Abstract

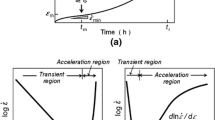

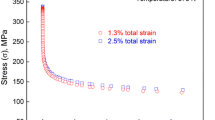

To systematically characterise the effect of plasticity on the creep resistance of a 10 % Cr steel, strain-controlled monotonic and cyclic/hold tests have been isothermally conducted at 600 °C. In particular, this work focuses on the influence of the magnitude of plastic strain transient(s) preceding the first peak tensile hold for two types of loading sequence. Along with the use of Norton–Bailey formulations assuming time- or strain-hardening, the effectiveness of a method developed by Woodford is explored for converting stress relaxation profiles to equivalent forward creep curves. For quantitative comparison and model validation, conventional creep tests have also been conducted on the same 10 % Cr steel at 600 °C for two different stress levels. Experimental results show that the creep deformation resistance of this steel is significantly reduced if the loading transient immediately preceding the hold is plastic. Furthermore, reduction in creep resistance is found to be more pronounced with increasing plastic strain amplitudes. Forward creep curve construction results indicate that all three assessment methodologies tend to offer qualitatively similar trends although the quantitative predictions differ slightly due to their respective underlying formulations. The creep-rate versus time plots for the constructed creep curves (until the attainment of steady-state conditions) also lead to a similar conclusion when compared with those from conventional creep tests. Finally, the successful implementation of the Woodford method to stress relaxation data from cyclic/hold tests broadens its current scope of applicability and its versatility can thus be further improved.

Similar content being viewed by others

References

Holdsworth S R, Mazza E, Binda L, and Ripamonti L, Nucl Eng Des 237 (2007) 2292.

Ellison E G, and Paterson A J F, Proc Inst Mech Eng 190 (1976) 319.

Sidey D, Part III—Fatigue: Micromechanisms, ICF4, Waterloo, 2 (1977), p 813.

Binda L, Holdsworth S R, and Mazza E, Mater High Temp 27 (2010) 21.

Holdsworth S R, ASTM STP1539, J ASTM Int 8 (2011) 3.

Vorpahl C, Möslang A, and Rieth M, J Nucl Mater 417 (2011) 16.

Holdsworth S R, Proceedings of the 12th International Conference on Creep and Fracture of Engineering Materials and Structures (CREEP 2012), Kyoto (2012).

Sarkar A, Vijayanand V D, Shankar V, Parameswaran P, Sandhya R, Laha K, Mathew M D, Jayakumar T, and Rajendra Kumar E, Fusion Eng Des 89 (2014) 3159.

Kalyanasundaram V, Ph D Dissertation, University of Arkansas, Fayetteville (2013).

Fournier B, Sauzay M, Caës C, Noblecourt M, Mottot M, Allais L, Tournie I, and Pineau A, Metall Mater Trans A 40 (2009) 321.

Sarkar A, Vijayanand V D, Parameswaran P, Shankar V, Sandhya R, Laha K, Mathew M D, Jayakumar T, and Rajendra Kumar E, Metall Mater Trans A 45 (2014) 3023.

Laflen J H, and Jaske C E, in Stress Relaxation Testing, (ed) Fox A, ASTM STP676 (1979), p 182.

Altenbach H, Naumenko K, and Gorash Y, Int J Mod Phys B 22 (2008) 5413.

Grzywinski G G, and Woodford D A, Mater Des 14 (1993) 279.

Woodford D A, Accelerated Testing for High-Temperature Materials Performance and Remaining Life Assessment, Report TR-114045, EPRI, Palo Alto (1999).

Krempl E, Cyclic Creep: An lnterpretive Literature Survey, Bulletin 195, Welding Research Council, NY (1974), p 63.

BS EN ISO 204, Metallic Materials—Uniaxial Creep Testing in Tension—Method of Test (2009).

Holdsworth S R, and Merckling G, Proceedings of the Sixth International Charles Parsons Turbine Conference, IOM, London (2003), p 410.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kalyanasundaram, V., Holdsworth, S.R. Prediction of Forward Creep Behaviour from Stress Relaxation Data for a 10 % Cr Steel at 600 °C. Trans Indian Inst Met 69, 573–578 (2016). https://doi.org/10.1007/s12666-015-0776-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0776-5