 89.7% at pH 8. Before the deposition of the Co–Cu alloy, the initial copper deposition occurred at − 0.24 V and peaked at − 0.66 V. This was followed by the deposition of the Co–Cu alloy at − 1.04 V, which occurred after the deposition potential of Cu2+ (− 0.24 V) and Co2+ (− 0.89 V). The current then increasesd with a small increment in applied potential due to subsequent diffusion-controlled copper reduction along with the co-deposition of Co. The variation in the kinetic parameters was also reflected in the current efficiencies, the deposit morphologies, the crystallographic orientations and the nucleation overpotential values. The percentage of cobalt content in the alloy was observed to decrease in at.% from 54.35% at pH 4 to 49.86% at pH 6 and further to 20.62% at pH 8. The structure of the deposited alloy confirmed the formation of a single solid solution phase having different planes such as (222), (311), (220), (200) and a sharp peak due to face-centred cubic structure with (111) plane. This strong peak along with other similar peaks were observed in all the XRD of the deposit obtained at pH 4, 6 and 8. The morphology of the deposit characterised by the SEM showed that the deposit changed from a bitter gourd to a regular cauliflower-like structure as the pH value changed from 4 to 8.

Similar content being viewed by others

References

Y Nakamoto, M Yuasa, Y Chen, H Kusuda, and M Mabuchi, Scr Mater58 (2008) 731.

T Cohen-Hyams, W D Kaplan, D Aurbach, Y S Cohen, and J Yahalom, J Electrochem Soc150 (2003) C28.

S Kashiwabara, and Y Jyoko, J Electrochem Soc144 (1997) L193.

E Gomez, A Labarta, A Llorente, and E Valles, J Electroanal Chem517 (2001) 63.

Y Z Fang, Y Liu, and L H Zhang, Appl Catal A Gen397 (2011) 183.

A Cao, G Liu, Y Yue, L Zhang, Y Liu, RSC Adv5 (2015) 58804.

S S Abd El-Rehim, S M Abd El-Wahab, S M Rashwan, and Z M Anwar, J Chem Technol Biotechnol75 (2000) 237.

T Nishizawa, and K Ishida, Bull Alloy Phase Diagr5 (1984) 161.

S Gu, P Atanasova, M J Hampden-smith, T T Kodas, Thin Solid Films340 (1999) 45.

Y Huai, M Chaker, H Pépin, S Boily, X Bian, and R W Cochrane, J Magn Magn Mater136 (1994) 204.

C Gente, M Oehring, and R Bormann, Phys Rev B48 (1993) 13244.

D L Khalyapin, P D Kim, J Kim, I A Turpanov, G V Bondarenko, and T N Isaeva, I Kim, Phys Solid State52 (2010) 1787.

P E Bradley, and D Landolt, Electrochim Acta45 (1999) 1077.

E Gomez, A Llorente, X Alcobe, and E Vallés, J Solid State Electrochem8 (2004) 82.

Labarta A, A Llorente, and E Valles, Surf Coat Technol153 (2002) 261.

R L Anton, M L Fdez-Gubieda, A Garcia-Arribas, J Herreros, and M Insausti, Mater Sci Eng A335 (2002) 94.

L T De Farias, A S Luna, R De Janeiro, R São, and F Xavier, Mater Res11(2008) 1.

S K Ghosh, T Bera, C Saxena, S Bhattacharya, and G K Dey, J Alloys Compd475 (2009) 676.

Y Liu, and W Wang, Electrochem Soc159 (2012) D375.

C D Grill, J P Kollender, and A W Hassel, J Electrochem Soc163 (2016) D3069.

Y Ueda, and M Ito, Jpn J Appl Phys33 (1994) L1403.

Y Jyoko, S Kashiwabara, and Y Hayashi, J Electrochem Soc144 (1997) L5.

H Zaman, A Yamada, H Fukuda, and Y Ueda, J Electrochem Soc145(1998) 565.

Y Ueda, T Houga, H Zaman, and A Yamada, J Solid State Chem147 (1999) 274.

L Péter, A Cziráki, L Pogány, Z Kupay, I Bakonyi, M Uhlemann, M Herrich, B Arnold, and T W K Bauer, J Electrochem Soc148 (2001) C168.

T Ohgai, X Hoffer, L Gravier, and J P Ansermet, J Appl Electrochem34 (2004) 1007.

Q-X Liu, L Péter, J Pádár, and I Bakonyi, J Electrochem Soc152 (2005) C316.

Y Lia, R Fan, M Moldovan, D P Young, W Wang, and E J Podlaha, ECS Trans2 (2007) 379.

S Zsurzsa, L Peter, L F Kiss, and I Bakonyi, J Magn Magn Mater421 (2017) 194.

T Wang, F Li, Y Wang, and L Song, Phys Stat Sol(a)203 (2006) 2426.

J H Min, J H Wu, J U Cho, Q X Liu, J H Lee, Y D Ko, J S Chung, J H Lee, K Y Kim. J Magn Magn Mater304 (2006) e100.

A Hannour, R Lardé, M Jean, J Bran, P Pareige, and J M Le Breton, J Appl Phys110 (2011) 63921.

A Franczak, A Levesque, P Zabinski, D Li, M Czapkiewicz, R Kowalik, F Bohr, Q Wang, and J-P Chopart, Mater Chem Phys162 (2015) 222.

A Tekgul, H Kockar, H Kuru, and M Alper, Z. Naturforsch73 (2018) 127.

T M de Souza, D C B do Lago, and L F de Senna, Mater Res22 (2019) 1.

J J Kelly, M Cantoni, and D Landolt, J Electrochem Soc148 (2001) C620.

J J Kelly, P E Bradley, and D Landolt, J Electrochem Soc147 (2000) 2975.

A E Mohamed, S M Rashwan, S M Abdel-Wahaab, and M M Kamel, J Appl Electrochem33 (2003) 1085.

M Gu, Electrochim Acta52 (2007) 4443.

K Ignatova, and L Petkov, J Univ Chem Technol Metall44 (2009) 133.

K Ignatova, and D Lilova, J Chem Technol Metall51 (2016) 173.

L Mentar, M R Khelladi, A Azizi, G Schmerber, and A Dinia, Trans Inst Met Finish89 (2011) 143.

L Mentar, M R Khelladi, A Azizi, and A Kahoul, Trans IMF90 (2012) 98.

M R Khelladi, L Mentar, A Azizi, L Makhloufi, G Schmerber, and A Dinia, J Mater Sci Mater Electron23 (2012) 2245.

G Senthilkumar, and S Ramachandran , in IEEE Proc Frontiers in Automobile and Mechanical Engineering, 25–27 Nov (2010) 257. https://doi.org/10.1109/fame.2010.5714837.

K G Mishra, and R K Paramguru, J Electrochem Soc143 (1996) 510.

K G Mishra, and R K Paramguru, Metall Mater Trans B 30 (1999) 223.

M Ved, N Sakhnenko, M Glushkova, and T Bairachna, Chem Chem Technol8 (2014) 275.

K G Mishra, and R K Paramguru, Afr J Pure Appl Chem4 (2010) 87.

S Mishra, S K Nathsharma, K G Mishra, and R K Paramguru, J Electrochem Soc165 (2018) D206.

R K Paramguru, and S B Kanungo, Can Metall Quart37 (1998) 389.

R K Paramguru, K G Mishra, and S B Kanungo, Can Metall Quart37 (1998) 395.

R K Paramguru, and S B Kanungo, Can Metall Quart37 (1998) 405.

K G Mishra, and R K Paramguru, J Electrochem Soc147 (2000) 3302.

M Kanungo, V Chakravarty, K G Mishra, and S C Das, Hydrometallurgy61 (2001) 1.

K G Mishra, P Singh, and D M Muir, Hydrometallurgy65 (2002) 97.

Mishra KG, Singh P, Hefter G and Muir D, Metall Mater Trans B33B (2002) 137.

R Y Ying, J Electrochem Soc135(1988) 2964.

E Gómez, A Llorente, and E Vallés, J Electroanal Chem495 (2000) 19.

G R Pattanaik, D K Pandya, and S C Kashyap, J Electrochem Soc149 (2002) C363.

P Jiao, N Duan, C Zhang, F Xu, G Chen, J Li, and L Jiang, Int J Hydrog Energy41 (2016) 17793.

T G de Lima, B C C A Rocha, A V C Braga, D C B do Lago, A S Luna, and L F Senna, Surf Coat Technol276 (2015) 606.

Acknowledgements

The authors are obliged to the SERB, DST, New Delhi, for the financial support, the Kalinga Institute of Industrial Technology, Deemed to be University, Bhubaneswar, and the IMMT, Bhubaneswar, for providing the necessary laboratory and characterisation facilities, respectively, for conducting this research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nathsharma, S.K., Mishra, S., Mishra, K.G. et al. The Effect of Bath Parameters on the Electrocrystallisation of Cox–Cu100−x Alloys on Stainless Steel Cathode. Trans Indian Inst Met 73, 377–387 (2020). https://doi.org/10.1007/s12666-019-01849-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01849-z