Abstract

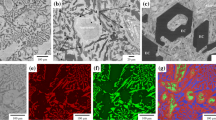

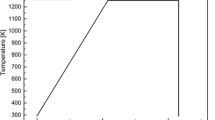

To study the effect of destabilisation period and post-destabilisation cooling rate on the as-cast microstructure, continuous annealing involving prolonged austenitisation for 4 h followed by furnace cooling and cyclic annealing using repeated austenitisation, each of 0.66 h duration, followed by forced-air cooling were carried out at 900, 950, 1000, 1050 and 1100 °C on a 8.0 wt% chromium white iron. Destabilised microstructures show precipitation of secondary carbides on a pearlite plus martensite matrix after continuous annealing treatment and on a martensite plus austenite matrix after cyclic annealing treatment. Both the treatments exhibit characteristic role in monitoring the size and distribution of the secondary carbides and also in modifying the eutectic pattern with varying annealing temperature. At higher temperatures of 1050 and 1100 °C, absence of the secondary carbides becomes a common feature for both the heat treatments; while fragmentation of the eutectic carbides happens to be an additional feature after cyclic annealing of the as-cast alloy.

Similar content being viewed by others

References

ASTM A532 – 87 ‘Standard specification for abrasion—resistant cast irons’, ASTM, Philadelphia.

Tabrett C P, and Sare I R, Scripta Mater 38 (1998) 1747.

Tabrett C P, and Sare I R, Wear 203–204 (1997) 206.

Zum Gahr K H, and Eldis G T, Wear 64 (1980)175.

Inthidech S, Sricharsenchai P, and Matsubara Y, Mater Trans 47 (2006) 72.

Zhi X, Xing J, Gao Y, Fu H, Peng J, and Xiao B, Mater Sci Eng A 487 (2008) 171.

Pearce J T H, Trans AFS 92 (1984) 599.

Laird G II, Rawers J C, and Adams A, Metall Mater Trans 23A (1992) 2941.

Wiengmoon A, Pearce J T H, and Chairuangsri T, Mater Chem Phys 125 (2011) 739.

Maratray F, and Poulation A, Trans AFS 90 (1982) 795.

Powell G L F, and Laird G II, J Mater Sci 27 (1992) 29.

Kuwano M, and Ogi K, AFS Trans 166 (1990) 725.

Yang H S, Jun W, Shen B L, Liu H H, Gao S J, and Huang S J, Wear 261 (2006) 1150.

Jacuinde A B, Bainforth M W, and Mejla I, Metall Mater Trans 44A (2013), 856.

Durman R W, Br Foundrym 69 (1976) 141.

Zum Gahr K H, and Scholz W G, J Metall 38 (1980) 34.

Parks J L, Trans AFS 86 (1978) 93.

Liu H, Wang J, Shen B L, Yang H, Gao S, and Si-Jiu H, Mater Des 28 (2007) 1059.

Wang J, Zuo R L, Sun Z P, Li C, Liu H, Yang H S, Shen B L, and Huang S J, Mater Charact 55 (2005) 234.

Kosasu P, Inthidech S, Sriprateep K, and Matsubara Y, Mater Trans 57 (2016) 174.

Speer J, Matlock D K, De Cooman B C, and Schroth J G, Acta Mater 51 (2003) 2611.

Hsu T Y, Mater Sci Forum 561 (2007) 2283.

Zuo X W, Chen N L, Gao F, and Rong Y H, Int Heat Treat Surf Eng 8 (2014) 15.

Jia X, Hao Q, Zuo X, Chen N, and Rong Y, Mater Sci Eng A 618 (2014) 96.

Jia X, Zuo X, Liu Y, Chen N, and Rong Y, Metall Mater Trans 46A (2015) 5514.

Tabrett C P, Sare I R, and Ghomaschi M R, Int Mater Rev 41 (1996) 59.

Matsuo T T, Kiminami C S, Fo W J B, and Bolfarini C, Wear 259 (2005) 445.

Lu B, Luo J, and Chiovelli S, Metall Mater Trans 37A (2006) 3029.

Kim C K, Lee S, and Jung J Y, Metall Mater Trans 37A (2006) 633.

Jacuinde A B, Correa R, Mejia I, Quezada J G, and Rainforth W M, Wear 263 (2007) 808.

Correa R, Jacuinde A B, Silva J Z, Cardoso E, and Mejia I, Wear 267 (2009) 495.

Chen X, and Li Y X, Mater Sci Eng A 528 (2010) 770.

Penagos J J, Ono F, Albertin E, and Sinatora A, Wear 340–341 (2015) 19.

Gates J D, de Glas M, Lakeland K D, and Cristaudo J W, in Proc Australian Foundry Inst. annu conf ‘Where is the 90’s?’ Gold Coast, Qld Oct (1990), p 16.

Durman R W, and Elwell D W J, UK Pat. No. 2167438A (1985).

Saha A, Mondal D K, Maity J, J Mater Eng Perform 20 (2011) 114.

Pearce J T H, Foundryman 95 (2002) 156.

Gasan H, and Erturk F, Metall Mater Trans 44A (2013) 4993.

Inrahim K M, and Ibrahim M M, J Metall. 2014 (2014) 856408.

Saverna J, Schissler J M, and Masounave J, Bull Cercle Etud Metaux 15 (1989) 19.6.

Powell G L F, and Heard L S, in Proc conf ‘Metals in Mining’, Gold Cost, Qld May (1981), p 633.

Wang J, Xiong J, Fan H, Yong H-S, Liu H-H, and Shen B-L, J Mater Process Technol 209 (2009) 3236.

Wang J, Li C, Liu H, Yang H, Shen B, Gao S, and Huang S, Mater Charact 56 (2006) 73.

Cullity B D, Elements of X-ray Diffraction, 2nd ed., Addison-Wisley Pub Co Inc, Boston (1978), p 412.

Tian Y L, and Kraft R W, Metall Mater Trans 18A (1987) 1403.

Maity J, Saha A, Mondal D K, and Biswas K, Philos Mag Lett 93 (2013) 231.

Speich G R, and Szirmac A, Trans Metall Soc AMIE 245 (1969)1063.

Kumar R, Physical Metallurgy of Iron and Steel, Asia Pub. House, Delhi (1968), p 92.

Wang Y P, Li D Y, Parent L, and Tian H, Wear 271 (2011) 1623.

Haasen P, Physical Metallurgy, 3rd ed., Cambridge Univ. Press, Cambridge (1997), p 168.

Acknowledgements

The authors would like to thank the Director and Dean-Research & Consultancy, National Institute of Technology, Durgapur, India for supporting the current research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mandal, S.S., Ghosh, K.S. & Mondal, D.K. Effect of Destabilisation Period and Post Destabilisation Cooling Rate on the Evolution of Microstructure in 8.0 wt% Chromium White Cast Iron. Trans Indian Inst Met 71, 2067–2081 (2018). https://doi.org/10.1007/s12666-018-1341-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1341-9