Abstract

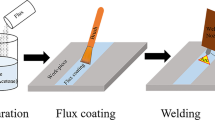

In this study, X80 pipeline steel was welded by self-made welding electrode with different Cu/Al ratios in flux coating. The microstructure and mechanical properties of X80 steel welding seam were investigated by optical microscope, energy-dispersive spectroscopy, scanning electron microscope, X-ray diffraction. The hardness, tensile and impact tests were carried out. The electrochemical corrosion and uniform corrosion properties of welding seam were also studied in sulfide environment. The experimental results reveal that alloying agent such as Cu and Al can transform to the welding seam very well. Furthermore, the microstructure and properties of welding seam can be improved effectively with a suitable Cu/Al content ratio. By reducing the Cu/Al content ratio, the mechanical properties and corrosion resistance properties increase initially and then decrease. When the Cu/Al ratio is maintained at 6:2 in the flux coating, the welding seam has more acicular ferrite, resulting in the best mechanical properties and corrosion resistance. Moreover, the addition of Cu and Al elements does not result in a serious deterioration of the resistance to HIC.

Similar content being viewed by others

References

Kong D J, Wu Y Z and Long D, J Iron Steel Res Int 20 (2013) 40.

Corbett K T, Bowen R R and Petersen C W, Int J Offshore Polar 14 (2004) 75.

Moro I, Briottet L, Lemoine P, Andrieu E, Blanc C and Odemer G, Mat Sci Eng A 527 (2010) 7252.

Huang B S, Chen X, Chen Y B and Li Y B, J Mater Eng 44 (2016) 107.

Wang Y X, Zhao W M, Ai H, Zhou X G and Zhang T M, Corros Sci 53 (2011) 2761.

Qi Y M, Luo H Y, Zheng S Q, Chen C F and Lv Z G, Mater Des 58 (2014) 234.

Deng W, Gao X H, Zhao D W, Du L X, Wu D and Wang G D, J Mater Sci Technol 26 (2010) 803.

Han S Y, Shin S Y, Seo C-H, Lee H, Bae J-H, Kim K, Lee S and Kim N J, Metall Mater Trans A 40 (2009) 1851.

Zhou M, J Wuhan Univ Technol 27 (2012) 252.

Strafford K N, Datta P K, Hampton A F and Mistry P, Corros Sci 29 (1989) 673.

La P Q, Meng Q, Yao L and Wei Y P, Acta Metall Sin 49 (2013) 739.

Chen G Q, Zhang B G, Liu W and Feng F C, Rare Metal Mat Eng 42 (2013) 452.

Habazaki H, Mitsui H, Ito K, Asami K, Hashimoto K and Mrowec S, Corros Sci 44 (2002) 285.

Zheng Y, Xiao W L, Ge S J, Zhao W T, Hanada S J and Ma C L, J Alloys Compd 649 (2015) 291.

Wu C-T, Lee S-L, Hsieh M-H and Lin J-C, Metall Mater Trans A 61 (2010) 1074.

Wang L W, Liu Z Y, Cui Z Y, Du C W, Wang X H and Li X G, Corros Sci 85 (2014) 401.

Shahi A S and Pandey S, J Mater Process Technol 196 (2008) 339.

Shim J-H, Cho Y W, Shim J-D, Oh Y-J, Byun J-S and Lee D N, Metall Mater Trans A 32 (2001) 75.

Hannerz N E, Weld World 26 (1988) 326.

Widgery D, Met Const 10 (1978) 480.

Wiengmoon A, Pearce J T H, Nusen S and Chairuangsri T, Mater Charact 120 (2016) 159.

Acknowledgements

This work was financially supported by Key Laboratory of Ministry of Education of Oil & Gas Equipment (Fund Number OGE201402-02) and Key Laboratory of Oil & Gas Fields Materials of Sichuan Province Universities and Colleges (Fund Number X151517KCL01).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, B., Zhao, X., Chen, P. et al. Influence of the Flux Coating with Different Cu/Al Ratios on X80 Pipeline Steel Welding Seam. Trans Indian Inst Met 71, 1137–1147 (2018). https://doi.org/10.1007/s12666-017-1249-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-017-1249-9