Abstract

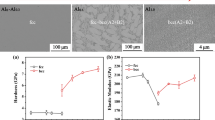

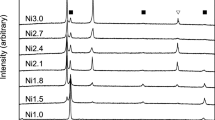

The present investigation reports the effect of aluminum addition on the microstructural evolution in the equiatomic CoCrFeMnNi high-entropy alloy. Aluminum was added to the alloy in varying quantity (0 ≤ Al ≤ 10 at.%) using the vacuum arc melting technique, and phase formation was probed using X-ray diffraction, scanning electron microscopy and transmission electron microscopy. The results indicate that the FCC phase in the alloy remains unaltered up to Al of 5 at.%. The higher amount of Al addition leads to the precipitation of B2 Al(Ni, Cr, Fe, Co, Mn) in the FCC matrix. For Al ≥ 7%, typical phase-separated microstructure consisting of FCC, and B2 phases have been observed. The microstructural changes lead to hardness variation from 1.3 to 2.2 GPa, mainly due to precipitation and solute solution hardening of FCC phase. For FCC phase, Al atoms being larger in size can lead to lattice distortion and improve yield strength. The results have been explained by detailed thermodynamic analysis using HEA3 database.

Similar content being viewed by others

References

Murty B S, Yeh J W, Ranganathan S, Chapter 1—A Brief History of Alloys and the Birth of High-Entropy Alloys. High Entropy Alloys. Butterworth-Heinemann, Boston (2014) p 1.

Sharma A S, Yadav S, Biswas K, Basu B, Mater Sci Eng R Rep 131 (2018) 1.

Miracle D B, Senkov O N. Acta Mater 122 (2017) 448.

Reddy T S, Wani I S, Bhattacharjee T, Reddy S R, Saha R, Bhattacharjee P P. Intermetallics 91 (2017) 150.

Wani I S, Sathiaraj G D, Ahmed M Z, Reddy S R, Bhattacharjee P P. Mater Charact 118 (2016) 417.

Cantor B, Chang I T H, Knight P, Vincent A J B. Mater Sci Eng A 375–377 (2004) 213.

Cantor B, Entropy 16 (2014) 4749.

Yeh J W, Ann Chim - Sci Mat 31 (2006) 633.

Kumar N, Tiwary C S, Biswas K, J Mater Sci 53 (2018) 13411.

Zhao Y Y, Nieh T G, Intermetallics 86 (2017) 45.

He J Y, Liu W H, Wang H, Wu Y, Liu X J, Nieh T G, Lu Z, Acta Mater 62 (2014) 105.

Sun X, Zhang H, Lu S, Ding X, Wang Y, Vitos L, Acta Mater 140 (2017) 366.

Otto F, Dlouhý A, Somsen C, Bei H, Eggeler G, George E P, Acta Mater 61 (2013) 5743.

Schuh B, Mendez-Martin F, Völker B, George EP, Clemens H, Pippan R, Hohenwarter A, Acta Mater 96 (2015) 258.

Tsai K Y, Tsai M H, Yeh J W, Acta Mater 61 (2013) 4887.

Stepanov N, Tikhonovsky M, Yurchenko N, Zyabkin D, Klimova M, Zherebtsov S, Efimov A, Salishchev G, Intermetallics 59 (2015) 8.

Liu T K, Wu Z, Stoica AD, Xie Q, Wu W, Gao YF, Bei H, An K, Mater Des 131 (2017) 419.

Moon J, Bae J W, Jang M J, Baek S M, Yim D, Lee B-J, Kim H S, Mater Chem Phys 210 (2018) 187.

Li C, Li J C, Zhao M, Jiang Q, J Alloys Compd 504 (2010) S515.

Li C, Li J C, Zhao M, Jiang Q, J Alloys Compd 475 (2009) 752.

Varalakshmi S, Kamaraj M, Murty B S, J Alloys Compd 460 (2008) 253.

Wang W R, Wang W L, Wang S C, Tsai Y C, Lai C H, Yeh J W, Intermetallics 26 (2012) 44.

Nelson J B, Riley D P, Proc Phys Soc 57 (1945) 160.

Biswas K, Phanikumar G, Holland-Moritz D, Herlach D M, Chattopadhyay K, Philos Mag 87 (2007) 3817.

Biswas K, Phanikumar G, Chattopadhyay K, Volkmann T, Funke O, Holland-Moritz D, Herlach D M, Mater Sci Eng A 375–377 (2004) 464.

Mridha S, Samal S, Khan P Y, Biswas K, Govind, Metall Mater Trans A 44 (2013) 4532.

Mohanty S, Gurao N P, Biswas K, Mater Sci Eng A 617 (2014) 211.

Mohanty S, Maity T N, Mukhopadhyay S, Sarkar S, Gurao N P, Bhowmick S, Biswas K, Mater Sci Eng A 679 (2017) 299.

Mishra A, Samal S, Biswas K, Trans Indian Inst Met 65 (2012) 725.

Toda-Caraballo I, Rivera-Díaz-del-Castillo P E J, Acta Materialia 85 (2015) 14.

Krishanu Biswas T, Gurao N P, Mater Sci Eng A 657 (2016) 224.

Sahu S R, Devi M M, Mukherjee P, Sen P, Biswas K, J Nanomaterials 2013 (2013) 1.

Acknowledgements

The authors would like to thank Mr. Niraj Nayan from VSSC, Indian Space Research Organization (ISRO) for technical assistance. The authors would like to acknowledge the funding received from ISRO under Respond scheme and Science and Engineering Research Board (SERB) of Department of Science and Technology (DST).

Funding

Funding provided by Science and Engineering Research Board and Indian Space Research Organization is duly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, J., Kumar, N., Das, S. et al. Effect of Al Addition on the Microstructural Evolution of Equiatomic CoCrFeMnNi Alloy. Trans Indian Inst Met 71, 2749–2758 (2018). https://doi.org/10.1007/s12666-018-1443-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1443-4