Abstract

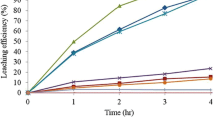

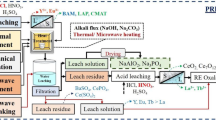

Phosphors made from compounds of rare earth metals (REMs) are very efficient. This material needs to be recycled for recovery of REMs after the fluorescent lamps (FLs) reach end of life. This work focuses on the leaching studies of REMs from phosphor. The phosphor was recovered from the spent linear FLs by end cut-push method. After detailed characterization of phosphor, effects of parameters viz. leachant, concentration, temperature, and pulp density were studied to determine the optimum leaching conditions. By using 9% (v/v) H2SO4, 98.6% (w/w) yttrium and 96.2% (w/w) europium could be leached out from phosphor at temperature, 70 °C, time, 4 h, and pulp density, 10% (w/v). The residue generated was treated with 54% (v/v) HCl to leach out 98.9% (w/w) lanthanum, 98.2% (w/w) cerium and 96.5% (w/w) terbium at temperature, 90 °C, time, 2 h, and pulp density, 10% (w/v). Kinetic studies of leaching reactions were also carried out.

Similar content being viewed by others

References

Gupta C K, and Krishnamurthy N, Extractive Metallurgy of Rare Earths, 2nd edn, CRC Press, Boca Raton (2016).

Bauer D, Diamond D, Li J, Sandalow D, Telleen P, and Wanner B, Critical Materials Strategy, a report by US department of energy. URL https://www.energy.gov/sites/prod/files/DOE_CMS2011_FINAL_Full.pdf (2011) (accessed 12.11.18).

Humphries M, Rare Earth Elements: The Global Supply Chain, (2013).

E-waste Market Grew Nearly 10% in 2010; Growth Expected Through Decade. URL https://www.sbireports.com/about/release.asp?id=2468 (2011) (accessed 3.4.17).

Meyer L, and Bras B, in Proc. International Symposium on Sustainable Systems and Technology, IEEE, Chicago, p 1 (2011).

Statistics for Lighting Industry in India, 2015. URL http://www.elcomaindia.com/wp-content/uploads/FINAL_2015_Lighting_Industry_India.pdf (2015) (accessed 3.15.17).

Liu H, Zhang S, Pan D, Tian J, Yang M, Wu M, et al., J Hazard Mater 272 (2014) 96.

Tunsu C, Petranikova M, Ekberg C, and Retegan T, Sep Purif Technol 161 (2016) 172.

Nakamura T, Nishihama S, and Yoshizuka K, Solvent Extr Res Dev, Jpn 14 (2007) 105.

Takahashi T, Takano A, Saitoh T, Nagano N, Hirai S, and Shimakage K, Shigen to Sozai 117 (2001) 579.

Tunsu C, Petranikova M, Gergorić M, Ekberg C, and Retegan T, Hydrometallurgy 156 (2015) 239.

Tunsu C, Ekberg C, and Retegan T, Hydrometallurgy 144–145 (2014) 91.

De Carolis R, Fontana D, Pietrantonio M, Pucciarmati S, and Torelli G N, Environ Eng Manag J 14 (2015) 1603.

Li H, Chin J Rare Met 34 (2010) 21.

De Michelis I, Ferella F, Varelli E F, and Vegliò F, Waste Manag 31 (2011) 2559.

Innocenzi V, De Michelis I, Ferella F, and Vegliò F, Waste Manag 33 (2013) 2390.

Yang F, Kubota F, Baba Y, Kamiya N, and Goto M, J Hazard Mater 254–255 (2013) 79.

Zhang S G, Yang M, Liu H, Pan D A, and Tian J J, Rare Met 32 (2013) 609.

Binnemans K, Jones P T, Blanpain B, Van Gerven T, Yang Y, Walton A, et al., J Clean Prod 51 (2013) 1.

Jüstel T, Nikol H, and Ronda C, Angew Chemie Int Ed 37 (1998) 3084.

Tan Q, Li J, and Zeng X, Crit Rev Environ Sci Technol 45 (2015) 749.

Belardi G, Ippolito N, Piga L, and Serracino M, Thermochim Acta 591 (2014) 22.

Otto R, and Wojtalewicz-Kasprzak A, US Patent 20120027651 A1, (2012).

Innocenzi V, De Michelis I, Ferella F, Beolchini F, Kopacek B, and Vegliò F, Waste Manag 33 (2013) 2364.

Levenspiel O, Chemical Reaction Engineering, 3rd ed., Wiley, London (1999).

Colussi I, Meriani S, and Monte U, Hydrometallurgy 10 (1983) 61.

Miller J D, and Wan R-Y, Hydrometallurgy 10 (1983) 219.

Vaughan D J, and Wogelius R A (Eds.), Environmental Mineralogy II: University Textbook, London European Mineralogical Union and the Mineralogical Society of Great Britain & Ireland, (2013).

Acknowledgements

Infrastructure of the Hydro and Electrometallurgy Department of CSIR-IMMT, CSC0101 (MULTIFUN) and Polymetallic Nodules Programme (MoES, New Delhi) is gratefully acknowledged. The authors are thankful to Dr S.K. Biswal and Mr. S.K Jena, CSIR-IMMT, for their support in characterization of REMs by ICP-OES. J. Samantray is thanked for her help with alkali digestion of phosphor and residue samples.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Anand, A., Singh, R., Sheik, A.R. et al. Leaching of Rare Earth Metals from Phosphor Coating of Waste Fluorescent Lamps. Trans Indian Inst Met 72, 623–634 (2019). https://doi.org/10.1007/s12666-018-1511-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1511-9