Abstract

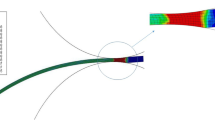

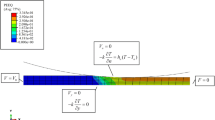

A transient thermo-mechanically coupled Finite Element Method based model for single pass hot rolling of AA 5083 aluminum alloy is developed. The formulation is based on thermo-viscoplastic behavior expressed by the Perzyna constitutive equation and rolling under plane-strain conditions. The finite element model is integrated with a microstructural model where dynamic recrystallization through particle stimulated nucleation and static recrystallization is considered. The dynamic recrystallization model is an adoption of discontinuous dynamic recrystallization model while static recrystallization model is based on Avrami equation. The simulation results indicate that accurate estimates of constitutive behavior of the alloy, efficiency of conversion of plastic deformation to heat, and heat transfer at the roll/metal interface are critical for precise hot rolling model.

Similar content being viewed by others

References

Oh S-I, and Altan T, Metal Forming and the Finite-Element Method, Oxford University Press, Oxford (1989).

Zienkiewicz O C, and Taylor R L, The Finite Element Method, Vol. 1, McGraw-Hill, London (1989).

Hwang S, Joun M S, and Kang Y, J Manuf Sci Eng, 115 (1993) 290.

Zienkiewicz O, Oñae E, and Heinrich J, Int J Numer Methods Eng 17 (10) (1981) 1497.

Alberti N, Cannizzaro L, and Micari F, CIRP Ann Manuf Technol 39 (1990) 231.

Montmitonnet P, Chenot J L, Bertrand-Corsini C, David C, Lung T, Buessler P, J Manuf Sci Eng 114 (1992) 336.

Shah R K, Roshan H M D, Sastri V M K, and Padmanabhan K A Thermomechanical aspects of manufacturing and materials processing. Hemisphere Publishing Corp., New York, United States (1992).

Wells M A, Maijer D M, Jupp S, Lockhart G, Van der Winden M R, Mater Sci Technol 19 (2003) 467.

Ahmed H, Wells M A, Maijer D M, Howes B ., and Van Der Winden M R, Mater Sci Eng A 390 (2005) 278.

Gottstein G, Integral Materials Modeling: Towards Physics-Based Through-Process Models, Wiley, New York (2007).

Hirsch J, Virtual Fabrication of Aluminum Products: Microstructural Modeling in Industrial Aluminum Production, Wiley-VCH, Weinheim (2007).

Sherstnev P, Melzer C, and Sommitsch C, Int J Mech Sci 54 (2012) 12.

Pietrzyk M, Kusiak J, Kuziak R, Madej Ł, Szeliga D, and Gołąb R, Metall Mater Trans A 45 (13) (2014) 5835.

Bambach M and Seuren S, J Mater Process Technol 216 (2015) 95.

De Pari L, and Misiolek W Z, Acta Mater 56 (20) (2008) 6174.

Shahani A R, Setayeshi S, Nodamaie S A, Asadi M A, and Rezaie S, J Mater Process Technol 209 (2009) 1920.

McQueen H J, Spigarelli S, Kassner M E, and Evangelista E, Hot Deformation and Processing of Aluminum alloys, CRC Press, Boca Raton (2011).

Montheillet F, and Jonas J, ASM Handb 22 (2009) 220.

Sandström R, and Lagneborg R, Acta Metall 23 (1975) 387.

ANSYS V, 10.0 User’s Manual, ANSYS Inc, Canonsburg (2004).

Montmitonnet P, and Buessler P, ISIJ Int 31 (1991) 525.

Chen B, Thomson P, and Choi S, J Mater Process Technol 30 (1992) 115.

Timothy S P, Yiu H L, Fine J M, and Ricks R A, Mater Sci Technol 7 (1991) 255.

Ahmed H, Wells M A, Maijer D M, Lockhart G, and Van der Winden M R, Metall Mater Trans A 38 (2007) 922.

Pietrzyk M, Cser L, and Lenard J, Mathematical and Physical Simulation of the Properties of Hot Rolled Products, Elsevier, Amsterdam (1999).

Perzyna P, Adv Appl Mech 9 (1966) p 243.

Devadas C, Samarasekera I, and Hawbolt E, Metall Trans A 22 (1991) 335.

Fletcher J, and Beynon J, Ironmak Steelmak 23 (1996) 52.

Choquet P, Fabregue P, Giusti J, Chamont B, Pezant J N and Blanchet F, Mathematical Modelling of Hot Rolling of Steel, CIM, Montreal (1990) p 34.

Hlady C O, Brimacombe J K, Samarasekera I V, and Hawbolt E B, Metall Mater Trans B 26 (1995) 1019.

Duan X, and Sheppard T, J Mater Process Technol 150 (2004) 100.

Canas J, Picon R, Pariis F, Blazquez A, and Marin J C, Comput Struct 58 (1996) 59.

Porter D A, Easterling K E, and Sherif M, Phase Transformations in Metals and Alloys, (Revised Reprint), CRC press, Boca Raton (2009).

Pietrzyk M, Metall Foundry Eng (Poland) 20 (1994) 429.

Davies C H, Scr Metall Mater 30 (1994) 349.

Pietrzyk M, J Mater Process Technol 125 (2002) 53.

Harlow D, Wei R, and Wang M, Metall Mater Trans A 37 (11) (2006) 3367.

Kamikawa N, Huang X, Tsuji N, and Hansen N, Acta Mater 57 (14) (2009) 4198.

Rollett A, Humphreys F J, Rohrer G S, and Hatherly M, Recrystallization and Related Annealing Phenomena, Elsevier, Amsterdam (2004).

Huang Y, and Humphreys F, Mater Chem Phys 132 (2012) 166.

Hensel A, and Spittel T, Kraft-und Arbeitsbedarf bildsamer Formgebungsverfahren, Deutscher Verlag für Grundstoffindustrie Leipzig.

Zhou M, and Clode M, Mech Mater 27 (1998) 63.

Hlady C O, Samarasekera I V, Hawbolt E B, and Brimacombe J K, Heat Transfer in The Hot Rolling of Aluminium Alloys, in Proceedings of International Symposium on Light Metals Processing and Applications: 32nd Conference of Metallurgists, Metallurgical Society of CIM Quebec City (1993).

Chen W, Samarasekera I, and Hawbolt E, Metall Trans A, 24 (1993) 1307.

Hodowany J, Ravichandran G, Rosakis A J, and Rosakis P, Exp Mech 40 (2000) 113.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nellippallil, A.B., De, P.S., Gupta, A. et al. Hot Rolling of a Non-heat Treatable Aluminum Alloy: Thermo-Mechanical and Microstructure Evolution Model. Trans Indian Inst Met 70, 1387–1398 (2017). https://doi.org/10.1007/s12666-016-0935-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-016-0935-3